Prototype 1

About design

I had to exclude a lot of things for my first attempt. From the beginning, it was difficult to put in many functions, and I decided to add functions little by little.

I designed my first prototype during computer controlled machining week. It is a key part of my project, where food waste is decomposed. I designed it to use gears to turn the mixing pedal, and I thought it was the first part to test.

Things to Improve

Prototype 2

CAD Design

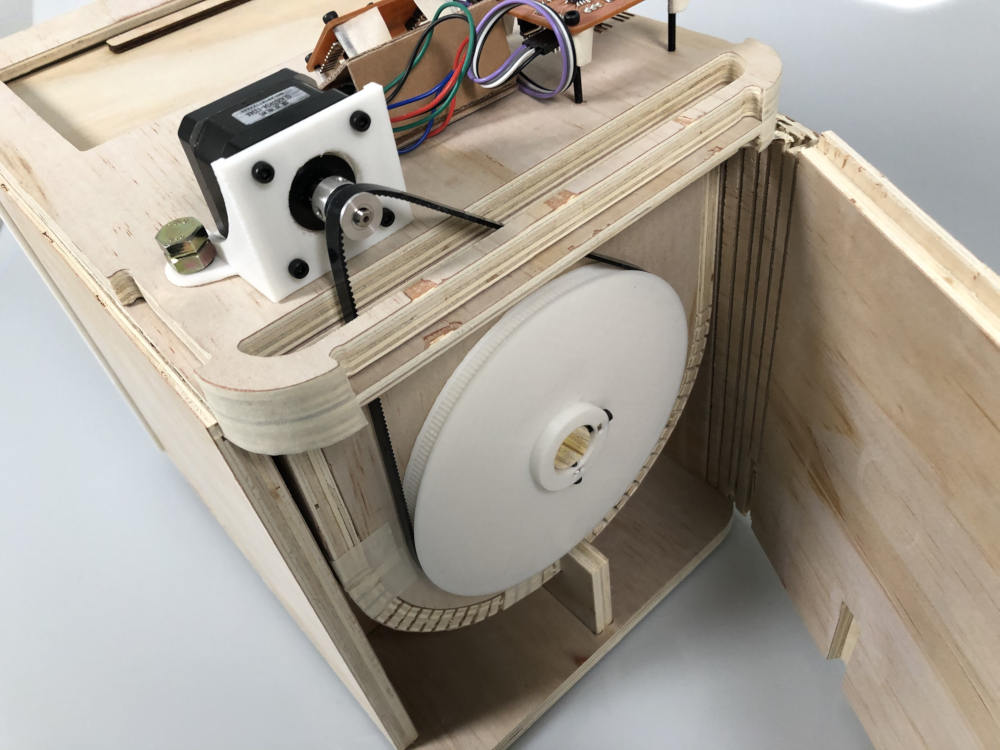

Improvements

- Made the outer frame and lid.

- There is a part where the board and the motor can enter.

- A space was created for the timing belt and timing pulley. (The timing pulley is made with a 3D printer.)

- And the parts to fix the motor were produced using a 3D printer.

- The curved part on the side was broken because the numbers did not fit well in the process of using the shopbot. So, it was replaced with auxiliary parts for 3D printers.