Squirtle Hoodie

Download files:

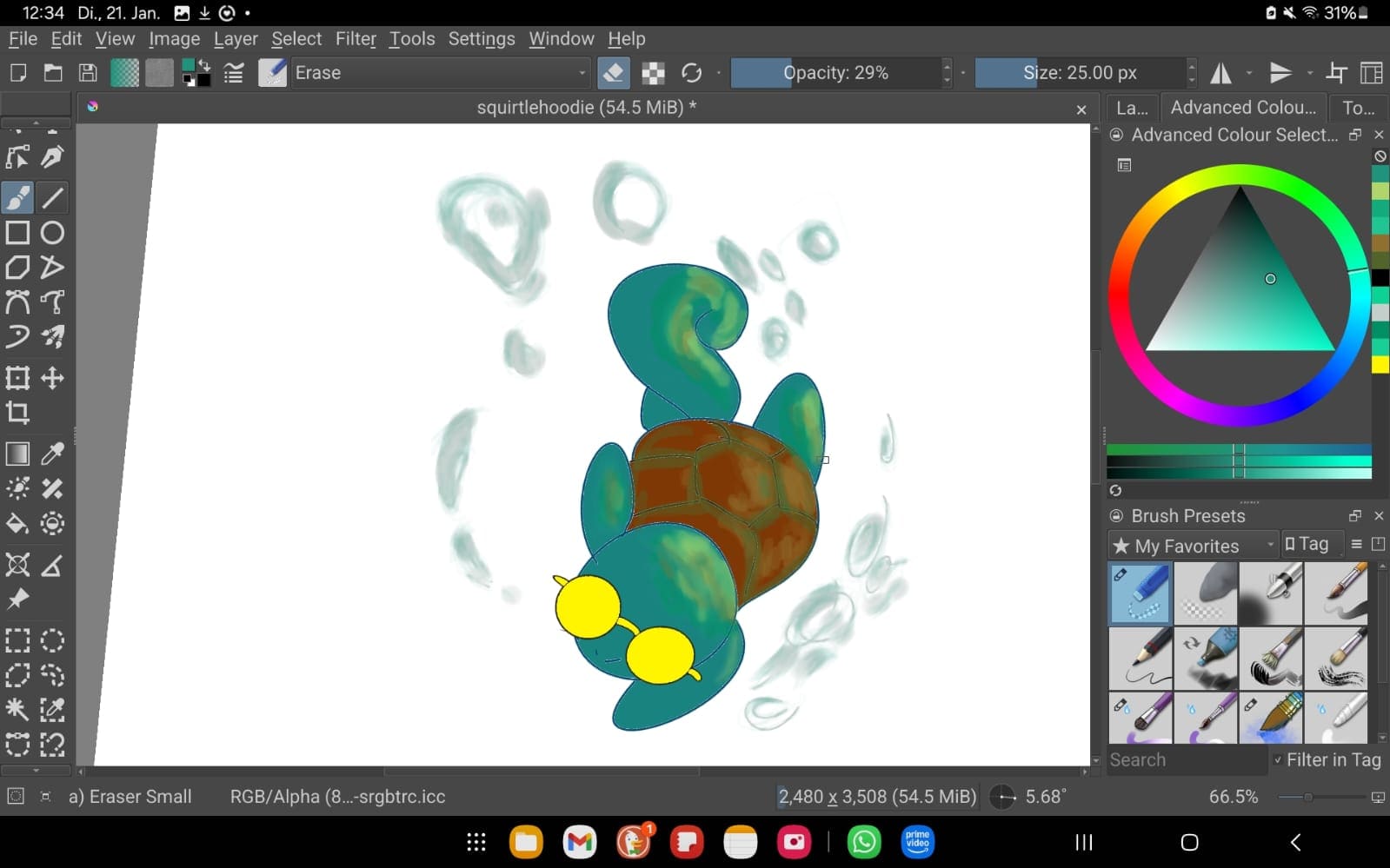

I saw an advertisement on Instagram: a beautiful Squirtle hoodie! Problem: the website that sells it is not trustable. Besides, I can make it myself! So, I opened Krita and painted Squirtle. I got myself some cheap Acryl colors for permanently painting a hoodie that I still have to buy (or sew, haven't decided yet).

This was my first time using the vinylcutter, so I'm going to document it a bit more thoroughly.

firstly, I was under the impression it worked like a printer and lasercutter - painting on the surface and then cutting out. As such, Squirtle has many blurred outlines and colors. As it turns out, our main vinylcutter can only cut. This means, that the sticker or whatever is being processed will only have the color of the material it is being cut from.

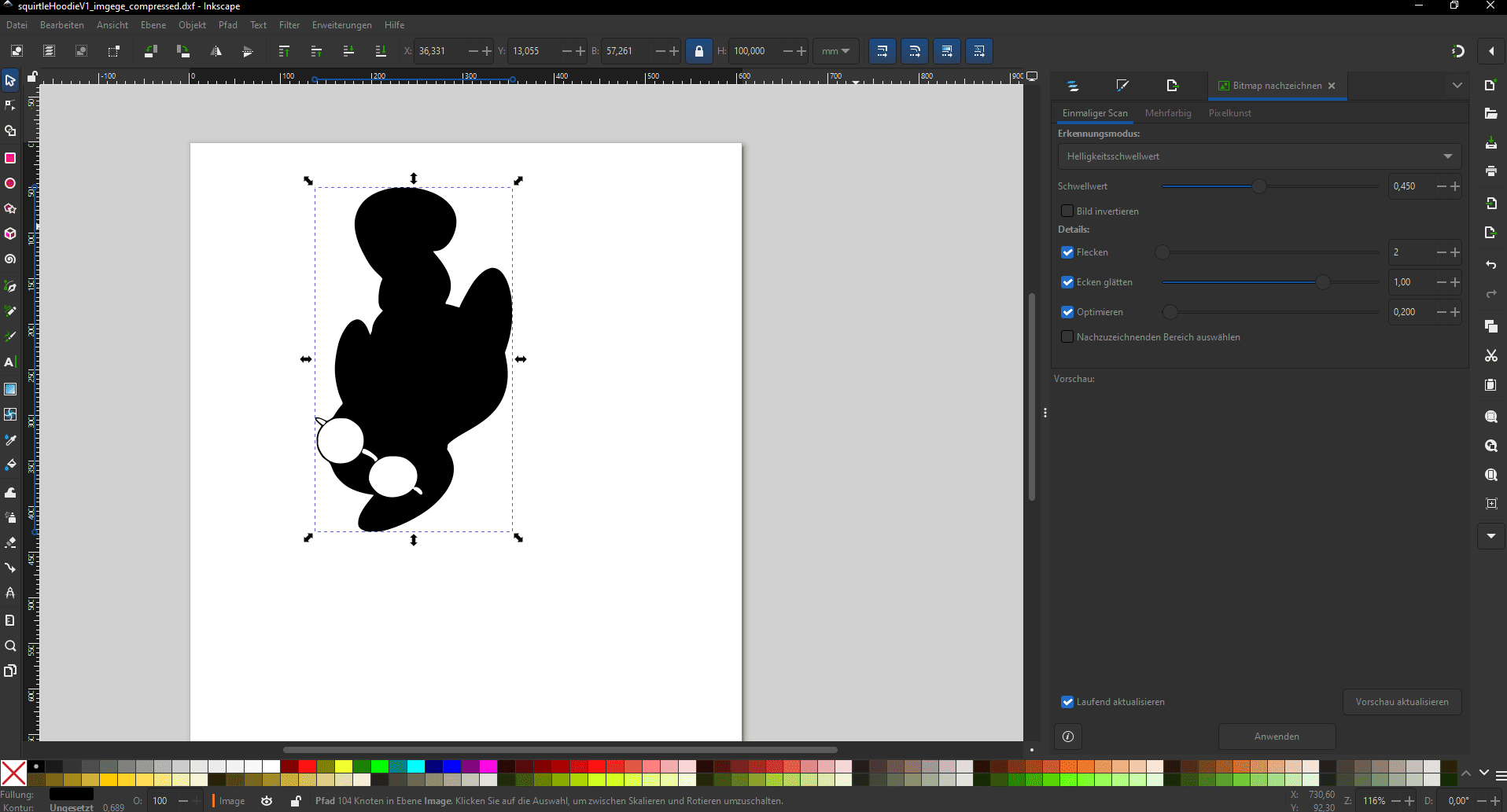

Alright, change of plans. With my instructor, we opened Inkscape and applied filters and pathed the outline. We then exported it in an svg format.

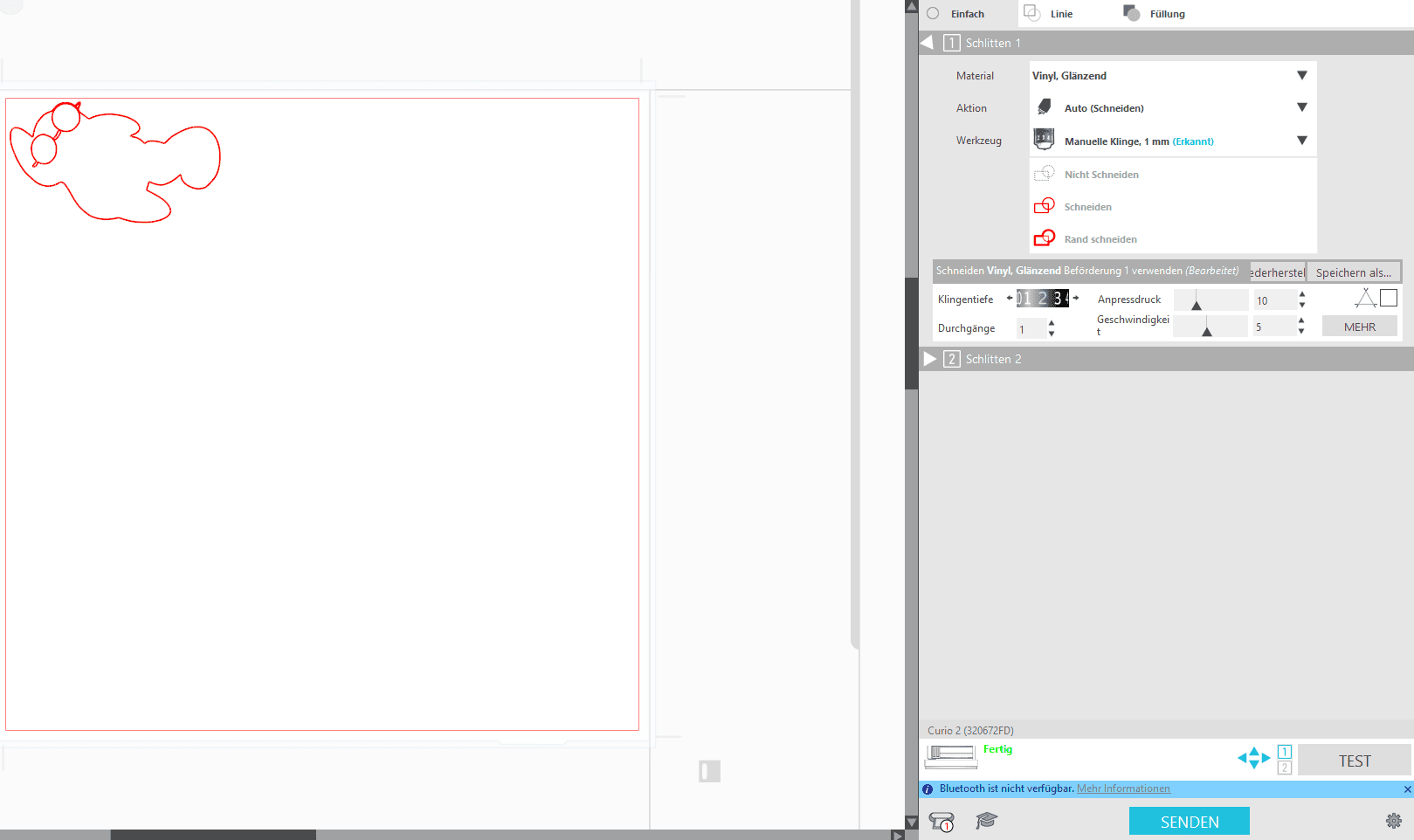

Open Silhuette Studio App->Import->Choose svg file. The size always gets increased to the maximum size, so it had to be resized using the parameters on the uppermost left corner of the screen. Luckily. The vinylcutter was already connected through Bluetooth, so we proceeded to set up the tip to our needs.

We tested the depth of the blade so that it only cuts through the uppermost layer of the acryl surface to not damage the machine. Squirtle was originally meant to be a design for a Hoodie, but seeing as all it's nice qualities got removed, we decided to make it a sticker instead. We decided the blade depth of 2 and set the parameter on the right middle side of the screen. Finally, we sent it to the cutter.

Apparently, we did not position the vinyl correctly on the adhesive plate: a part of Squirtle's arm did not fit on it. Apart from that, the process was very quick.

As there was only 1 solid component of my sticker, we were actually done here, but my instructor insisted on doing it thoroughly. So, we 'hashed' (or rather removed the negative shape of the sticker) it and covered it with the removal tape. Now we were done.

I can definitely see myself doing PCBs with this machine: a copper/ or other flat conductive piece with a a layer of acryl/ sth thin that is not conductive and were done way faster than with the CNC-mashine! I am looking forward a lot to trying this out in the upcoming weeks!