5. 3D Scanning and printing¶

Assignments in this week¶

Group Assignment:

- [X]Test the design rules for your 3D printers

Individual assignment:

- [X] Design and 3D print an object(small, few cm3, limited by printer time) that coundl not be amade subtractively

- [X] 3D scan an object(and optionally print it)

Test the 3D printers¶

Learn about our 3D printers¶

-

Tools

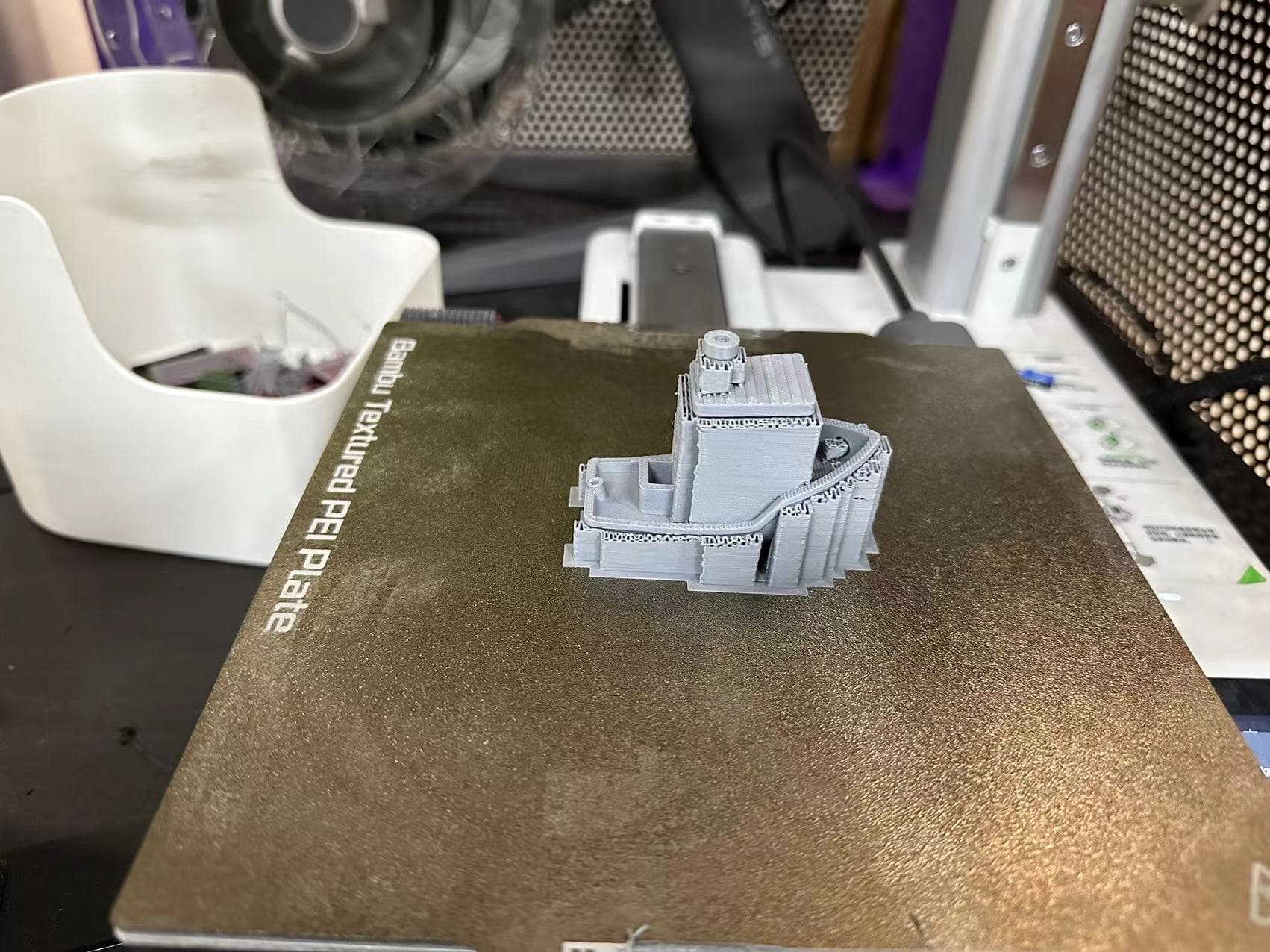

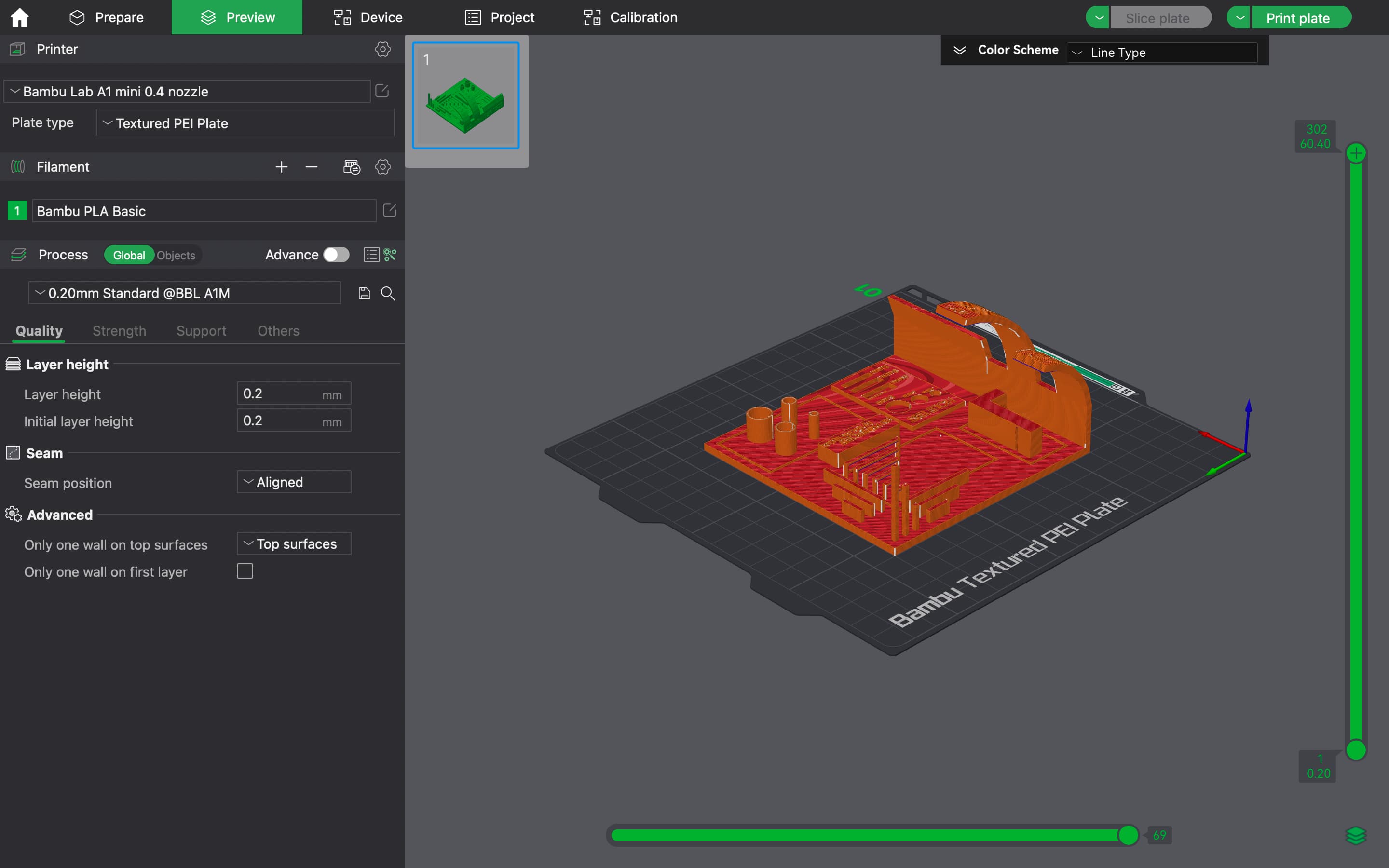

I have experience using 3D printers before, so I am going to use some new machines in this course. It happened that in our office, a colleague bought a new 3D printer, and I decided to try it out again. -

Babulab A1 3D Printer

This 3D printer have lots of automation setting funtion which is very user-freindly.

-

- Install the software and apps.

- Install the software and apps.

-

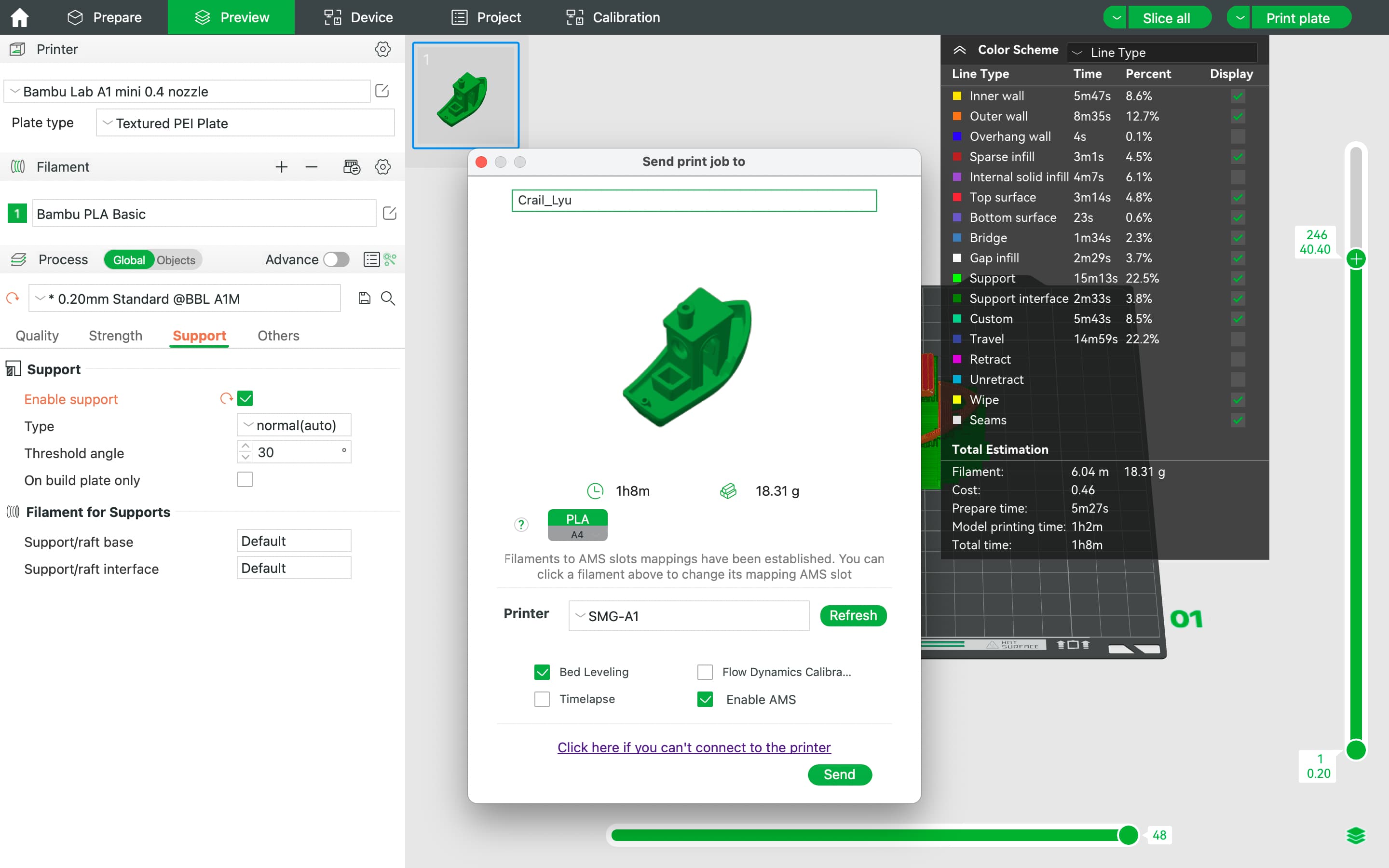

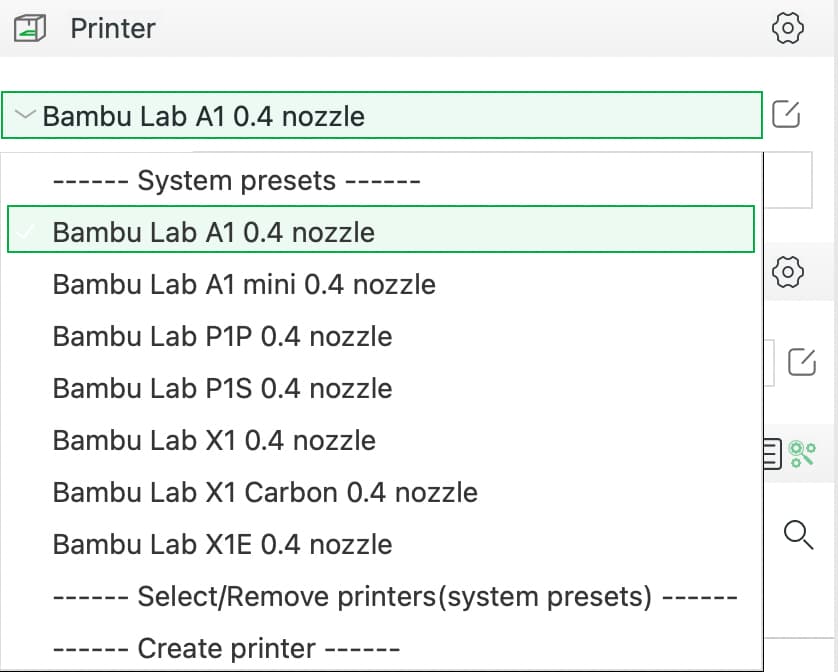

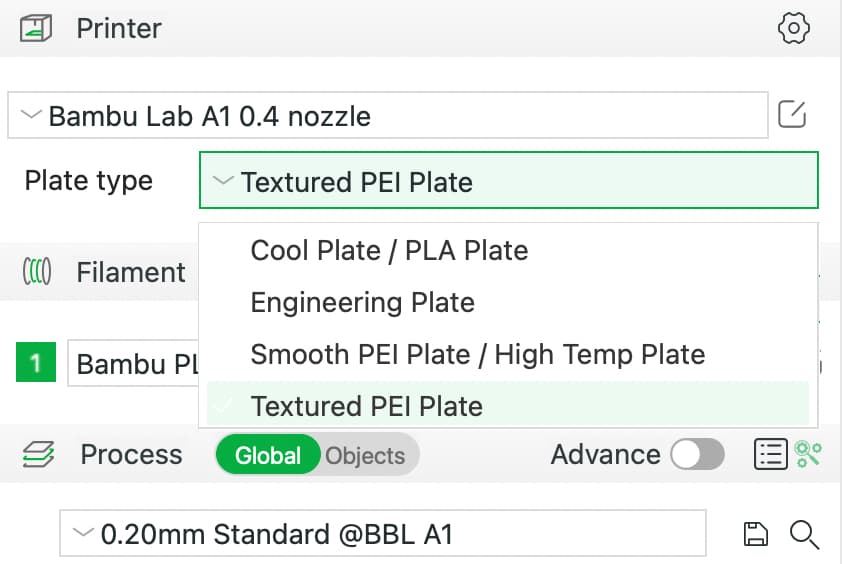

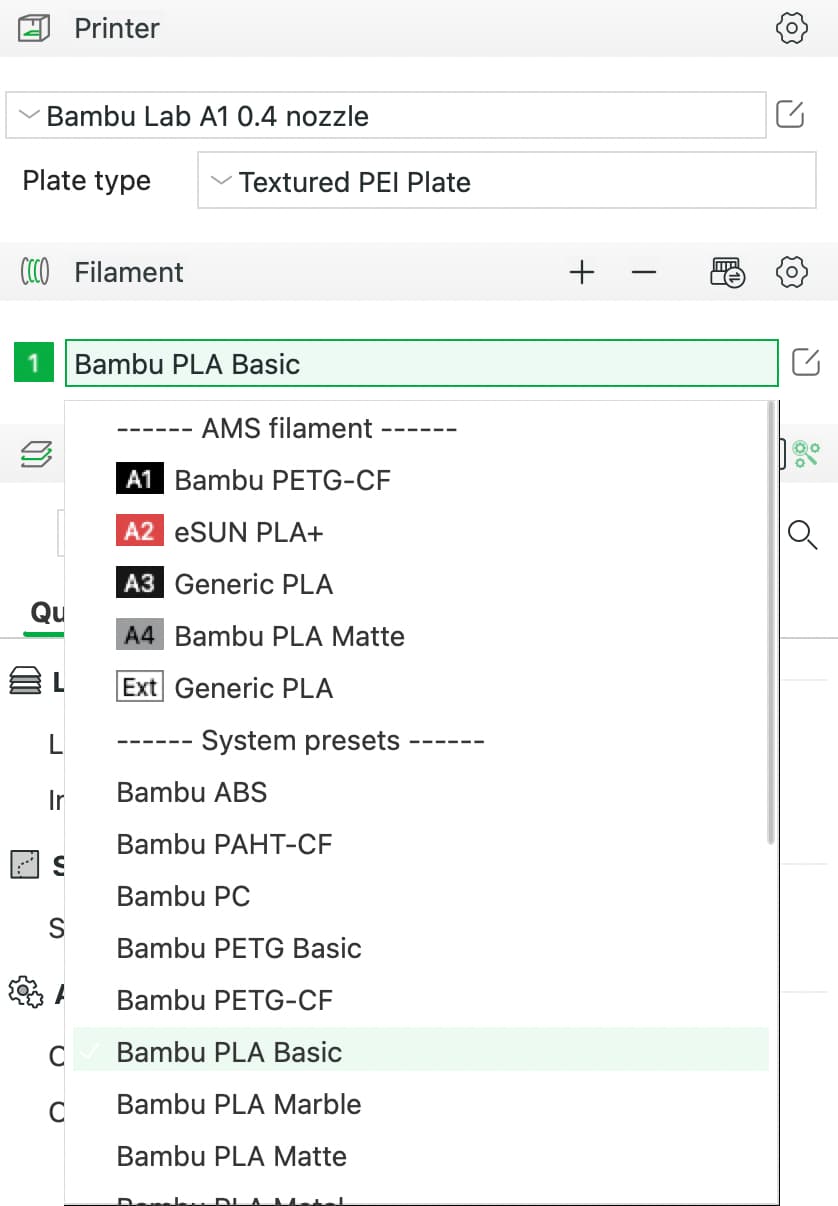

- Set the 3D printer parameters.

3D printer Model >> Plate Types >> Filament Selection.

- Set the 3D printer parameters.

-

- Set the printing parameters.

- Set the printing parameters.

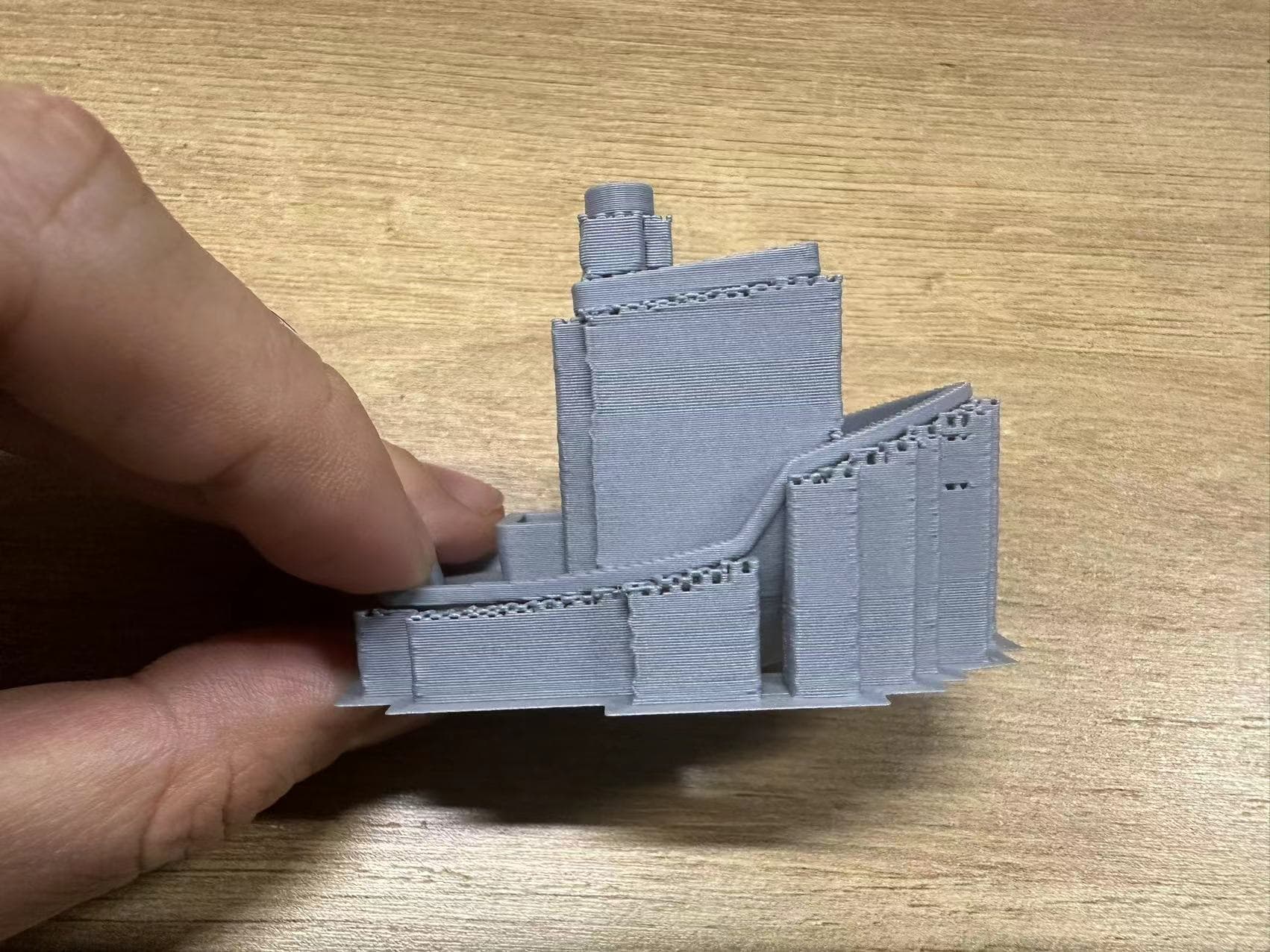

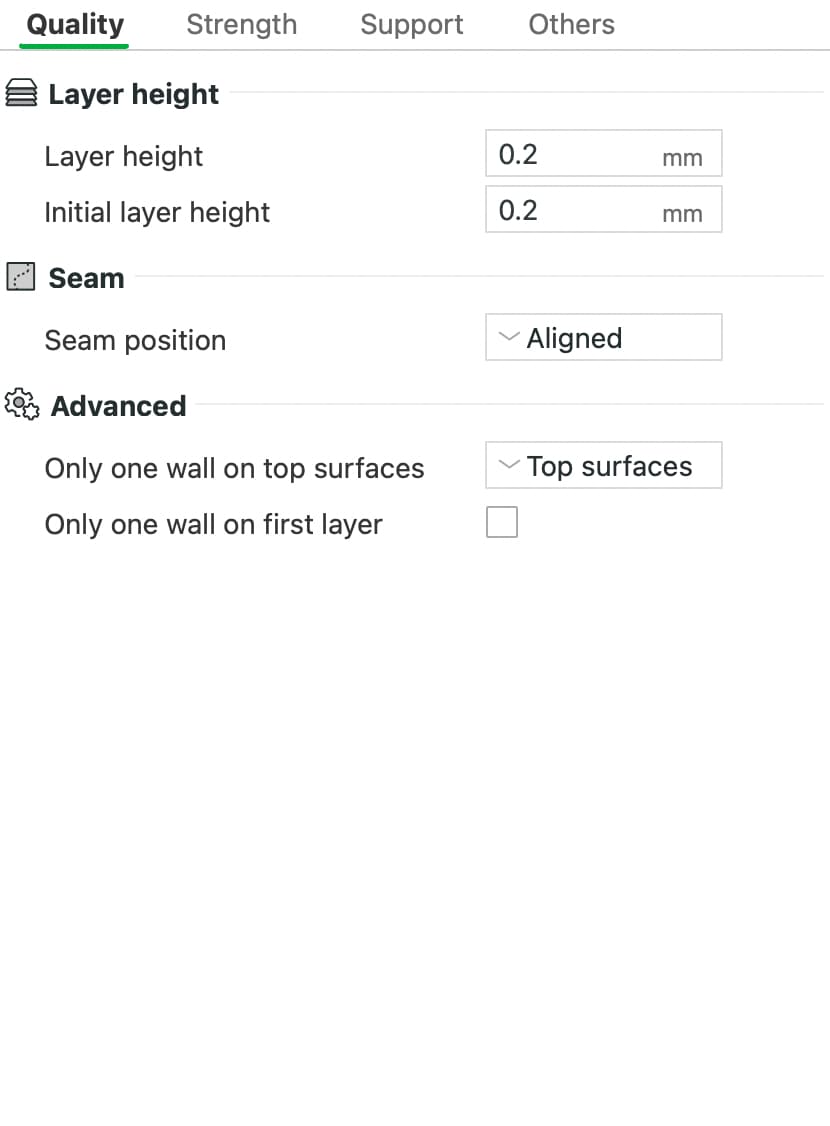

- Quality: Its normally determined by the 3D printers.Layber height will determined the quality of the printing. The Initial layer height will determined the printing stability.

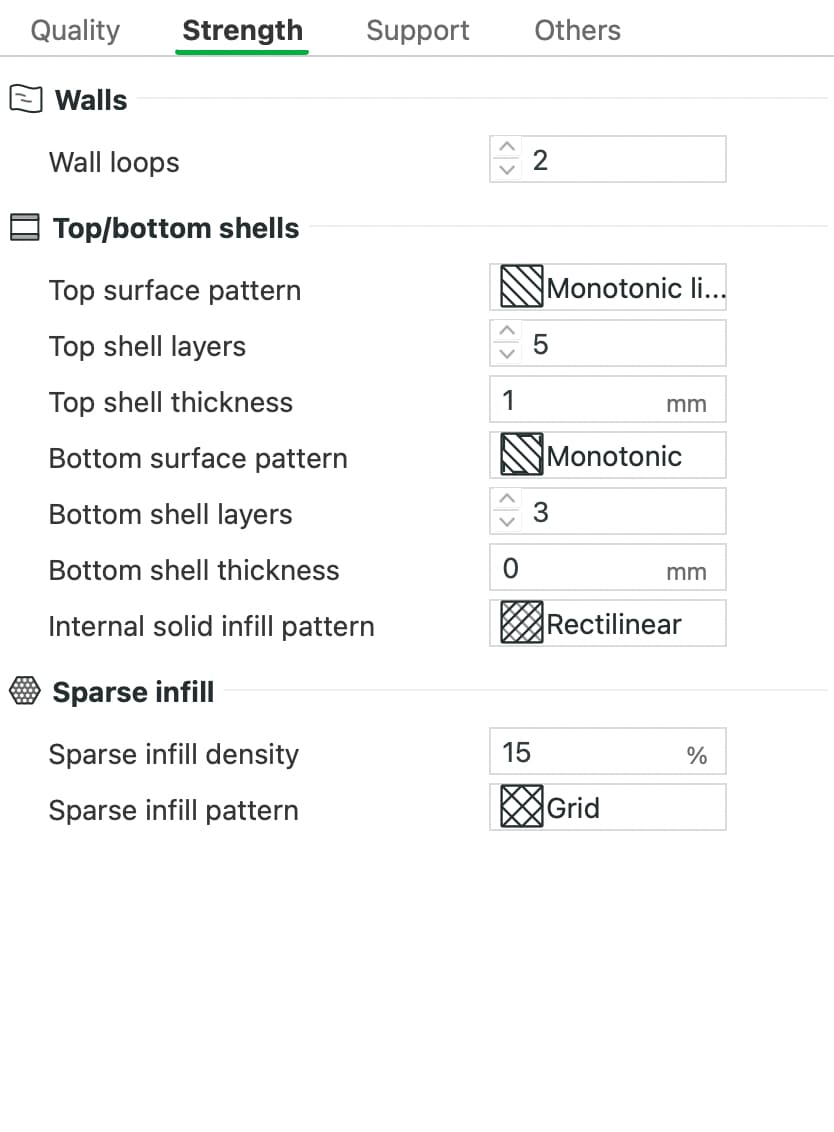

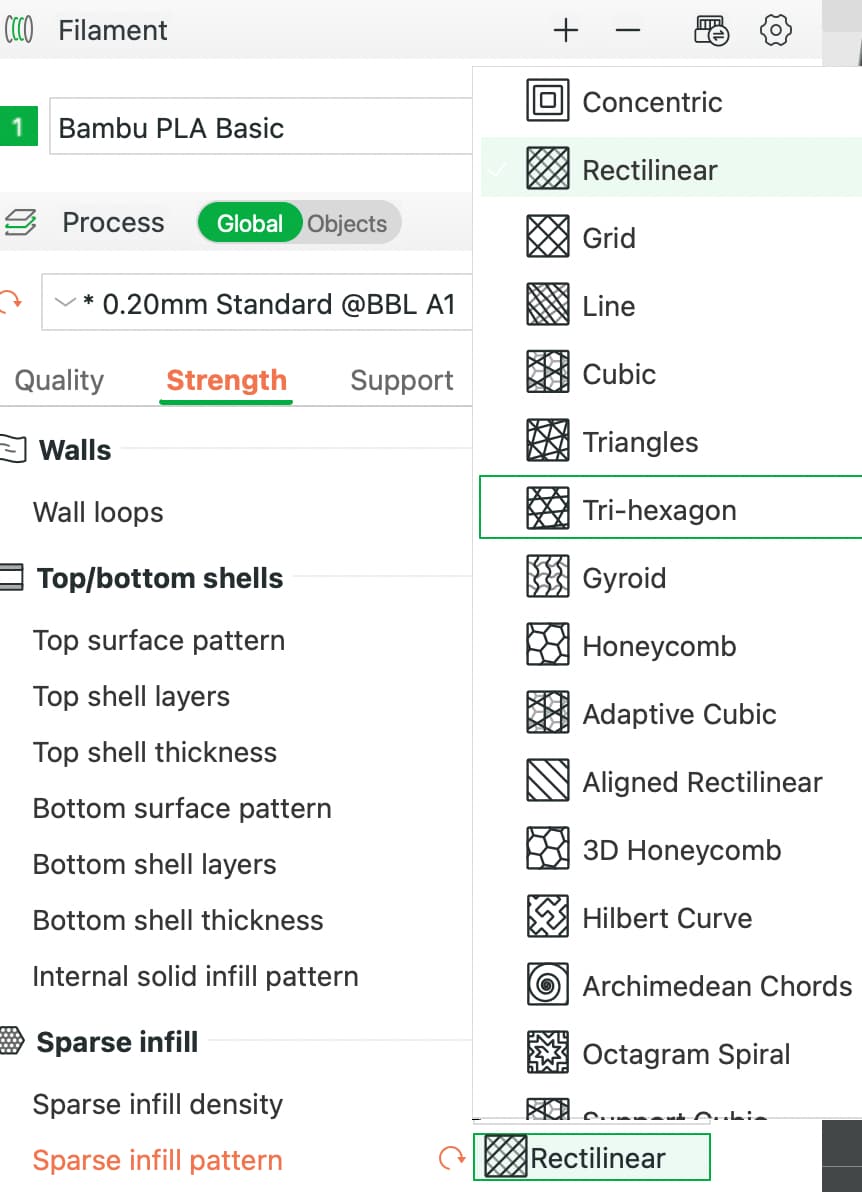

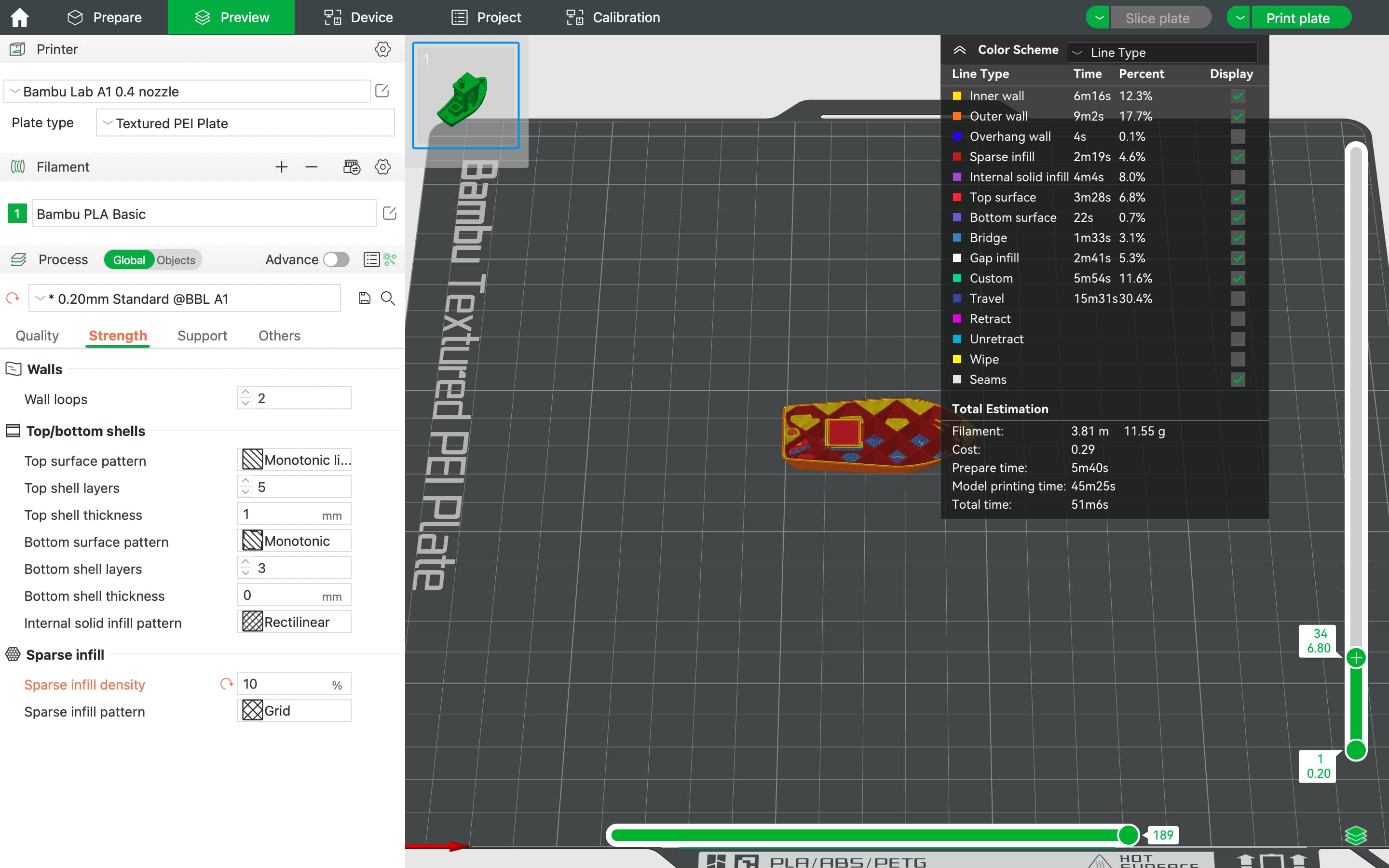

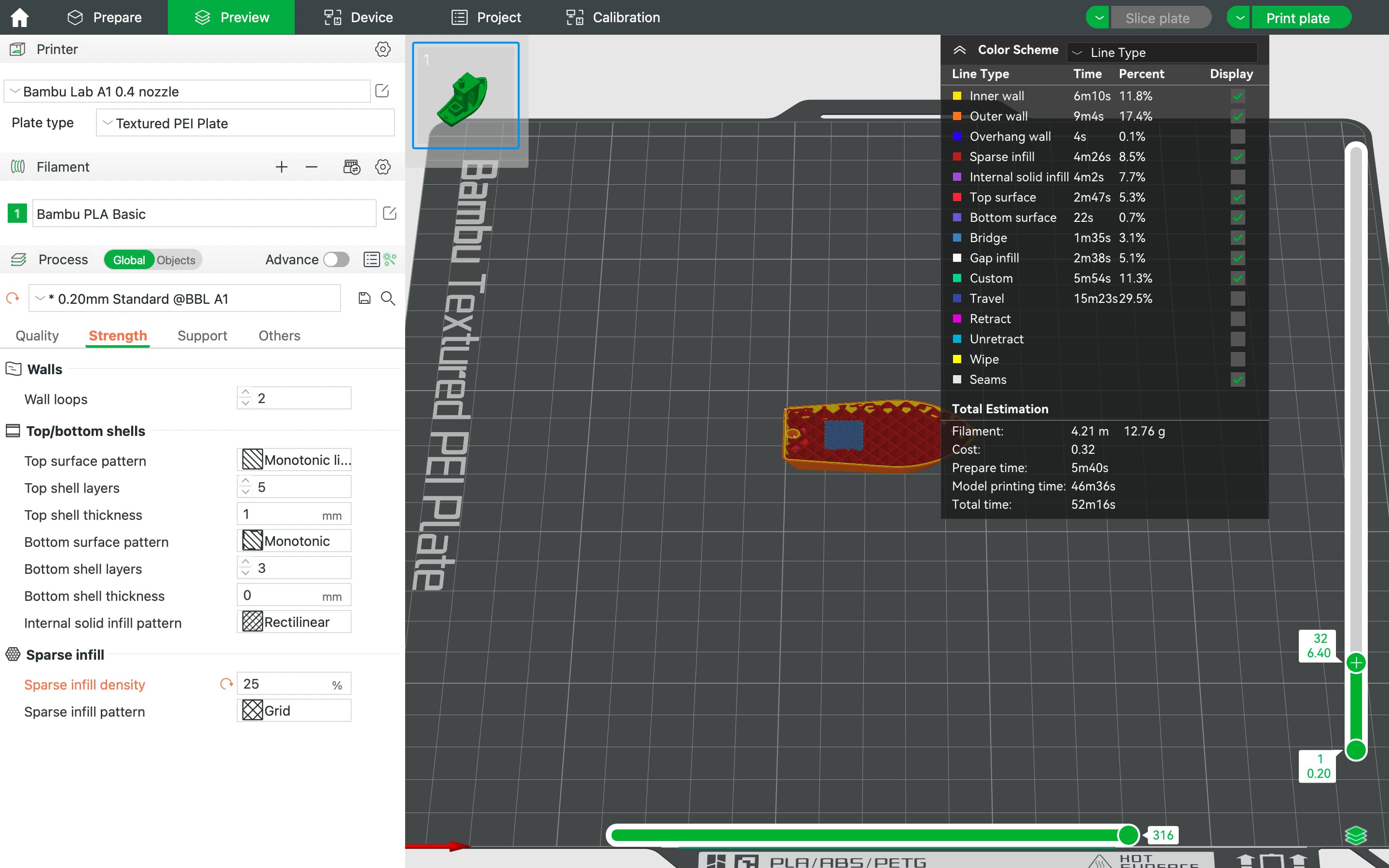

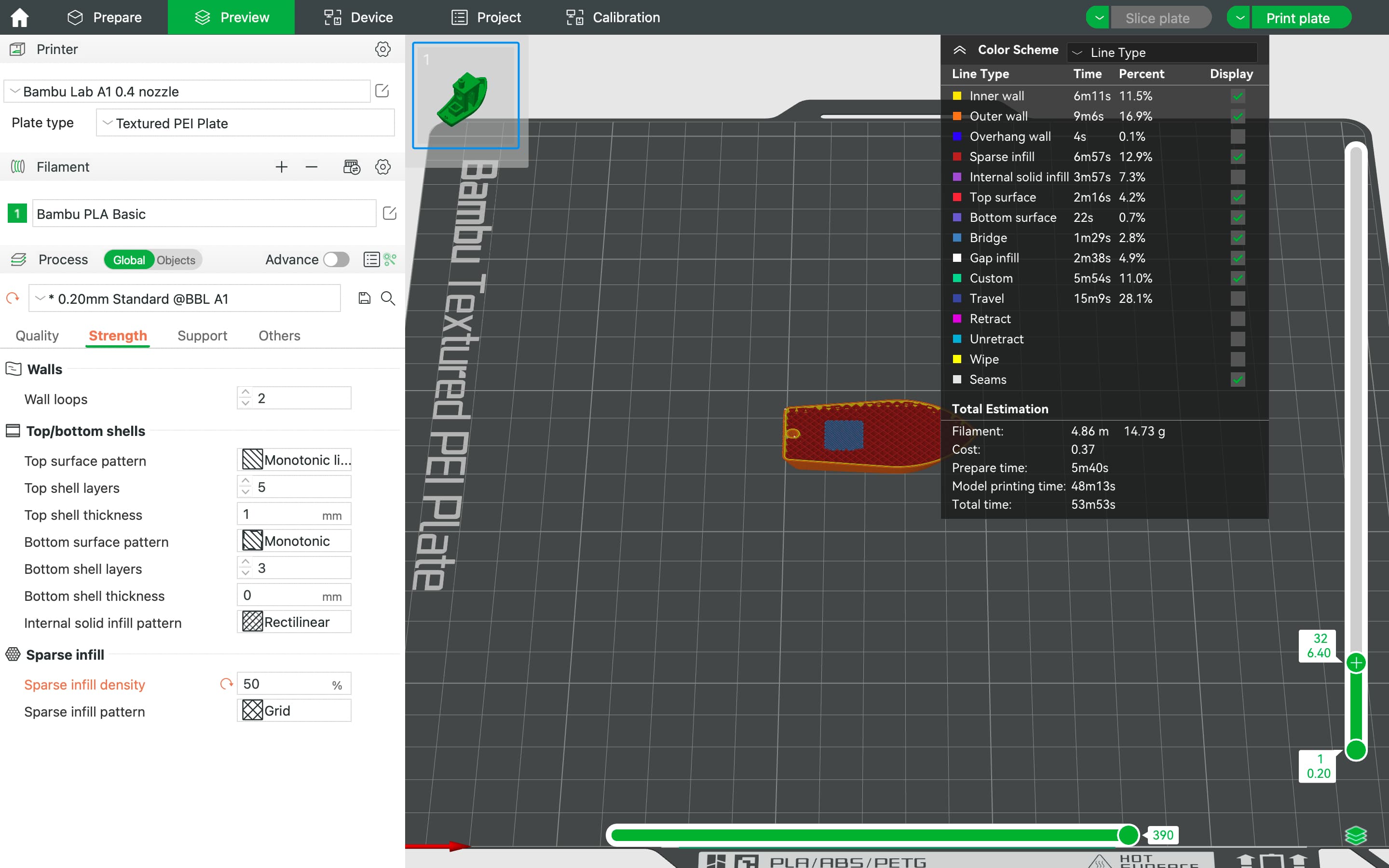

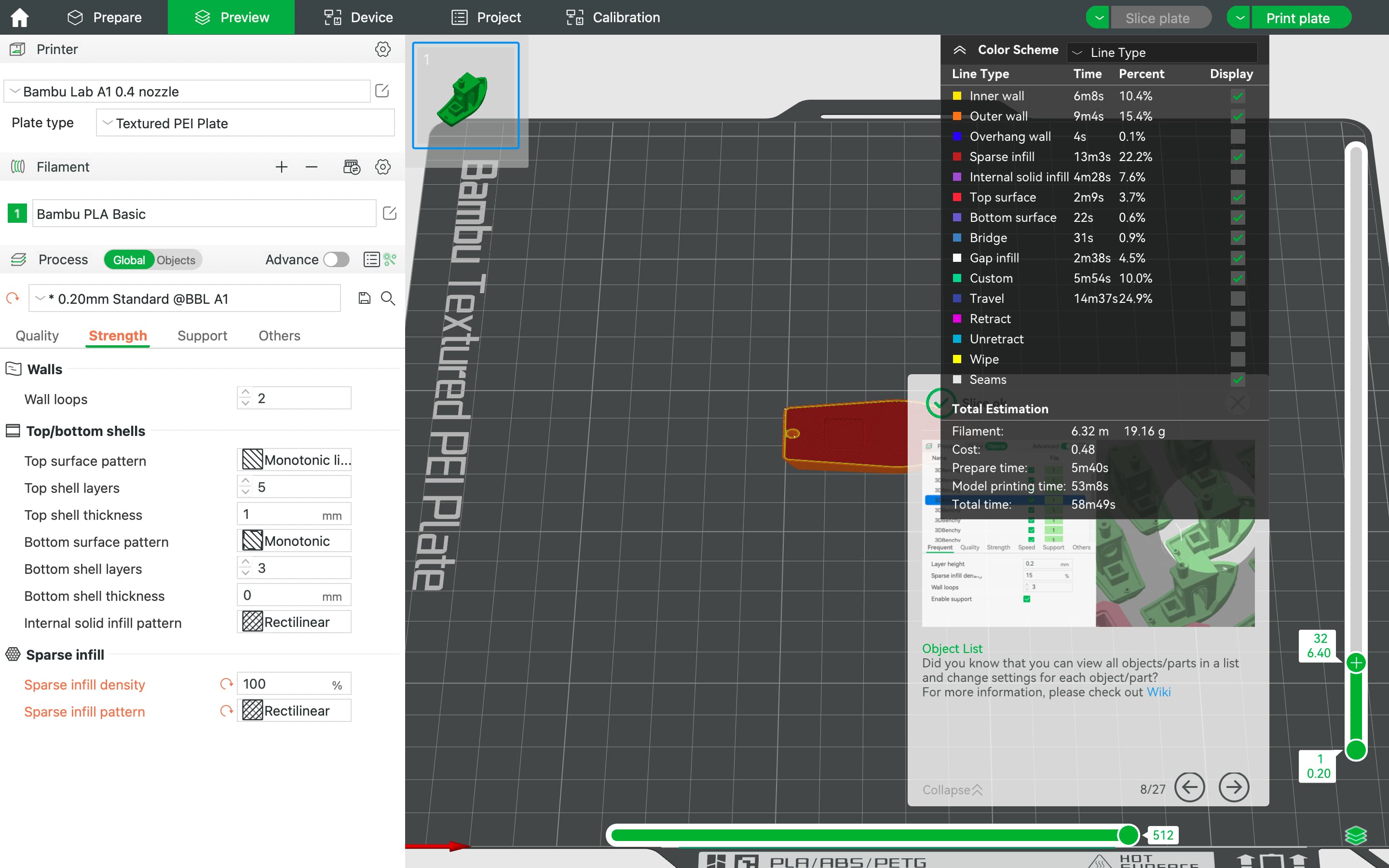

- Stregth: By adjusting the sparse infill density can determined how much materials we will cost and how much time we will need to print it. Meanwhile, the sparse infill patterns will indluence the printing efficiency.

- Sparse infill Pattern have lots of selection. Wall loops will determind the thickness of the surfaces.

- Sparse infill density: 10% >> 25% >> 50% >> 100%

- Ailament consumption: 3.81m(11.55g) >> 4.11m(12.76g) >> 4.86m(14.73g) >> 6.32m(19.16g)

- Time consumption: 51m6s >> 52m16s >> 53m52s >> 52m16s

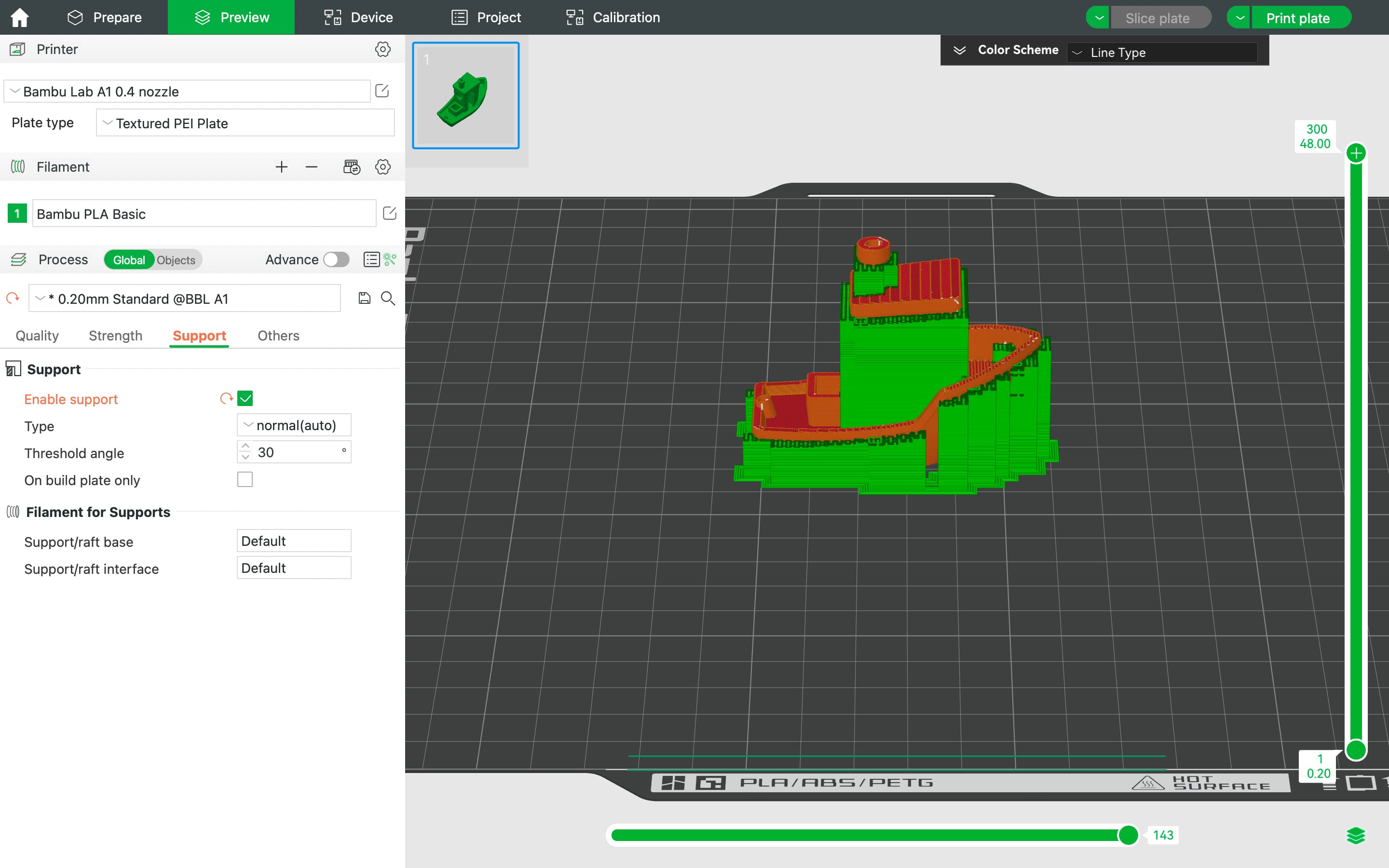

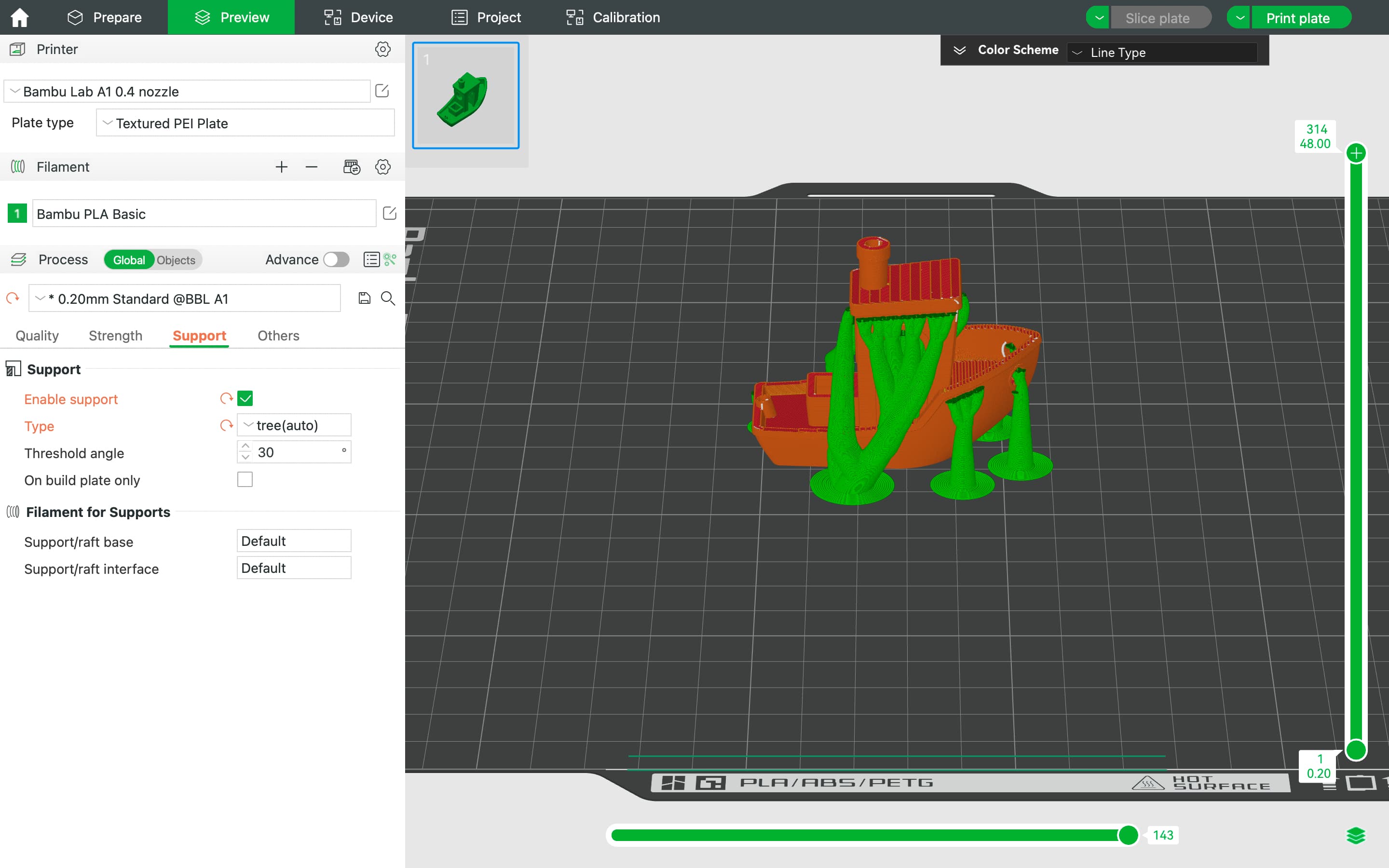

- Support: Support is normaly used for some printing area when there is no holding parts. To dissemble the support parts easily, I can choose diffrent support type such as normaly or tree size and the threshold angle.

On the other hands, the support will also cost more time and more prining materials.

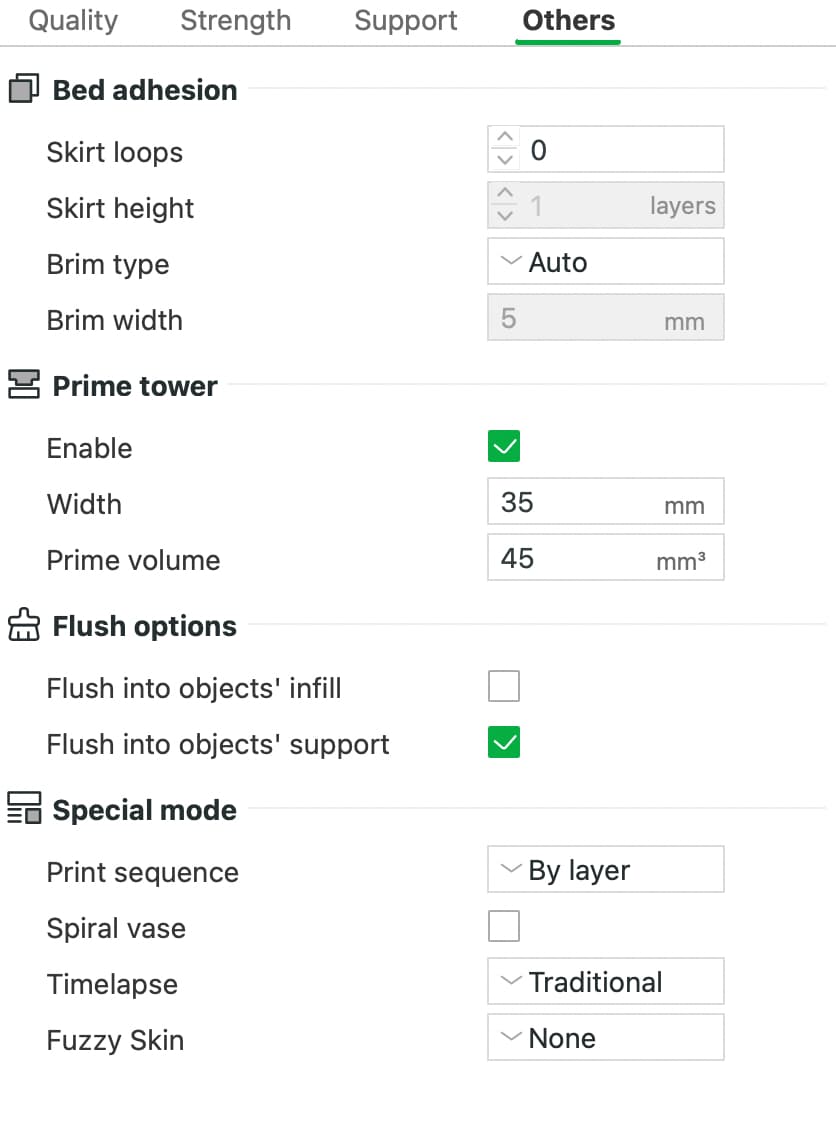

- Quality >> Stregth >> Support >> Others

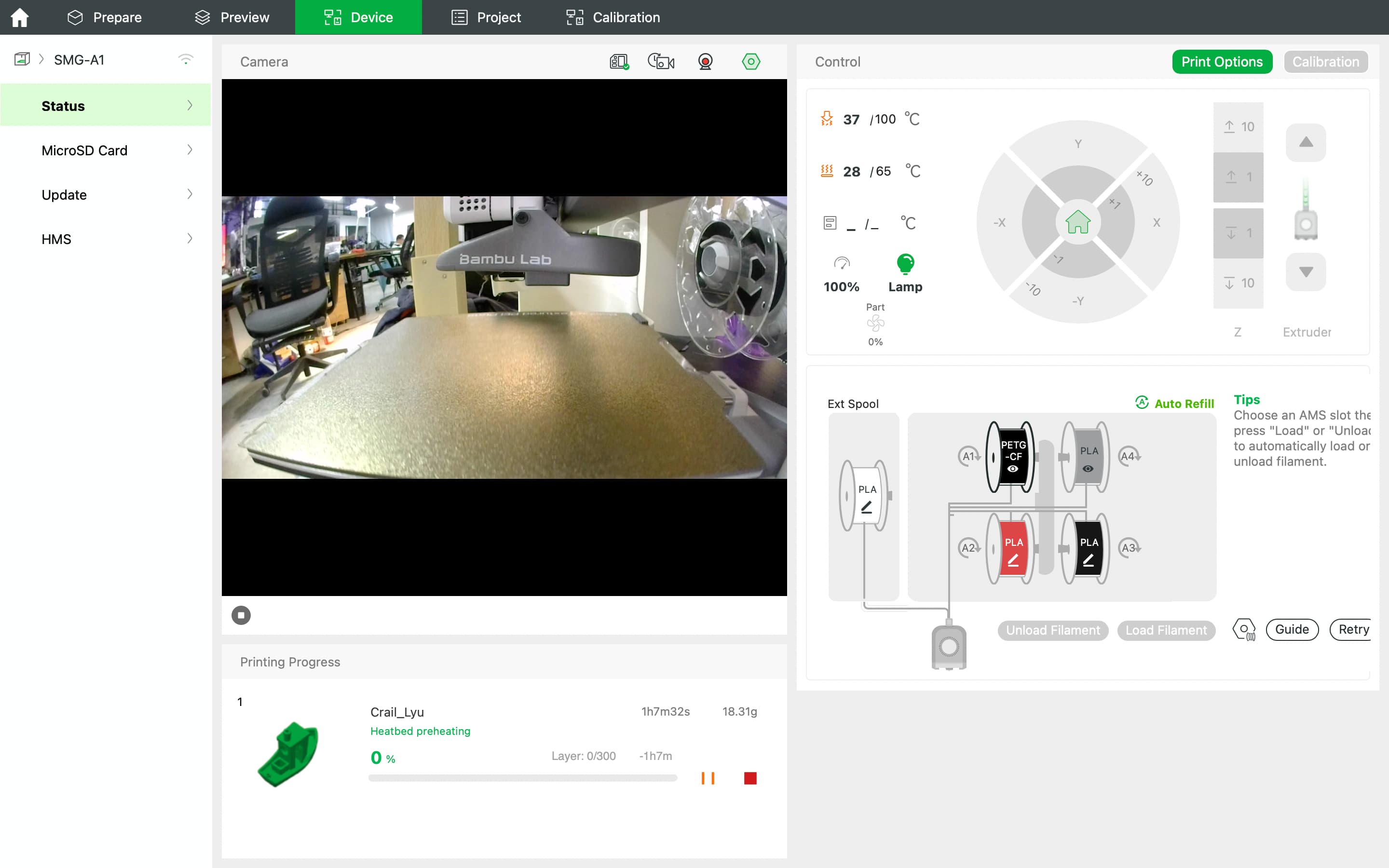

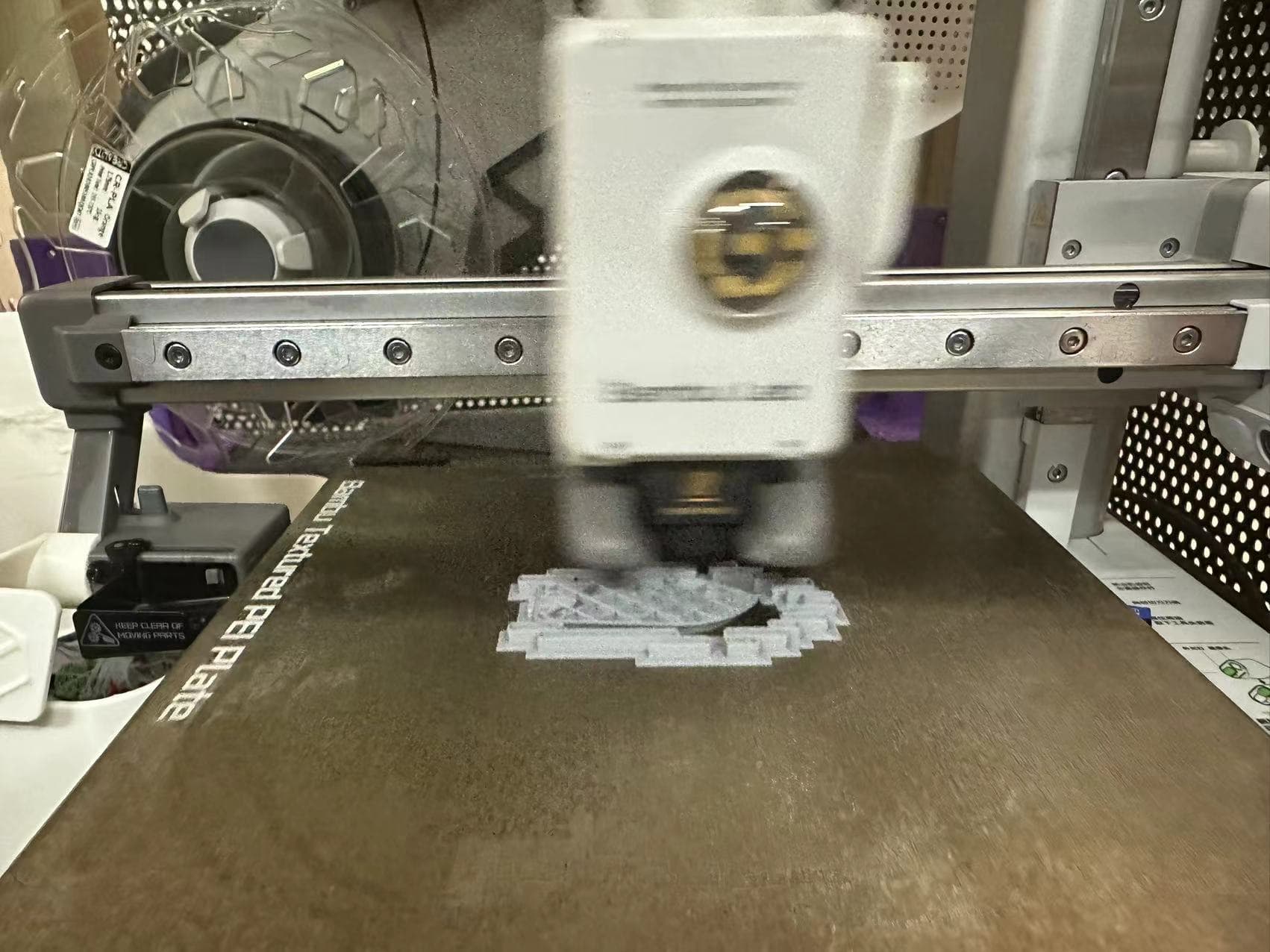

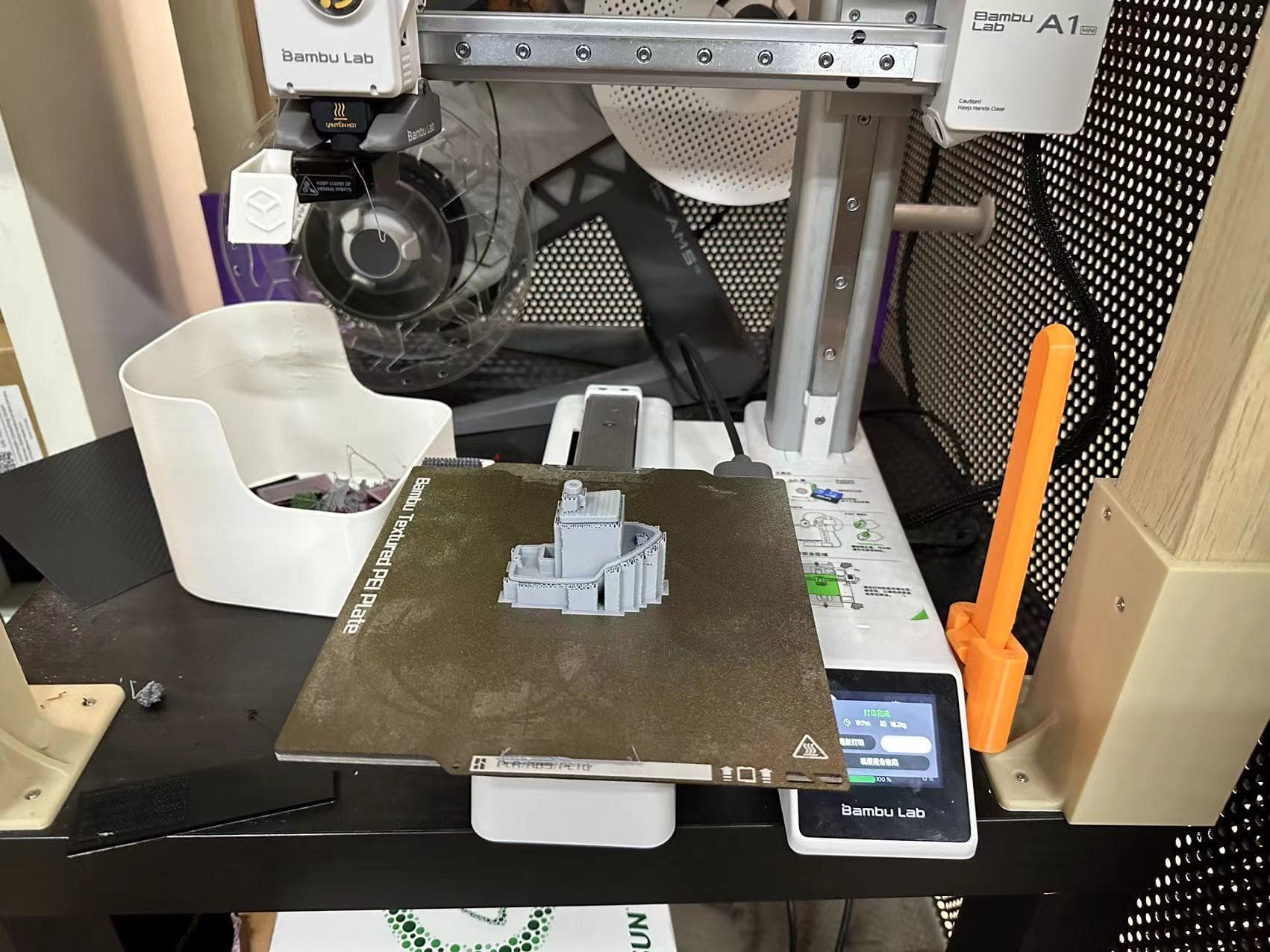

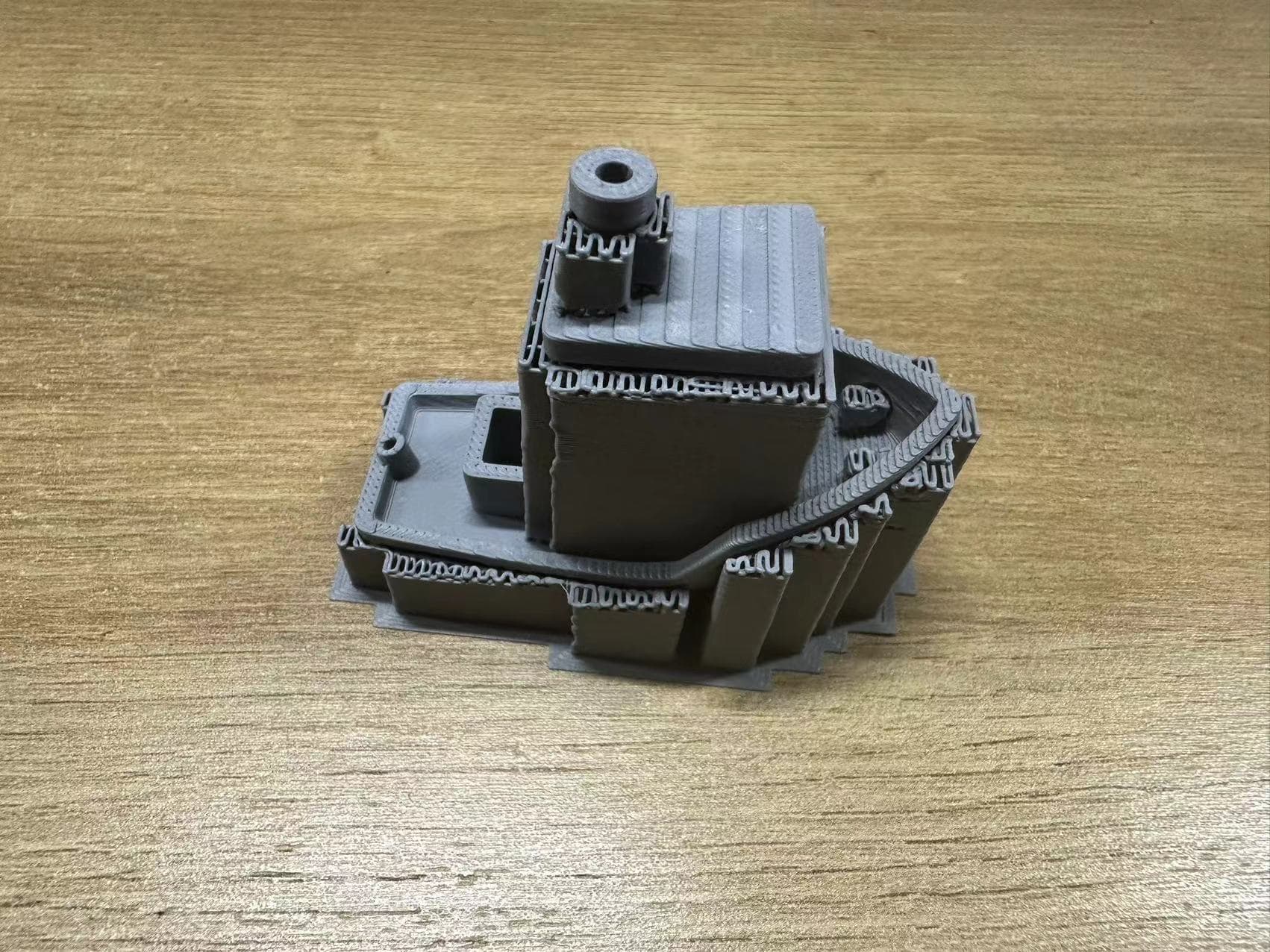

3D Printing Prctice

¶Testing the 3D Printer¶

Practicing on 3D Printer¶