18. Wildcard week¶

For this week’s assignment, I decided to use the Vaquform machine in the lab. I had a lot of options for process or machines to use this week, I chose Vacuum forming because I wanted to work with another process of creating molds. Week 10 (Molding & Casting) was the first time I had worked with molds, and the process was nothing as I expected. It was messy and left room for a lot for error, but it’s still the main way we manufacture the goods we use on a daily basis.

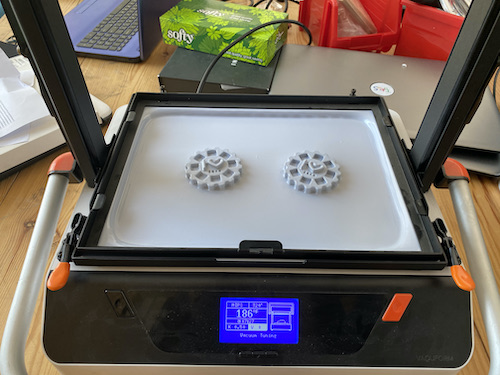

The process of using a vacuum former is first to design your 3D object, print it, then place it on the tray, secure the plastic sheet over the object, after a few minutes its ready to be used!

Design:¶

I wanted to design something with detail so I could test how much detail I can get with a vacuum former mold. I started by creating a sketch of the geometry I wanted, extruded the surfaces to multiple heights, and added fillets where needed.

I then saved as an STL, opened the file in Cura and started the printing process - for more details on 3D printing please visit this page.

Final:

Mold:¶

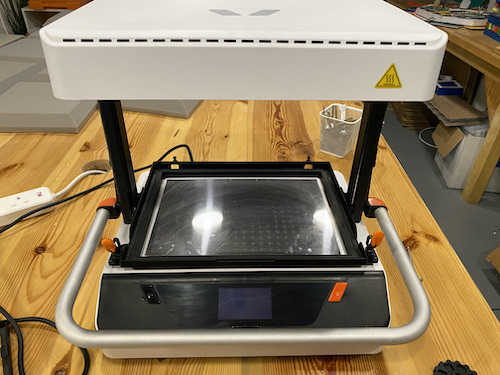

The machine I will be using is a desktop vacuum former, Vaquform. It’s very easy to use and operate, the machine interface was pretty easy to understand.

The steps I followed were:

I first pulled the lever down, removed the inner frame by opening the clamps

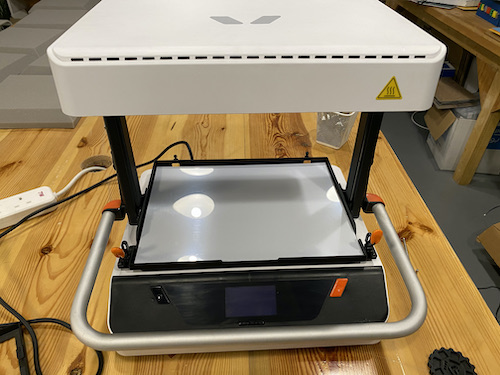

placed my plastic sheet, secured the frame back in place, and pulled the lever up.

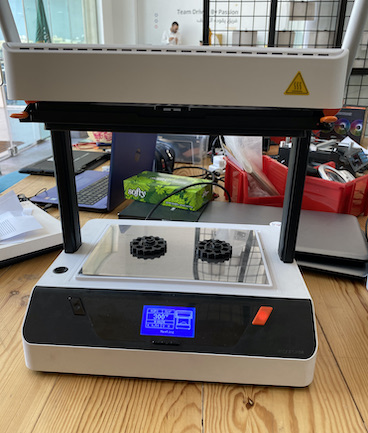

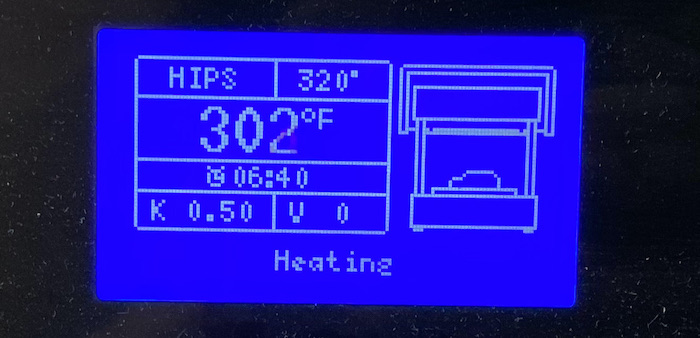

I then placed my 3D objects, turned on the machine, made sure the material selected was the one I worked with HIPS, changed the thickness to .50 and pressed start. This is the tutorial I followed.

Once the machine starts heating, make sure to keep your hands away from the table. Once it’s ready, the machine will make a buzzer like sound, pull the lever down, wait a few minutes, then remove the plastic sheet.

One error message I had when setting up the machine was “IR Blocked” - When the machine started the heating process, I got an error message saying “IR blocked” - I looked it up and came across this support page mentioning that it might be the thickness of the material. I initially followed the same settings as another Fab Academy student, and inserted the paper width to 1.50 - I changed it to .50 and it worked. If you will be using a vacuum former, make sure to insert the value as per the packaging.

Cast:¶

I chose chocolate as casting material - I poured it in and let it sit for a while, below is the final result.

The plastic mold broke off pretty quickly, it might be the material I chose but it’s not reliable to use if I needed to use the mold more than once (pretty wasteful).