Week 12: Mechanical and Machine Design

Group Project Summary

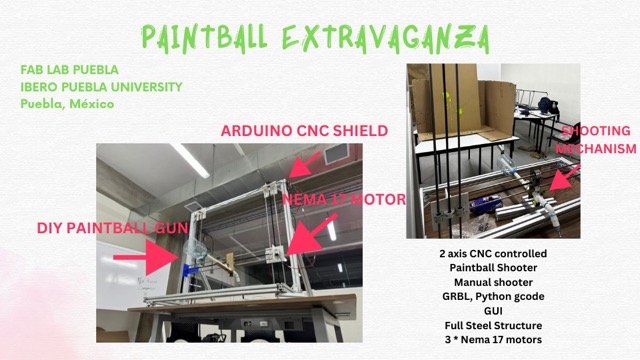

This project was originally developed as part of the 2024 Fab Academy group assignment at Fab Lab Puebla. For that assignment, we designed and built a Paintball CNC Machine — a creation that merges the precision of CNC motion with the beautifully chaotic energy of paintball.

The machine is capable of shooting paintballs in programmed patterns to create large-scale, colorful artwork. It’s an unconventional take on digital fabrication that proves engineering doesn’t always have to be serious to be effective — sometimes, it just needs air pressure and a splatter-friendly wall.

While the bulk of the assembly was carried out at Fab Lab Puebla, part of the team traveled to Ibero Mexico City — also my workplace — to retrieve structural materials and get some hands-on support during final adjustments.

You can visit the team’s full documentation here.

My Personal Contributions

Although I live in a different city and collaborated mostly remotely, I actively contributed to key aspects of the project:

- Preparation and Provision of Frame Materials:

- Provided all aluminum profiles needed for the mechanical structure.

- Cut the aluminum profiles precisely to the design dimensions. (See image below for my improvised but effective cutting setup.)

- Organized and sorted bolts, nuts, T-nuts, and assembly accessories required for frame construction.

- Explained to Hector (Hector's webpage) how to use and sort the fastening materials, improving efficiency in later assembly steps.

- Mechanical Design Supervision:

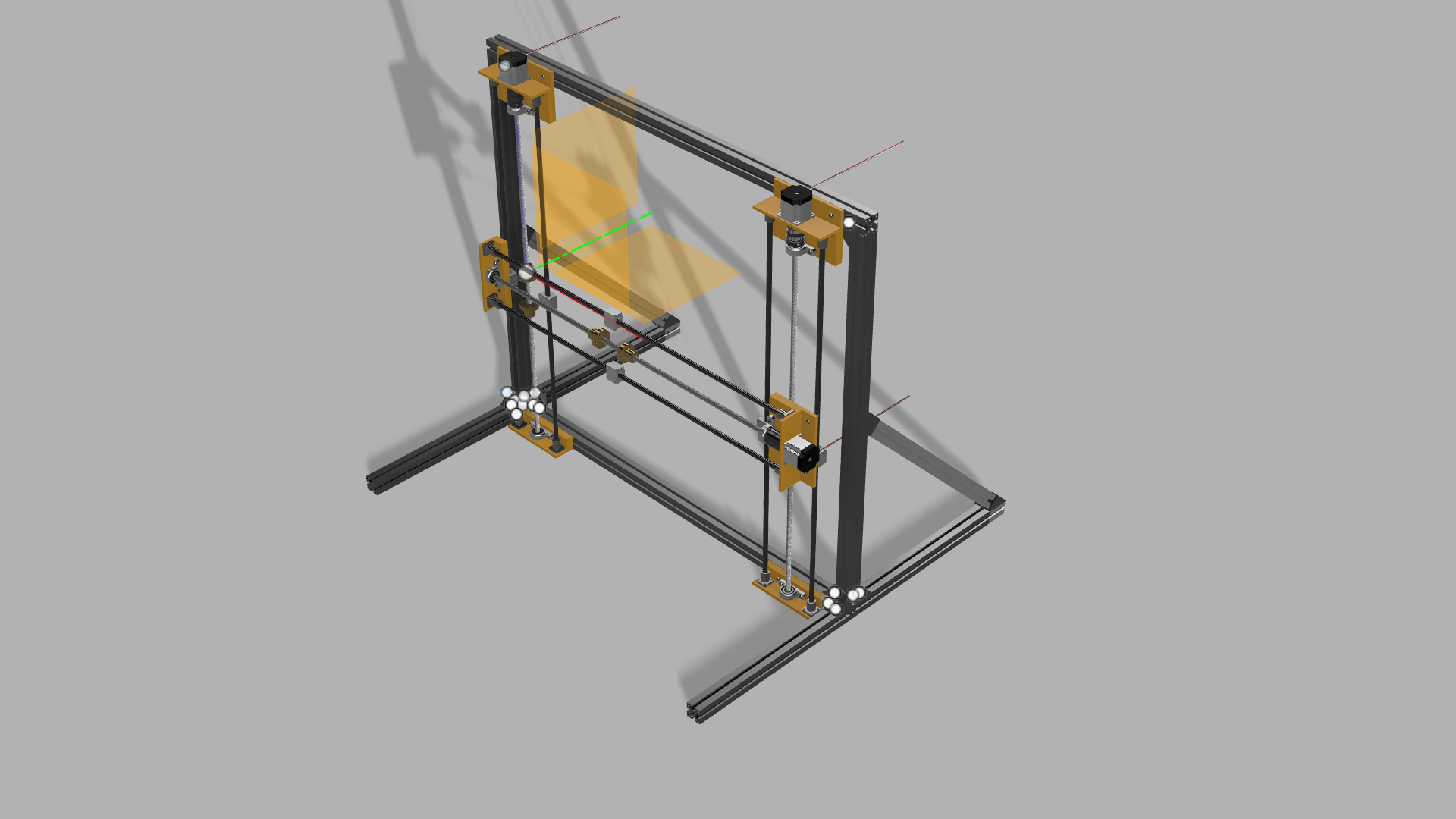

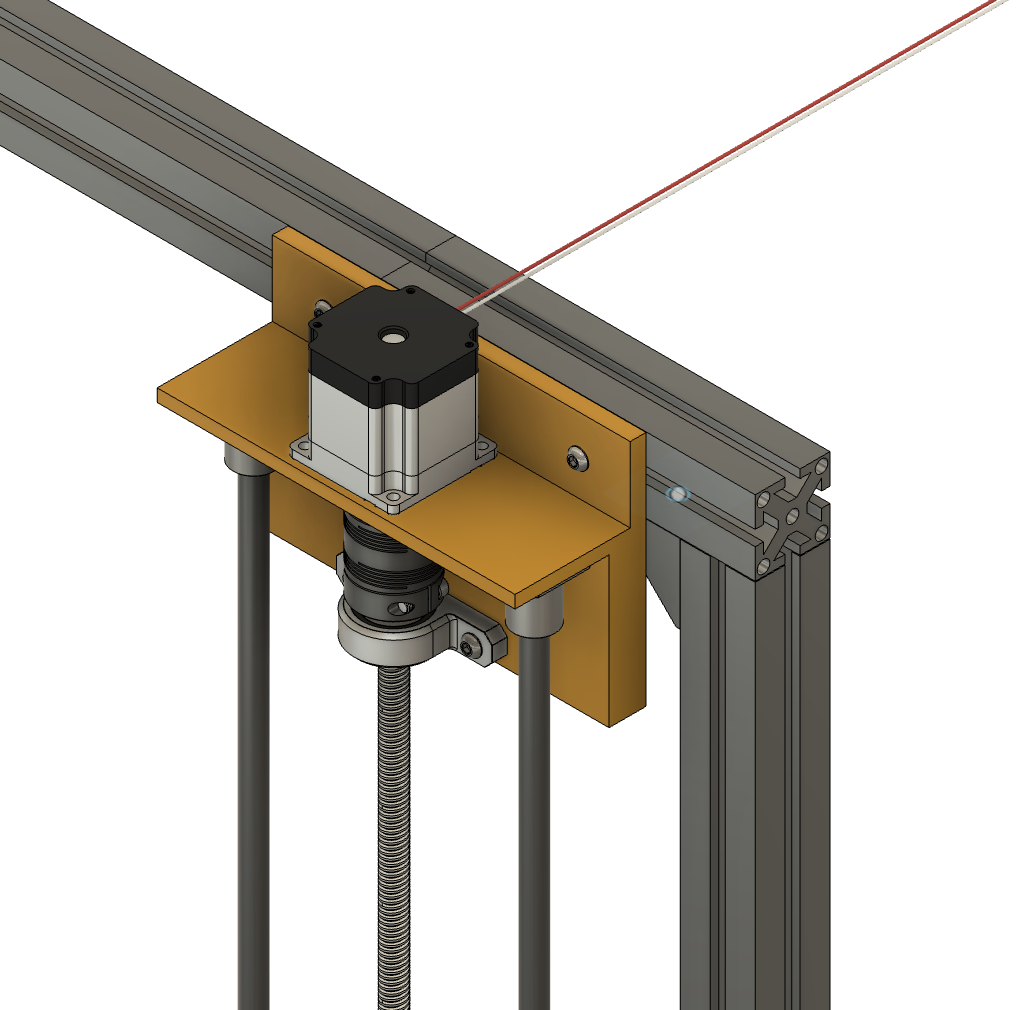

- Assisted in dimensioning the frame and ensuring mechanical feasibility and stability.

- Supervised remotely the dimensioning process through meetings.

- Provided advice on structural integrity and assembly sequence.

- Gave feedback to ensure the frame could handle vibrations and backlash from the compressed air compressor.

- On-Site Assembly Guidance:

- Provided technical know-how for correct frame assembly during critical stages.

- Helped verify and adjust frame dimensions during final build stages.

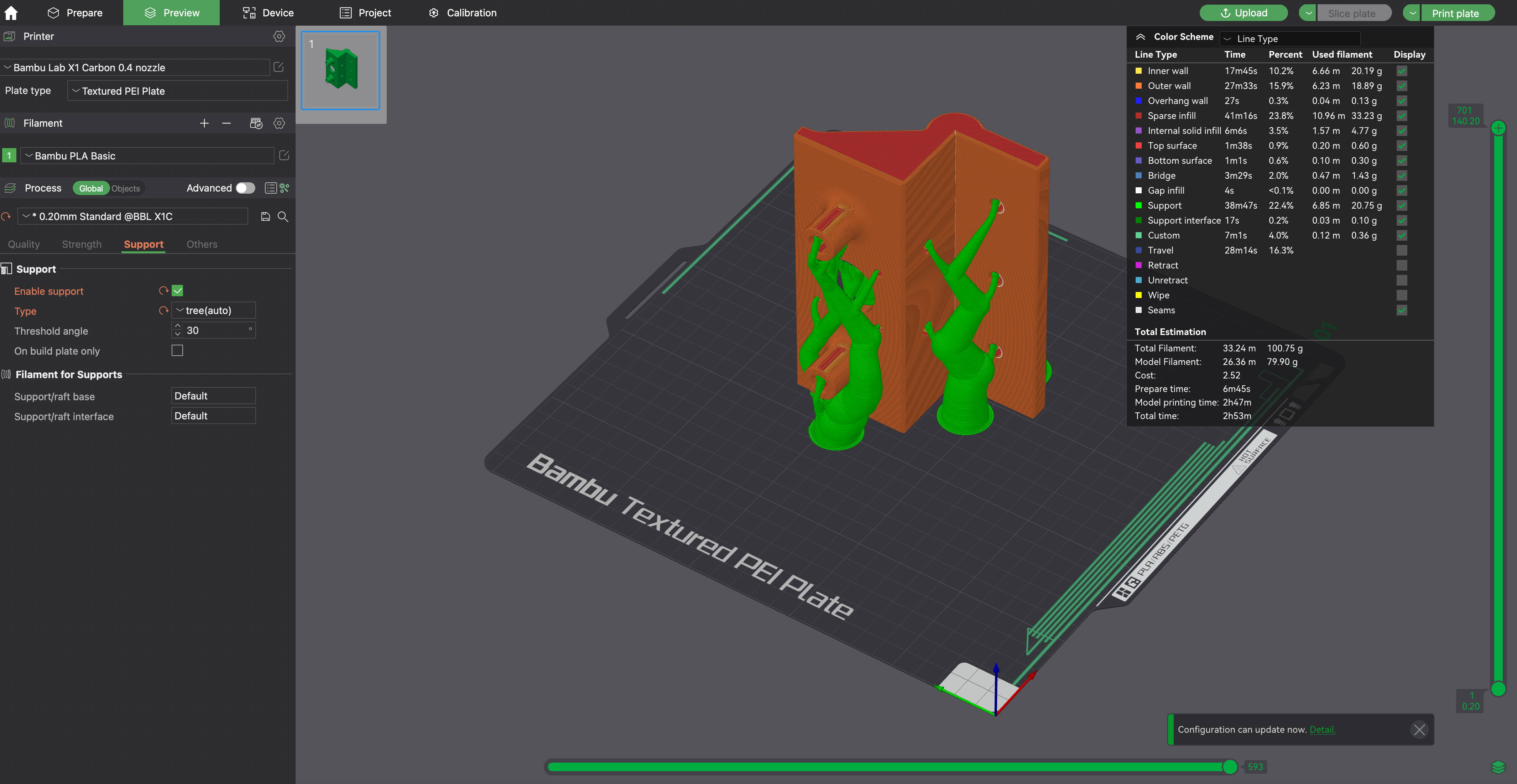

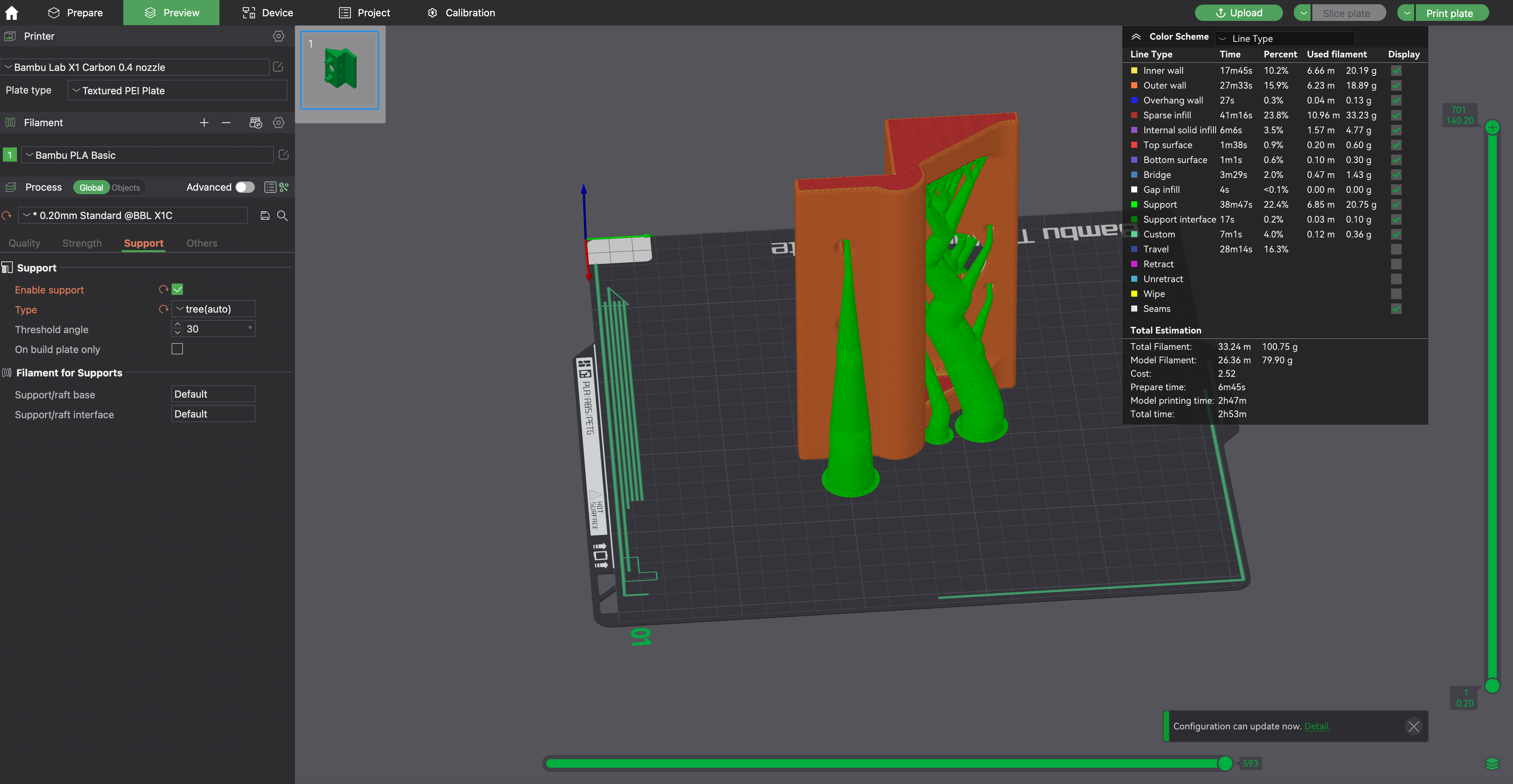

- 3D Printing and Parts Preparation:

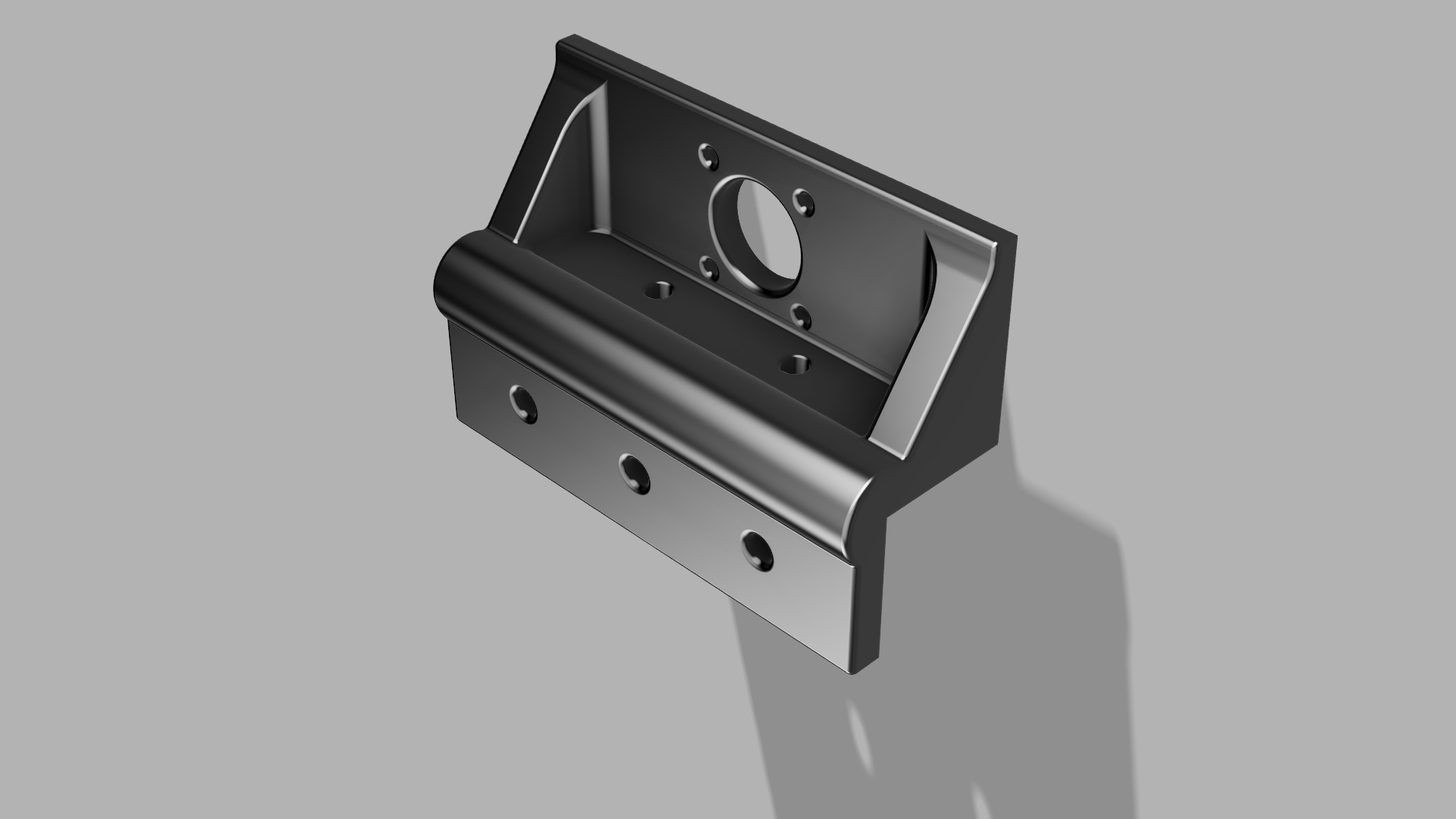

- Printed backup components, including a version of Bernardo’s redesigned compressor holder (which fortunately wasn’t needed — great job, Bernardo) (Bernardo's webpage).

- Used slicer software to prepare prints for precise fit and mechanical strength.

- Support in Final Redesign:

- Suggested improvements for final machine presentation and structure optimization.

Totally safe method for cutting long aluminum profiles on the floor (do not try this at home).

Sorting bolts and nuts in a red tool cart and walking Hector through usage.

Backup print of Bernardo's compressor holder redesign (wasn’t needed, nice!).

Challenges Faced

Working remotely presented some natural challenges, which I addressed throughout the project:

- Remote Coordination: Maintaining alignment with the team required frequent and effective communication.

- Documentation: Some personal media files were lost, so part of my work is described based on detailed notes and team material.

- Material Management: Organizing, preparing, and ensuring safe delivery of all frame components demanded careful planning.

Reflections

Contributing to this machine from a distance pushed me to rethink how experience and logistics can be leveraged beyond physical presence. While I wasn’t at the lab every day, the materials, feedback, and structural decisions I provided became foundational to the project.

It's easy to underestimate the importance of “frame stuff” — until it fails. Designing with structural integrity in mind, while enabling creative chaos like launching paintballs with precision, was both a challenge and a joy. This project was a great reminder that sometimes, enabling others to build is just as important as building itself.

Also, it’s worth noting: teaching doesn’t mean stepping back — it means knowing when to step in, when to trust the team, and when to just print a backup part... just in case.

This assignment was completed as part of a collaborative group effort between Fab Lab Puebla and Ibero Mexico City.

Back to Assignments | Back to Top