Week15. Wildcard Week--Composites

Assignments

- Group assignment:

- produce test coupons for your composite fabrication process(es)

- Individual assignment:

- read the safety data sheet (SDS) and technical data sheet (TDS) for the resins that you're using design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it, with resin infusion and compaction

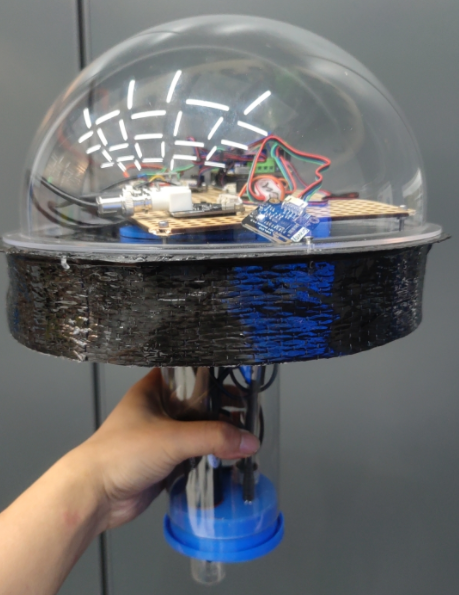

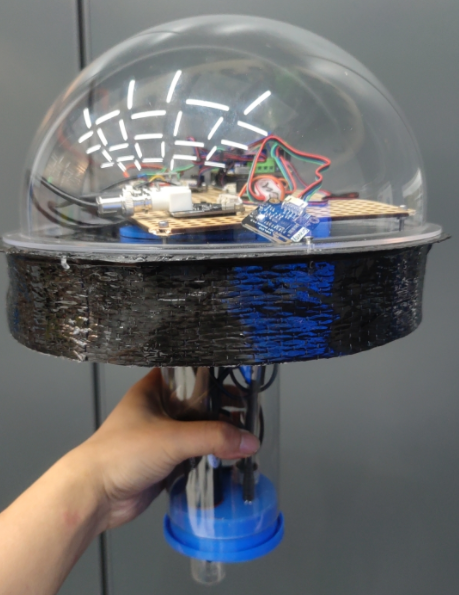

Hero Shot

Group Assignment

Safety Rules

- Workspace

- Ensure the workspace is well-ventilated to avoid inhaling resin fumes.

- Cover work surfaces with disposable materials to protect them from resin spills.

- Personal Protective Equipment

- Gloves: Wear nitrile gloves to protect hands from direct contact with resin and carbon fiber dust.

- Mask: Wear a respirator mask to avoid inhaling harmful fumes or dust, especially in large-scale work or poorly ventilated areas.

- Eye Protection: Wear safety goggles to protect eyes from resin splashes and carbon fiber particles.

- Clothing: Wear long sleeves and long pants to minimize skin exposure. For large-scale work, use disposable protective suits.

- Handling Carbon Fiber Fabric

- Cutting: Use sharp scissors or shears specifically for cutting carbon fiber fabric to avoid fraying. Wear a mask to prevent inhaling fine fibers.

- Storage: Store carbon fiber fabric in a dry, clean place away from direct sunlight to maintain its integrity.

- Mixing Resin

- Ratio: Follow the manufacturer's instructions for the correct ratio of resin to hardener to ensure proper curing.

- Ventilation: Mix resin in a well-ventilated area or under a fume hood to avoid inhaling toxic fumes.

- Tools: Use disposable mixing containers and tools to avoid contamination and facilitate cleanup.

- Application

- Brushes and Rollers: Use brushes and rollers designed for epoxy resin to apply the resin evenly on the carbon fiber fabric.

- Layers: Apply resin in thin, even layers to ensure proper saturation and avoid air bubbles.

- Curing

- Environment: Allow the resin to cure in a dust-free, debris-free, and well-ventilated area.

- Temperature: Maintain the curing temperature range recommended by the resin manufacturer.

- Cleanup

- Disposal: Dispose of used gloves, brushes, rollers, and mixing containers according to local hazardous materials regulations.

- Cleaning Tools: Immediately clean reusable tools with appropriate solvents (e.g., acetone) after use.

- Emergency Measures

- Spills: If resin spills, clean up immediately with absorbent materials and dispose of waste properly.

- Skin Contact: If resin comes into contact with skin, wash immediately with soap and water. Do not use solvents to clean skin.

- Inhalation: If fumes are inhaled and cause discomfort, move to fresh air. Seek medical attention if symptoms persist.

Technical Data Sheet (TDS)

- 300g Carbon Fiber Cloth:Carbon fiber cloth is made from carbon fiber yarn. The carbon fibers are produced through high-temperature carbonization, resulting in fibers with over 90% carbon content. Due to its high strength, low weight, corrosion resistance, and heat resistance, it is widely used in aerospace, automotive manufacturing, building reinforcement, and sports equipment.

- Weight (G/M): 300

- Theoretical Thickness (MM): 0.167

- Tensile Strength (MPA): >=3000

- Elastic Modulus (GPA): >=210

- Elongation (%): >=1.5

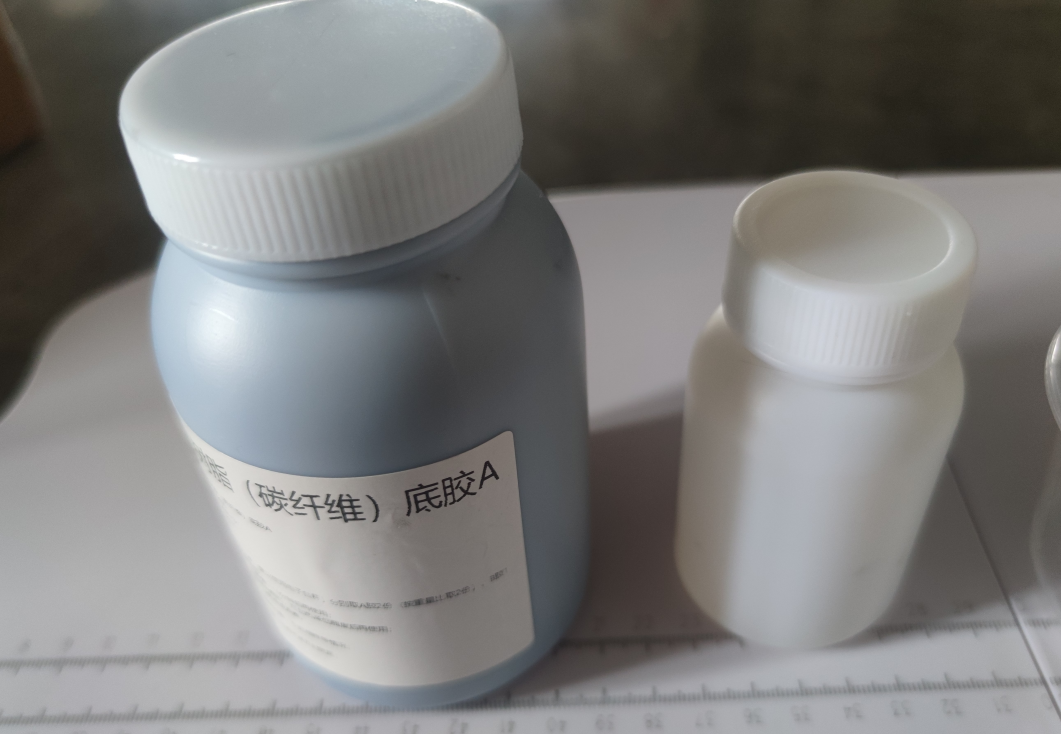

- Base Glue: Applied to the surface of the model to fix the carbon fiber cloth. It consists of two parts, A and B, mixed in a ratio of 3:1 (A:B). The mixture becomes a black, viscous substance with a curing time of 6 hours at room temperature and 20 minutes at 80°C. Note that the mixed resin will release some heat, so take appropriate safety precautions.

- Top Glue: Applied to the surface of the carbon fiber cloth, featuring high transparency, easy defoaming, and high hardness. It also consists of two parts, A and B, mixed in a ratio of 2:1 (A:B). The mixture becomes a colorless, transparent liquid with a curing time of about 10 hours at room temperature (25°C).

This week I'm going to test composites because I need them to be waterproof and strong enough to work. I chose carbon fiber materials and woody materials for testing, familiar with the operation steps, precautions and actual effects of carbon fiber cloth.

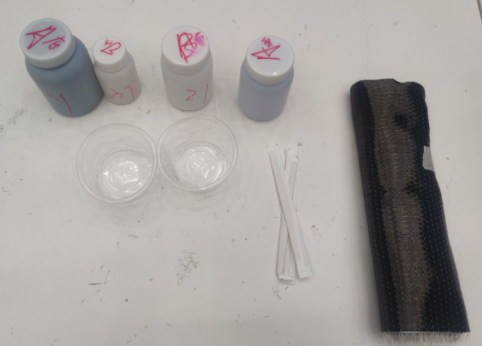

Materials

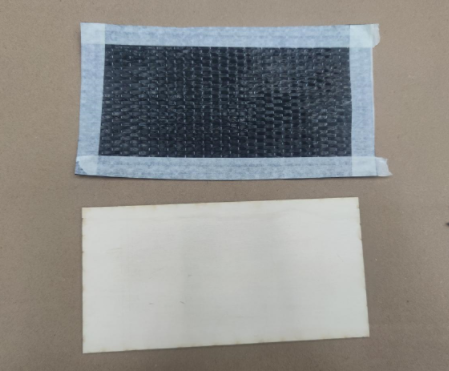

I prepared 300g carbon fiber cloth and the glue used for the bottom and surface; prepared a test board, and cut the carbon fiber cloth of the same size according to the size of the board.

Note: When cutting carbon fiber cloth, it is important to wear a dust mask and disposable gloves to prevent inhalation of fine fibers and cuts on the fingers. During the cutting process, you can use painter's tape to secure the carbon fiber cloth, and then cut according to its size. This will help reduce the risk of fine carbon fibers and finger injuries.

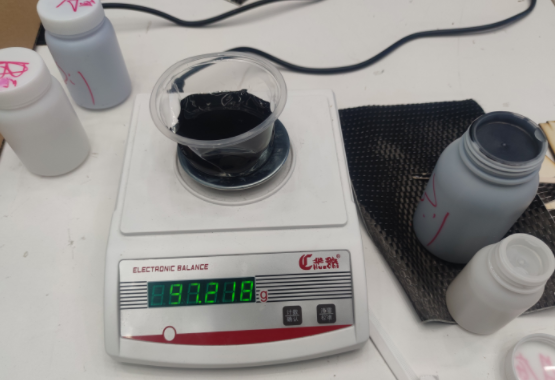

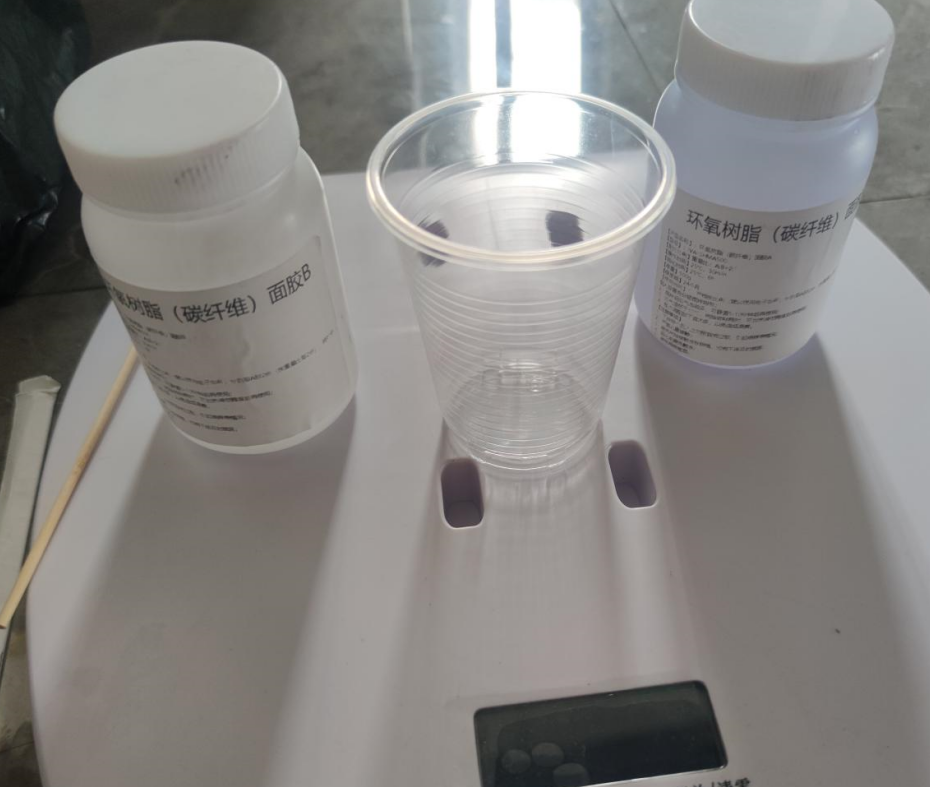

Formulated Glue

The fixation of carbon fiber cloth requires the use of two types of mixed glue: the first is ground glue, mainly applied directly to the board, and carbon fiber cloth covered in glue, play a fixed role; the second is surface glue, is a transparent liquid, directly applied to the hardened carbon fiber material, can further harden the material, enhance the appearance. When preparing mixed glue, it is necessary to strictly follow the preparation ratio, wherein the mixing ratio of glue on the bottom surface is (3:1=A:B), and the mixing ratio of glue on the surface is (2:1=A:B).

Glue

In this step I apply the glue mixture to the board and cover it with carbon fiber cloth, waiting for it to harden.

Surface Treatment

After the bottom glue hardens, you can apply the surface glue to the surface and wait for it to harden. After bending and waterproof tests, there are significant improvements

Idea

The idea for this week's assignment came from my work school experience. In school I teach a course called digital fabrication, where students will choose a theme and complete a comprehensive project over the course of a year. Students learn and design the campus fish and vegetable symbiosis system and use IOT hardware to detect the water quality indicators of the system. However, the detector of IOT equipment is relatively extensive in the sink, and the main controller and some drivers are exposed to the environment, which is very susceptible to weather. So I started thinking about how to use the content and time of study to solve this problem.

To solve this problem, it should be noted that the device is waterproof and can maintain good condition in long-term blistering and sun environment; second, the device can float in vegetable tank water (because the fish and vegetable symbiosis system designed here is a deep-water floating raft mode). Based on these conditions, I learned about composites this week-carbon fiber cloth-and decided to try to make a part that floats in water. In the design, I borrowed inspiration from underwater buoys.

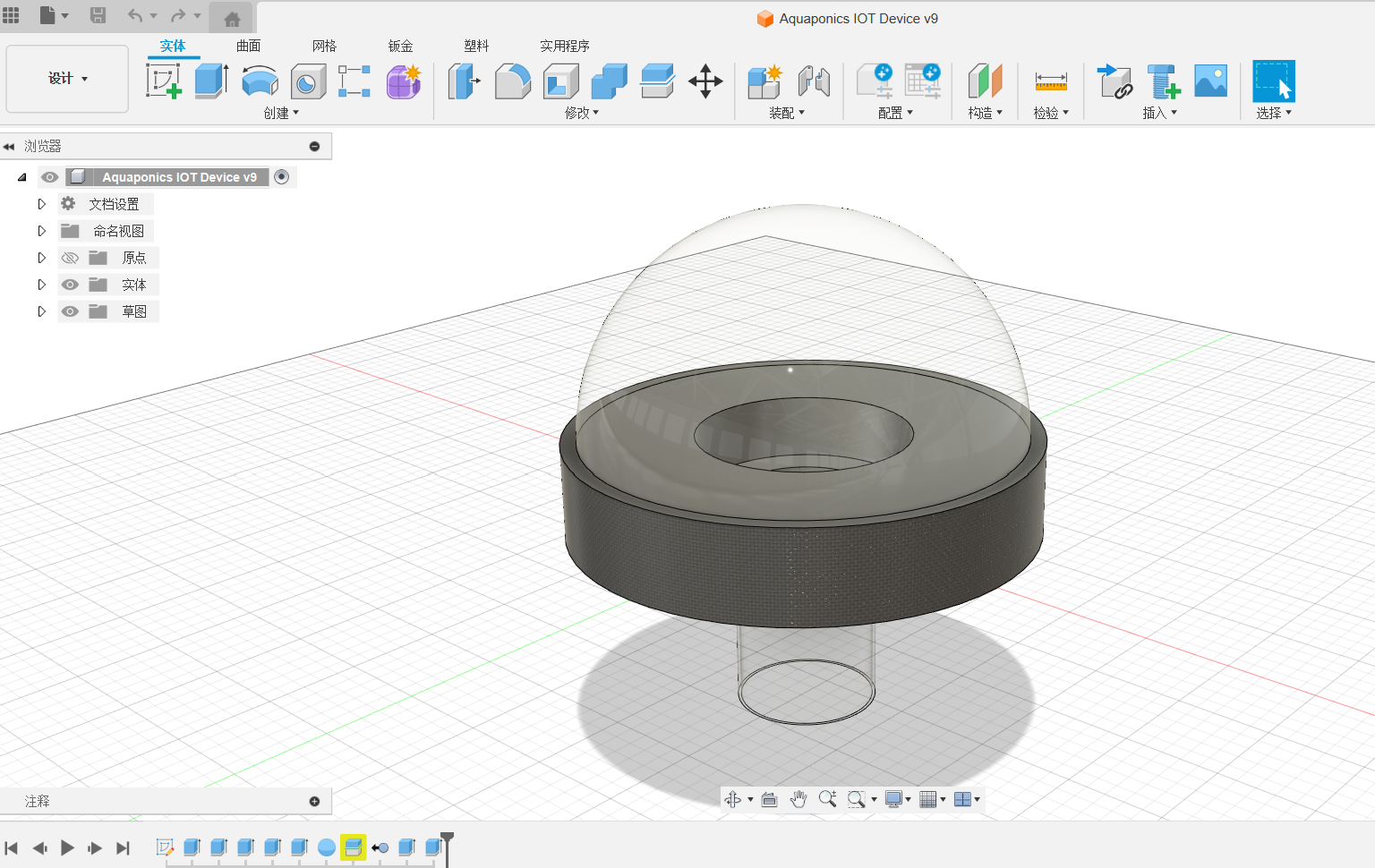

Design

After determining the idea, I used Fusion360 software to design the appearance structure of the device. The design method of upper, middle and lower layers was adopted. The upper layer was acrylic transparent hemisphere cover, which could observe the state of the main control panel and facilitate the subsequent upgrade of solar panels; the middle layer was foam layer, and the surface was coated with carbon fiber cloth material, which provided the buoyancy of the whole device in water; the lowest layer was the position of liquid sensor, which went deep into the water, and the sensor obtained the value and sent it back to the server. In order to facilitate the fixing of the sensor, the fixing structure is designed according to the size of the sensor.

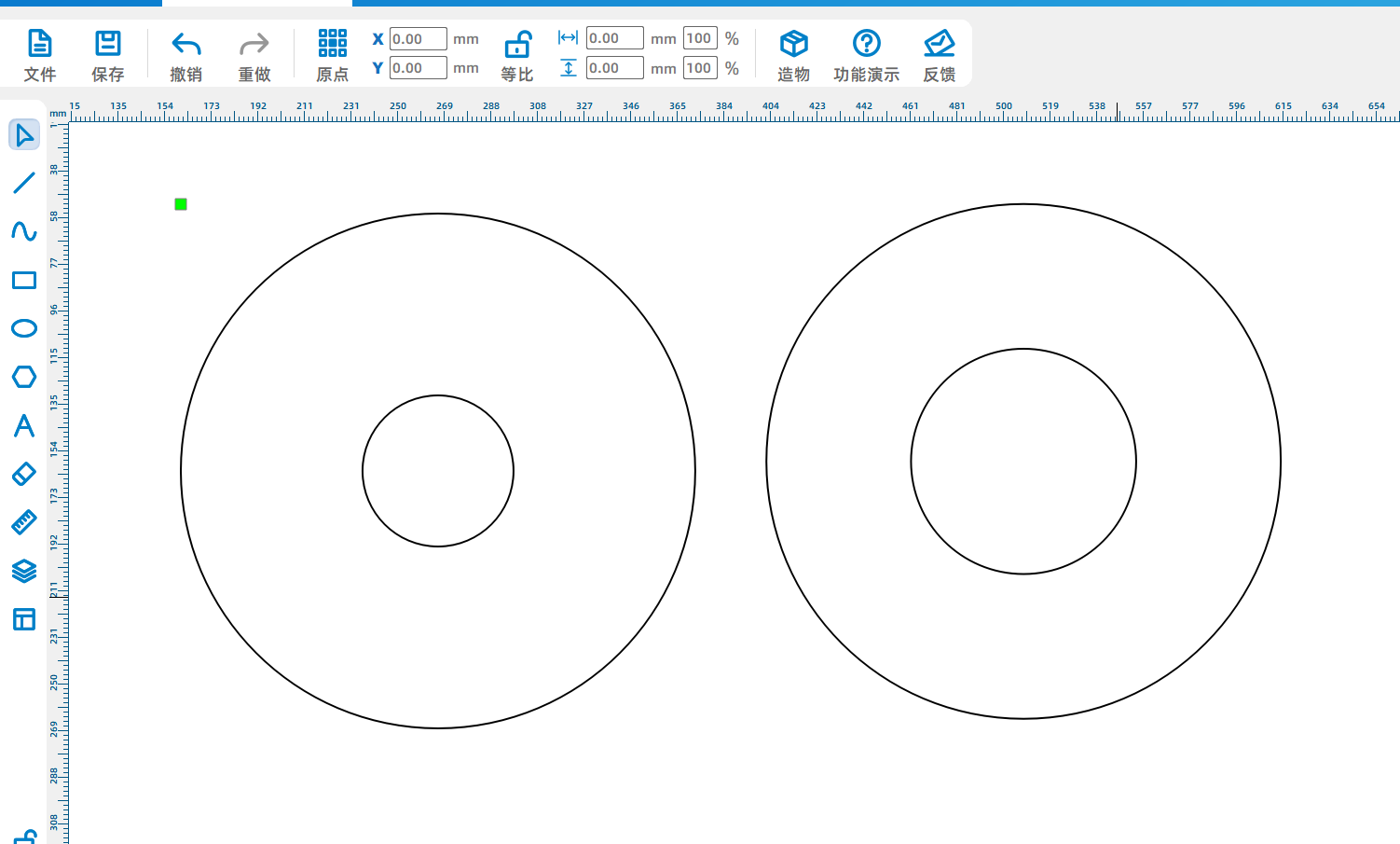

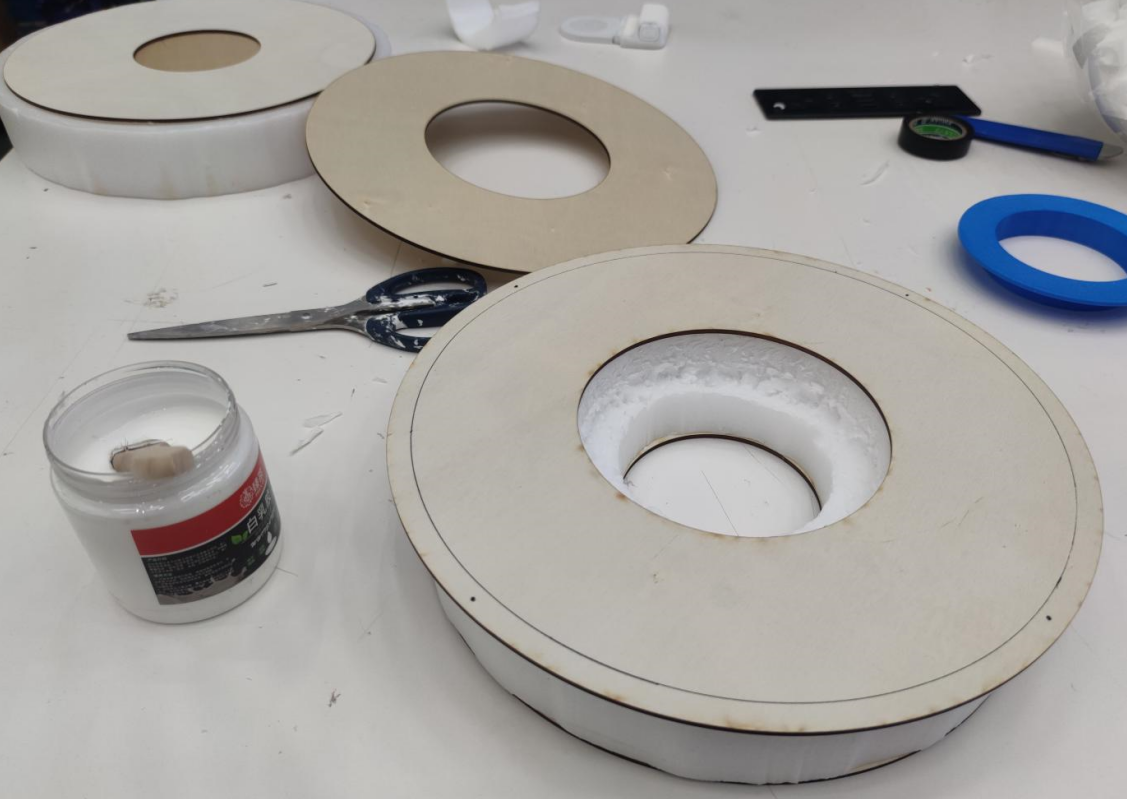

In the design, considering that the material used in the middle layer is foam, it is difficult to fix the upper hemispherical transparent mask with foam in practice, so try to design and use wood and foam combination, and use carbon fiber to completely wrap and cover. The size of the middle layer drawn is shown below.

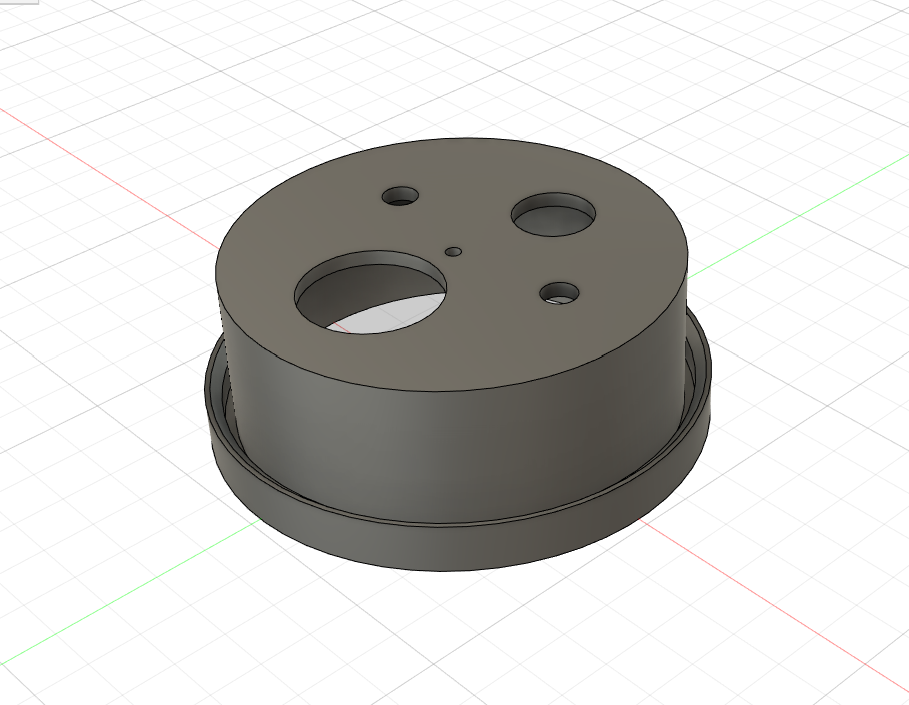

Cutting

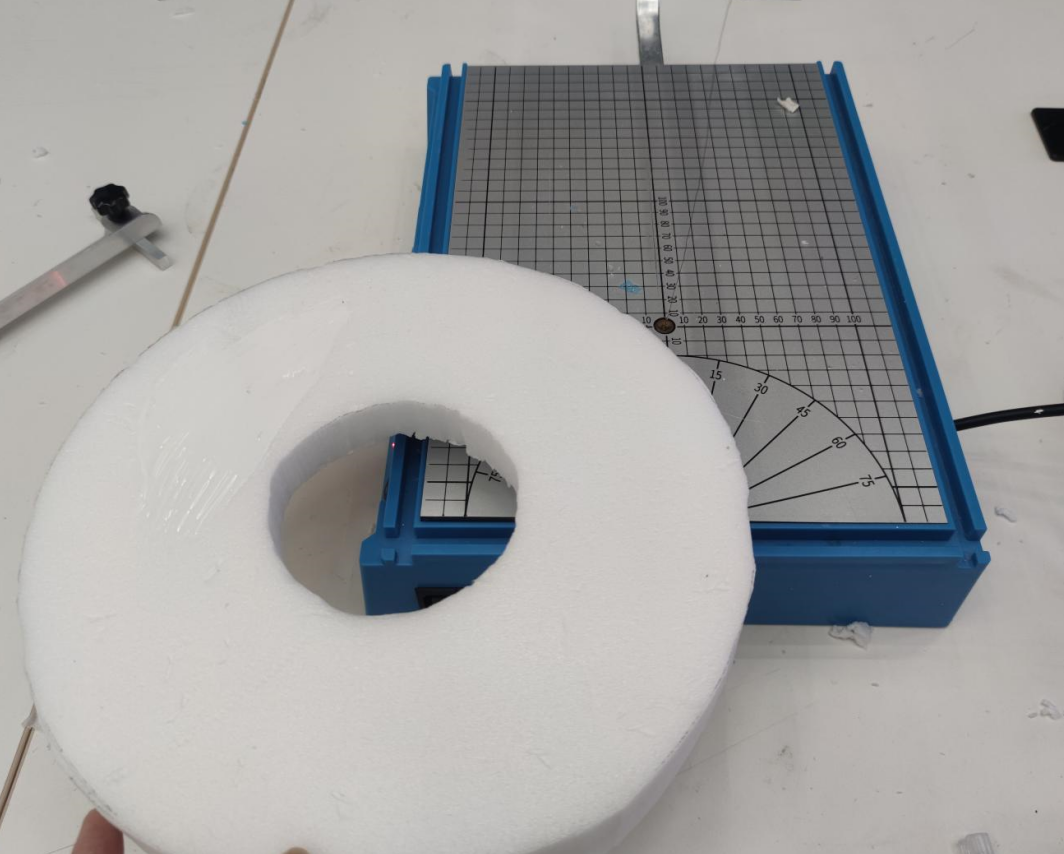

Use a hot wire foam cutter to cut the foam into the desired shape. The machine is electrified resistance wire, resulting in resistance wire heating, the use of heat will foam cutting. Pay attention to the safety of hands and the shape of foam during operation. A laser cutter is also used to cut the boards into corresponding shapes. The two materials are glued together using white latex.

Carbon fiber fabric

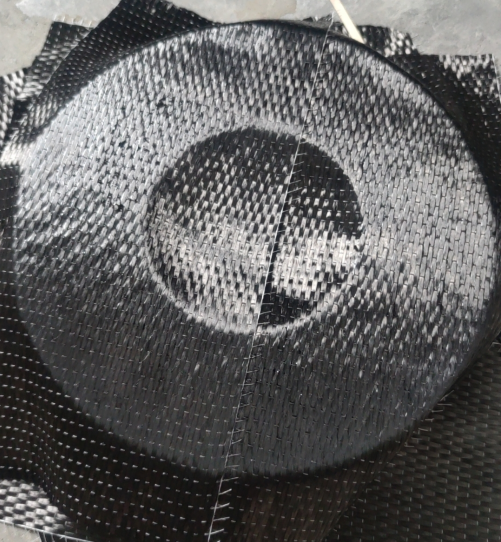

Carbon fiber cloth wrapping material needs two kinds of glue: primer and surface glue, that is, glue coated on the bottom and glue coated on the surface of carbon fiber cloth. First, prepare carbon fiber cloth and glue, cut carbon fiber cloth to a suitable size; secondly, fully mix the primer according to the instructions for use (A:B=3:1); then apply the mixed glue on the foam device, apply it evenly, and then cover the carbon fiber cloth on it and press it flat.

Because of the foam structure ring, so need to subtract excess carbon fiber cloth, and in turn the structure of the reverse and around the package

After waiting for three hours, the carbon fiber cloth is completely fixed. At this time, prepare the surface glue, configure the mixed glue according to the instructions for use (A:B=2:1), stir evenly and apply it on the surface of the carbon fiber cloth in turn. Attention should be paid to slow application to reduce the generation of bubbles.

Release agent and Pressure bag

In general, when we use carbon fiber to create accessories or products, we need molds, release agents, pressure bags, and other auxiliary materials to help shape the carbon fiber. In this week's project, my goal was to apply the carbon fiber material as a protective layer over the target object. Before curing, I used bottom adhesive to ensure the carbon fiber cloth adhered smoothly to the surface of the ring, eliminating the need for a release agent or pressure materials to assist with shaping.

Installation

Prepare structural parts and sensor equipment and assemble the whole device.