week15. System integration

Assignment

Individual assignment

- Design and document the system integration for your final project

Individual Assignment

For this week’s assignment, I worked on integrating the PCB and 3D-printed enclosure for my final project. This process included the following steps:

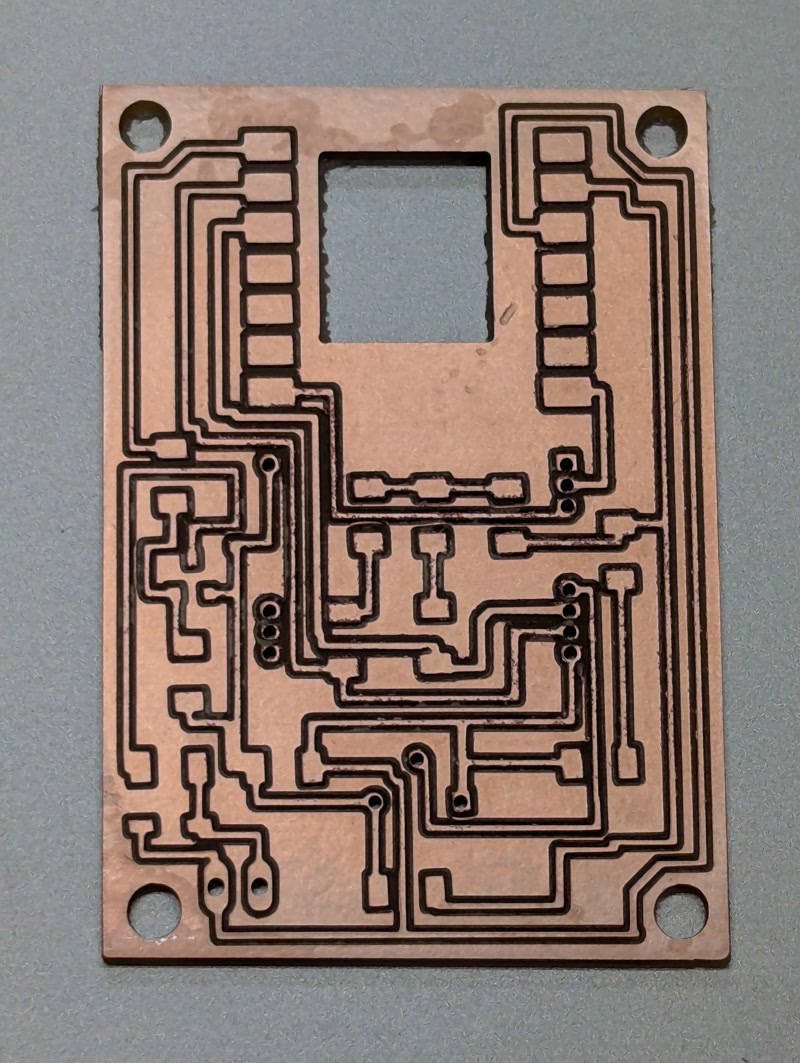

1. PCB Design

To enable system integration, I designed a custom PCB using Fusion 360 tailored to the final project.

The board includes headers for connecting sensors, power input, and communication pins.

Design Process

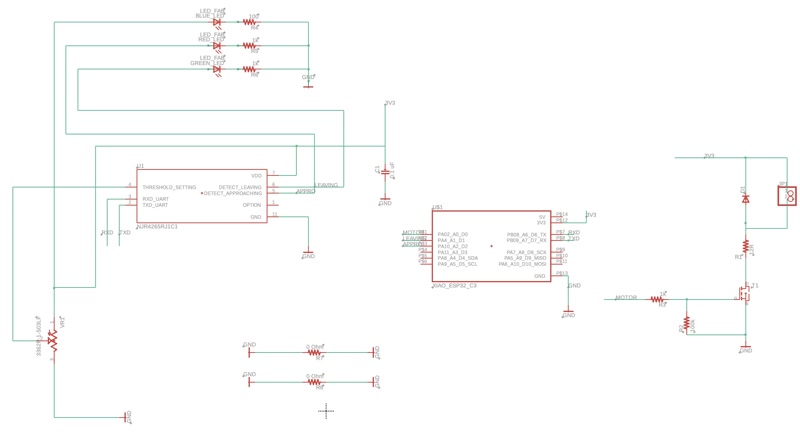

- Circuit Schematic Design

I first created a circuit schematic in Fusion 360 and placed key components such as:

- ESP32-C3 microcontroller

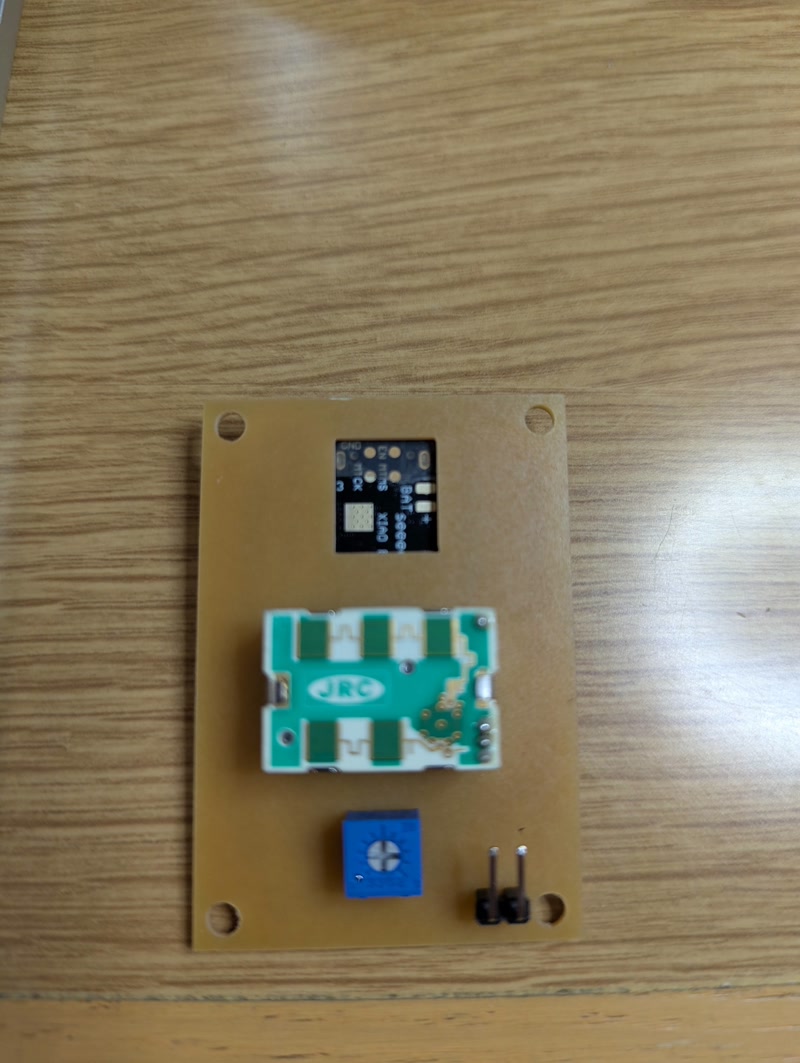

- 24GHz motion detection / Doppler radar sensor module

- Transistors

- Resistors and capacitors

- Pin headers for external motor connection

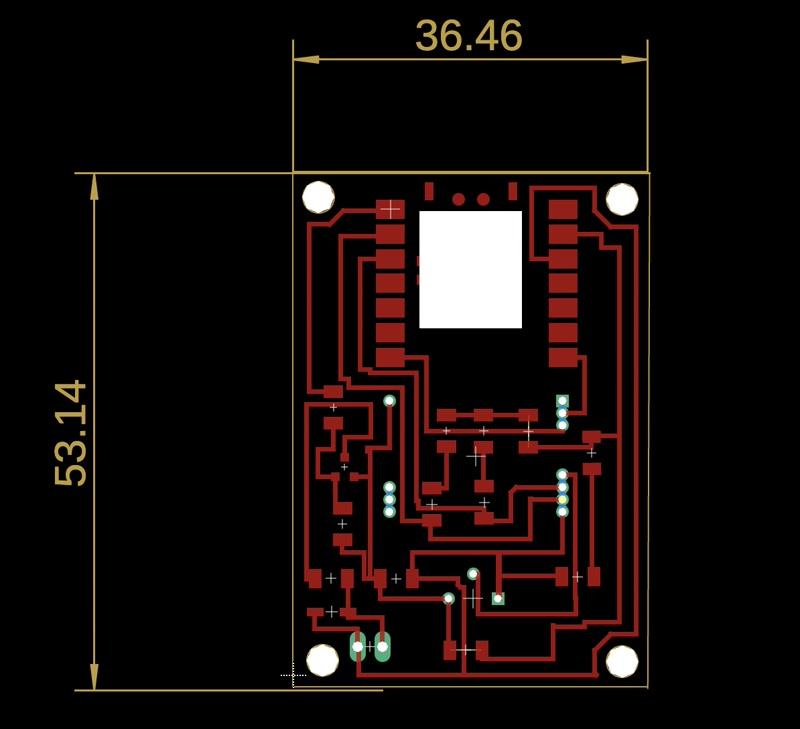

- PCB Layout

After completing the schematic, I moved on to the PCB layout.

- I routed the traces carefully to avoid interference.

- I added mounting holes to match the design of the enclosure.

- Exporting PNG Files

To fabricate the PCB using a CNC milling machine, I exported the following files:

traces.png: for milling copper tracesmillholes.png: for drilling component holesoutline.png: for cutting the board outline

TIP

- All traces were verified using Design Rule Check (DRC).

2. Enclosure Design

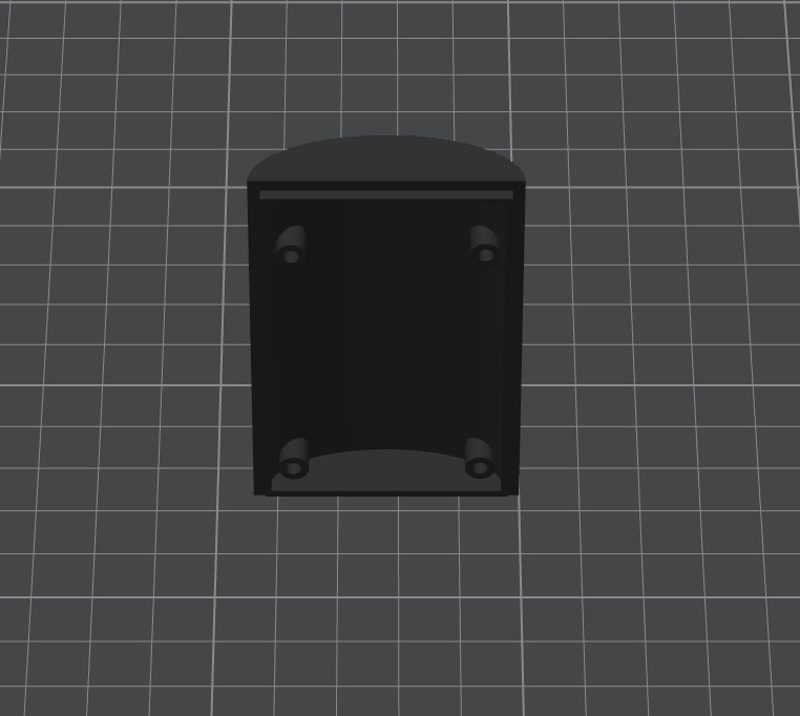

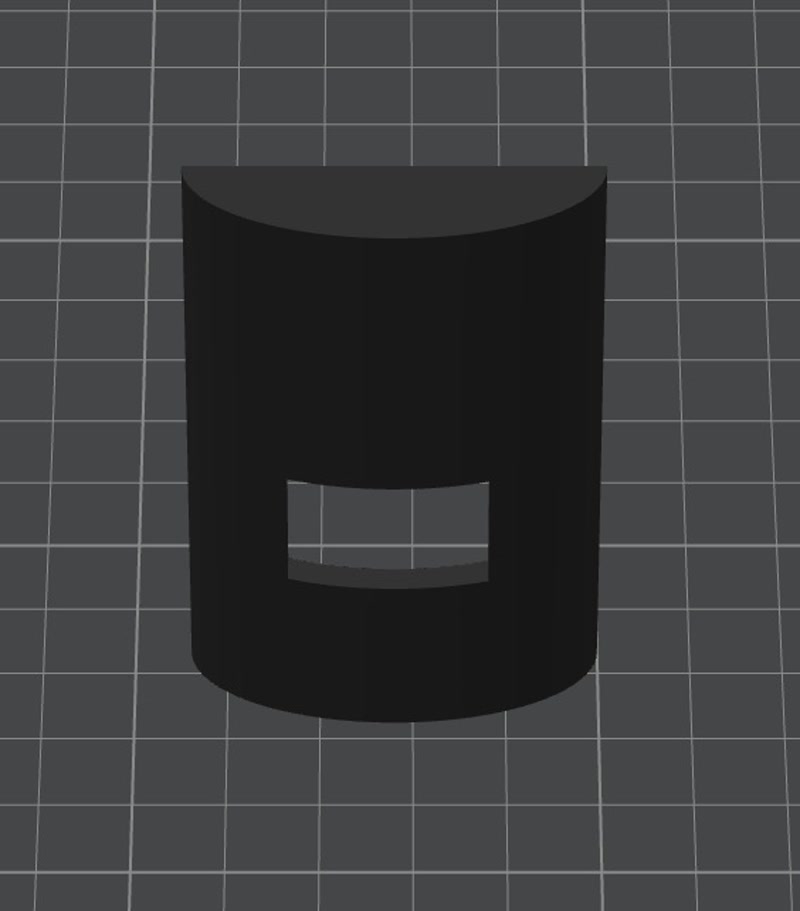

I modified the 3D model created in week02 to accommodate the PCB.

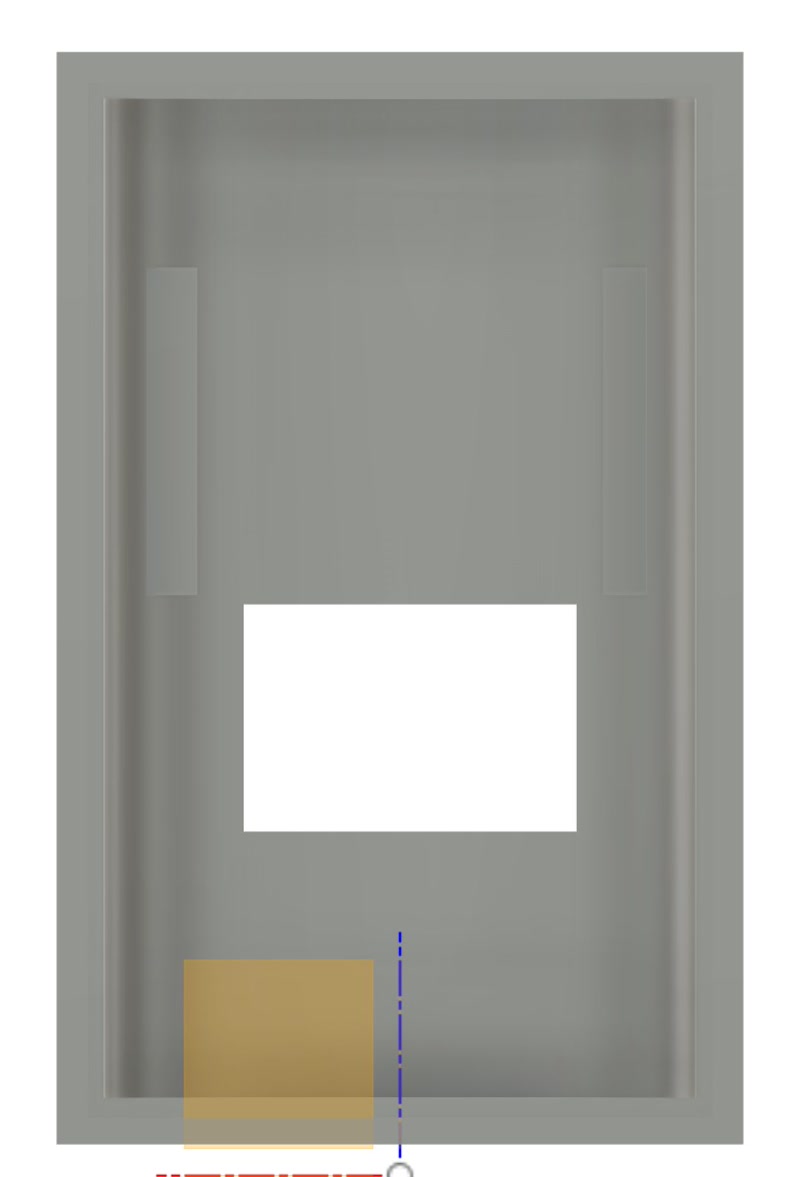

3. Integration of PCB and Internal frame

- Import the 3D model of the PCB into the Fusion 360 enclosure design and align it for a perfect fit to the internal frame.

- Adjusted mounting holes and support structures based on the PCB dimensions and connector positions.

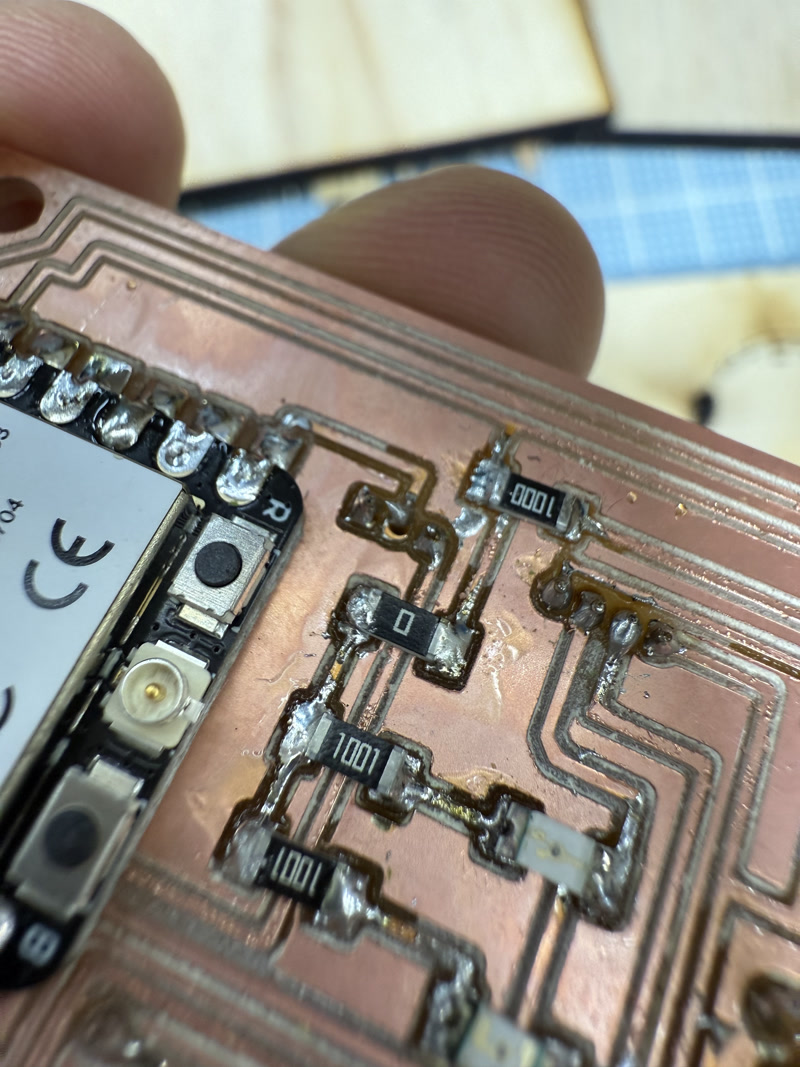

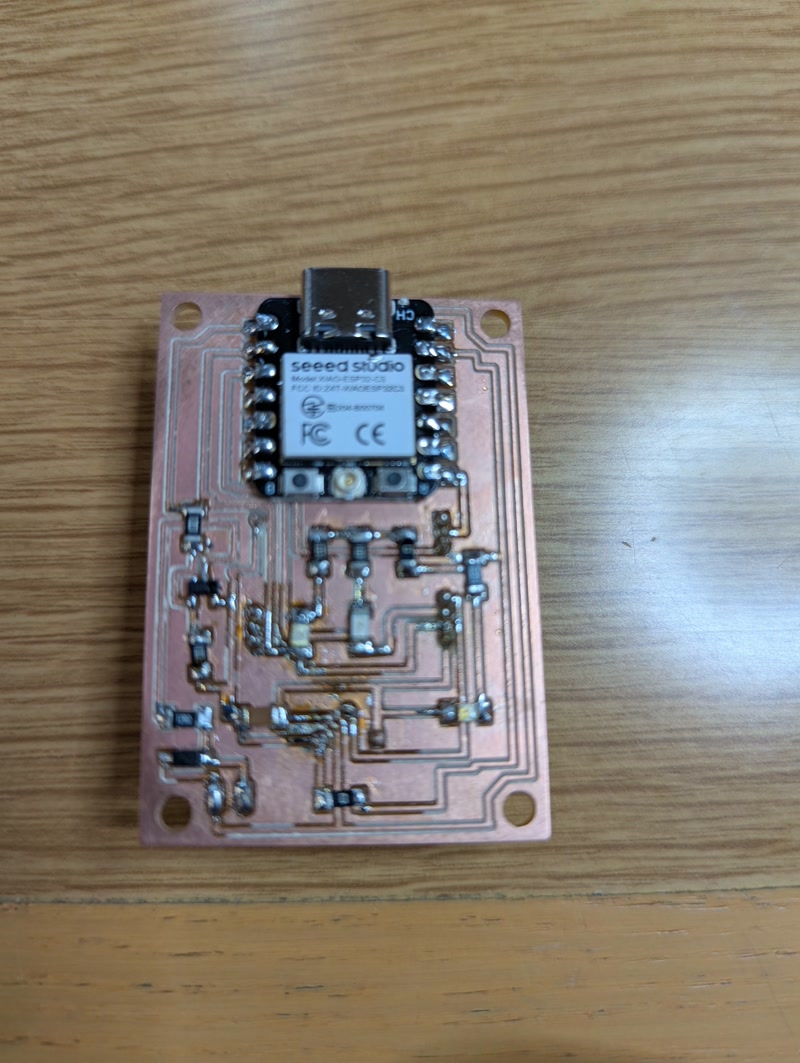

4. PCB Fabrication and Assembly

Based on the PCB data designed in Fusion 360, I physically fabricated the board using a CNC milling machine.

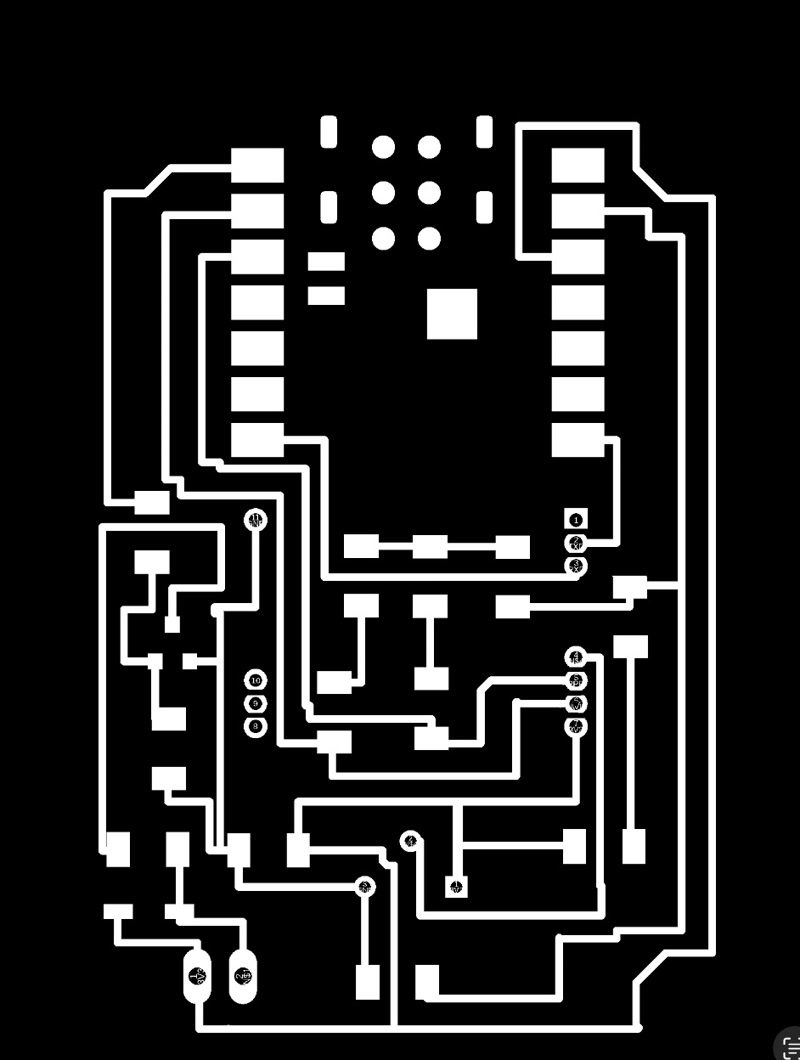

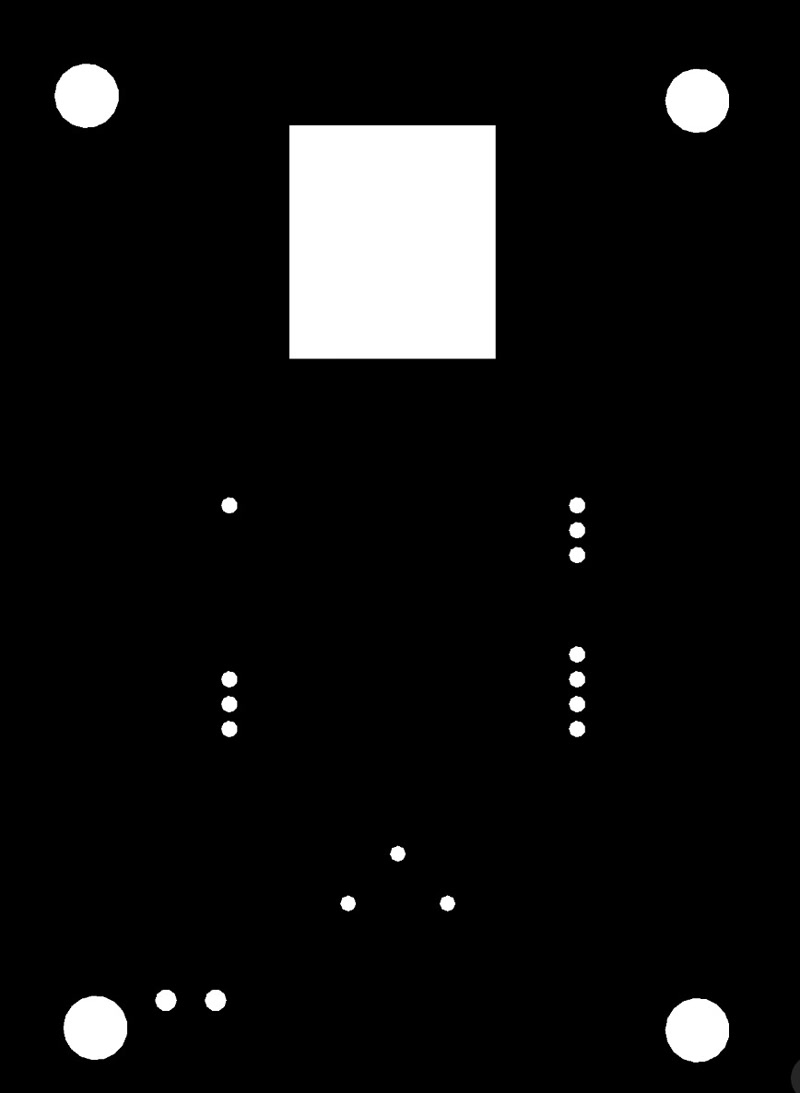

PCB Milling

- Equipment used: CNC router (e.g., Genmitsu PROVerXL 4030)

- Bits used: 0.1mm V-bit (for traces), 0.7mm end mill (for holes and outline)

- Fabrication steps:

- Milled copper traces using

traces.png - Drilled component holes using

millholes.png - Cut the PCB outline using

outline.png

- Milled copper traces using

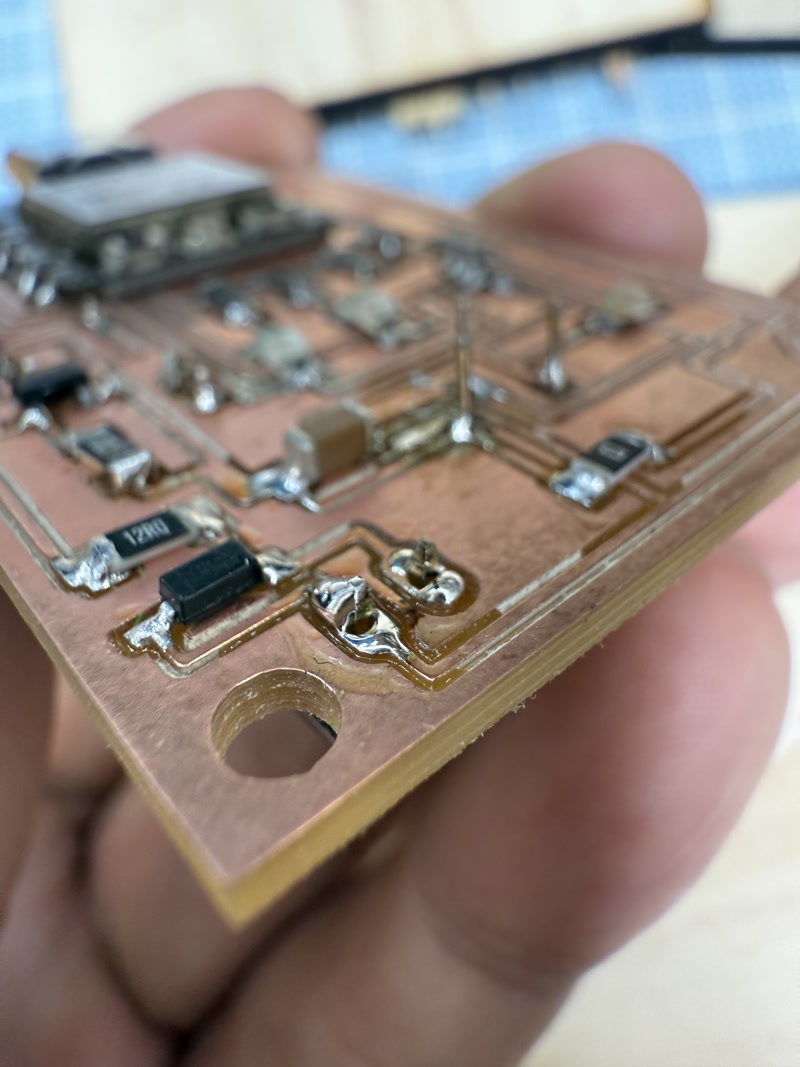

Mounted components:

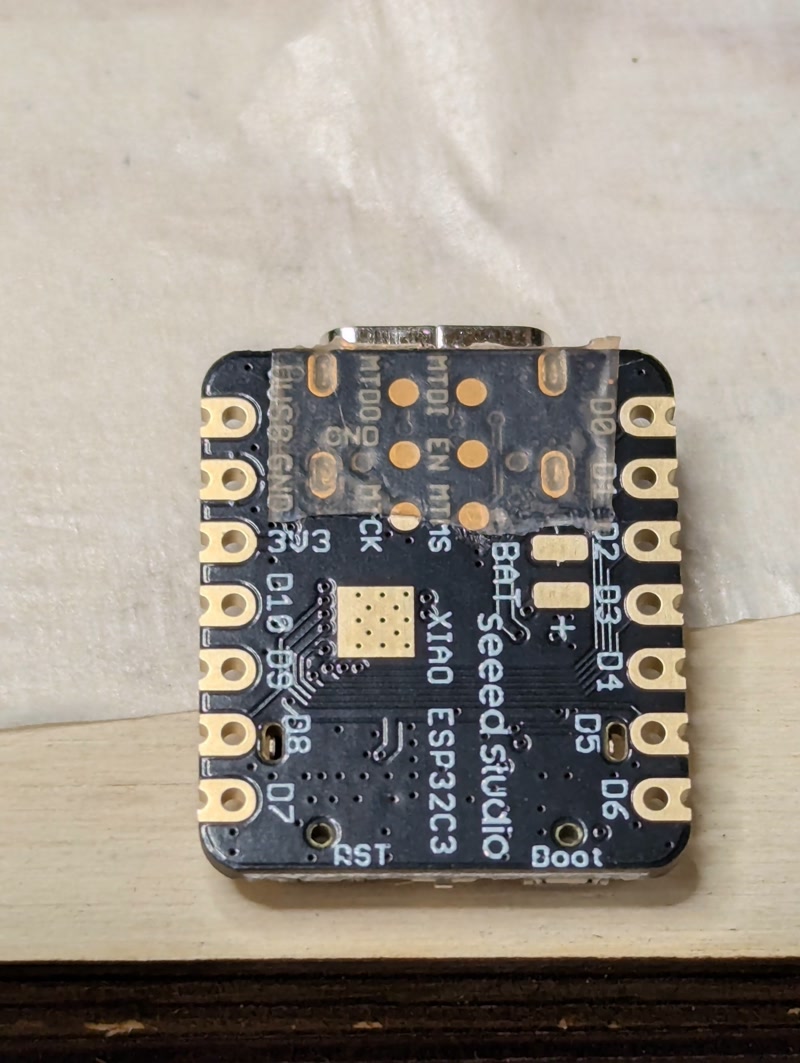

- ESP32-C3 microcontroller

- 24GHz radar sensor (NJR4265RJ1C1)

- Resistors and capacitors (SMD and through-hole)

- Transistors

- Pin headers (for motor control)

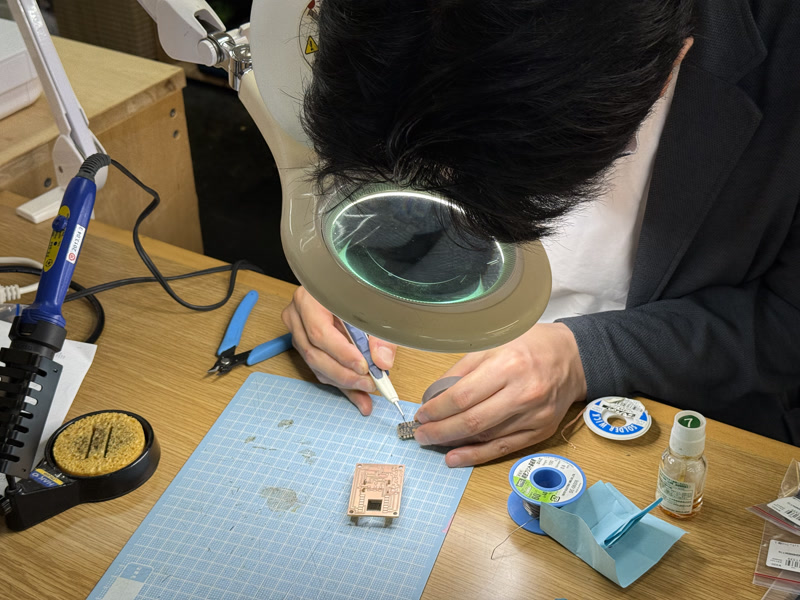

Soldering method:

Through-hole components were soldered manually

SMD components were soldered using tweezers and a temperature-controlled soldering iron

Insulation tape was applied to the bottom of the ESP32-C3 module before mounting to prevent the underside pads from contacting other conductive surfaces

Inspection:

- Performed continuity checks and confirmed power voltage

- Performed continuity checks and confirmed power voltage

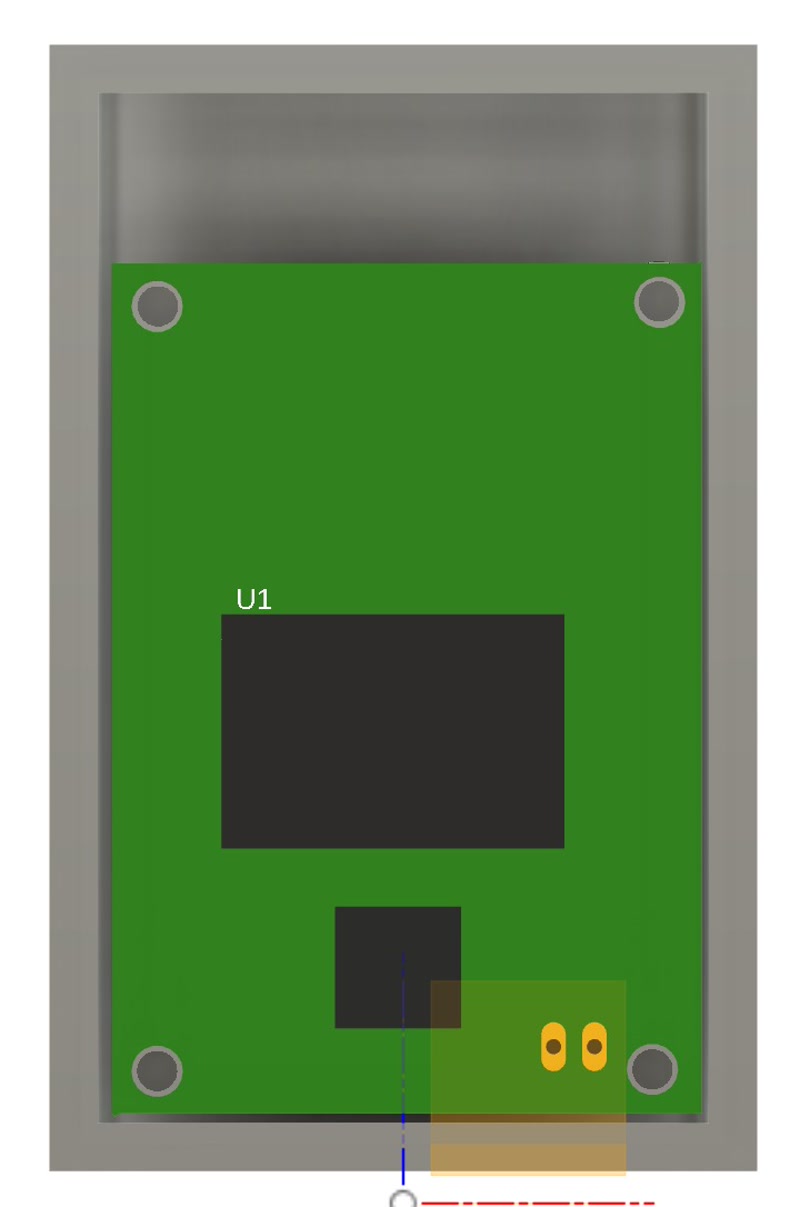

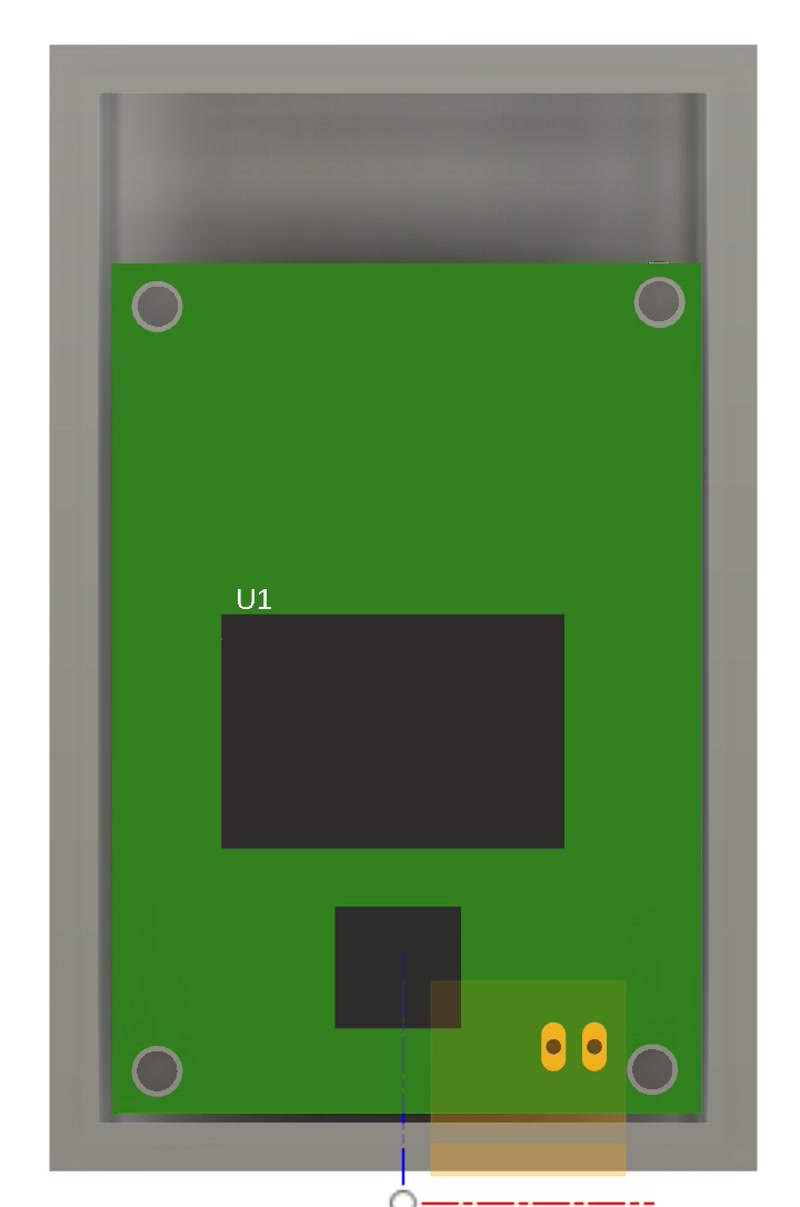

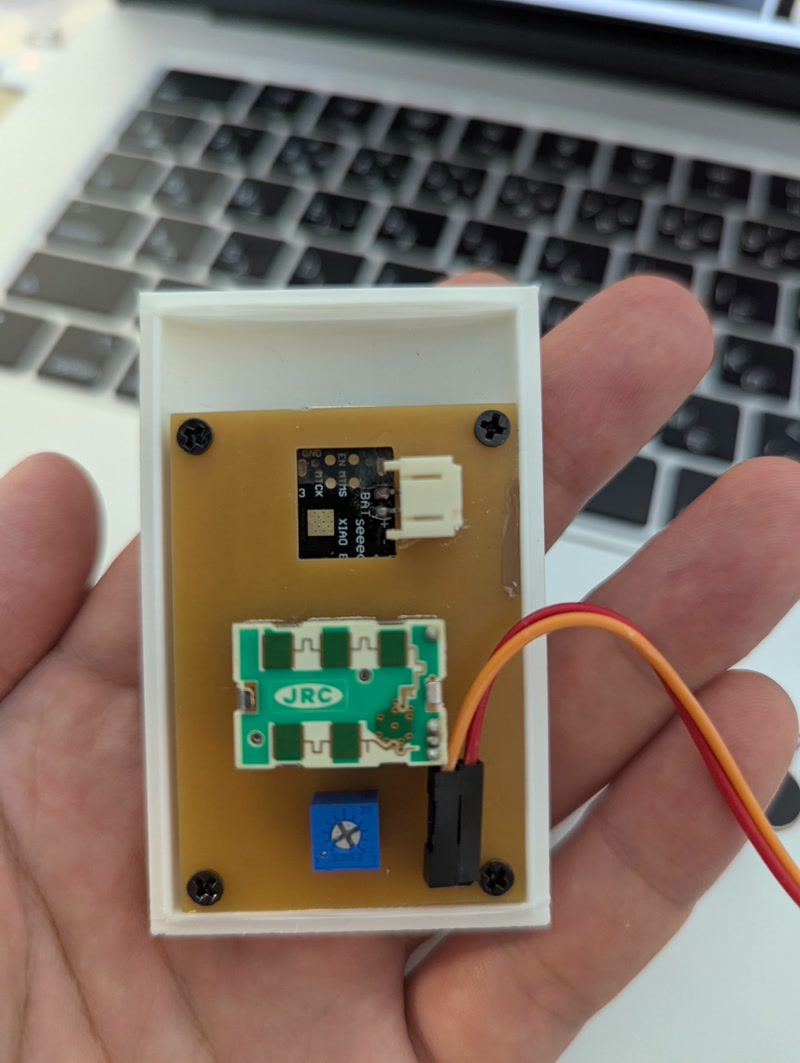

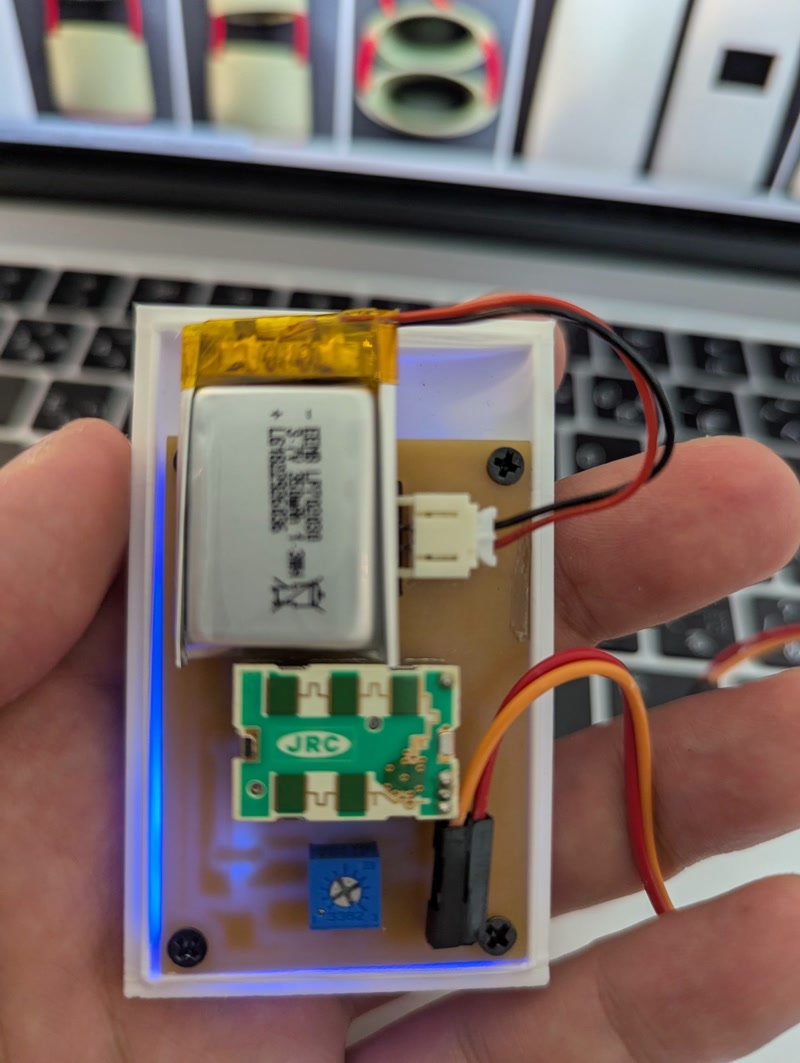

Final Assembly Photos

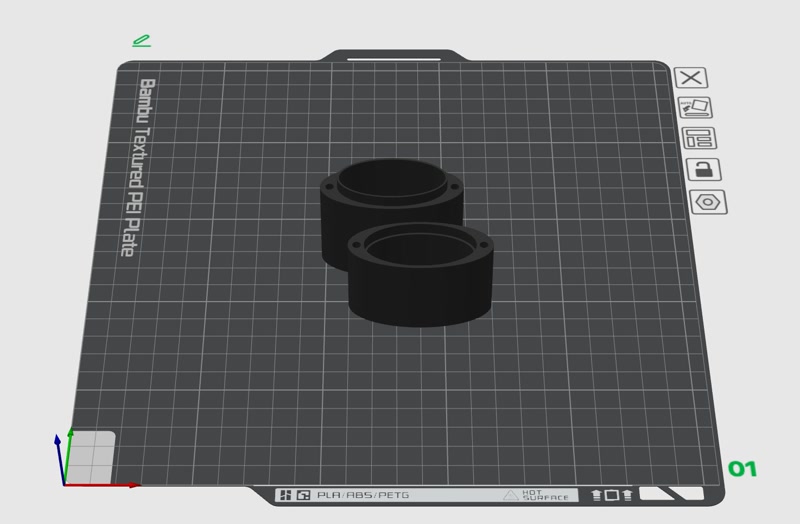

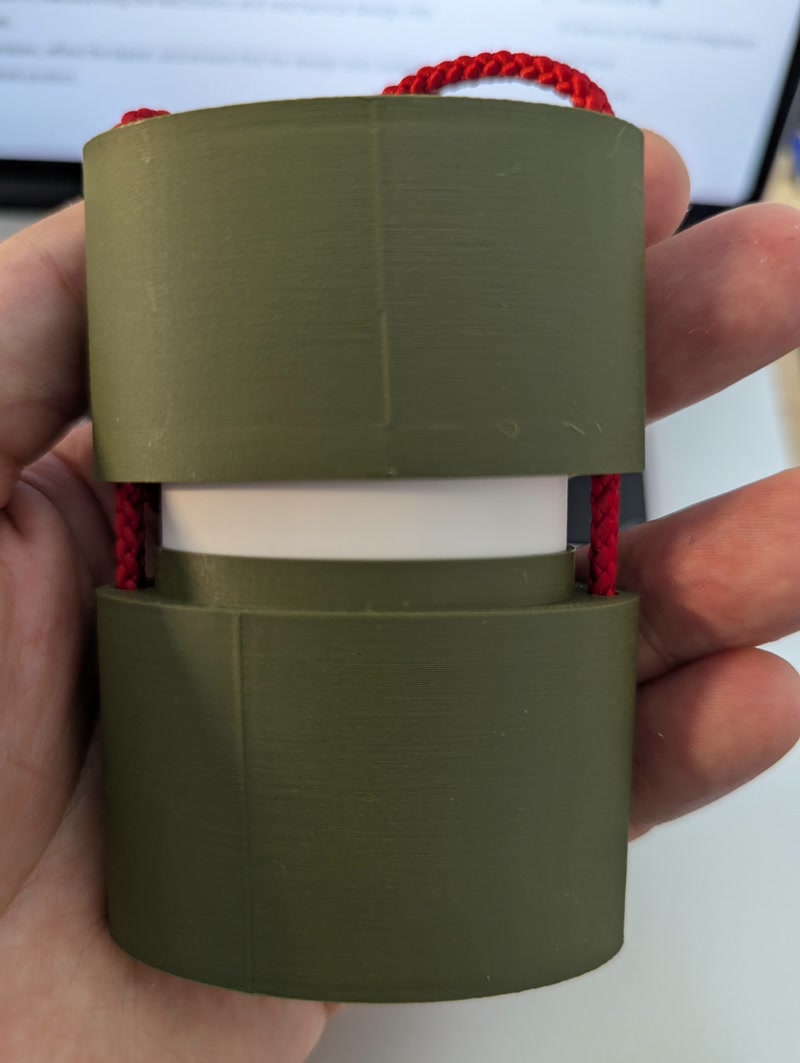

5. 3D Printing of Enclosure and Internal Frame & PCB Integration

After completing the PCB, I printed the designed enclosure and internal frame using a 3D printer, and integrated the PCB.

3D Printing

- Printer used: Bambu Lab P1S

- Filament: PLA (white/green), nozzle diameter: 0.4mm

- Print settings:

- Layer height: 0.2mm

- Infill: 15%

- Supports: auto-generated where needed

Integration Process

- Secured the PCB to the internal frame using screws and confirmed the positions of pin headers and sensors

- Inserted the frame into the enclosure and checked for fit and clearance

- Finalized alignment of external connectors and power input before closing the enclosure

6. Sticker Creation and Decoration

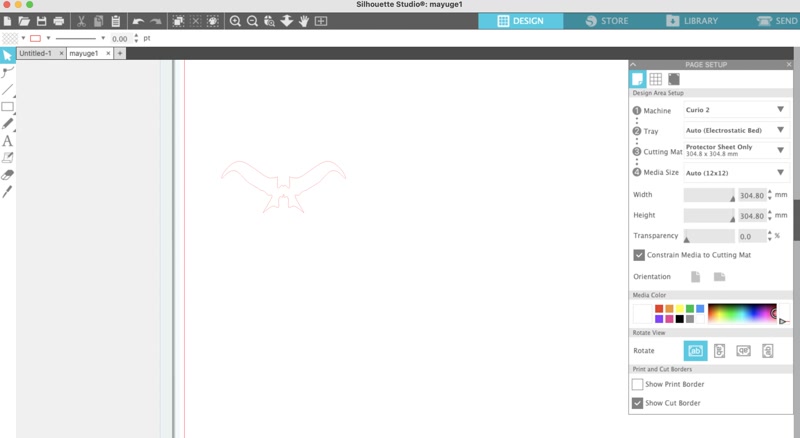

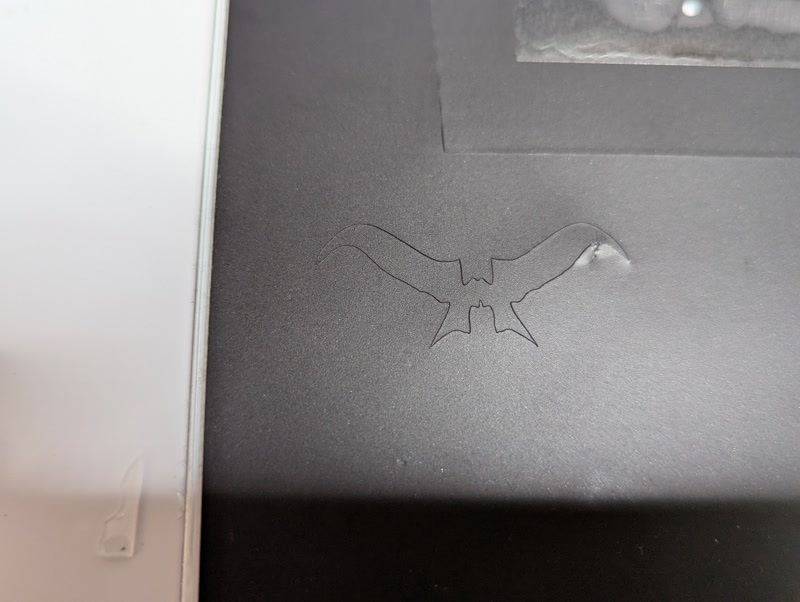

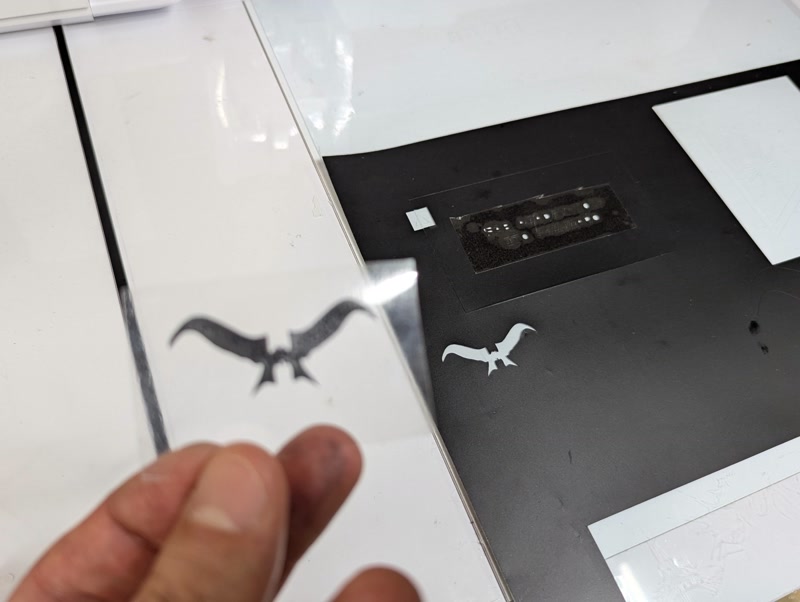

To add character to the enclosure's appearance, I used the Silhouette Curio 2 to create and apply a sticker of Golgo 13's iconic eyebrows.

Sticker Creation Steps

Design preparation: Prepare an image of Golgo 13’s eyebrows

Editing in Silhouette Studio:

- Launch Silhouette Studio and import the image

- Use the tracing tool to convert the image into a path ([Trace Area] → [High Threshold Trace])

- Remove unwanted borders and noise, keeping only the eyebrow path

- Adjust the size and orientation as needed

Cutting Setup:

- Equipment: Silhouette Curio 2

- Material: Black vinyl sheet

- Settings: Adjust cutting pressure, blade depth, and speed based on test cuts

Cutting Execution: Accurately cut the eyebrows from the vinyl and weed out unnecessary areas

Transfer and Application:

- Use transfer tape to position the sticker carefully on the front of the enclosure

- Remove air bubbles, press firmly, and peel off the transfer tape

Result

- Adding the sticker emphasized the unique identity of the Golgo 13 Machine

- It enhanced the visual impact and made it a standout feature for presentations and exhibitions

Evidence of System Integration

- The PCB is properly positioned and securely mounted inside the custom-designed enclosure.

3D file Download

PCB file Download

Sticker file Download

Reflection

This integration step was crucial in transforming the electronics and mechanical design into a cohesive, functional system.

I was able to validate dimensions, refine the layout, and ensure that the design both looked and functioned like a finished product.