Assignments: plan and document a final project that integrates the range of units covered

My plan of final project kept chaging through units of FabAcademy. But stil the root of the idea is same.

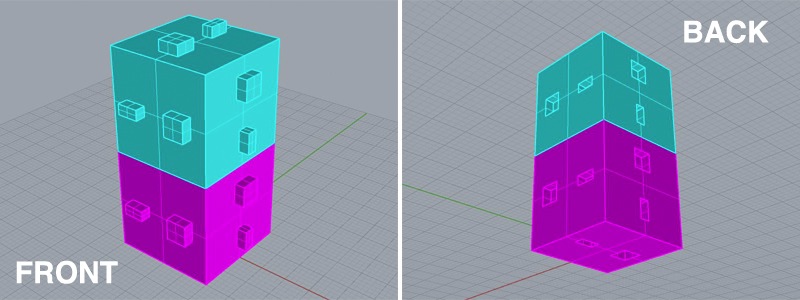

I want to develop tangible interface for 3D modelling and here is plan.

what will it do?

It will be set of cubes containnig magnets so user can combine like building blocks.

One of cubes has USB port to connect with Software running on PC.

After making shape by stacking cubes, the geometry made of cubes can be exported to PC as 3D model by the software.

So it's sort of tangible 3D modelling interface people can use without any exclusive knowledge about 3D modelling.

who's done what beforehand?

Cubecube is Open-source tangible CAD interface.

It works by combination of a grid board and bunch of white small cubes containing resistor inside. User can make shape by stacking small cubes on the board and software generates 3D CAD data which is scanned from board. Simple and clean system make it easy to be made by others but cubes can be stacked only in one direction.

what materials and components will be required?

All price are listed in fablab inventory

- Transparent acrilyc plate (3mm thickness)

- 3M #1126 copper tape 6inch x 36yds $246.04

- ATmega88/328 $1.3 ~ $2

- MAGNET 1/2inch diameter $0.9

where will they come from?

Parts to make this project are choosen from fablab inventory as much as I can.

- acrily: fablab

- copper tape: fablab

- ATmega88/328 and other components: fablab

- Magnets: fablab

how much will it cost?

The cost per a cube is...

- Transparent acrilyc plate (3mm thickness) _ 150 squar cm _ $1.1

- 3M #1126 copper tape _ 150 squar cm _ $0.7

- ATmega88/328 _ x1 _ $1.3 ~ $2

- MAGNET 1/2inch diameter _ x6 _ $5.4

what parts and systems will be made?

-

Magnet connector:

The cube has a magnet inside each face. So it's easy to assemble and remove them. And the connecter offers four conductors.

-

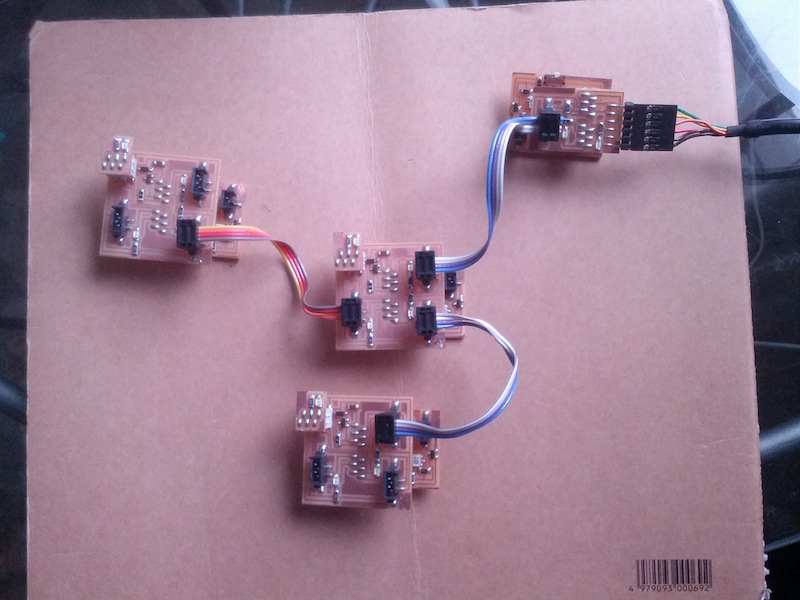

APA network:

Each cube contains ATmega88 and these micro controller commnicates each other through the magnet connector I mentioned above.

To scan the geometry of connection of cubes, Feature of APA network which send data packet not with address like normal neteorking but with route to the destination node.

-

Python Software:

The software running on PC to visualize and do interfacing the system will be wrote in Python. The sofware will be able to scan the geometry of cubes by using APA network and generate 3D model to export it.

-

Copper tape circuit with ATmega88:

Circuit will be made by cutting copper tape with vynal cutter so i can stick to inside of the cube. It keeps the cube looks clean without messy wiring.

what processes will be used?

-

3D modelling:

To design the cube, Rhinocerous will be used as 3D modelling software. Size, mechanical joint, and style of the cube will be figure out in this process. -

circuit layout:

By using Eagle, circuit layout will be designed based on 3D model already made with Rhino. -

Laser cutting:

To make cubes, transparent acrylic plates will be cut with laser cutter. -

Vinyl cutting:

To make circuit which will be embedded inside of the cube, copper tape will be cut with vinyl cutter.

-

Python coding:

To develop interface application, Python and its widget and 3D library will be used. -

C coding:

To make AVR chip inside the cube works as node of APA network, C coding is required. It will be wrote beased on datasheet.

what tasks need to be completed?

- Modelling final 3D design

- Layout cirucuit with ATmega88

- Cutting material with laser and Vinyl cutter

- Coding AVR and PC side source code (C & Python).

what questions need to be answered?

Connection of circuits which are separated into 6 faces inside the cube.

And way to close the cube. (Glueless, snap fit, or just fixed with glue?)

what is the schedule?

5/21 - 5/29: Making hardware.

5/30 - 6/3: coding & debugging.

how will it be evaluated?

The system generates 3D model based on combined cubes.