Kazutoshi Tsuda

19. project presentation (Jun 4, 2014)

Document a final project

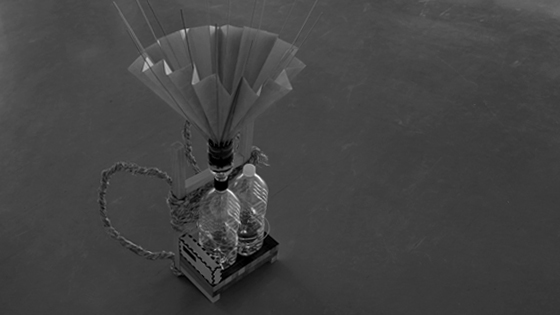

The final prototype

I made WATER BACK CARRIER, a backpack-type carry bone with water utilization modules which collect rainwater and purify it to gain hot water and emergency drinkable water everywhere. My purpose is not only making folk tool from local resources by digital fabrication. I invented this prototype for archiving and inheriting precious knowledge of how to utilize local resources in each community. In other words, through making this prototype you could learn twisting rope, weaving bamboo, and jointing wood. And also you would have a chance to know how to get those materials and how to cultivate their mountain, bamboo forest and farms. The slide for my final presentation is here.

Water back carrier.

Rainwater collector.

Water filtration unit.

Solar water disinfection container with thermometer.

Working in progress

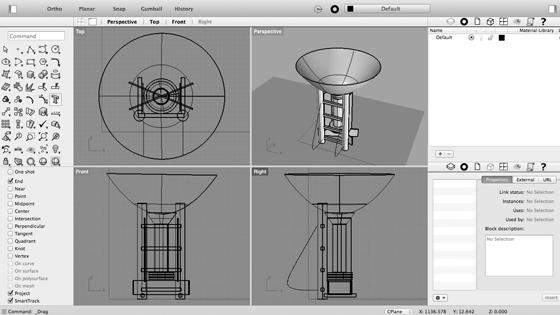

Screen capture of Rhinoceros. The process of 3D modeling.

Back carrier

This unit consists of two parts: one is a ladder and rack made of wood, and the other is shoulder straps and back support cushion made of rice straw. I chose Hinoki cypress (25 mm x 25 mm x 1920 mm) for ladder for this project. This wood is light, easy to cut and engrave, and smooth. I determined the ladder's size to fit my own build and cut out the material.

The process of making the ladder.

I used the mortise and the tenon joints one of the most common joints used by woodworkers. The mortise was made by the CNC router (Woodpecker) with 3 mm endmill.

The process of engraving by large format CNC router.

The tapered tenon was made by the band saw.

The process of cutting Hinoki cypress by band saw.

I used rice straw, an important by-product of rice cropping, as materials of rope for shoulder strap and back support cushion. I made a thick rope for the shoulder straps, and a thin rope for the back support cushion.

Though I could get enough amount for this prototype Shoro palm is also useful material for making ropes. Shuro palm's fiber is durable and resistant to water. Because of its property the fibers have been used for making ropes to tie boat and dock (Tomozuna) and connect oar to the boat (Kaihimo). I plan to use the rope of Shuro palm to fasten some components tightly in the next prototype.

The process of making rice straw rope.

Straw rope.

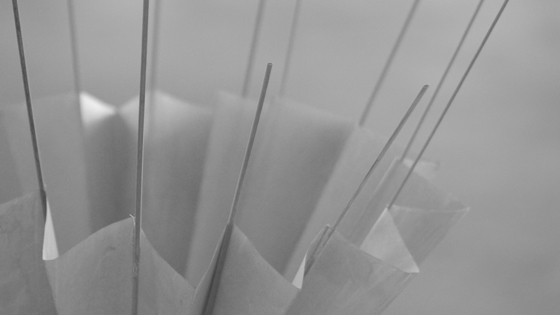

Rainwater collector

I folded Washi paper (560 mm x 810 mm) by simple Origami method and applied persimmon tannin on the surface of the paper repeatedly.

The process of applying persimmon tannin.

I tried to make thiner bamboo stripes but it was too difficult for me. I really need more training and experience.

Tools for making the thin strip of bamboo.

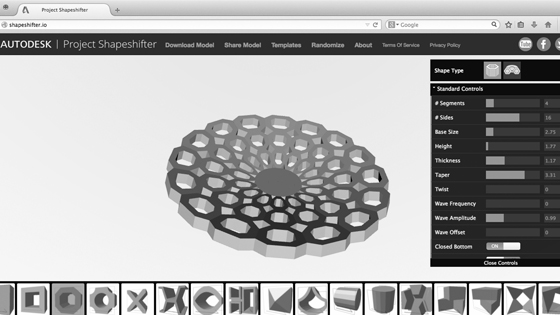

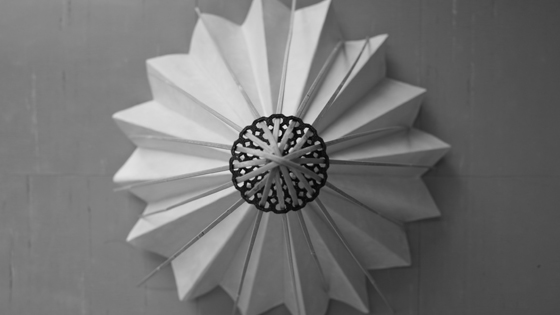

I applied the thin strips of bamboo as the rib of the umbrella-like component to collect water. So I made connector that joins these ribs by 3D modeling and printing. For 3D modeling, I used Autodesk Project Shapeshifter, which provides an easy parametric design to create 3D printable models.

Screen capture of Project Shapeshifter. The process of 3D modeling.

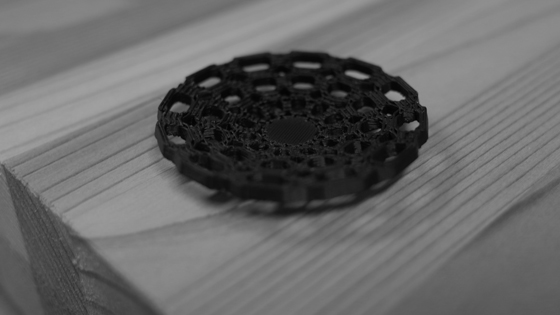

3D printed connector, modeled by me.

The connector is also part of the water filter. I have thought that I would like to use a used PET bottle as materials of container for water filtration unit, therefore I set the diameter of the connector to fit the inner diameter of 500 ml PET bottle.

Ribs joined by the connector I made.

Finished rainwater collector (bottom view).

Water filtration unit

I made a charcoal for one of the material of water filter by DIY wood gas stove, which provides heat generation and charcoal production.

The process of making charcoal by DIY wood gas stove.

I cut the bottom of the used 500 ml PET bottle and turned it upside down. Then I connected it to 2 L PET bottle for storing water.

Water filter. From bottom to top: connector, cotton, charcoal, Shuro palm, and connector.

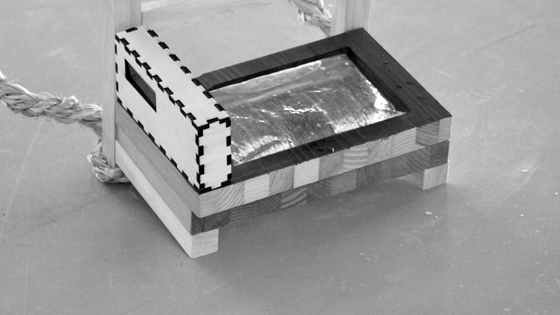

Solar water disinfection container

Solar water disinfection is a simple method for decentralized water treatment. Water is filled in a clear container and exposed to the sun for 6 hours on a clear day. During this time, the ultraviolet (UV) radiation and heat of the sun inactivate the pathogens.

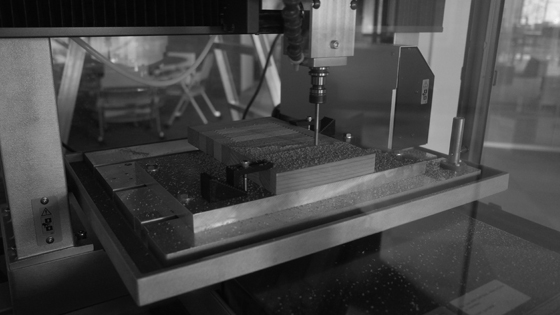

I chose Sugi cedar butcher block (375 mm x 250 mm x 25 mm) from forest thinning process. I used CNC milling (Roland Modela Pro II MDX-540) with 6 mm endmill (R3 x 18 x 60) to engrave the wood.

The process of CNC milling.

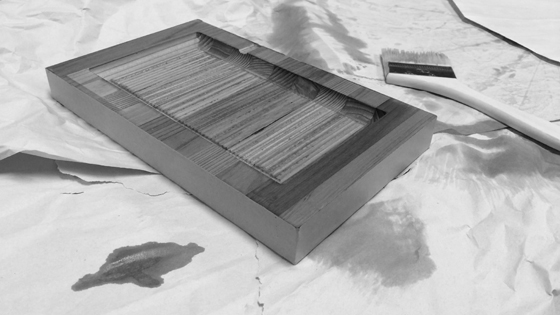

The process of painting the container black.

Thermometer

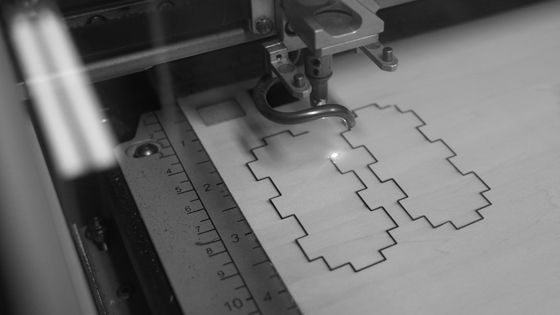

The press-fit box for the input/output device was cut out from used 4 mm plywood sheet by laser cutter (Epilog Mini 24 Laser: 24" x 12" work area).

The process of laser cutting.

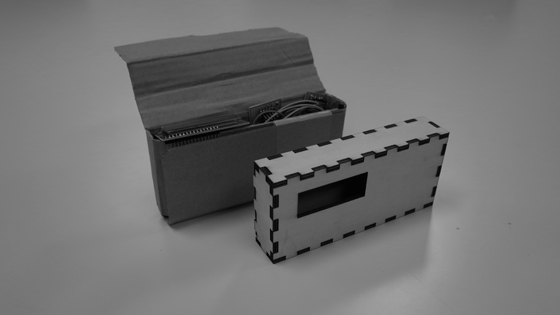

Cardboard prototype (left) and finished press-fit box (right).

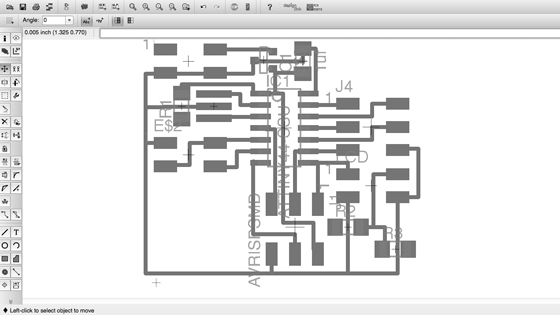

I collected the electronics components listed below and then I designed the board with Eagle referring to the hello board series in this class.

- Input sensor: temperature sensor (LM61CIZ)

- Microcontroller: ATtiny44-SSU-ND

- Output device: 16x2 character LCD module 16x2 character

- CER resonator: 20 MHz SMD (ECS-CR2-20.00-B-TR)

- IC regulator: 5V (LM3480IM3-5.0)

- Resistor: 1k, 10k, 100k Ohm

- Capacitor: 1uF

- Battery and etc.

Screen capture of Board layout in Eagle.

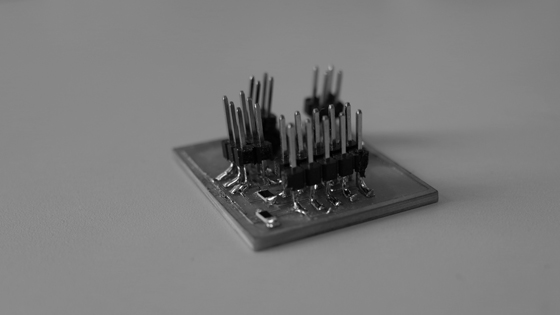

My board.

Sketch code

#include

int sensorPin = 7;

// LiquidCrystal display with:

// rs on pin 4

// rw on pin 5

// enable on pin 6

// d0, d1, d2, d3 on pins 11, 12, 13, 14

LiquidCrystal lcd(4, 5, 6, 11, 12, 13, 14);

void setup(){

lcd.begin(16,2);

}

void loop(){

lcd.clear();

int tempValue = analogRead(sensorPin);

int tempMilliVolt = (unsigned long)5000 * tempValue / 1023;

float temp = (tempMilliVolt - 600) / 10.0;

lcd.setCursor(0,0);

lcd.print("Temp: ");

lcd.print(temp);

lcd.setCursor(10,0);

lcd.write(0xDF); // character degrees

lcd.print("C"); // character Celsius

delay(1000);

}

Result example.

Bill of materials (BOM)

Rice straw: -

Bamboo: $2 (200 Yen)

Wood - Hinoki cypress: $8 (828 Yen)

Wood - Sugi ceder: $1

Washi paper: $4

Shuro palm: -

Cotton: -

Persimmon tannin: $0.5

PLA filament: $1 ($50/kg)

used PET bottle: -

Microcontroller - ATtiny44A-SSU-ND: $1.5

Temperature sensor - LM61CIZ: $0.5

LCD module 16x2 character: $9.5 (961 Yen)

Battery: $1.5

Others: $3

------------------------------

Total: $32.5

Weight

Back carrier: 740 g

Rainwater collector: 100 g

Water filter: 80 g

Water storing unit: 20 g

Solar water disinfection container: 300 g

Thermometer: 210 g (incl. battery: 100 g)

------------------------------

Total: 1470 g

Download

You can download the data file from following link.

Water Back Carrier 1.0.0

- mortise.dxf

- connector.stl

- sodis.stl

- pressfitbox.dxf

- traces.png

Acknowledgements

Special thanks to Neil Gershenfeld (professor), Astrid van Roij Lubsen (assistant instructor), Dave Goenner (assistant instructor), Alex Schaub (instructor), Masato Takemura, Ken Fujiyoshi, Takuma Oami, Ted Hung, Akiko Matsui, Hideki Ichida, Hiroki Yatou, Hiroko Takano, Hiroya Tanaka, Junko Tsuda, Kaoru Matsumoto, Kazuhiro Yagi, Keishiro Hara, Kohei Morimoto, Koichi Shiraishi, Mao Matsuda, Masato Iritani, Michinori Uwasu, Misato Yamagata, Miyoko Tsuda, Nobuyuki Tsuda, Rie Mochizuki, Takako Higashihata, Tomohiro Inoue, Yoji Miyake, Yuji Takiuchi, and all members of FabLab Kitakagaya and Fab Lab Network.