ELECTRONICS PRODUCTION

FIRST STEPS

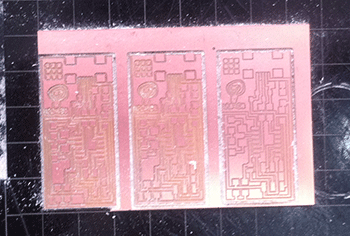

This assignment consists of manufacture and programming of FAB-ISP that serves as developer of Academy plates. This programming is done under Ubuntu 12.04 environment using the milling machine Roland Modela MDX20. For the production of the plates we use the interface of fabmodules.

PROCESS

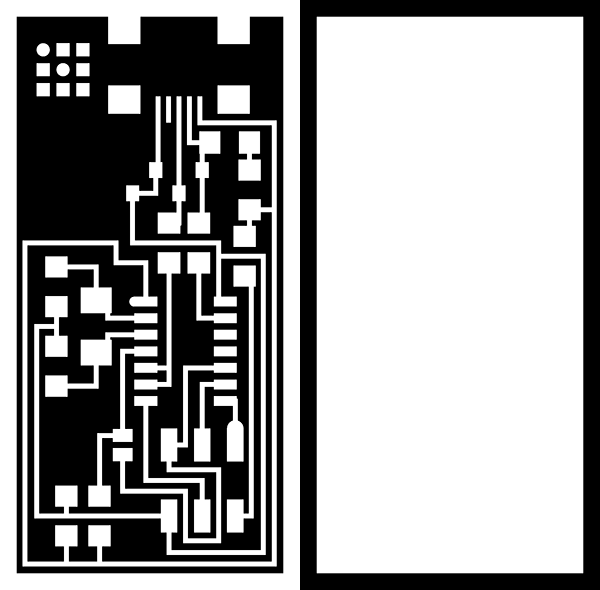

1. Download .png archives from here:

http://academy.cba.mit.edu/classes/embedded_programming/hello.ISP.44.res.traces.png

http://academy.cba.mit.edu/classes/embedded_programming/hello.ISP.44.interior.png

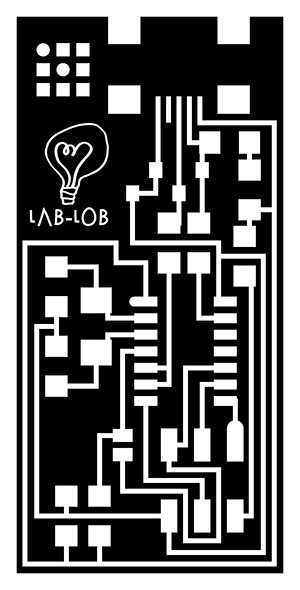

2. You can modificate all what you want this archive. I insert the logo of my studio:

The essential elements for the work are:

- Mills: Used of two types, 1/64 and 1/32, the first is for the stroke and the second to complete the internal plate cutting.

- Wrenches or screwdrivers: Used to adjust the mill. Is widely used when calibrating the Z axis

- Double-sided tape: Used to adhere the copper plate to the workbench.

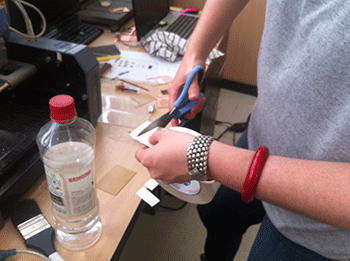

3. We clean the plate, the machine and the work area and check that this plate doen´t have curvatures.

4. With double-sided tape we adhere to the copper plate avoiding bubbles because this could cause adhesion problems.

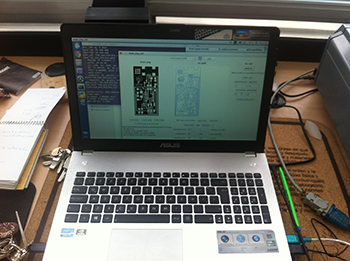

5. We open the fabmodules.

6.We adjust the parameters in fabmodules.

7. We mill the archive.

You can see a video of the process:

CONCLUSIONS

I have had a lot of problems making this assignment, because it is my first time making electronics. For me the worst part of all the process were the solders. It is very difficult to do well, you need a lot of trainning.

Finally, as you can see in the video, when I checked my plate with FABISP something went wrong (I had an intermitent orange light). I think the problem is in the solders, because some components were not soldered completely.