Final Project¶

In the month of August 2018, My state faced a severe flood. Almost a million people were affected and around 500 people lost their lives. This was something for which we were not prepared. A lot of people rose upto the occasion and a big chunk of the rescue mission was handled by civillians who had no training in handling situations like this.

At the same time, makers who wanted to help made some DIY Powerbanks. These were airdropped to the stranded. People charged their phones with these powerbanks & shared the location & current situation to rescue teams over phone. This was a vital step to understand the ground reality.

My Project is simply an extension of the Powerbank idea. What I am trying to do is make a hand-crank power bank which is cheaper & faster to make. The concept is to use unaffected fablabs as emeregency rapid production setups for these power banks in a future crisis.

Guidelines¶

- KISS (Keep It Simple Stupid)

- Try to achieve 100% dependence on materials and machines available in Fablabs

- No need to look good or last for long term use

- Should survive airdrops

- Minimise Fabrication time & cost

The entire fabrication workflow will be designed in a way that it can be done within a fablab, that too with whatever resources is available within. This is important because there is no guarantee that we could source the materials from outside if the transportation system is affected. Since we have no idea what material will be available in which fablab at that time, I am trying to come up with two or three designs with different materials and different fabrication approaches as a failsafe. Hopefully something fruitfull will come out of this

Update 1¶

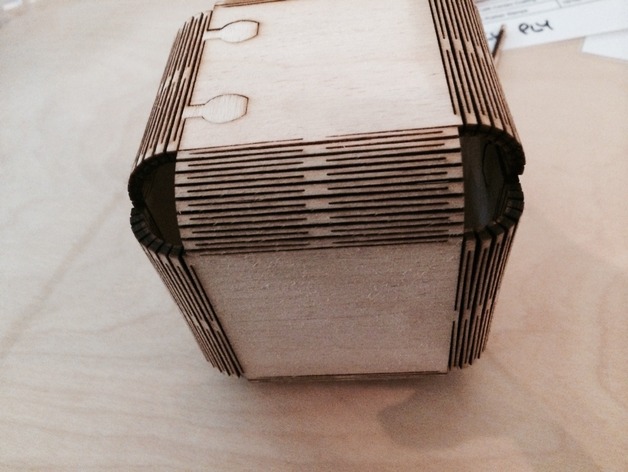

I was thinking of making the body of the powerbank using accrylic with press fit and to use a sillicone molded bumber case of sort with the radius around the side edges. But I got to see a laser cut method called living hinge.

So Now the final design needs to be redrawn to show this.

The advantages of this method is that this will be much quicker process compared to making the mold and casting siliconne bumber cases. But I feel the problem with this will be these might break during air drops

Materials¶

| Qty | Description | Price | Link | Notes |

|---|---|---|---|---|

| 1 | Black Acryllic Sheet 3mm |