Input Devices

Group Assignment

- Probe an input device's analog levels and digital signals.

Individual Assignment

- Measure something: add a sensor to a microcontroller board that you have designed and read it.

For this week, I attempted to use an DS18B20 shield as my input device to check whether I still need to order LM35 temperature sensor for my LapTable

DS18B20 Temperature Sensor Module Measurement Module

Image source: DS18B20 Sensor Module – DIYshop

D1 Mini DS18B20

Shield is a digital thermometer that can measure temperatures accurately over range

of -55°C to +125°C, With an accuracy of ±0.5°C between -10°C and +85°C.

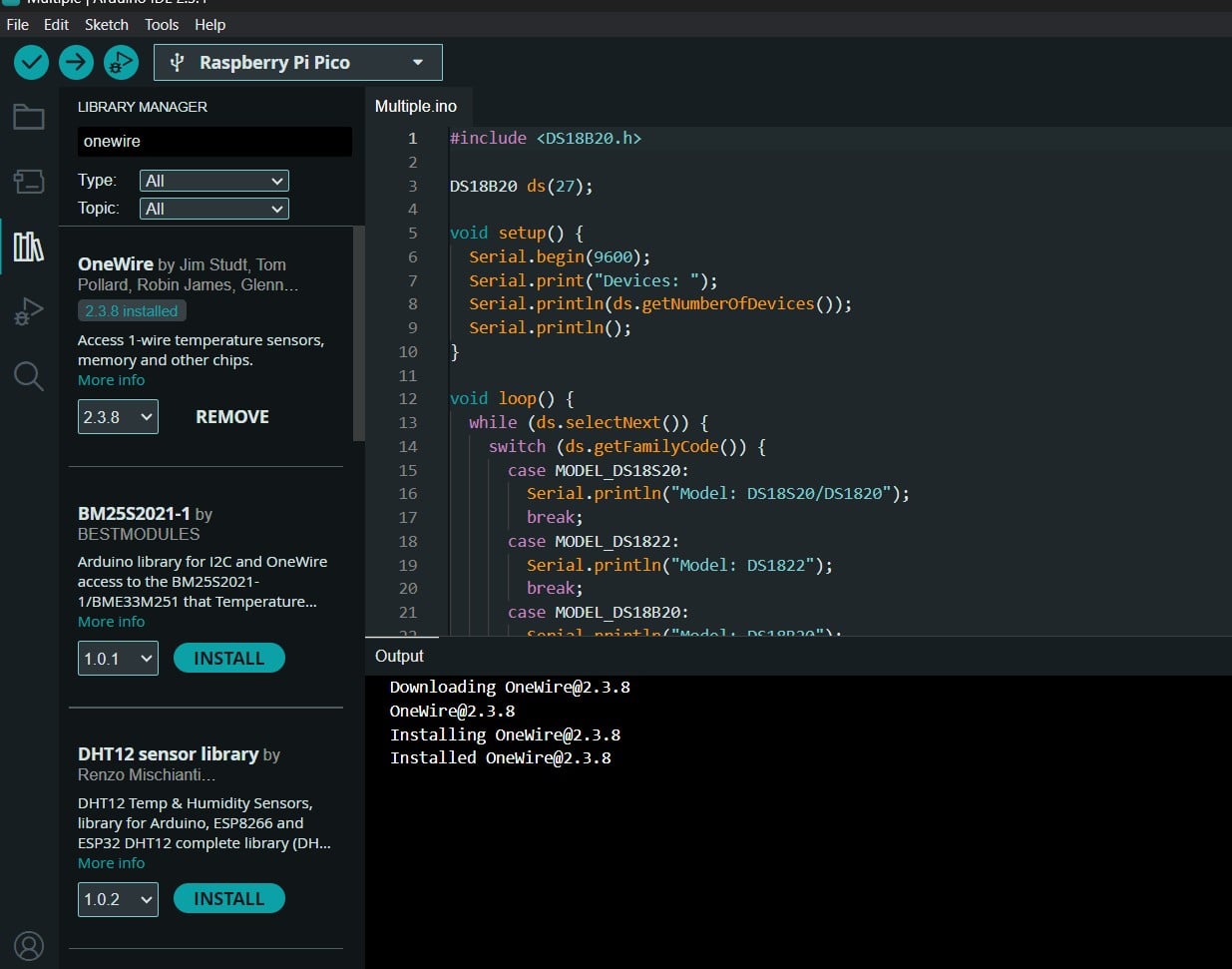

It connects to a central CPU via a 1-Wire bus, which only needs a ground connection and one

data line. In order to test it, I modified example code from the libraries OneWire and

Dallas Temperature.

For more information, find the datasheet here!.

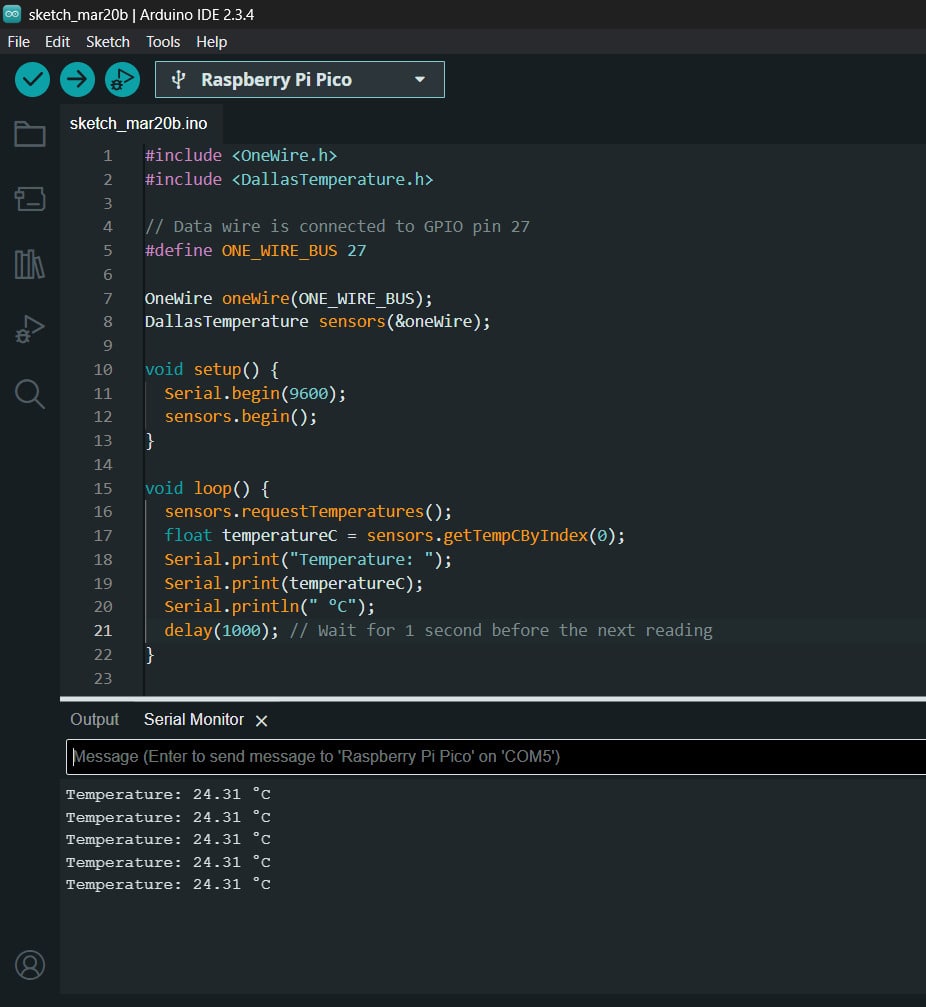

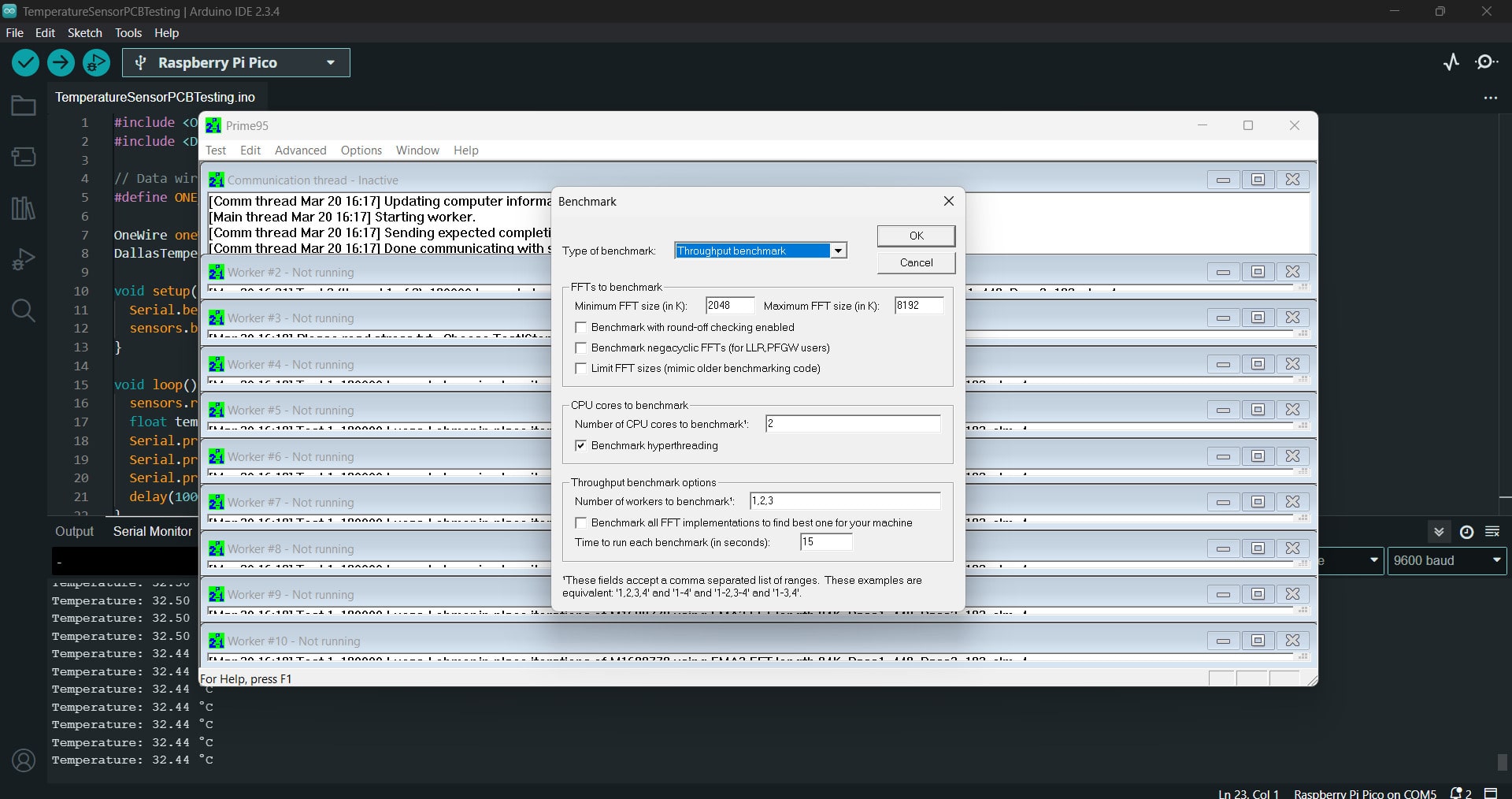

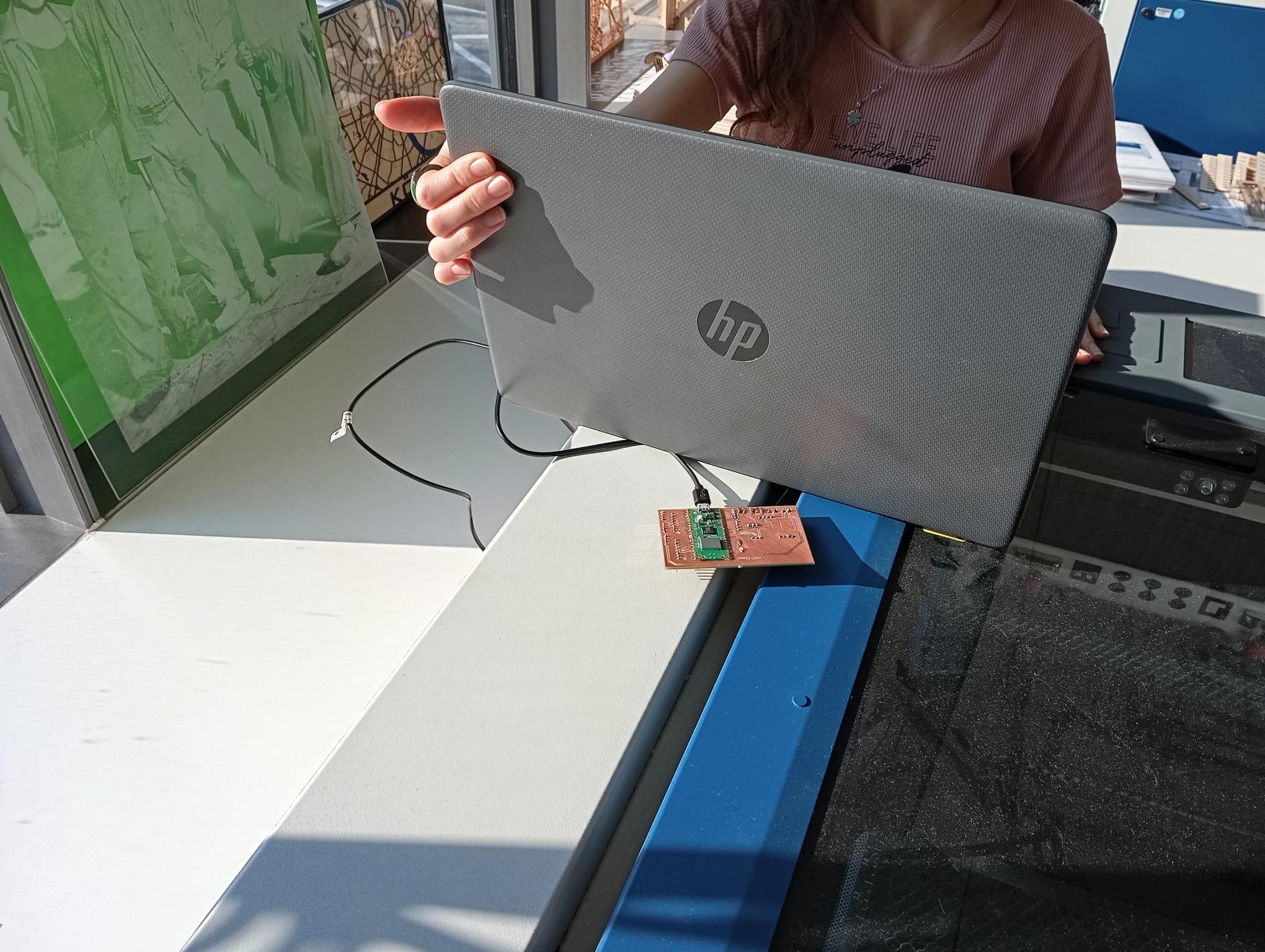

DS18B20 Sensor Test with my personal PCB

I linked the DS18b20 to pinheaders I soldered on the board I produced in Week8-

Electronics Production. One pin is connected to common GND, one pin is connected to

5V, and the third one is connected to GPIO 27 (output).

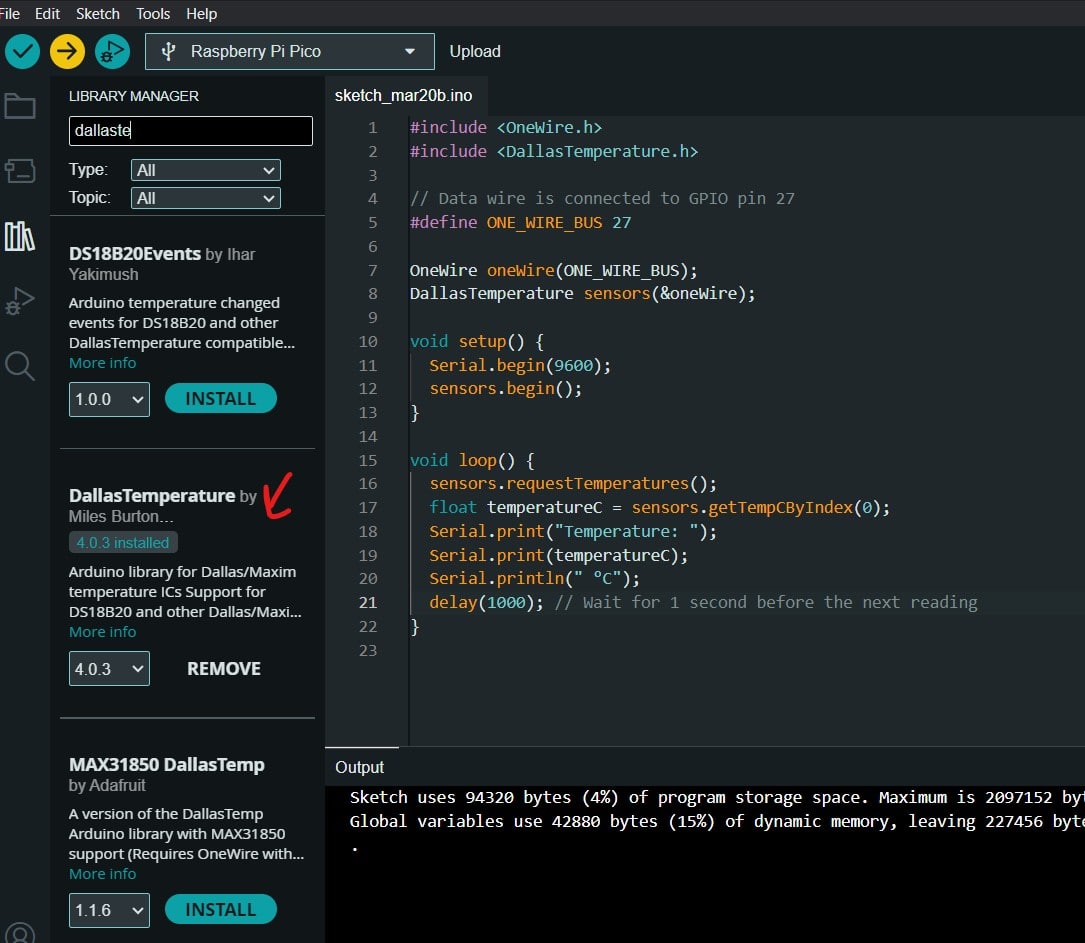

In ArduinoIDE, I ran the code example

single from the library and I read the temperature on the serial monitor in Celsius

degrees.I figured it was roughly around room temperature (~24°C).

Arduino Code

*#include

#include

// Data wire is connected to GPIO pin 27

#define ONE_WIRE_BUS 27

OneWire oneWire(ONE_WIRE_BUS);

DallasTemperature sensors(&oneWire);

void setup() {

Serial.begin(9600);

sensors.begin();

}

void loop() {

sensors.requestTemperatures();

float temperatureC = sensors.getTempCByIndex(0);

Serial.print("Temperature: ");

Serial.print(temperatureC);

Serial.println(" °C");

delay(1000); // Wait for 1 second before the next reading

}

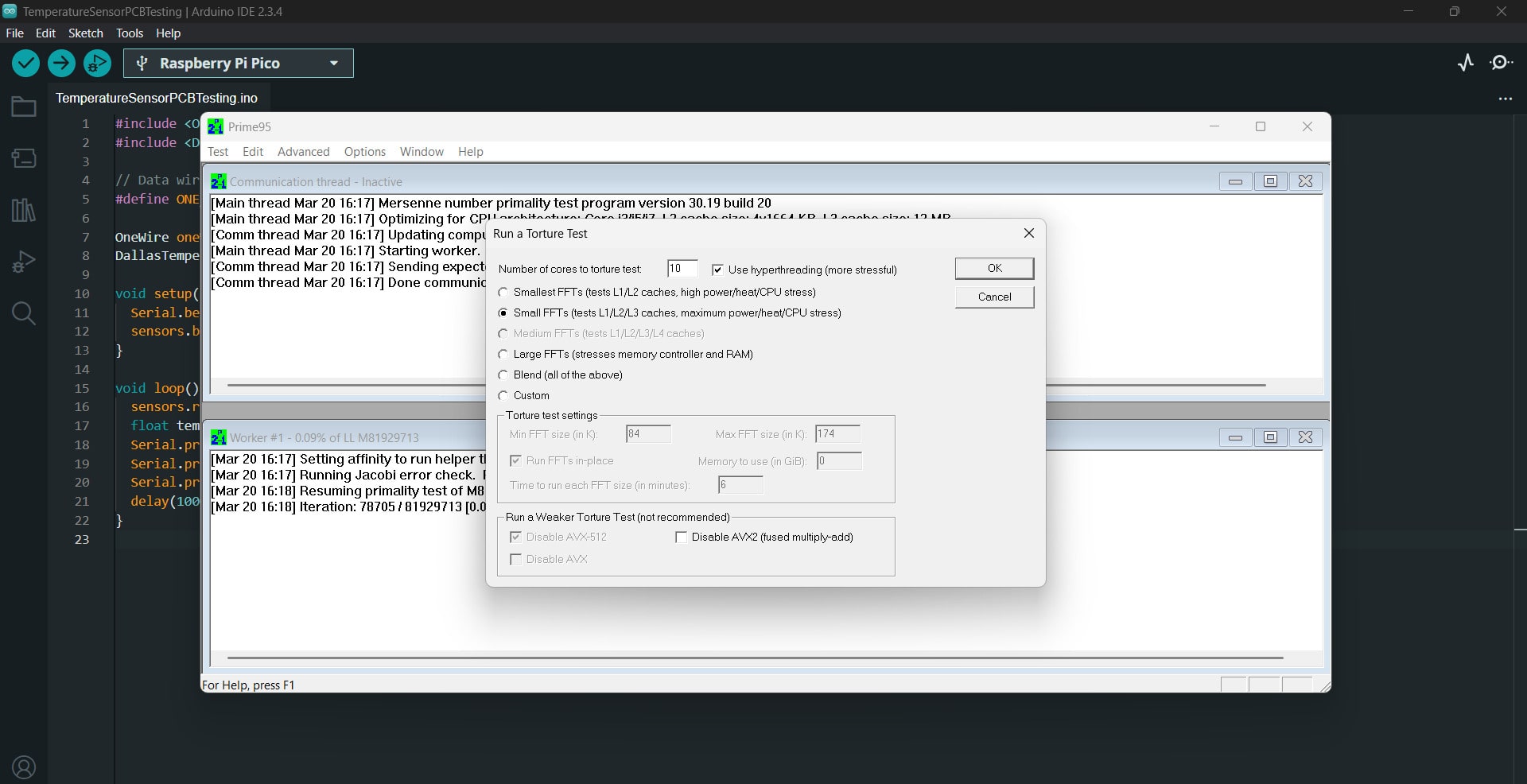

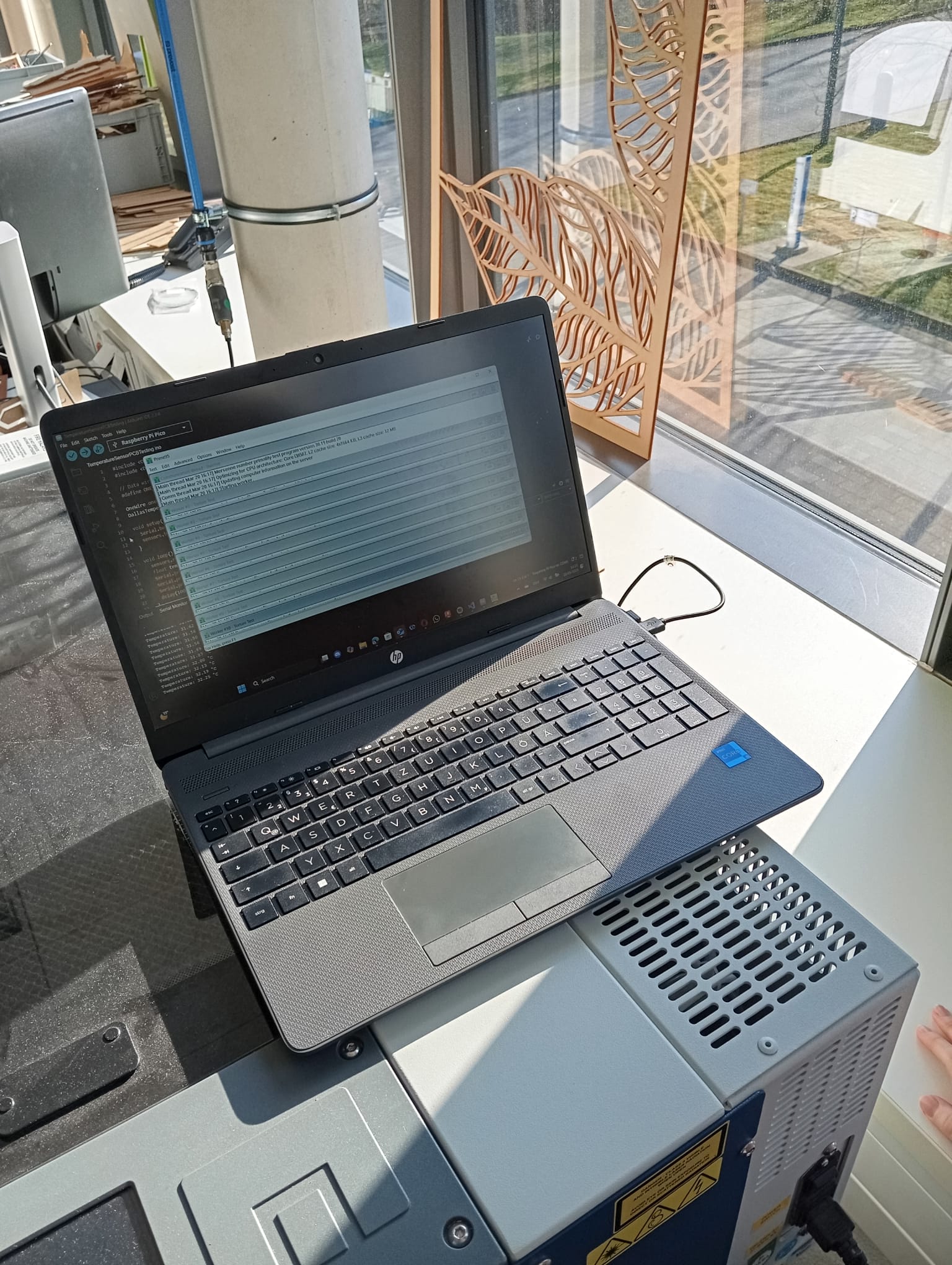

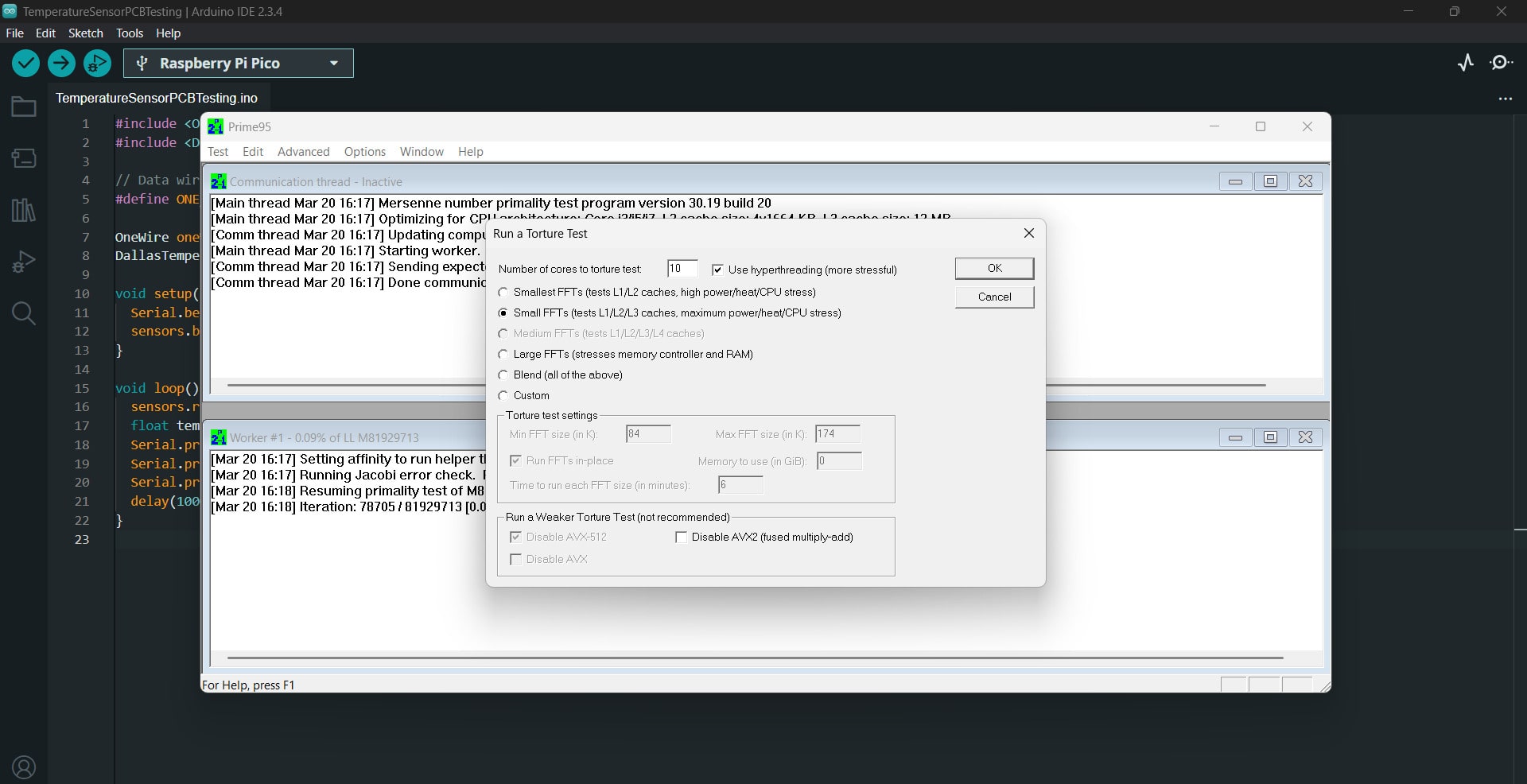

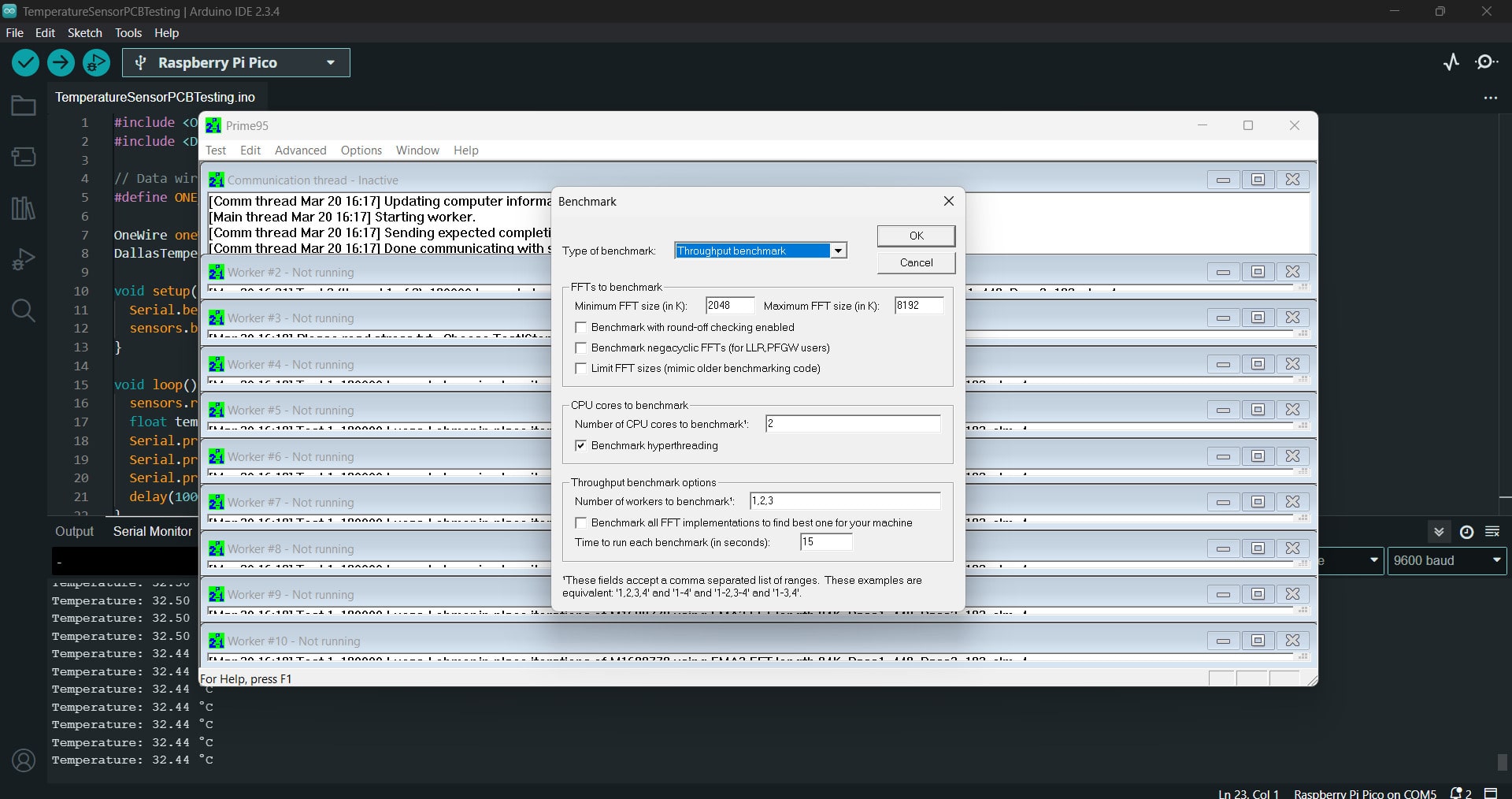

Stress and Benchmark Test

However, in order to push the laptop to its limit, Using Prime95, I conduct a stress test for the

CPU to determine how hot my laptop gets. A stress test is a process that deliberately pushes

the computer system beyond its normal operational capacity to evaluate its stability and

identify its weaknesses.

This will help me determine more precisely what kind of fans I will eventually need and

where to mount the temperature sensors for the most accurate temperature reading when the

laptop is stressed while using multiple softwares simultaneously that require high CPU

performance.

From the Prime95 options, I selected torture test and I ticked on

Small FFTs to push the laptop to the limits. Then, Pressed ok and ran the

test. I repeated the same process but with a throughput benshmark test.

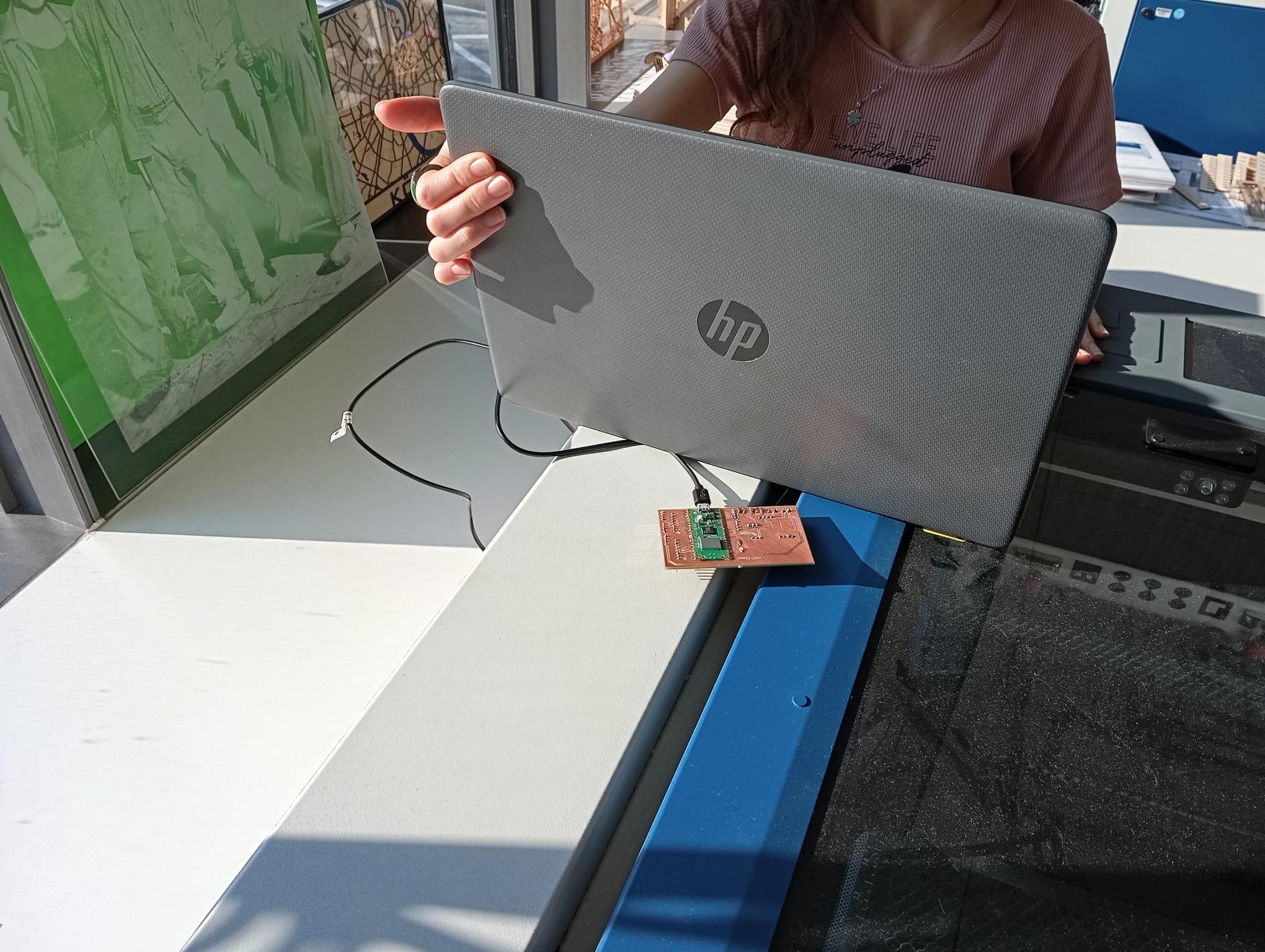

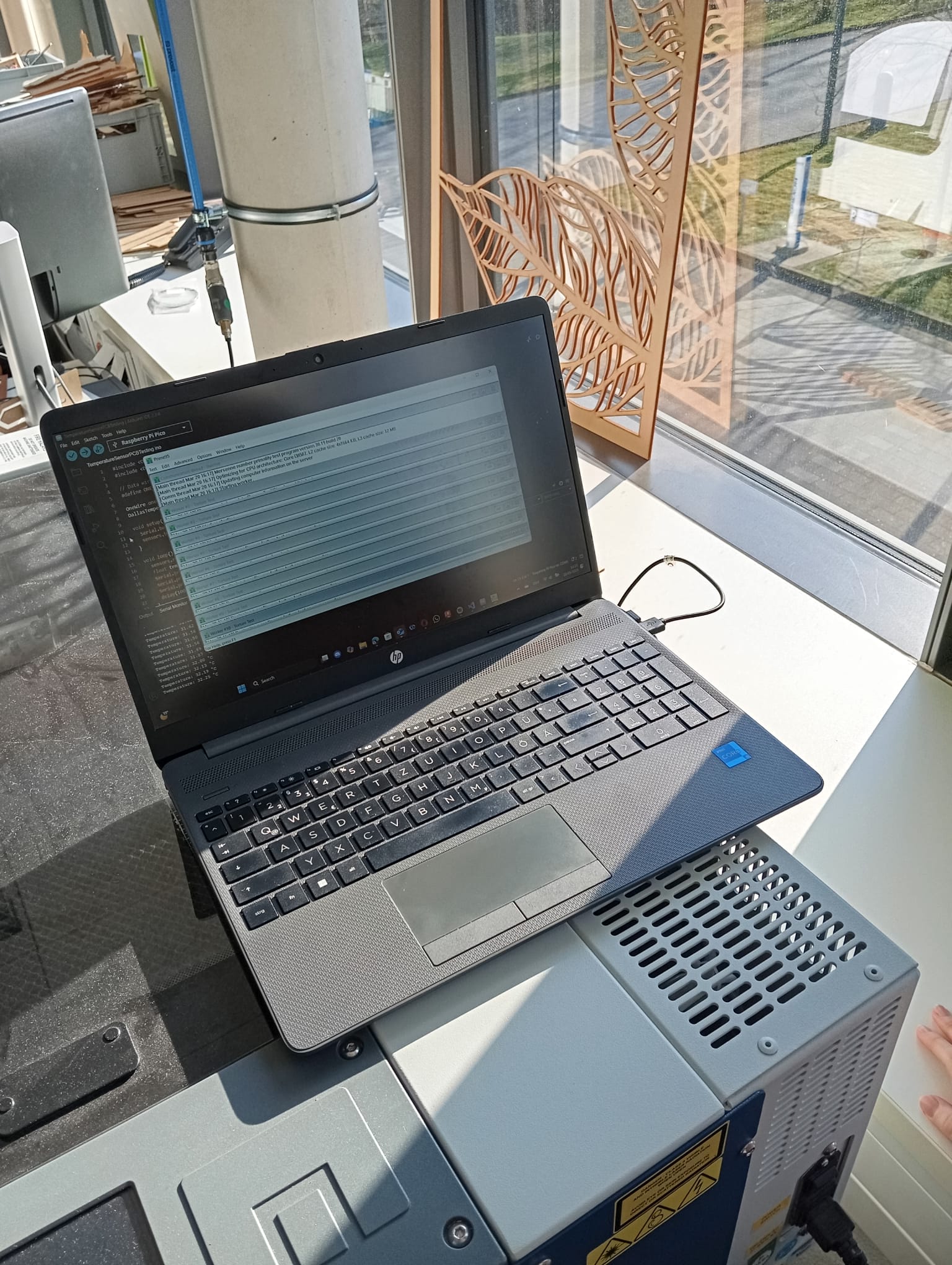

To amplify even more, I placed my setup under the sun and fixated the temperarure sensor on

the laser cutter under the laptop, where the CPU is placed (middle upper section of the

laptop's bottom surface)

To amplify even more, I placed my setup under the sun and fixated the temperarure sensor on

the laser cutter under the laptop, where the CPU is placed (middle upper section of the

laptop's bottom surface)

Reading the temperature on the Serial Monitor, I noticed how it raised up to 33°C. This

means that the sensor in fact detected the impact of the sun, as well as the stress and

benchmark test on the heat of the laptop's CPU.

Comparison to HWMonitor

Nevertheless, this can be considered still safe temperatures, as it is still under 70°C

(see:

Normal CPU Temperature). Therefore, I need to find a way to measure the actual

internal temperature of the CPU and turn on the fans for my final project accordingly.

Therefore, I used H HWMonitor to

determine what is the actual heat laptop reaches when under pressure. Comparing to

temperature monitored via HWMonitor I performed in Stress

Test Laptop's CPU - Week 6,

I found out that P-cores (performance Cores) max temperature to be 69°C, and the E-Cores

(Efficiency Cores) Max Tempemperature to be 66°C.

This means that my laptop's CPU is still in the safe zone; remaining under 70°C.

However, the heat on the bottom suface is still visible and working with softwares such

as Fusion360 requires constant monitoring and controlling to keep temperature under 70°C

and to prevent thermal throttling to maintain standard performance.

Thus, I theoretically should set up the threshold of the temperatures detected to be

70°C for the fan to turn on and cool the CPU down.

Next Step - Copper Pad

Using copper pad (~20 × 20 mm) can greatly increase thermal conductivity between the

heat source (CPU) and the sensor (LM35), which improves the accuracy of temperature

measurement from the laptop's bottom surface.

This can be place somehow flushed in the bottom middle surface of the table, so it has

consistent contact with the laptops bottom surface and fixate the temperature sensor on

it.

This still has to be tested once the fan and the temperature sensors are ready, and the

design of the table is modified accordingly.

Conclusion and Reflection

The project for this week helped me better understand input devices and how they are

used in embedded systems in the real world. Using my custom-designed PCB and the DS18B20

digital temperature sensor, I was able to correctly read and interpret temperature

information through an Arduino IDE code.

Furthermore, benchmarking and stress testing the laptop helped me understand realistic

thermal loads and how surface temperature may be greatly impacted by outside factors

like sunshine.

I was able to determine the sensor's limitations and the significance of utilizing a

copper pad or thermal interface to enhance contact and accuracy by comparing the DS18B20

data with internal diagnostics from HWMonitor.