Interface and Application programming

Group Assignment

- Compare as many tool options as possible

Individual Assignment

- Write an application that interfaces a user with an input &/or output device that you made.

Introduction

For this week’s assignment, my task was to create a GUI (Graphical User Interface) that the

user can interact with, after sending the PC via USB cable readings from my input device,

aka temperature sensor DS18B20 (I decided to take the code

I did in final

code draft - week 11 progress, clean it and simplfy the logic).

For my electronics, please check out Week

8 - Electronics Production and Week

9 - Input Devices documentation!

Based on my instructor's recommendation, I downloaded Processing 4. software to visualise my data

in a GUI.

Processing is a beginner-friendly Java-based environment for coding interactive graphics and

hardware interfaces.

To prepare myself, I reviewed the basics: how to open a serial port and send/receive data

using the Serial library,

how to remap raw sensor readings into a fixed range with the map() function (you can also check

out Medium

tutorial),

and how to build a simple GUI (toggles and buttons) using ControlP5 library by following the

ControlP5 guide (you can also check

out the Processing.py

ten-lessons to understand ControlP5 callbacks).

Overall, the processing official site's Documentation reference list was my go to reading

reference to understand different functions and be able to create my code with the help of

ChatGPT.

One last thing I remembered to consider in my prompt was the sensor's library. Since I want

to avoid using library other than the one I found from my last test, I had to explicitly

specify it to make sure I do not receive any other library.

Prompt

"Hi! I’m working on Fab Academy’s Interface & Application Programming week and I need two

matched programs—one for my Raspberry Pi Pico W in the Arduino IDE and one in Processing 4.

I am new to Processing, so please keep everything clear and fully commented.

MicroDS18B20<26> sensor1; and MicroDS18B20<27> sensor2; exactly as written; do not

switch to DallasTemperature.

- PART 1 – Arduino-IDE sketch for the Pico

- Board: Raspberry Pi Pico W (RP2040).

- Sensors: two DS18B20 sensors on GPIO 26 and GPIO 27.

- LED: GPIO 22.

- Firmware requirements:

- every second start a 12-bit conversion, read both sensors, and compute their mean

- send exactly one CSV line per second in the format mean;t1;t2\n (two decimals, no extra text)

- light the LED automatically when the mean ≥ 23 °C unless overridden

- listen for a single-byte command from the computer: '1' forces LED ON, '0' forces LED OFF, the override stays until the next byte

- baud rate must be 9600 to match Processing;

- no banners or debug prints—only the CSV line.

- >Visualisation: draw

- a dial gauge for the mean temperature, scale 20 °C (left) → 30 °C (right), sweep 225° → –45°, color-fade blue → green → red as the value rises, and display the numeric value

- a scrolling strip-chart under the gauge, 10 pixels per second so 60 samples fit the window.

- GUI with ControlP5:

- a toggle switch labelled Stream that, when OFF, pauses or hides the visuals but continues receiving data; when ON, resumes drawing

- a push-button that flips the LED—first click sends '1', second click sends '0', and the caption toggles between “LED ON” and “LED OFF”.

- Deliverables

- A complete Arduino sketch (.ino) that compiles unchanged with microDS18B20.

- A complete Processing 4 sketch (.pde) that runs immediately after ControlP5 is installed through the Library Manager.

ArduinoIDE Programming

Before uploading the sketch to the Pi Pico W, I faced into the same issue I previously ran

into (check Reflection

and Struggles - Week 11); the port disconnecting and getting stuck in the boot mode

UF2. This time, I decided to download the flash_nuke.uf2

file from Raspberry

Pi, reboot the board while holding BOOTSEL, and drag-and-drop that UF2 to reinstall

the bootloader.

Finally, I managed to see the COM7 port and uploaded the code I wrote with

ChatGPT.

ArduinoIDE Code: ChatGPT version

This code uses the microDS18B20 library I already tested two weeks ago and

read two temperature values every second, computes their mean value, and then prints out a

single CSV line in the format mean;t1;t2\n at 9600 baud for the

Processing code to pick up.

It also overrides the automatic LED logic: when it receives 1 > LED is

ON, and when it receives 0 > LED is OFF.

Outside of override mode, the code drives the LED based on whether the mean temperature is

above the threshold = 23°C.

#include // Include the microDS18B20 library

MicroDS18B20<26> sensor1; // DS18B20 sensor on GPIO 26

MicroDS18B20<27> sensor2; // DS18B20 sensor on GPIO 27

const int ledPin = 22; // LED on GPIO 22

bool overrideActive = false; // Flag: are we in override mode?

bool overrideState = LOW; // Forced LED state when overridden

void setup() {

Serial.begin(9600); // Start serial at 9600 baud (no banners)

pinMode(ledPin, OUTPUT); // Configure LED pin as output

}

void loop() {

// 1) Start a new temperature conversion on both sensors

sensor1.requestTemp();

sensor2.requestTemp();

// 2) Wait for conversion to complete (12-bit ≈750 ms; wait 1 s to be sure)

delay(1000);

// 3) Read temperatures (in °C) from the sensors

float t1 = sensor1.getTemp();

float t2 = sensor2.getTemp();

// 4) Compute the mean of the two readings

float meanTemp = (t1 + t2) / 2.0;

// 5) Check for an incoming override command ('1' or '0')

if (Serial.available() > 0) {

char cmd = Serial.read();

if (cmd == '1') {

overrideActive = true;

overrideState = HIGH;

}

else if (cmd == '0') {

overrideActive = true;

overrideState = LOW;

}

}

// 6) Control the LED: override if active, else auto on mean ≥23 °C

if (overrideActive) {

digitalWrite(ledPin, overrideState);

} else {

if (meanTemp >= 23.0) digitalWrite(ledPin, HIGH);

else digitalWrite(ledPin, LOW);

}

// 7) Send one CSV line: mean;t1;t2\n (two decimals, no extra text)

Serial.print(meanTemp, 2);

Serial.print(';');

Serial.print(t1, 2);

Serial.print(';');

Serial.print(t2, 2);

Serial.print('\n');

}

Processing Code: ChatGPT Version

Processing software has a very similar GUI to ArduinoIDE. Hence, navigating through it for

the first time was not difficult. In order to be able to run the sketch, you need to close

the ArduinIDE sketch first. Moreover, you can't open two sketches in parallel in Processing;

it will show you Port busy error. Hence, run only one sketch at a time!

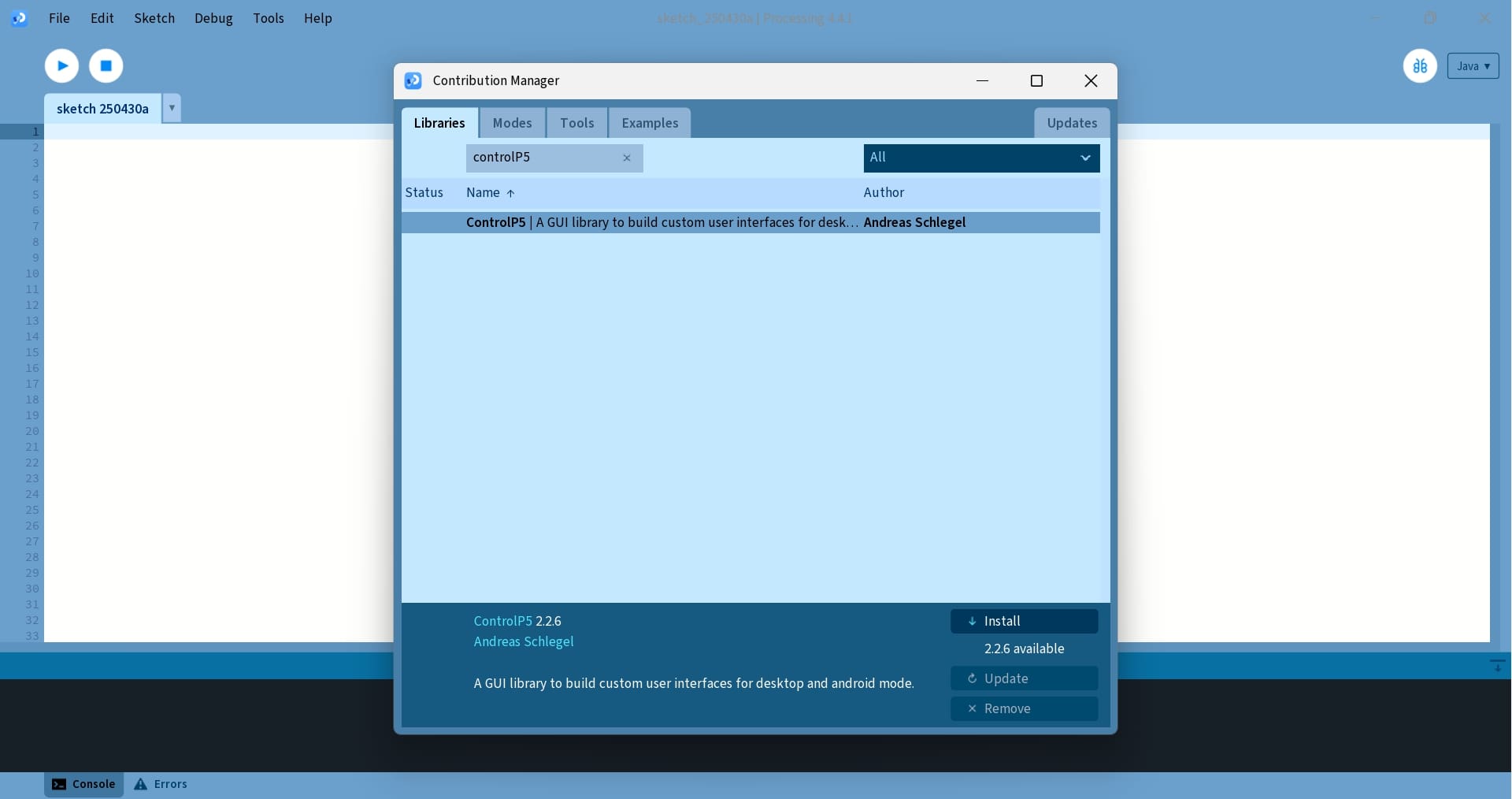

First, I had to download the ControlP5 library from the library manager to

be able to run the code.

Then, I pasted the code I acquired from ChatGPT.

In this code, COM ports were listed in the Draws a simple dial that shows the mean temperature between 20 °C and 30 °C. For

styling, the needle moves around the arc and changes color from blue to green to red as

the temperature increase, and the value is printed underneath .

Draws a line chart of the last 60 temperature records .

Lastly, when the Stream switch is toggled or the LED

button is clicked, all events go through one function:

setup(), then the Pico’s port was

opened with bufferUntil('\n'), at a baudrate of 9600 (to match the baud rate

from the Arduino code).

Furthermore, it generates a Stream toggle and LED button via ControlP5

library. Then, the draw() funcion starts by clearing the screen. If the

Streamswitch is on, the sketch does two things:

controlEvent().

This function receives with button has been pressed by the user, updates the internal on/off

state, sends the 1 or 0 character over serial accordingly,

and updates the button label.

import processing.serial.*; // import serial library

import controlP5.*; // import ControlP5 for GUI

Serial myPort; // The serial port object

ControlP5 cp5; // ControlP5 instance

Toggle streamToggle; // Toggle to pause/resume drawing

Button ledButton; // Button to flip the Pico's LED

boolean ledState = false; // Track current LED state (false=off)

int totalSamples = 60; // buffer length for 1-minute history

float[] data = new float[totalSamples];

int dataIndex = 0;

boolean dataFull = false;

float currentMean = 0; // Latest mean value

void setup() {

size(600, 600); // Window size

// Serial setup

println(Serial.list()); // List available ports

String[] ports = Serial.list();

int portIndex = 0; // ← change this to your Pico's index

myPort = new Serial(this, ports[portIndex], 9600);

myPort.bufferUntil('\n'); // Deliver full lines

// GUI setup

cp5 = new ControlP5(this);

streamToggle = cp5.addToggle("stream")

.setPosition(20, 20)

.setSize(50, 20)

.setLabel("Stream")

.setValue(true);

ledButton = cp5.addButton("ledButton")

.setPosition(100, 20)

.setSize(80, 20)

.setLabel("LED ON");

}

void draw() {

background(255); // White background

if (streamToggle.getState()) { // Only draw when streaming

drawGauge();

drawStripChart();

}

}

// Called when a full CSV line arrives

void serialEvent(Serial p) {

String line = p.readStringUntil('\n');

if (line != null) {

line = trim(line);

String[] parts = split(line, ';');

if (parts.length == 3) {

float mean = float(parts[0]);

// Add to circular buffer

data[dataIndex] = mean;

dataIndex = (dataIndex + 1) % totalSamples;

if (dataIndex == 0) dataFull = true;

currentMean = mean;

}

}

}

// Draw the dial gauge for currentMean

void drawGauge() {

float cx = width/2;

float cy = height/3;

float radius = 150;

// Gauge arc

stroke(0);

noFill();

arc(cx, cy, radius*2, radius*2, radians(225), radians(-45));

// Compute needle angle (20→30 °C maps 225°→-45°)

float angle = map(currentMean, 20, 30, radians(225), radians(-45));

// Color fade: blue→green→red

color c;

if (currentMean <= 20) c = color(0, 0, 255);

else if (currentMean >= 30) c = color(255, 0, 0);

else if (currentMean <= 25) c = lerpColor(color(0, 0, 255), color(0, 255, 0), map(currentMean, 20, 25, 0, 1));

else c = lerpColor(color(0, 255, 0), color(255, 0, 0), map(currentMean, 25, 30, 0, 1));

// Draw needle

pushMatrix();

translate(cx, cy);

stroke(c);

strokeWeight(3);

float nx = radius * cos(angle - HALF_PI);

float ny = radius * sin(angle - HALF_PI);

line(0, 0, nx, ny);

popMatrix();

// Numeric readout

fill(0);

textAlign(CENTER, CENTER);

text(nf(currentMean, 0, 2) + " °C", cx, cy + radius + 20);

}

// Draw the scrolling strip-chart

void drawStripChart() {

float chartY = height * 2/3;

float chartH = height/3 - 40;

// Border

noFill();

stroke(0);

rect(10, chartY, width - 20, chartH);

// Data polyline

noFill();

beginShape();

int count = dataFull ? totalSamples : dataIndex;

for (int i = 0; i < count; i++) {

int idx = (dataIndex + i) % totalSamples;

float x = map(i, 0, totalSamples - 1, 10, width - 10);

float y = map(data[idx], 20, 30, chartY + chartH, chartY);

vertex(x, y);

}

endShape();

}

// Handle LED button clicks

void controlEvent(ControlEvent e) {

if (e.getController().getName().equals("ledButton")) {

if (ledState) {

myPort.write('0'); // Turn LED OFF on Pico

ledState = false;

e.getController().setLabel("LED ON");

} else {

myPort.write('1'); // Turn LED ON on Pico

ledState = true;

e.getController().setLabel("LED OFF");

}

}

}

Arduino Code Modified

After testing, I decided to slightly adjust the Arduino code better reliability. First, I

wrote few comments at the beginning to intruduce briefly what the code does.

Then, I added error checks on each

readTemp() for debugging. Afterwards, I

defined the constant tempThreshold.

Lastly, I simplified the override logic for controlling the LED, so that incoming

0s/1s commands are processed immediately in one block at the bedginning of

loop() (by removing nested if-statements and using only one condition to set

the LED state > behavior becomes more predictable).

/*

- Raspberry Pi Pico W + two DS18B20 sensors + status LED

• Built-in error check on readTemp() → GUI only sees valid data

• When overrideActive==true → tempThreshold logic is bypassed

• Outputs every 1 s: mean;t1;t2\n

• Accepts single-byte commands: '1'→LED ON, '0'→LED OFF

*/

#include // DS18B20 MicroMicro library

// Pins Definition

MicroDS18B20<26> sensor1; // DS18B20 on GPIO 26

MicroDS18B20<27> sensor2; // DS18B20 on GPIO 27

#define LED_PIN 22 // status LED

// Temperature Threshold

const float tempThreshold = 23.0; // auto-LED ON above this mean °C

// Set-up

void setup() {

Serial.begin(9600); // baudrate should match the Processing sketch

pinMode(LED_PIN, OUTPUT);

}

// Global variables

bool overrideActive = false; //initially OFF

bool overrideState = false;

void loop() {

// Process any incoming 1s/0s commands immediately

while (Serial.available()) {

char c = Serial.read();

if (c == '1') {

overrideActive = true;

overrideState = true;

}

else if (c == '0') {

overrideActive = true;

overrideState = false;

}

// ignore anything else

}

// Kick off conversions

sensor1.requestTemp();

sensor2.requestTemp();

delay(1000); // wait for the DS18B20 sensor

// Read temperature values and compute mean

bool ok1 = sensor1.readTemp();

bool ok2 = sensor2.readTemp();

if (ok1 && ok2) {

float t1 = sensor1.getTemp();

float t2 = sensor2.getTemp();

float meanT = 0.5 * (t1 + t2);

// apply LED logic with override

if (overrideActive) {

digitalWrite(LED_PIN, overrideState ? HIGH : LOW);

} else {

digitalWrite(LED_PIN, meanT >= tempThreshold ? HIGH : LOW);

}

// send CSV line

Serial.print(meanT, 2); Serial.print(';');

Serial.print(t1, 2); Serial.print(';');

Serial.println(t2, 2);

}

// loop back and wait for next command!

}

The code works as expected. Nevertheless, the gauge lacks ticks or a digital readout, and

the strip chart only shows the mean value line, which makes it hard to differential between

the two sensors readings.

Moreover, toggling buttons of the stream and the LED is

quite confusing, since they lack the labels.

Processing Code Modified

Since I wasn't satisfied with the appearance of my GUI, I decided to modify the code. First,

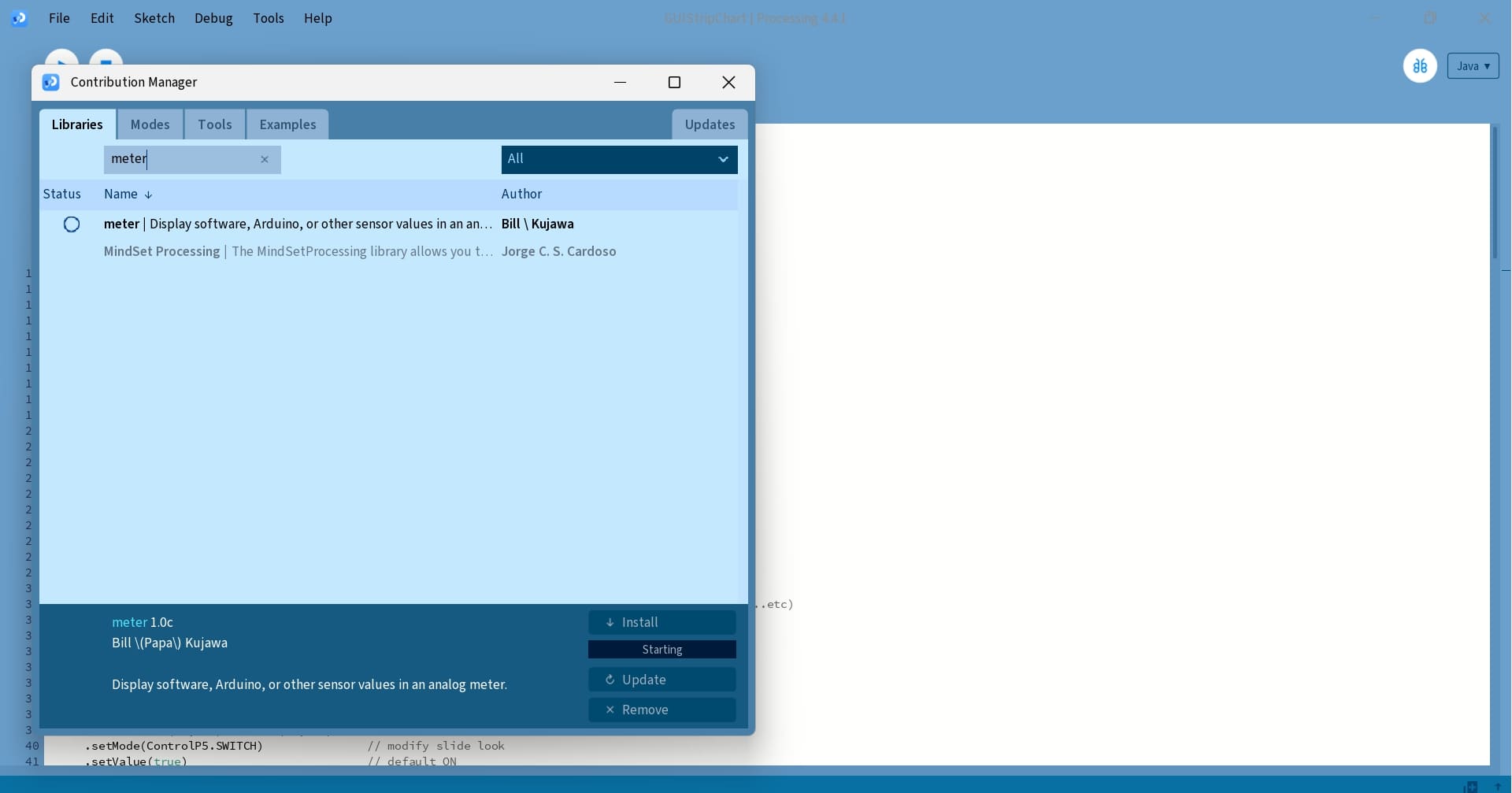

after watching

the youtube video tutorial I attached at the end, I decided to download the Meter

library.

Second, I went through the library examples on Github, specifically SetAllValues

example to understand how I can tweak the styling of the gauge for temperature

readings (titles,

ticks, arc thickness, needle,).

Moreover, I reviewed the code example from Electronic

Clinic gauge tutorial to understand how I can map raw sensor values onto an arc and

smoothly fade

the dial color (blue > green > red).

This led me to replace the arcs with

tempGauge.set…() calls,

replace fixed

values with constants MIN_T and MAX_T, and enable a

digital readout.

Lastly, I upgraded the strip chart, so each DS18B20 sensor has its own color, with axes and

a legend for

better visualisation (you can check out Double Sensor

Graphs

example).

/*

- Pi Pico 2 + two temperature sensors DS18B20 + LED

- Libraries used: Serial (built-in) | ControlP5 | Meter

*/

// Import Libraries

import processing.serial.*; // built-in serial commmunication

import controlP5.*; // ControlP5 GUI widgets

import meter.*; // external Meter library

// Declare global objects

Serial pico; // serial port to Pico

ControlP5 cp5; // ControlP5 controller

Meter tempGauge; // Meter gauge object

// History buffers for each sensor

float[] hist1 = new float[60]; // buffer for sensor 1

float[] hist2 = new float[60]; // buffer for sensor 2

// State variables

int dataIndex = 0; // current write index into dataIndex

boolean stream = true; // true = draw visuals, false = paused

boolean ledOn = false; // track LED override state

float currentT = 0; // latest mean temperature

// Gauge range constants

final float MIN_T = 20; // lower bound on gauge

final float MAX_T = 30; // upper bound on gauge

// Trace colors

color col1 = color( 0, 200, 255); // cyan for sensor 1

color col2 = color(255, 100, 100); // salmon for sensor 2

void setup() {

size(900, 600); // set canvas to 900×600 pixels

surface.setTitle("Temperature Readings"); // window title bar text

// Serial Port Setup

println("Ports:", Serial.list()); // print available COM ports in console

pico = new Serial(this, Serial.list()[0], 9600); // open first port @ 9600 baudrate

pico.bufferUntil('\n'); // call serialEvent() on each newline

// ControlP5 setup

cp5 = new ControlP5(this); // create GUI controller

// Stream toggle

cp5.addToggle("stream") // auto-calls stream(boolean)

.setPosition(20, 20) // place at x=20, y=20

.setSize(60, 25) // width=60, height=25

.setMode(ControlP5.SWITCH) // render as on/off switch

.setValue(true) // default state = ON

.getCaptionLabel()

.set("Stream"); // label the switch “Stream”

// LED button

cp5.addButton("LED") // auto-calls LED() on click

.setPosition(100, 20) // place to the right of toggle

.setSize(80, 25) // width=80, height=25

.setCaptionLabel("LED OFF"); // initial button text

// Meter gauge setup

tempGauge = new Meter(this, width/2 - 150, 20); // position gauge

tempGauge.setTitleFontName("Arial Bold"); // set gauge title font

tempGauge.setTitleFontSize(20); // set title font size

tempGauge.setTitle("Mean Temp (°C)"); // set title text

// Clamp gauge input to [MIN_T,MAX_T]

tempGauge.setMinInputSignal((int)MIN_T); // min physical reading

tempGauge.setMaxInputSignal((int)MAX_T); // max physical reading

tempGauge.setMinScaleValue((int)MIN_T); // min tick label

tempGauge.setMaxScaleValue((int)MAX_T); // max tick label

// Build tick labels at 2 °C intervals

String[] labels = new String[(int)((MAX_T - MIN_T) / 2) + 1];

for (int i = 0; i < labels.length; i++) {

labels[i] = nf(MIN_T + i*2, 0, 0); // format “20”, “22”, …, “30”

}

tempGauge.setScaleLabels(labels); // apply tick labels

// Visual styling for the gauge

tempGauge.setArcColor(color(60)); // track (rim) color

tempGauge.setArcThickness(15); // track arc thickness

tempGauge.setNeedleThickness(4); // set pointer thickness

tempGauge.setDisplayDigitalMeterValue(true);// show digital number

}

void draw() {

background(0); // set screen to black

// Draw dial gauge or paused message

if (stream) {

tempGauge.updateMeter(int(currentT)); // update gauge reading

} else {

fill(255); // white text (range from 0 to 255 → black to white)

textSize(18); // font size

textAlign(CENTER, CENTER); // center alignment

text("Stream OFF", width/2, 140); // draw paused label

}

// Draw the strip-chart below

drawPlot(); // call custom plot function

}

// called by ControlP5 when the toggle changes

public void stream(boolean active) {

stream = active; // store new state

}

// called by ControlP5 when the "LED" button is clicked

public void LED(int theValue) { // callback signature (e.g. user interaction with a button) must accept an integer (click count)

ledOn = !ledOn; // flip local LED state flag

pico.write(ledOn ? '1' : '0'); // send '1' if ledOn true, else '0'

cp5.get(Button.class, "LED") // retrieve the Button named "LED"

.setCaptionLabel(ledOn ? // set its label to match the new state

"LED ON" : "LED OFF");

println("LED() callback, ledOn = " + ledOn); // debug print to confirm it fired

} // end of LED callback

// called whenever a full line arrives on serial

void serialEvent(Serial s) { // serialEvent triggered on '\n'

String line = trim( // read up to newline

s.readStringUntil('\n')); // trim whitespace

if (line == null || line.isEmpty()) // if nothing valid was read

return; // exit the handler

String[] parts = split(line, ';'); // split the CSV "mean;t1;t2" by semicolons

float m = parseFloat(parts[0]); // parse mean temperature

float t1 = parseFloat(parts[1]); // parse sensor 1 reading

float t2 = parseFloat(parts[2]); // parse sensor 2 reading

currentT = m; // store mean for gauge update

hist1[dataIndex] = t1; // push sensor1 into its circular buffer

hist2[dataIndex] = t2; // push sensor2 into its circular buffer

dataIndex = (dataIndex + 1) % hist1.length; // advance buffer index, wrapping at 60

} // end of serialEvent handler

void drawPlot() {

// compute plotting bounds and spacing

int plotTop = 300; // y-pixel position of the top edge of the chart area

int plotBottom = height - 40; // y-pixel position of the bottom edge of the chart area

int marginLeft = 60; // x-pixel offset from the left where the y-axis is drawn

// horizontal spacing so 60 samples fill from marginLeft → (width - 20)

float spacing = float(width - marginLeft - 20) / (hist1.length - 1);

// draw sensor #1 trace in cyan

stroke(col1); // set stroke color to col1 (cyan)

strokeWeight(2); // set line thickness to 2 pixels

noFill(); // disable filling any shapes

beginShape(); // start recording vertices for a continuous line

for (int i = 0; i < hist1.length; i++) {

int p = (dataIndex + i) % hist1.length; // wrap buffer index to get oldest → newest sample

float x = marginLeft + i * spacing; // compute x-position of this sample

float y = map(hist1[p], MIN_T, MAX_T, plotBottom, plotTop); // map temp → vertical pixel

vertex(x, y); // add this point to the shape

}

endShape(); // draw the connected line

// draw sensor #2 trace in salmon, nudged +0.5°C for visibility (since they are essentially recording identical temperatures)

stroke(col2); // set stroke color to col2 (salmon)

strokeWeight(2); // set line thickness to 2 pixels

noFill(); // disable fill

beginShape(); // begin new shape for sensor 2

for (int i = 0; i < hist2.length; i++) {

int p = (dataIndex + i) % hist2.length; // wrap buffer index for sensor 2

float x = marginLeft + i * spacing; // compute x-position for this sample

// temporary offset (+0.5°C) so the two traces don’t overlap exactly

float y = map(hist2[p] + 0.5, MIN_T, MAX_T, plotBottom, plotTop);

vertex(x, y); // add point to the second shape

}

endShape(); // draw the second connected line

// draw the y-axis line and its min/max labels

stroke(180); // set stroke to light gray for axis

strokeWeight(1); // set axis line thickness to 1 pixel

line(marginLeft, plotTop, marginLeft, plotBottom); // draw vertical axis

noStroke(); // disable stroke for text

fill(200); // set fill color for labels

textAlign(RIGHT, CENTER); // right-align labels horizontally, center vertically

text(MIN_T + "°", marginLeft - 5, plotBottom); // draw minimum temp label just left of axis bottom

text(MAX_T + "°", marginLeft - 5, plotTop); // draw maximum temp label just left of axis top

// draw legend entries for each sensor trace

textAlign(LEFT, CENTER); // left-align legend text

fill(col1); // set fill to sensor 1 color

text("Sensor 1", marginLeft + 5, plotTop + 10); // label for sensor 1

fill(col2); // set fill to sensor 2 color

text("Sensor 2", marginLeft + 5, plotTop + 30); // label for sensor 2

}

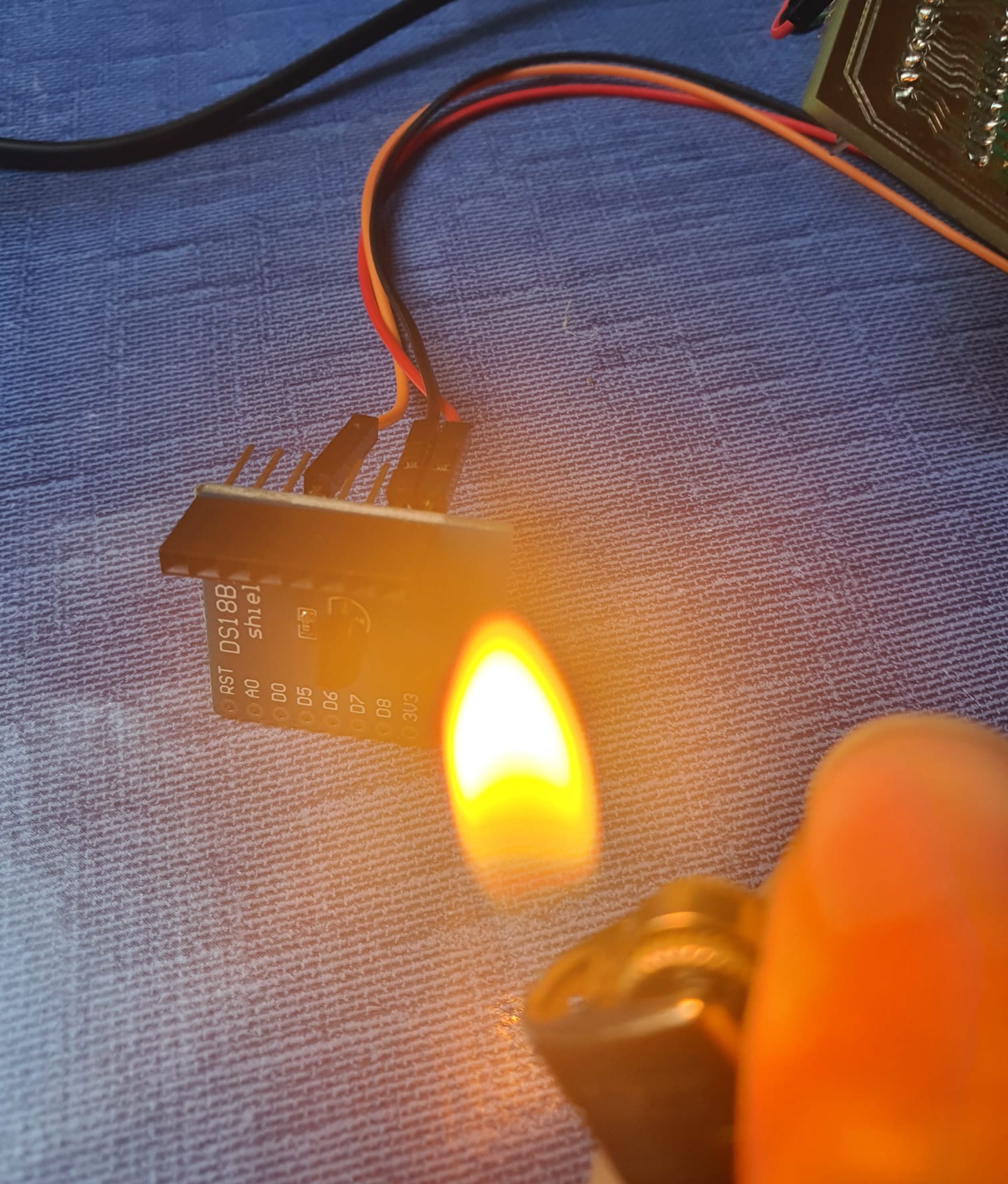

To see the changes in the needle color, I turned on a lighter right infront of the DS18B20

sensor so the

temperature increases fast and changes can be visible faster.

In the video on theleft, we can see modified code, which looks much more

polished. The tick

marks are clearly labeled on the gauge, the live temperature values beneath it, and the

dual-color strip

chart with its own axes and legend to represent values from both DS18B20 sensors.

Whereas in the video on the right, we can confirm that the LED button is

fully functional:

each click sends either 1 or 0 over serial, and the button

label toggles

between LED ON and LED OFF accordingly.

This visual response confirms that the override logic is working perfectly fine on the Pico

W.

Conclusion and Reflection

This week’s task was about turning raw temperature readings into a interactable GUI. I

achieved this by reusing my week 11 draft code, but immediately faced the same issue with

the port. Therefore, I flash the bootloader with flash_nuke.uf2 file in

BOOTSEL mode to bring COM7 port back and upload the code.

Once that was solved, I used ChatGPT to write both the Arduino and Processing sketches.

Nevertheless, the outcome was not matching my expectations, hence, I did some more readings

on Processing Serial guide, ControlP5 callback guides, and the Meter library’s examples to

enhance my GUI I achieved with ChatGPT. Last result was more or less good for a first timer:

dial gauge with ticks and a live digital curve with legends and axes labels.

Overall, Processing is a powerful and beginner-friendly software. It has clear syntax, good

documentation, and various library examples that one can start off with to build a

well-designed GUI!

YouTube Tutorials:

- The Coding Train, 2015, 0.0: Introduction - Processing Tutorial

- The Thinker Teacher, 2023, Programming in Processing (JAVA) for Beginners - Part 1

- Digitale Profis, 2023, DIESER CHATGPT PROMPT IST DER WAHNSINN

- Electronics Clinic, 2022, Arduino Sensor Values on Gauges designed in Processing Software, Sensors Dashboard

Files

- Arduino Code: ChatGPT Version

- GUITempSerialGPT.ino

- Processing Code: ChatGPT Version

- GUIStripChartGPT.pde

- Arduino Code: Modified

- GUITempSerial.ino

- Processing Code: Modified

- GUIStripChart.pde