Computer-Controlled Cutting¶

group assignment¶

- [X] Characterize your lasercutter’s focus, power, speed, rate, kerf, joint clearance and types.

- [X] Document your work to the group work page and reflect on your individual page what you learned.

We designed some pieces in Inkscape and Fusion 3D (depending on our affinity with each of these softwares) to try out the laser cutter and understand the paramters that are important to keep in mind.

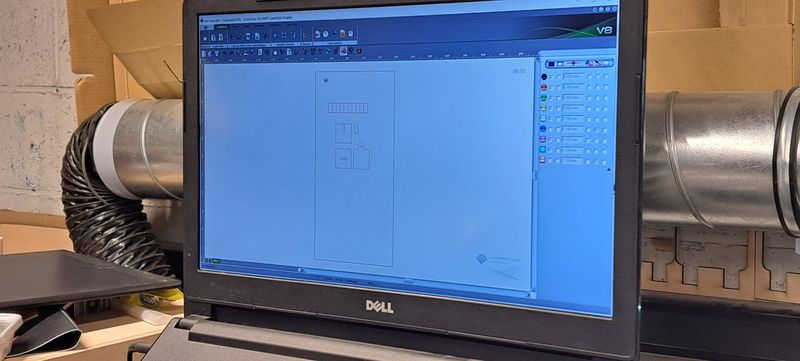

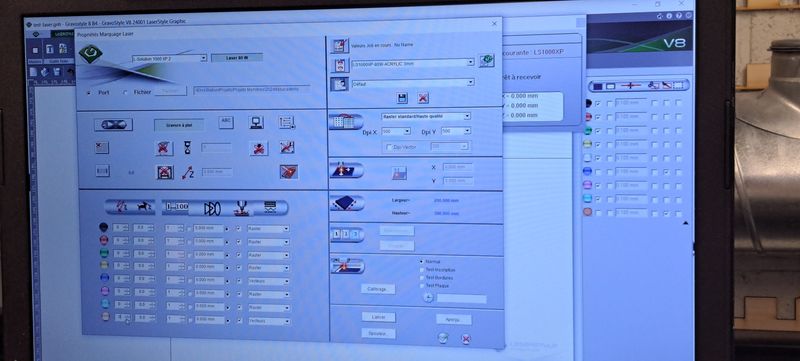

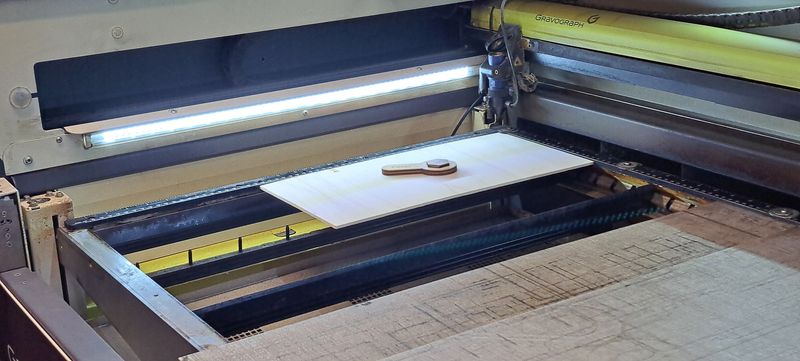

Our laser cutting machine is a Gravograph LS1000 XP.

You can only their on program which is Gravostyle but it is pretty simple.

We imported our file in the program, adjusted the cutting parameters for our material.

In this case it was a wood board of 4mm so we put the speed at 10% and the power at 80%. We let the DPI at is default number, 500.

Focus¶

As the focus setting is really important because it’ll determine the right cutting of the material, we’ve learned how to do it manually.

First step, we had to put the material on the laser cutter tray and make sure it is flat everywhere (to avoid a difference in the cutting or engraving at some places) and enter the right cutting parameters.

Then we put a piece on our material that has the right height for the perfect focus.

By using the arrow buttons on the right side of the machine, we moved the laser so that it ends right above the “DIY focus measure piece”.

We lowered the laser cutter tray and moved it back up until the “DIY focus measure piece” touches lightly the palper of the machine.

Picture of the palper touching the DIY focus measure piece. Last step, push the “check” (“V”) button, close the machine and press the green start button

Power and Speed¶

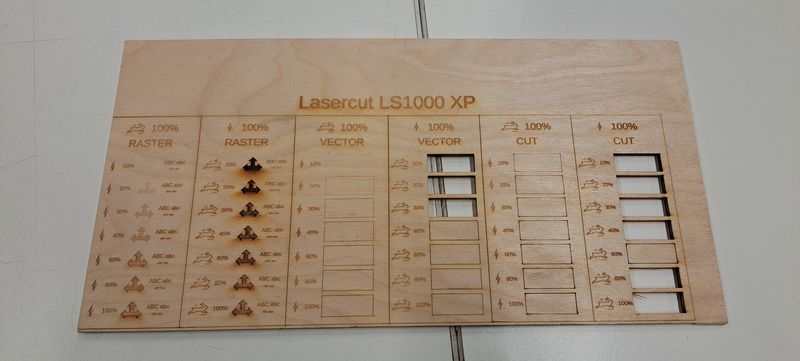

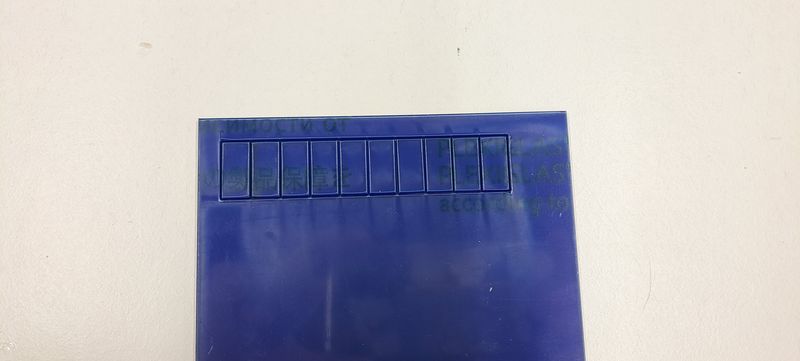

To determine the power and speed of the laser, there is a test jig that allows you to view different parameters.

But you have to be careful, these parameters are valid only as an indication, it will be necessary to test it before, especially if the material is not the same.

Kerf¶

The kerf is also called “cutting width” or “laser line thickness”. It is a key parameter to consider when creating files for laser cutting (or any machine that cuts digitally or not) :

- To make perfect interlocking joints which is important for the fit. For example, for a notched box, you can create a model that assembles by force and does not require nails or screws. For other volumes, this allows sufficient support while the glue sets.

- To better anticipate the final result.

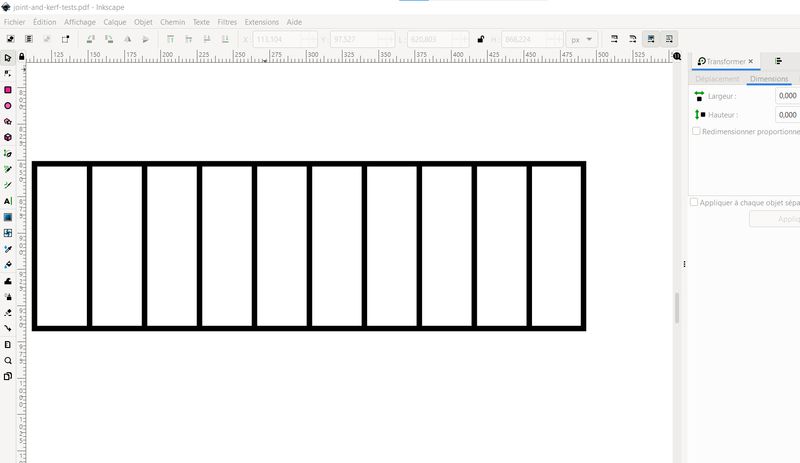

- To determine how much material you can leave when cutting. When you want to remove a lot of material to leave very fine lines, knowing this information is essential. Generally, it is said that it is better to leave as much width as thickness of material. To get the right kerf measure for our laser cutter machine, we designed 10 rectangles of 10mm length each that we put side by side to get a 100mm length big rectangle.

We took care to not design each rectangle completely (we only traced the top, bottom and right sides, and closed the drawing by adding the left side only at the last piece) to avoid a double passage of the laser and by then compromise the result.

We took care to not design each rectangle completely (we only traced the top, bottom and right sides, and closed the drawing by adding the left side only at the last piece) to avoid a double passage of the laser and by then compromise the result.

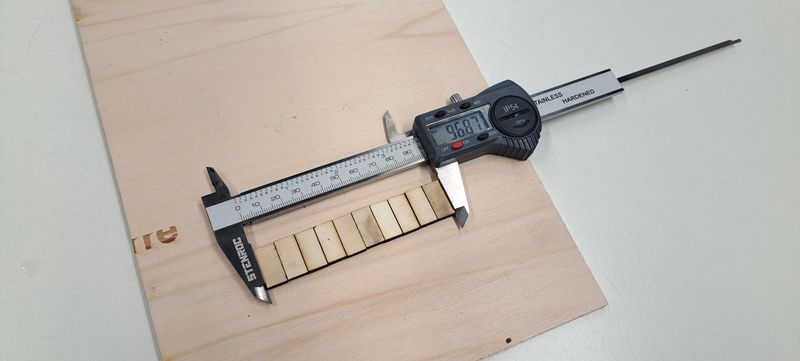

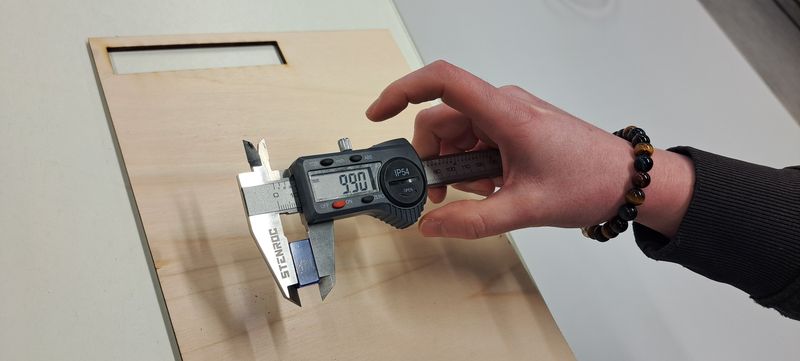

After cutting the pieces in a 4mm wood plate, we measured the length of the big rectangle hole in the plate, then the length of one of the little pieces and a the end the length of all the little pieces together to really realize the difference because of the kerf.

After a small calculation to determine this kerf we got as result :

100 mm - 96.87 mm = 3.13 mm

3.13 mm / 10 = 0.313 mm

After a small calculation to determine this kerf we got as result :

100 mm - 96.87 mm = 3.13 mm

3.13 mm / 10 = 0.313 mm

kerf = 0.31 mm so ~0.3 mm

We did the same process with a 3mm plexiglas plate and it gave us this result : 100 mm - 98.17 mm = 1.83 mm 1.83 mm / 10 = 0.183 mm

kerf = 0.18 mm so ~0.2 mm

Joint types¶

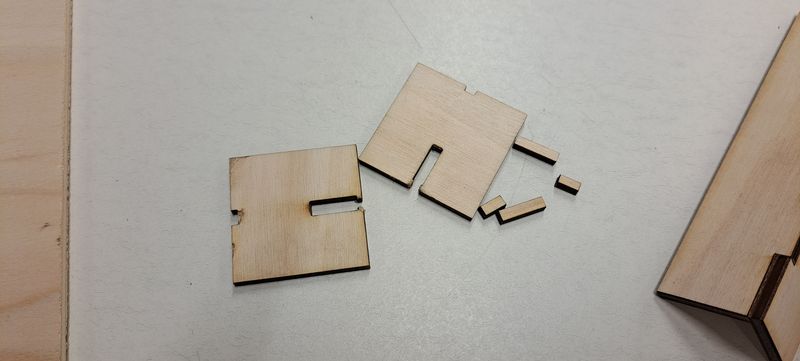

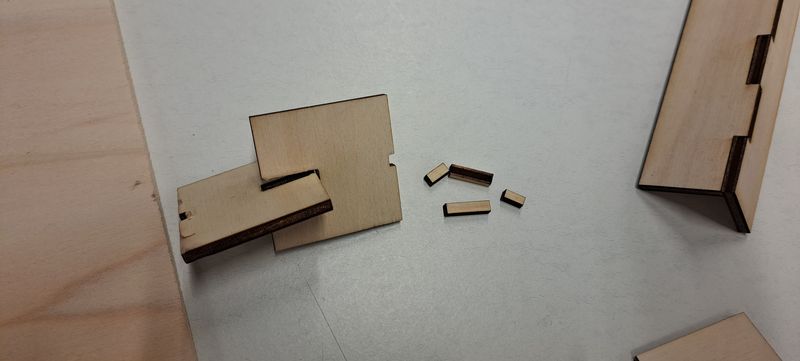

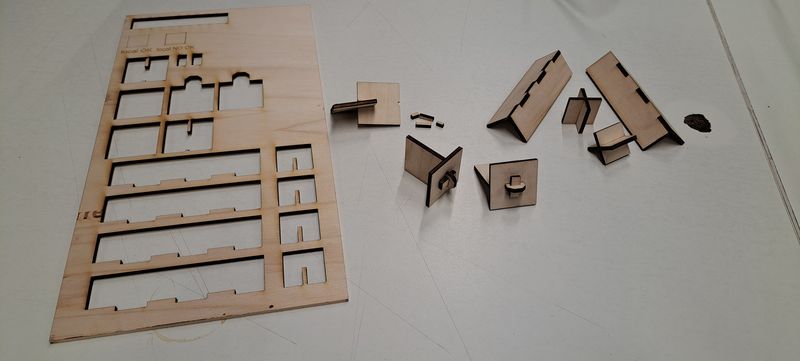

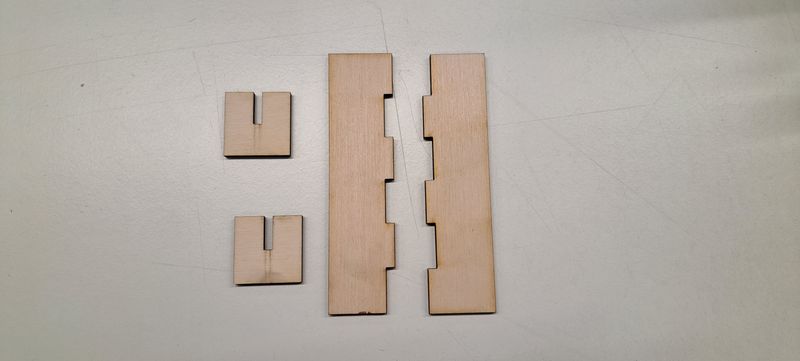

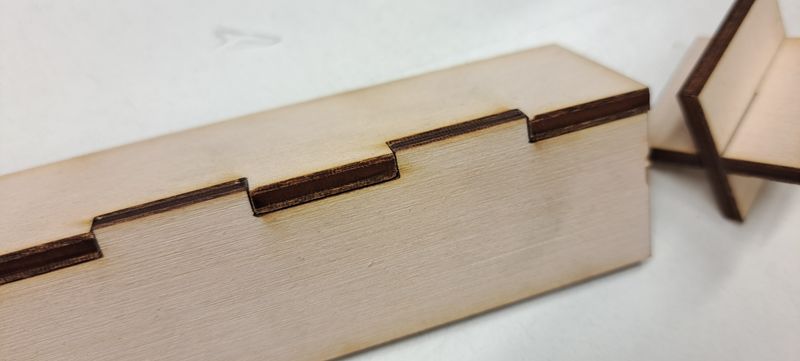

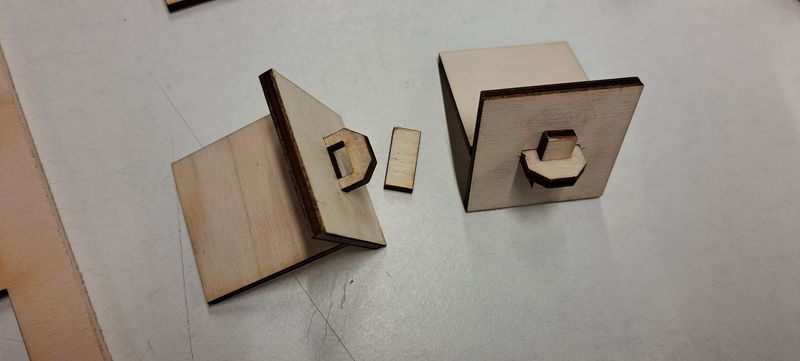

We’ve selected 4 different types of joints and shared the work of creating the designs.

We joined then to prepare the laser cutter machine and cut the pieces.

For the easiest pieces, we had no problem. The sizes were right.

For the easiest pieces, we had no problem. The sizes were right.

The 2 others were trickier.

The 2 others were trickier.

We made 2 size tests for the wedge joints and had difficulties to put the pieces together with one of them. It was too tight.

And for the snap-fit joint, it was a fail. This one really isn’t so easy to design. We will try it again.

And for the snap-fit joint, it was a fail. This one really isn’t so easy to design. We will try it again.