Computer-Controlled Machining

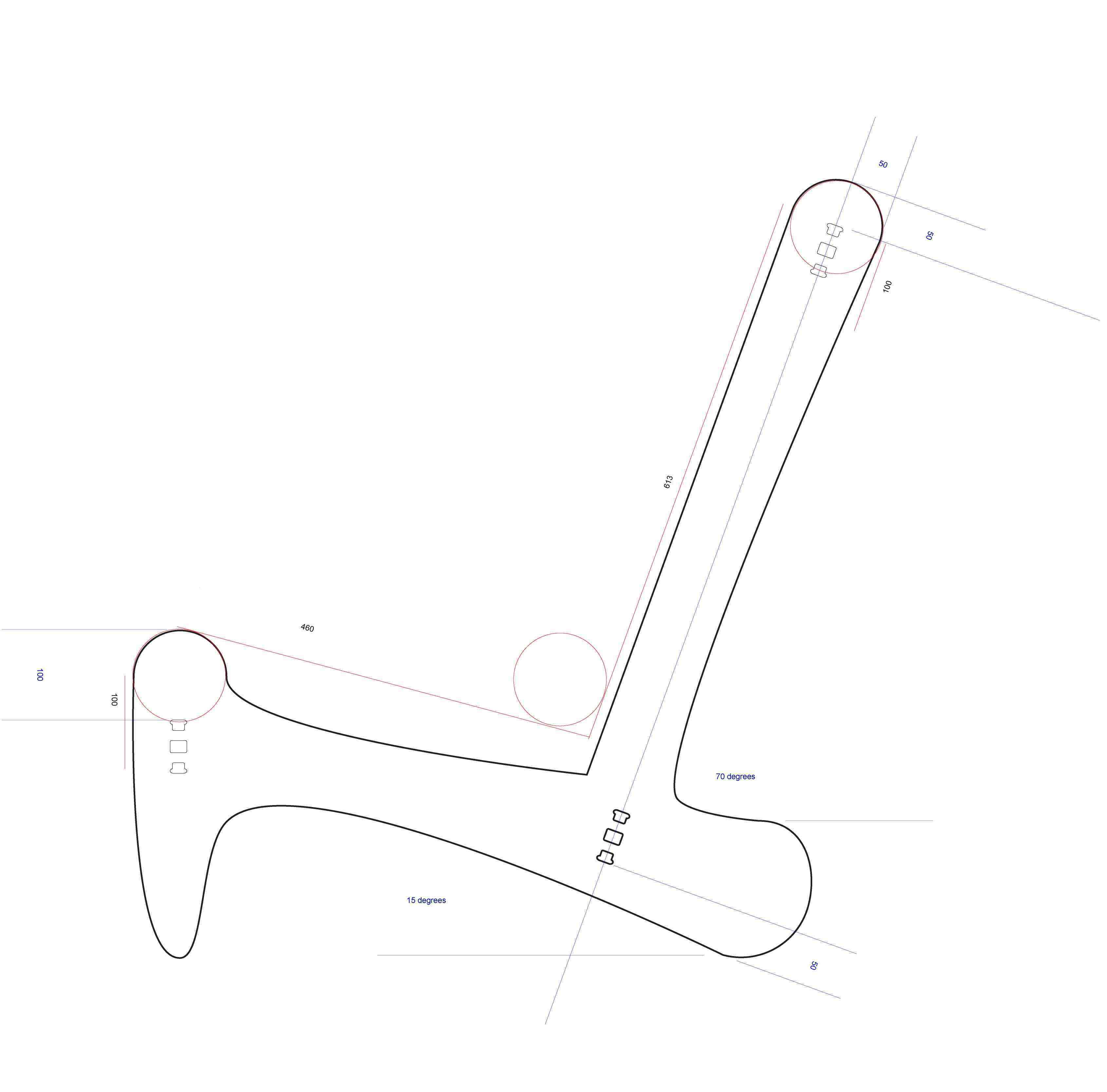

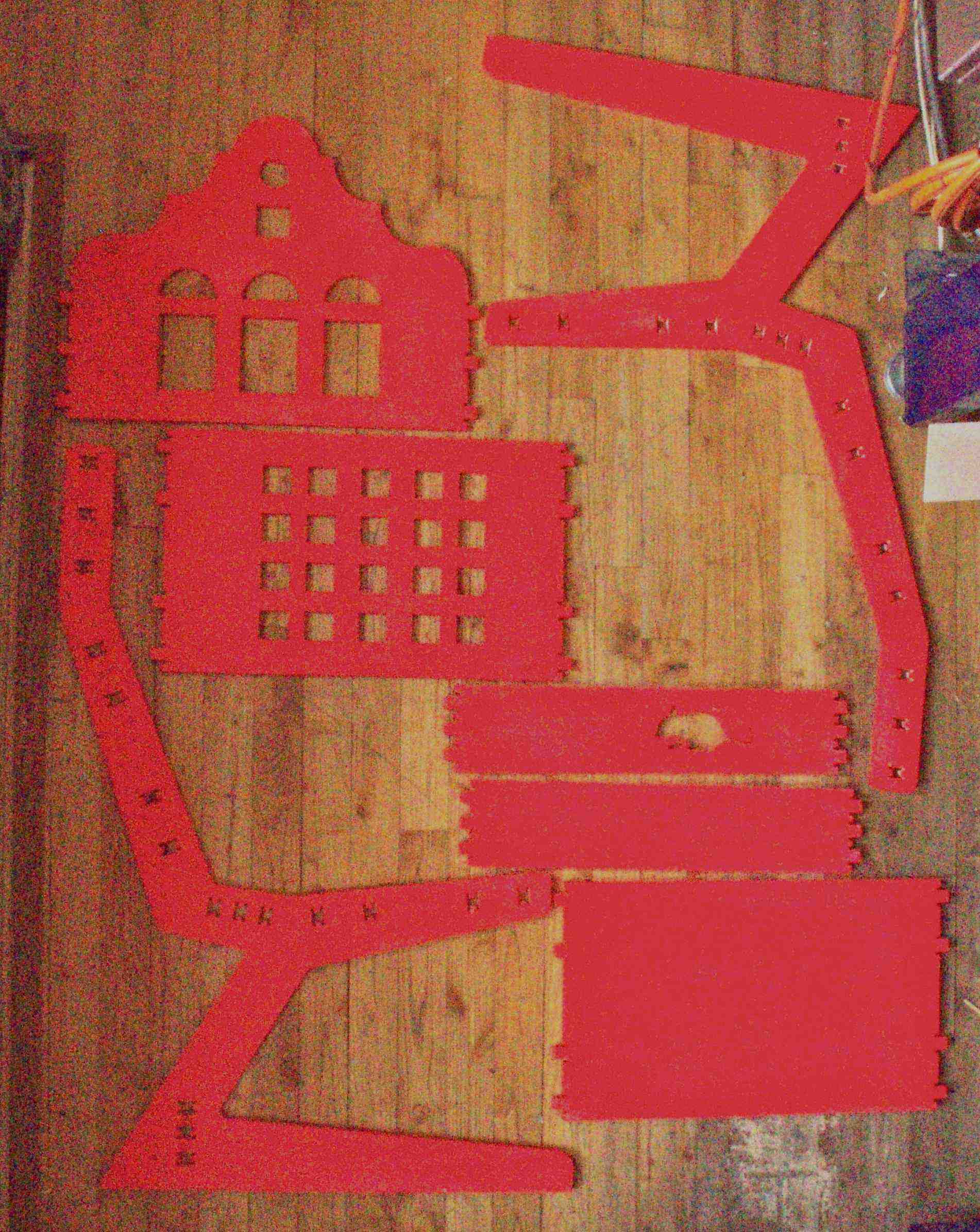

Assignment: Make something BIG

|

| Chair cut from one sheet of 12mm plywood. |

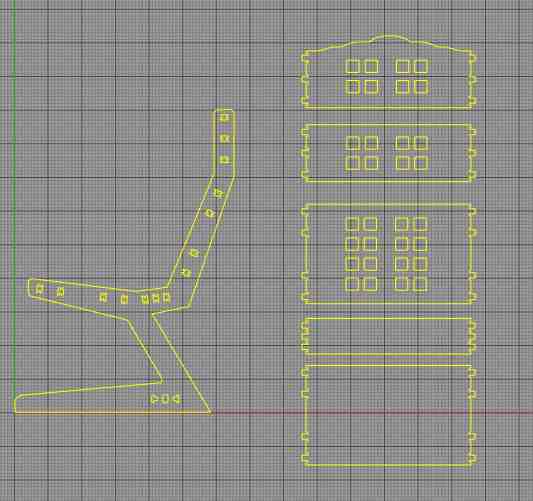

Designing

- Designing the chair in Abode Illustrator was a mistake giving it is not most accurate design tool.

- Import initial design from Abode Illustrator to Rhino3d

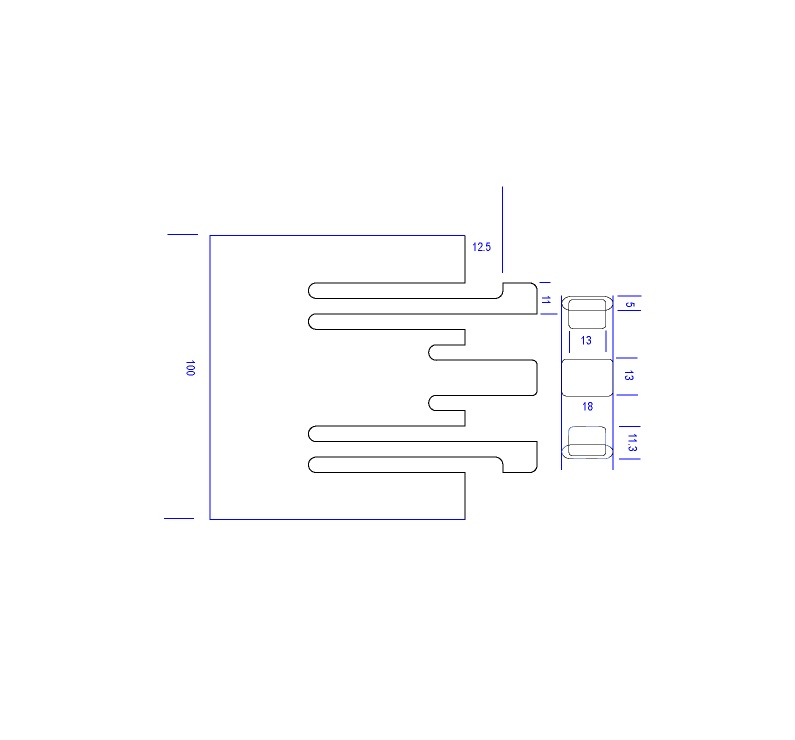

- Wood connection resource: Digital-Wood-Joints

PartWorks

Preparing vector design

- Save drawing as a DXF

- Open PartWorks 2d on ShopBot

- Open the dxf file to cut

- Enter material size width and length

- Enter material thickness

- Set zero (I set my zero to the top of the material)

- Remove the default check "Use origin zero"

- Confirm that the size of your image was exported correctly otherwise you will have to use the option in the path screen to scale

- Select the regions to machine, for example, drill holes to hold down the material.

- Specify the tool details and calculated toolpaths.

- Preview the job.

- Save each toolpath in a seperate file. I usually add a number to the file name so I remember the order, for example, 1DrillPath 2MillPocket 3CutOutline

ShopBot

Cutting design

- Go to abs zero of machine

- Place material on bed of ShopBot

- Jog spindle to appropriate zero position (K - key opens jogging window)

- Record x and y value then zero x and y axis

- Put in selected end mill

- Zero z axis with magnetic bar

- Start vacuum

- Load file

- Start spindle

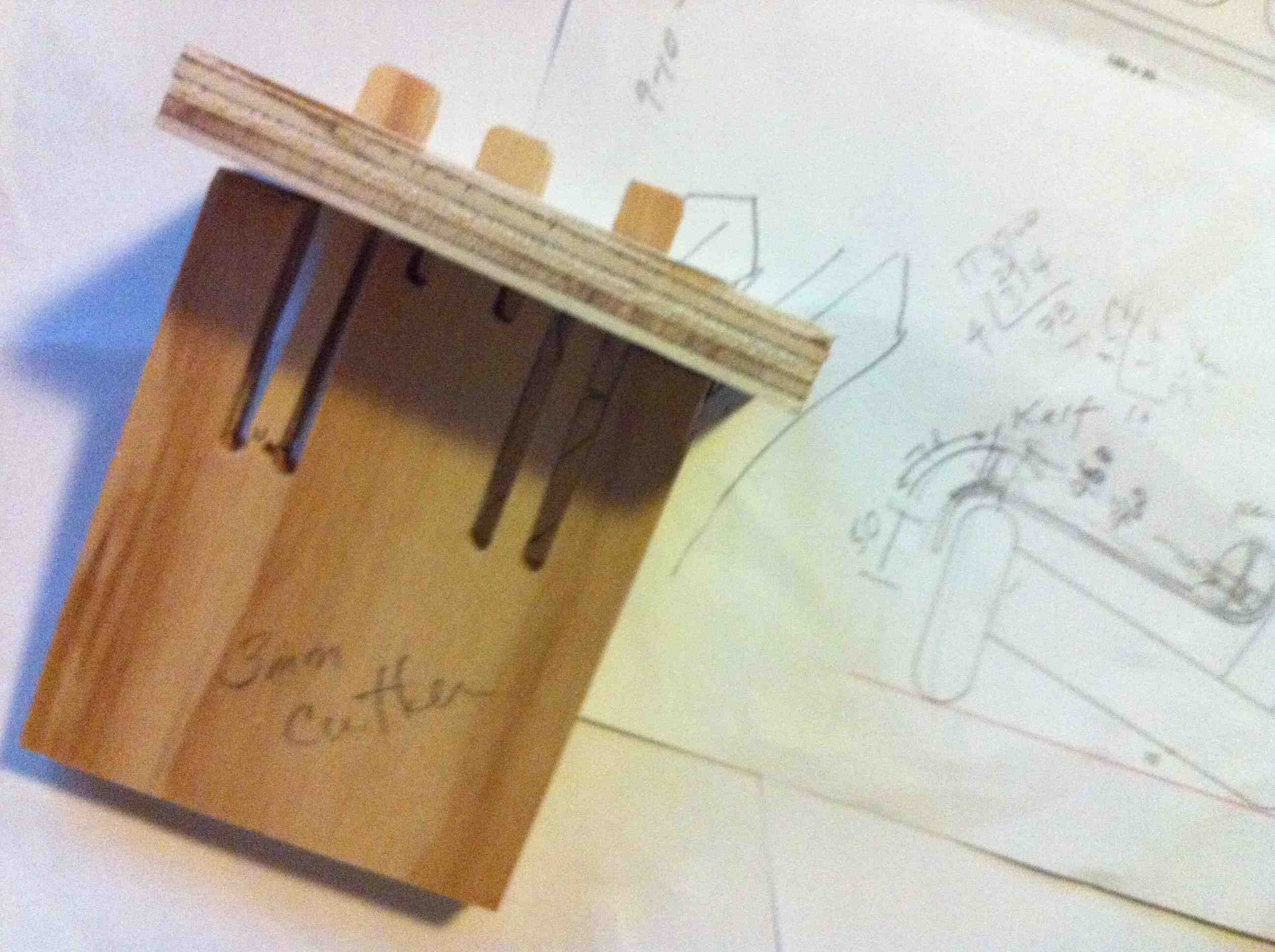

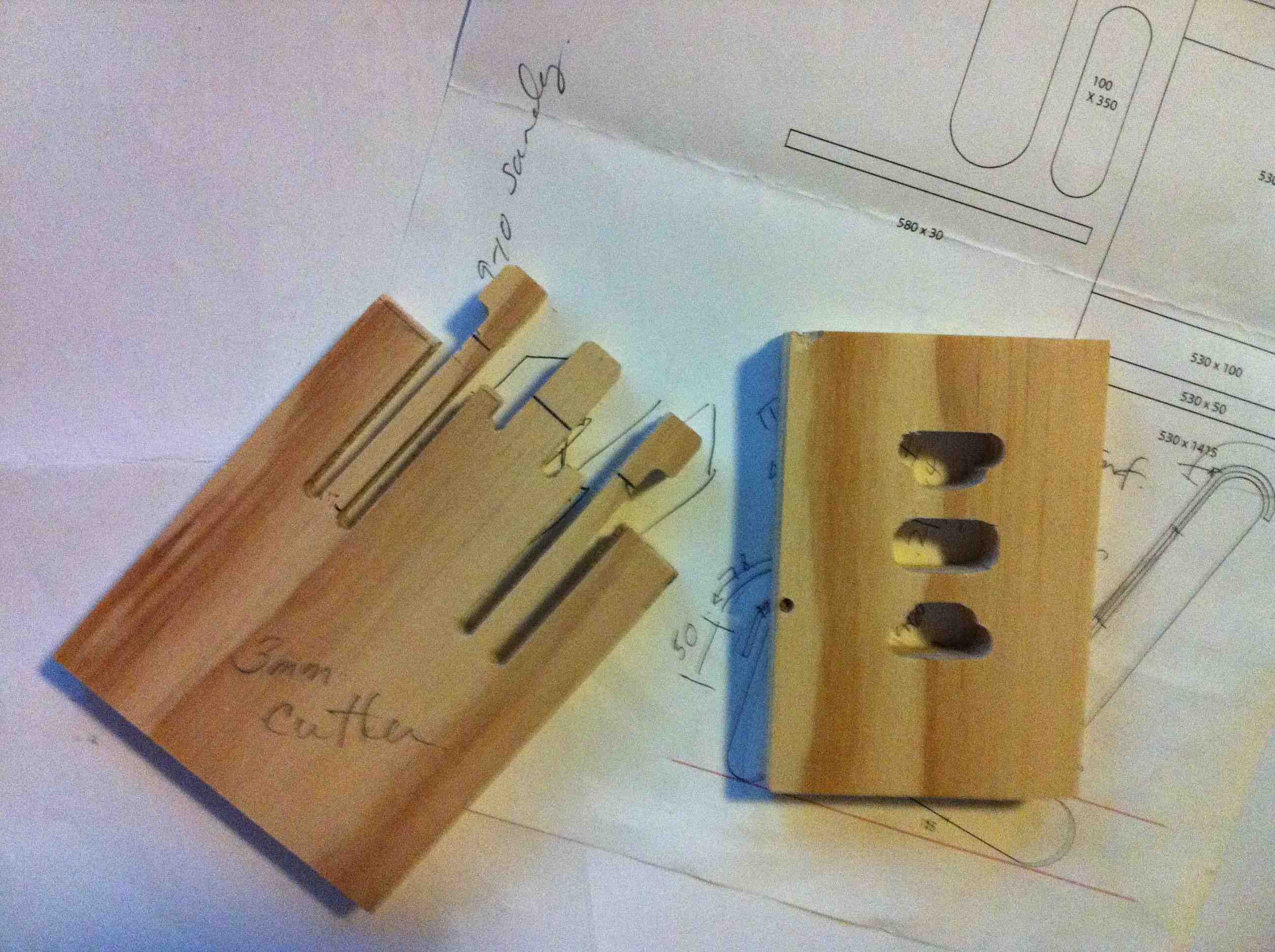

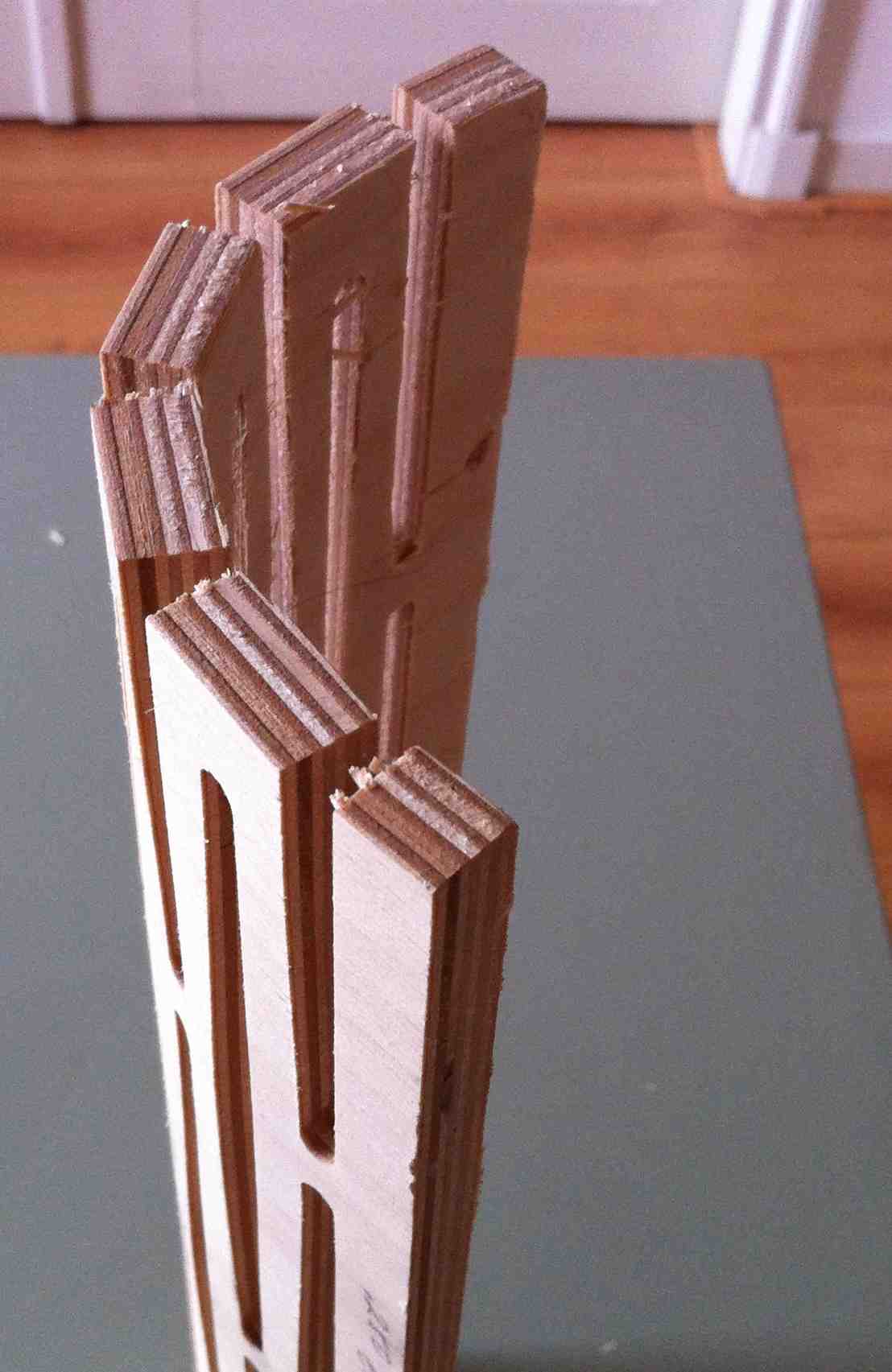

Testing Design

Final Design and Chair

Lessons learned

Lessons learned

- Design with known material size otherwise you will be redrawing design.

- Test cuts on ShopBot on the endmills and material of your final design.

- Record x and y axis position always before zeroing machine.

- Plan and follow a workflow of each stage of cutting on ShopBot.