3. Computer controlled cutting¶

Group Assignment:

- [x] do your lab’s safety training

- [x] characterize your lasercutter’s focus, power, speed, rate,

- [x] kerf, joint clearance and types

Individual assignment:

- [x] cut something on the vinylcutter

- [x] design, lasercut, and document a parametric construction kit,accounting for the lasercutter kerf, which can be assembled in multiple ways,

- [x] and for extra credit include elements that aren’t flat

Types and principles of computing controlled cutting.¶

These are most based on the materlas of the cutting objects. Due to the difference of the cutting materials, it will have different cutting knife to cut the materials by touch methods or none touch methods.The basic materials will be paper, clothes, wood or metal.

1. Knife cutting. It normally have a knife to cut the materials by using the computer to control the trails of knife or cutting materrials in 2D plane.

2. Print and cutting. It normall used in cuttting the giant painting materials.

3. Laser cutting. It will based on an laser knife to cutting the thin wooden borads or other not easyly burned materials.

4. Plasma or CNC cutting. It will be used to cutting the thick woods or metal.

5. Waterjet cutting. It’s used to cutting the metal boards.

6. Hot Wire cutting. It will be used cutting the plastic materials.

7. Wire EDM cutting. This is high adcanced methods which integrated lots of knife for different materials.

Group Assignment¶

This week we have used the laser cutting machine. Since I have experience in using it before, the process of using and learning is relatively easy. As group assignment, we will test the laser cutting machine.

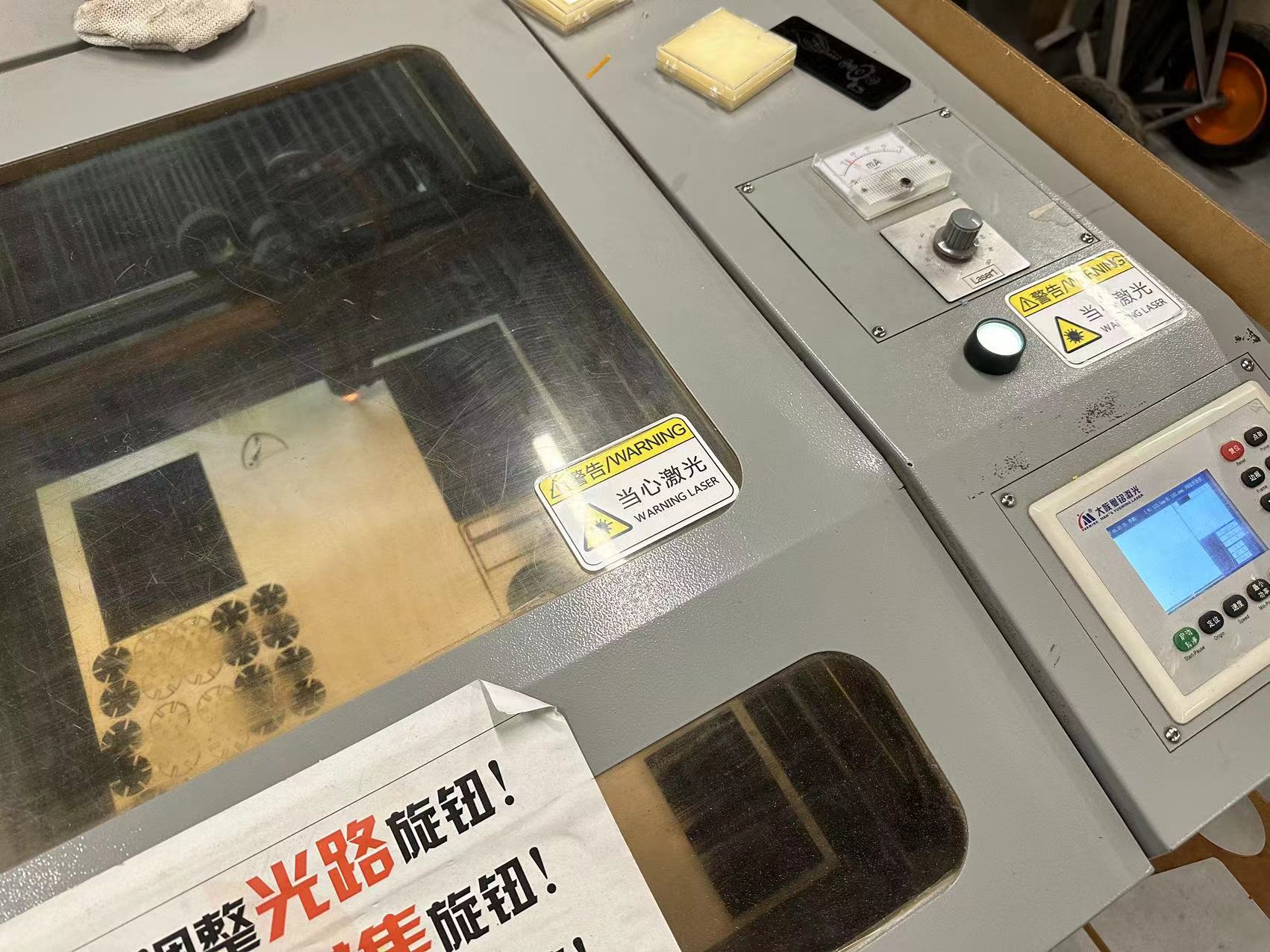

Here is the laser cutting machine in Chaihuo makerspace. Before opening this equipment, we actually need to open the rest of the auxiliary equipment, such as the laser tube water cooling system, exhaust gas treatment system, control computer, etc. Only after turning on some auxiliary equipment can the laser cutting machine equipment be officially turned on.

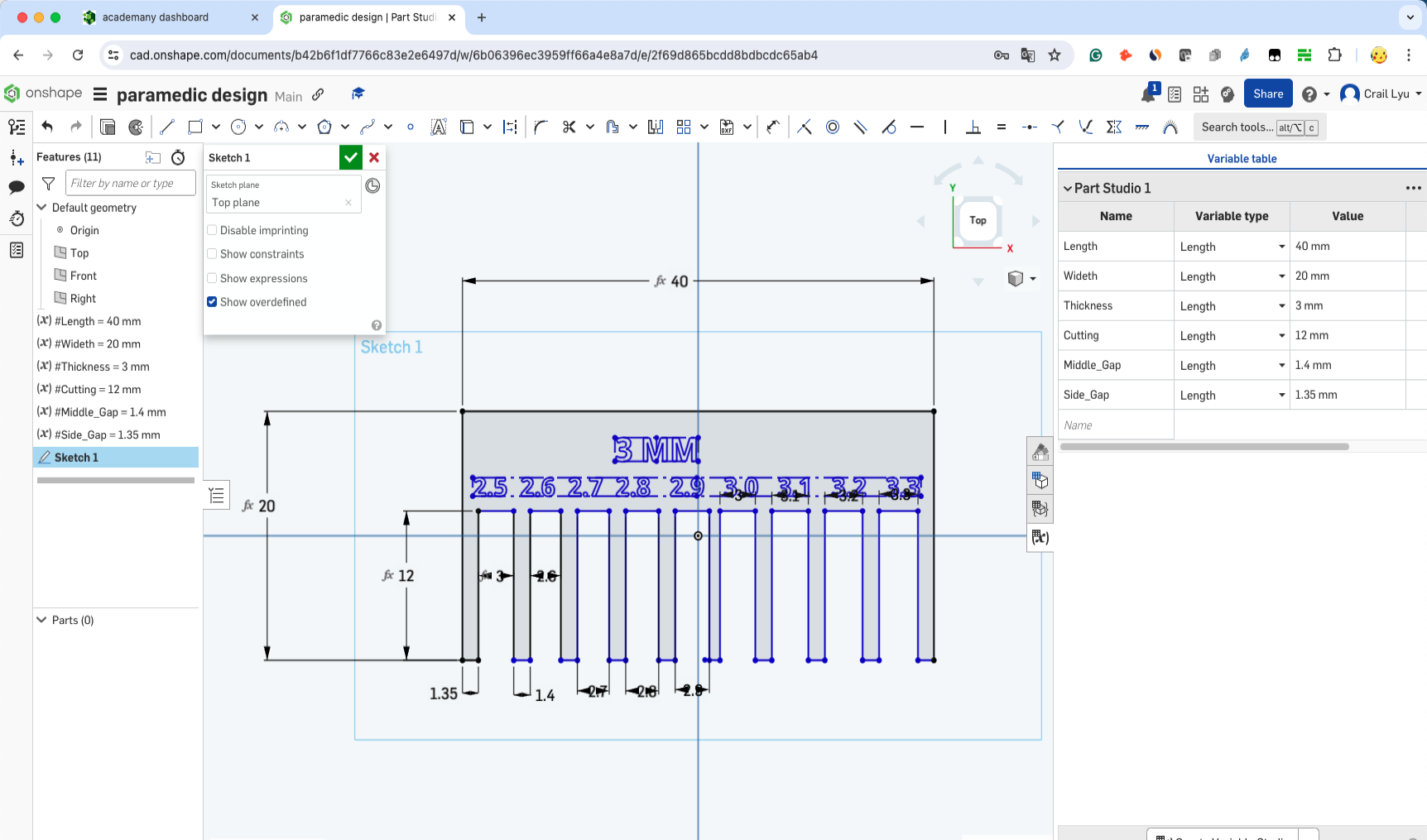

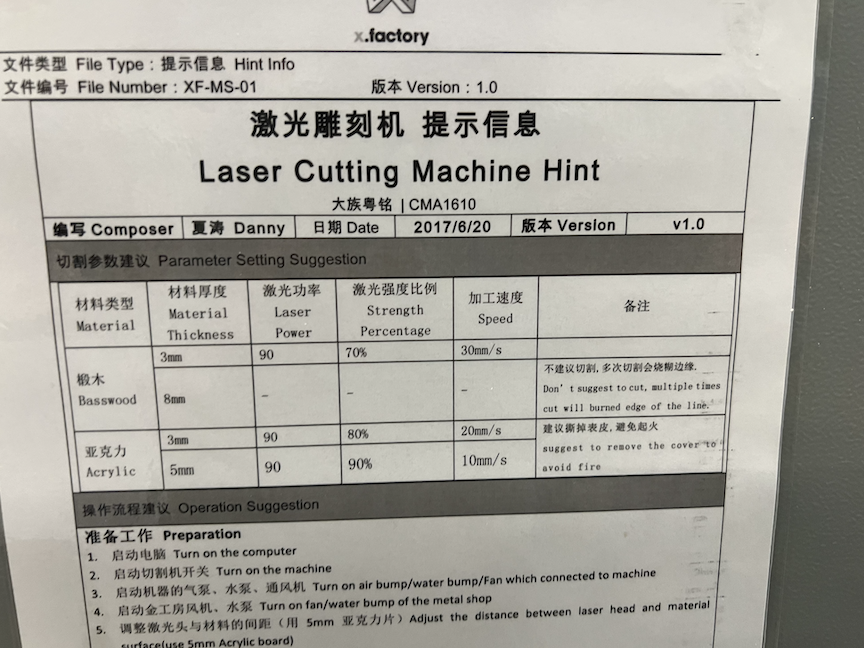

Before starting the test, we need to debug the laser focus of the laser cutting machine. Since the equipment in the space has been debugged, the operator only explained to us how to use the focus adjustment piece for debugging. Before the formal cutting test, we need to create a laser test file to measure the laser power and corresponding parameters. We use onshape to drwaing the testing file.

About the paramteric design part.

This part of the design is mainly to verify whether our laser cutting machine will process the parts we start with according to the actual design size.

Because every machine has laser processing precision.

When our team was measuring, we designed a rectangle, and then based on the range of 2.5 to 3.3mm, we designed grooves with different widths by increasing 0.1mm one by one for measurement. The design thickness of the entire board is for 3mm wood or acrylic boards. For laser cutting. Of course, different materials have different requirements for different laser powers, which will also affect the final laser cutting effect and accuracy.

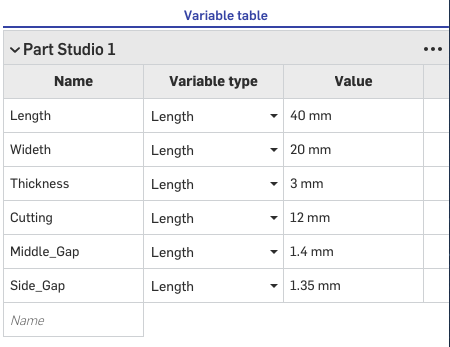

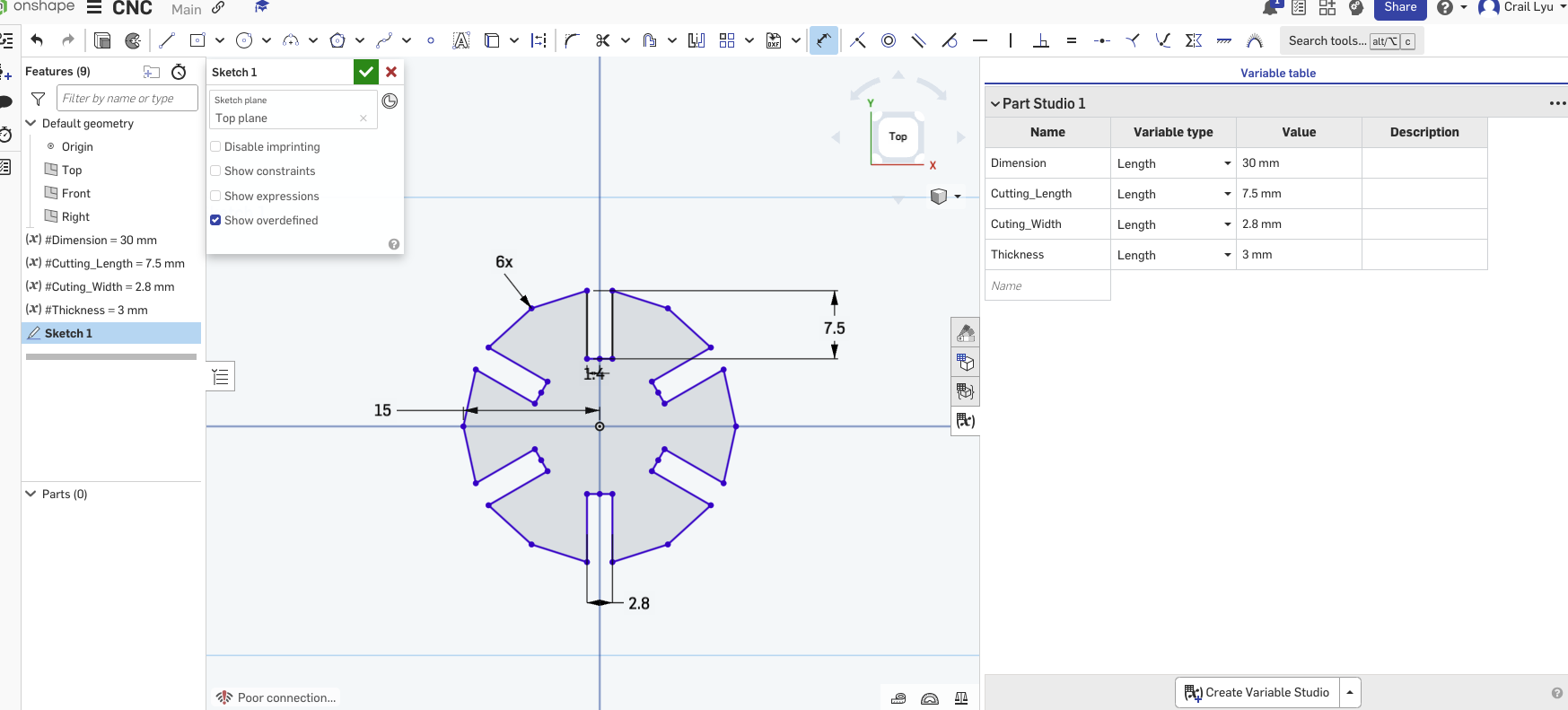

In parametric design, I first specified the dimensions of the shape.

Then I specified the depth of the cut, as well as the gap.

Length:40mm

Wideth:20mm

Thickness:3mm

Cutting:12mm

Middle_Gap:1.4mm

Side_Gap:1.35mm

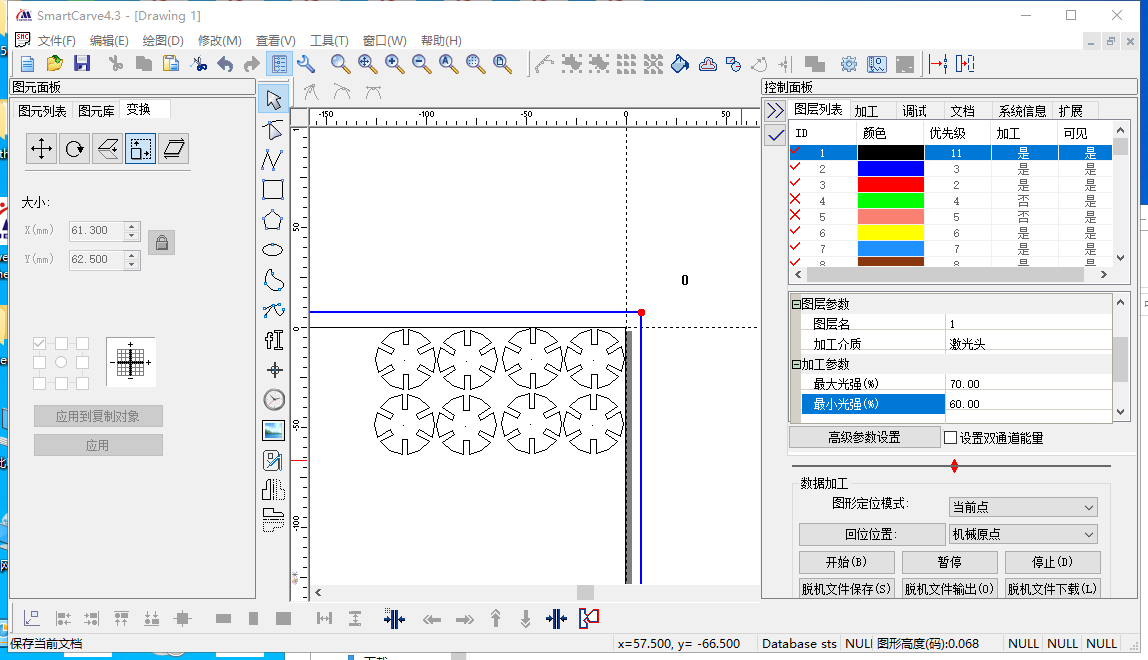

Then we transfer it into DXF file format for laser cuting machine.

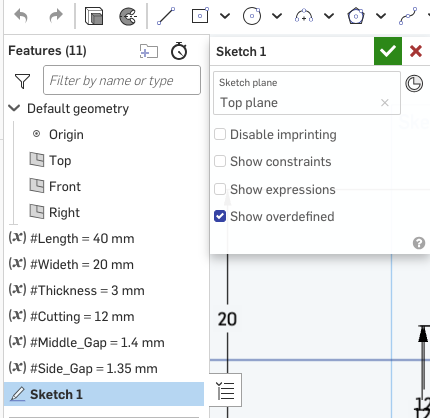

For laser cutting parameter settings, our laboratory has a guide for parameters setting as follows.

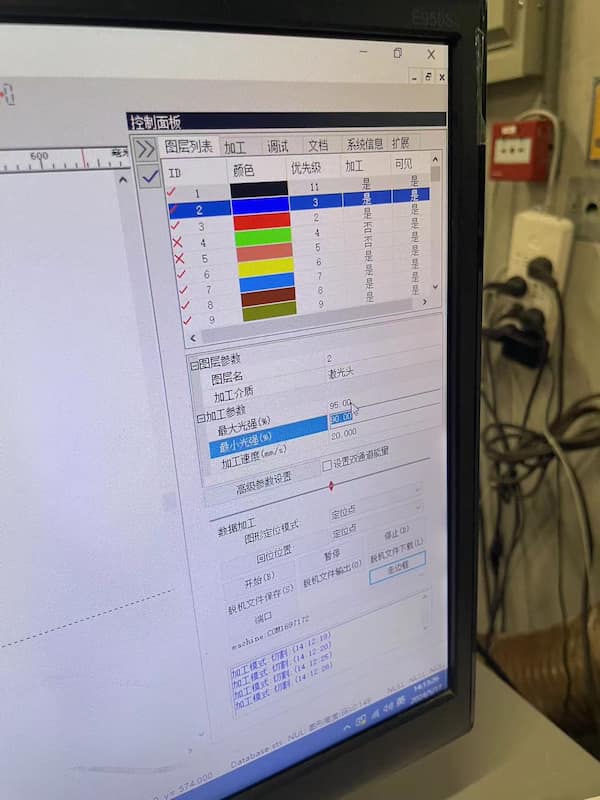

We need to set cutting parameters according to different cutting material types and material thicknesses. The main parameters to set are laser power, laser intensity ratio and processing speed.

Under the relevant parameter setting requirements of the equipment, the laser power will basically be kept at 90. At this time, we only need to set the laser intensity ratio and processing speed according to different materials and different thicknesses. Since I am using 3mm acrylic, I set the laser cutting intensity ratio to 80% and the processing speed to 20mm/s.

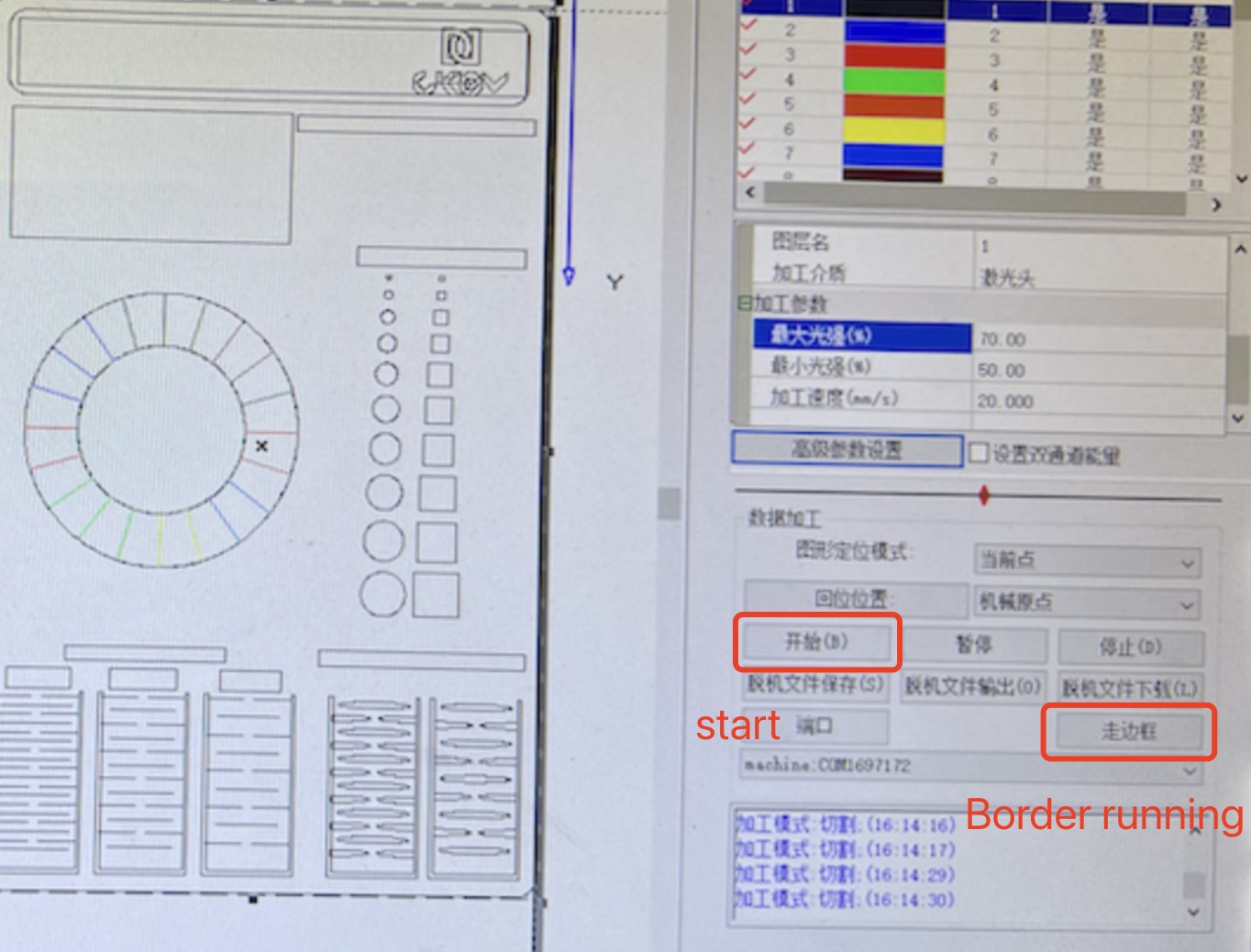

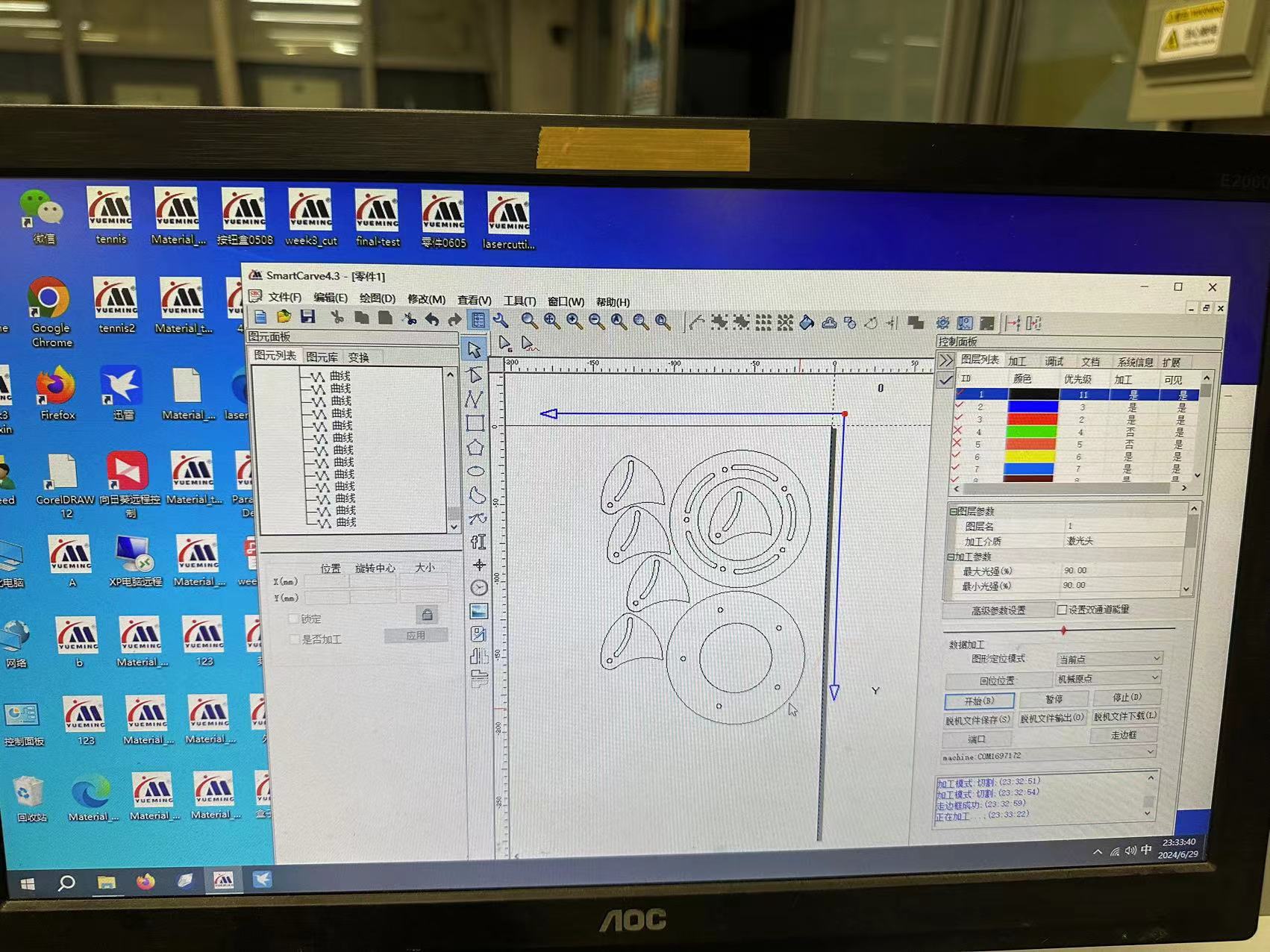

We put it the test file into laser cutting machine and make the laser power setting and speed. The most important is we need to make the zero position very careful. Meanwhile, it need to set the Max and min laser power.

Before start the laser, we need to let the machine goes edge at first so that we can positioning the cutting area. Once the postioning is finished, we will need press the start button and start cutting.

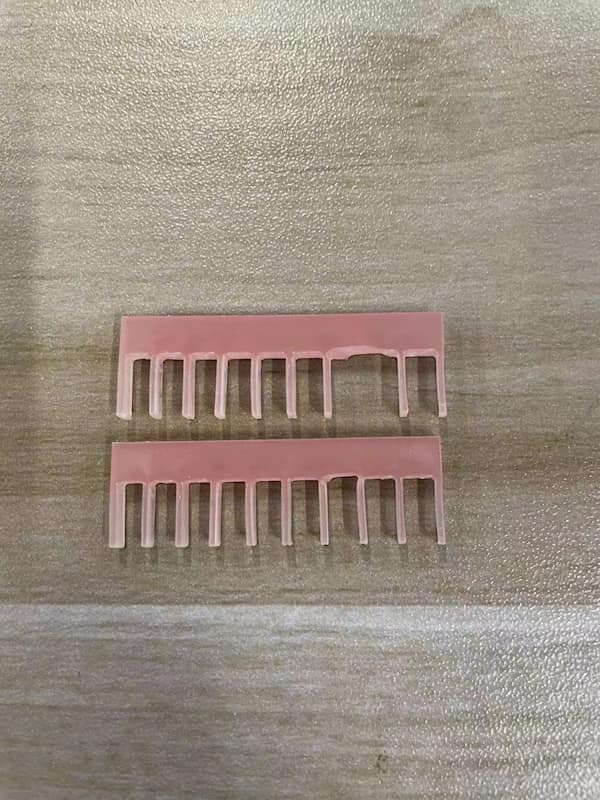

Here is the finnal cuting materials with acrylic boards. It looks good as we design and not too much errors and the curf should be 0.6mm

Individual Assignment¶

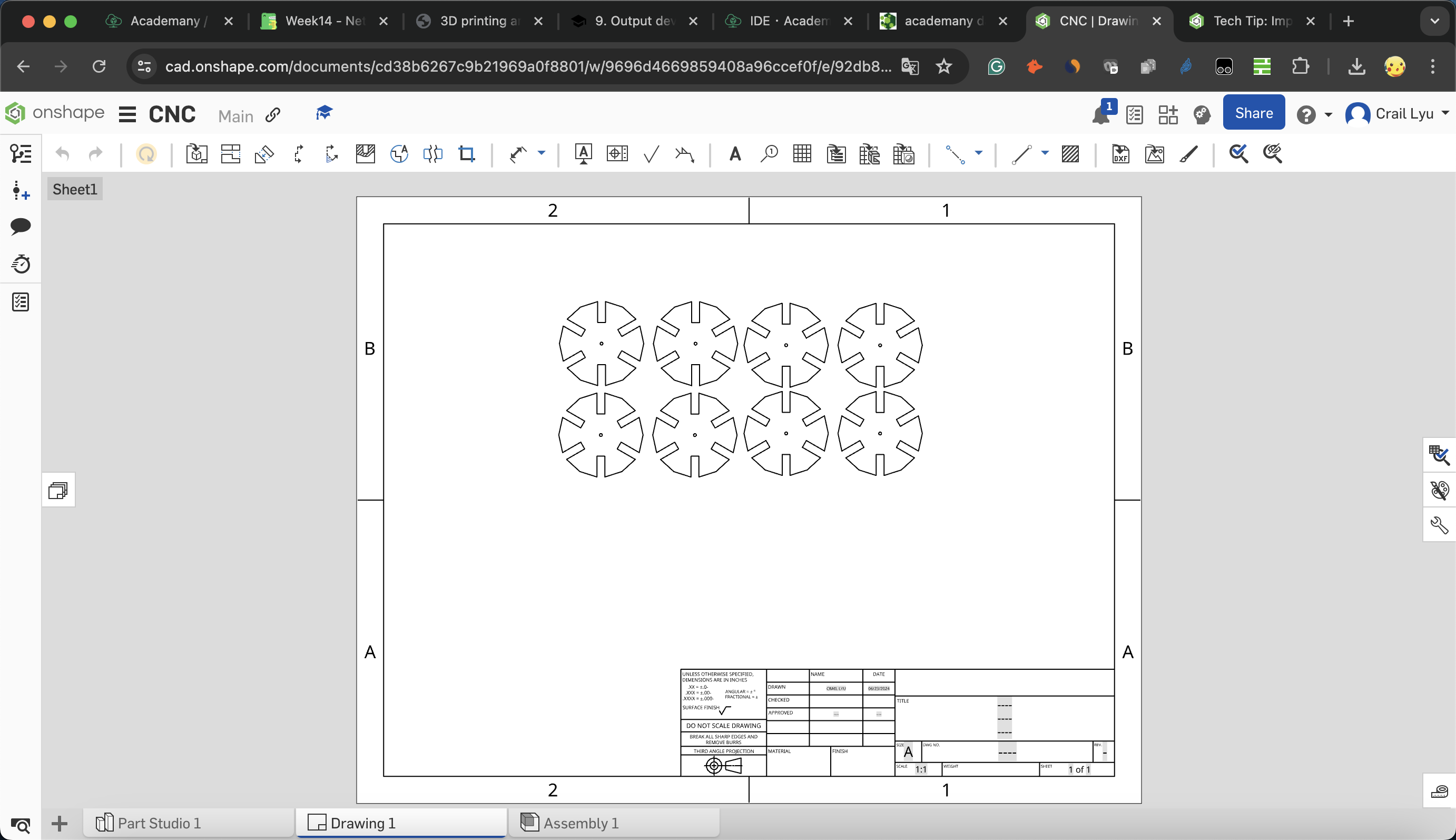

Cut something on the vinyl cutter Design,lasercut, and document a parametric construction kit,accounting for the lasercutter kerf, which can be assembled in multiple ways,

(1) Design the draf.

There are so many ways to design the laser cutting things. usually I can use AutoCad or Inkscap to design the laser cutting stuff.

Firstly, I use Onshape to design the draf then export it into DXF format. Because the thickness of the board is 2.8mm. So that I desigh with this length.

About the press-fit construction design.

First, I drew a regular hexagon, ensuring that the six corners of the regular hexagon formed a circle with a radius of 30mm. By drawing a rectangle about 15mm long and 2.8mm wide on each side of the regular hexagon Grooving. In order to ensure that the position of each slot is correct, I obtained the slots on each side by arraying the center of the circle.

Dimension: 30mm

Cutting_Length:7.5mm

Cutiting_Width:2.8mm

Thickness:3mm

(2) Adjust the laser cutting machine.

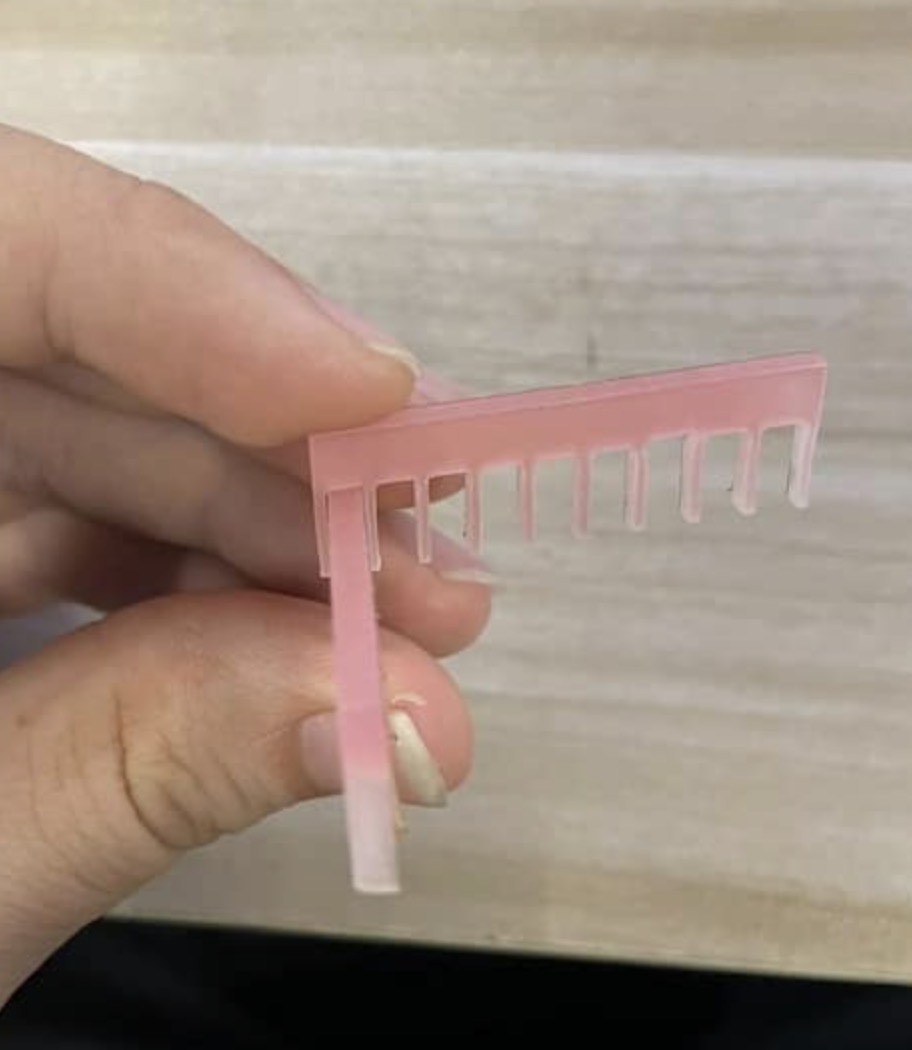

Then I put this dcf file into the laser cutting machine. I set the laser power to 90%. Then found out the gap is too big due the laser power and its not match the deisgn.

Therefor, I adjust the laser power from 90% to 70% and 50%. Finally the 50% laser power is perfect to my design as 2.8mm gap.

(3) Samples for laser cutting. Here is teh final design and asambleing boards.

Design Files in this week¶

Onshape in Laser Cutting Design

FreeCAD in 3D design

Cue something on vinyl cutter¶

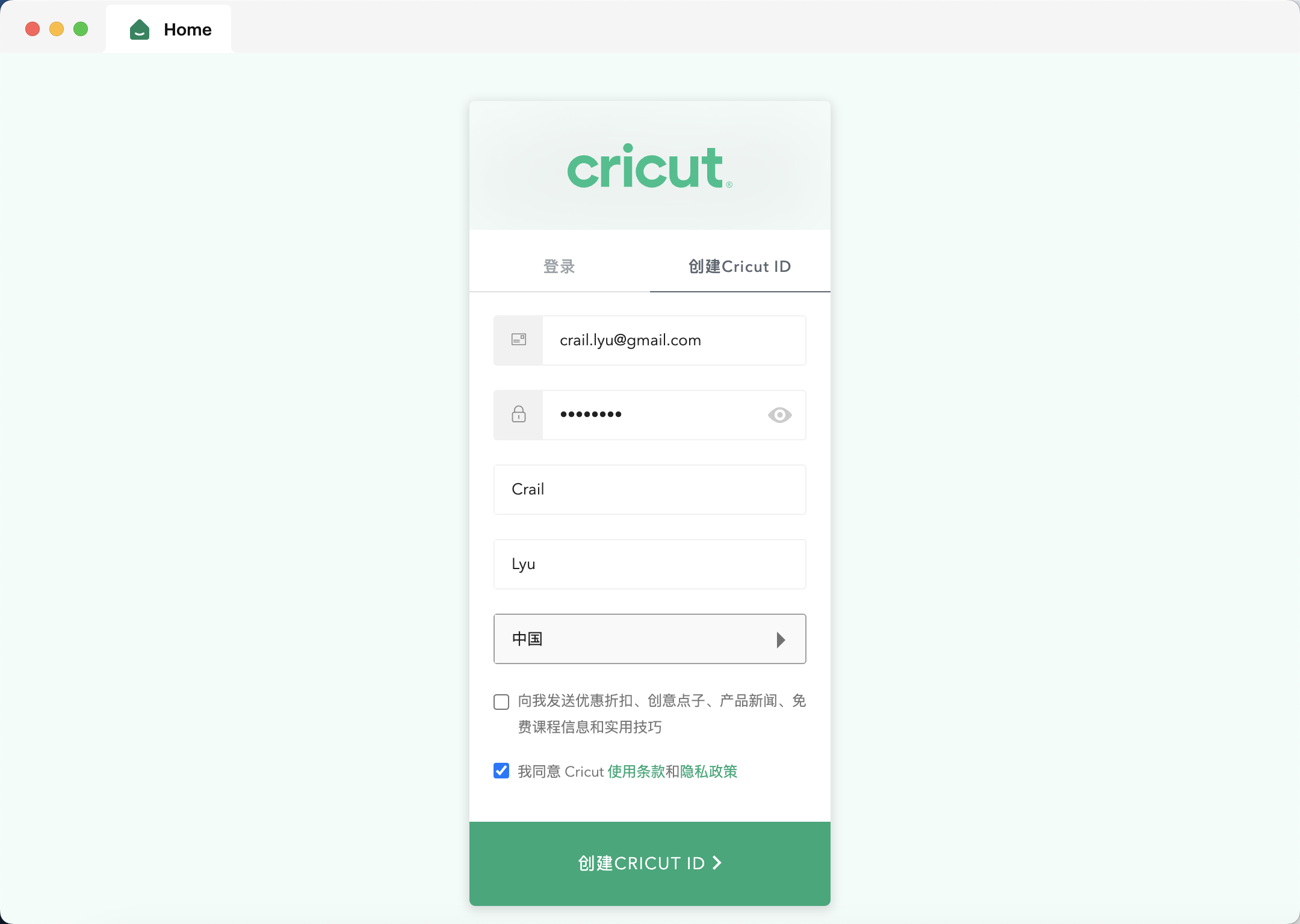

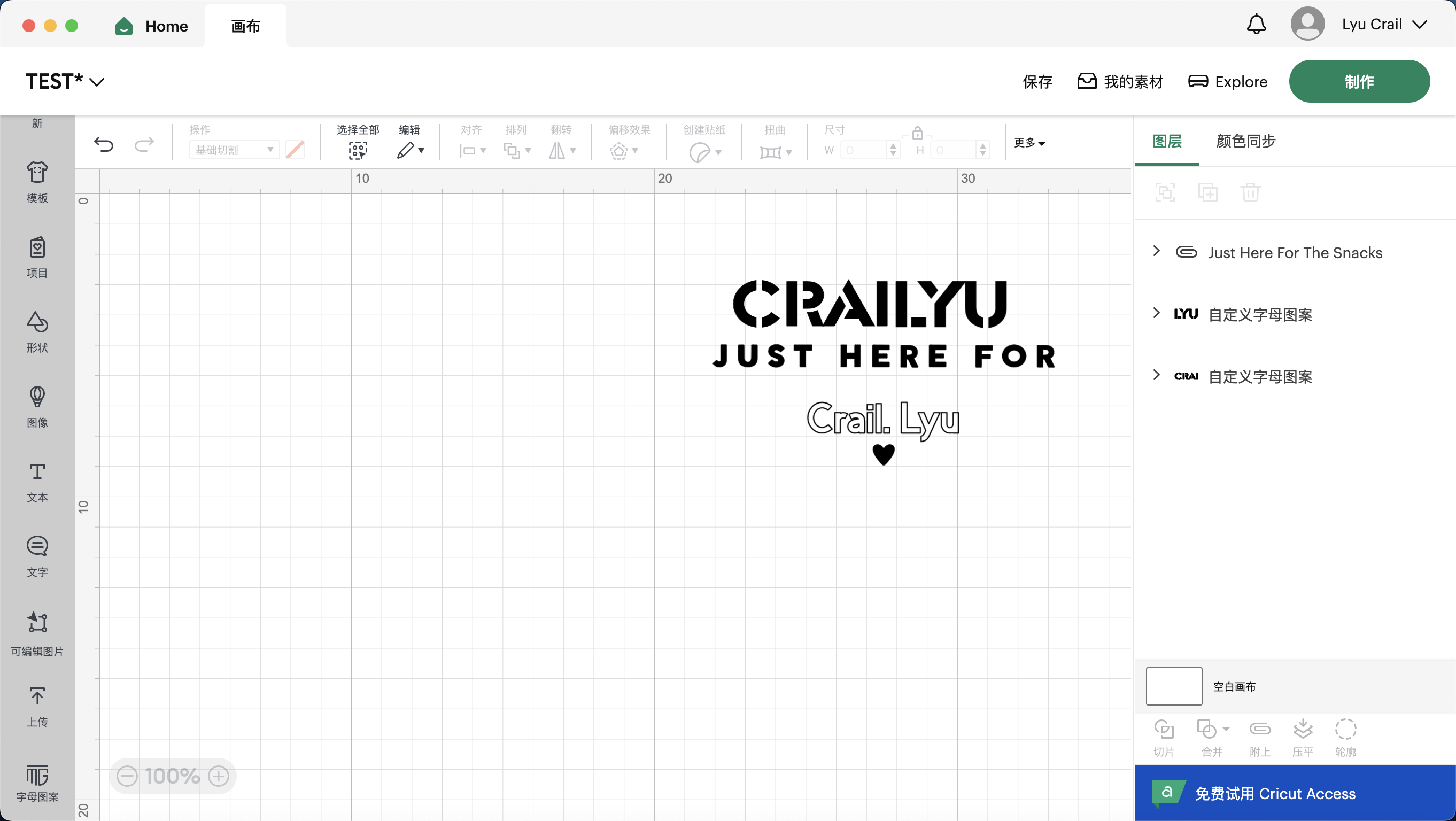

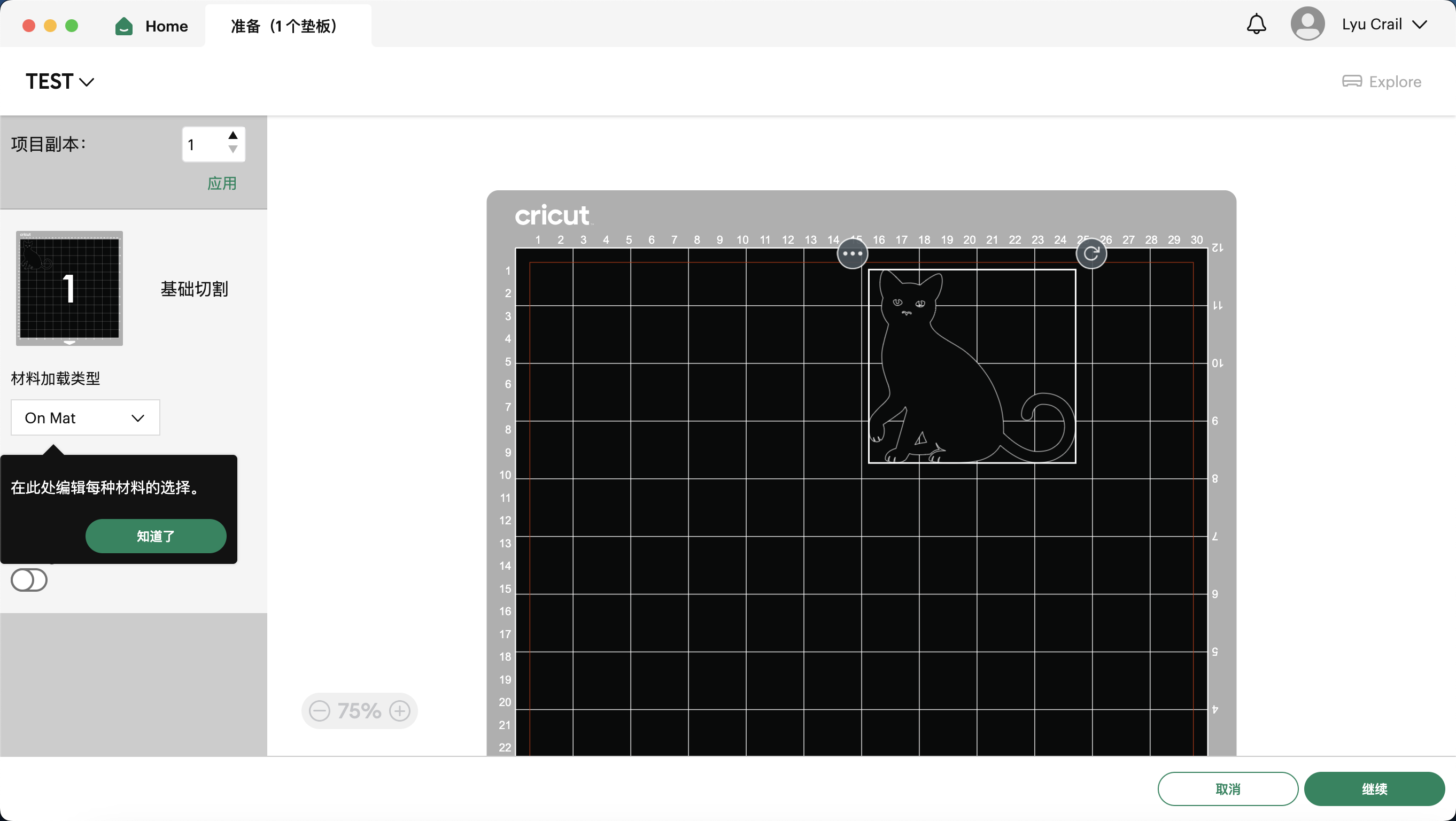

- Download and install the cricut software.

- Register an account on cricut. Because i just use the free version and didnt subscribe it so that there are some format limitation.

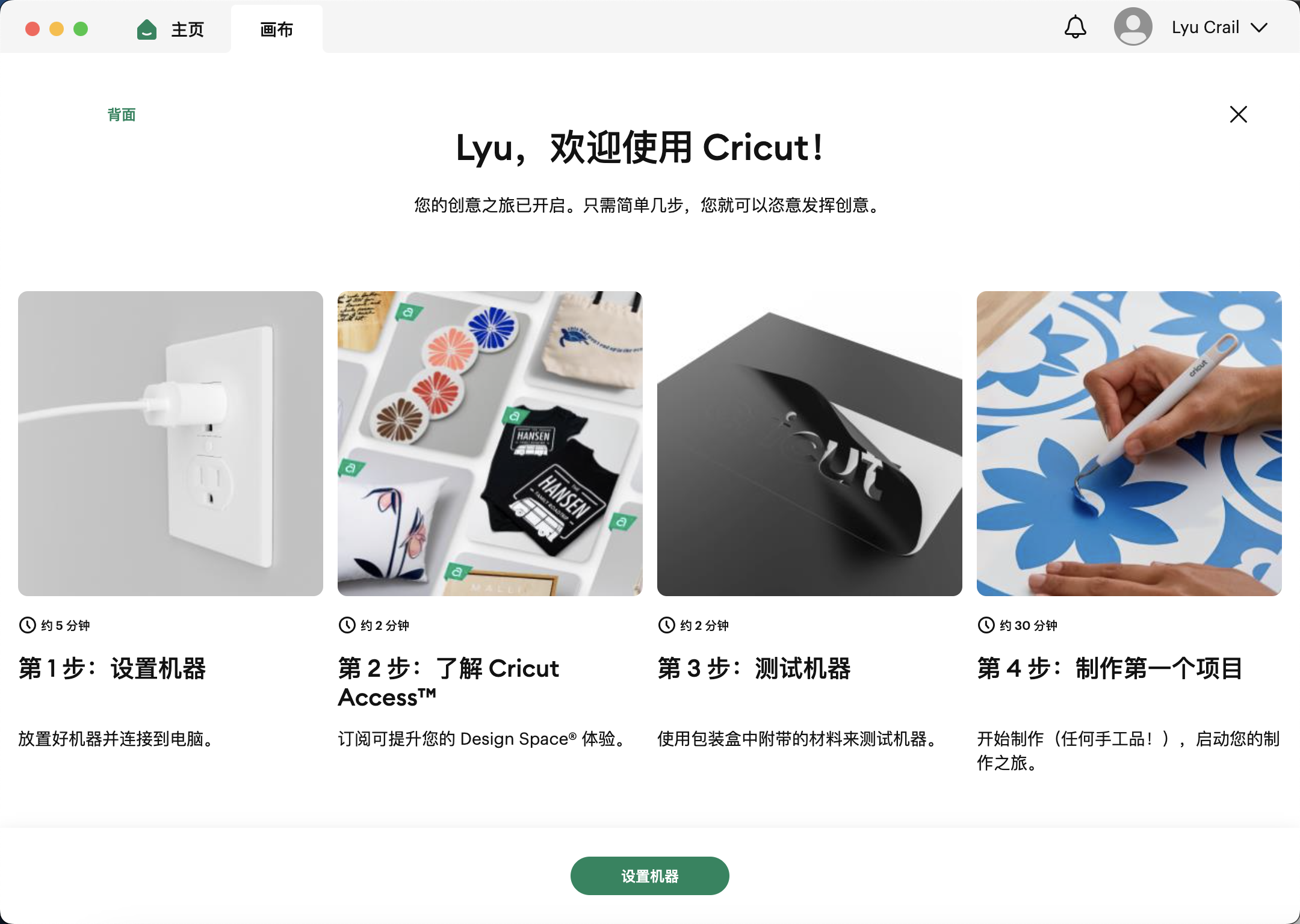

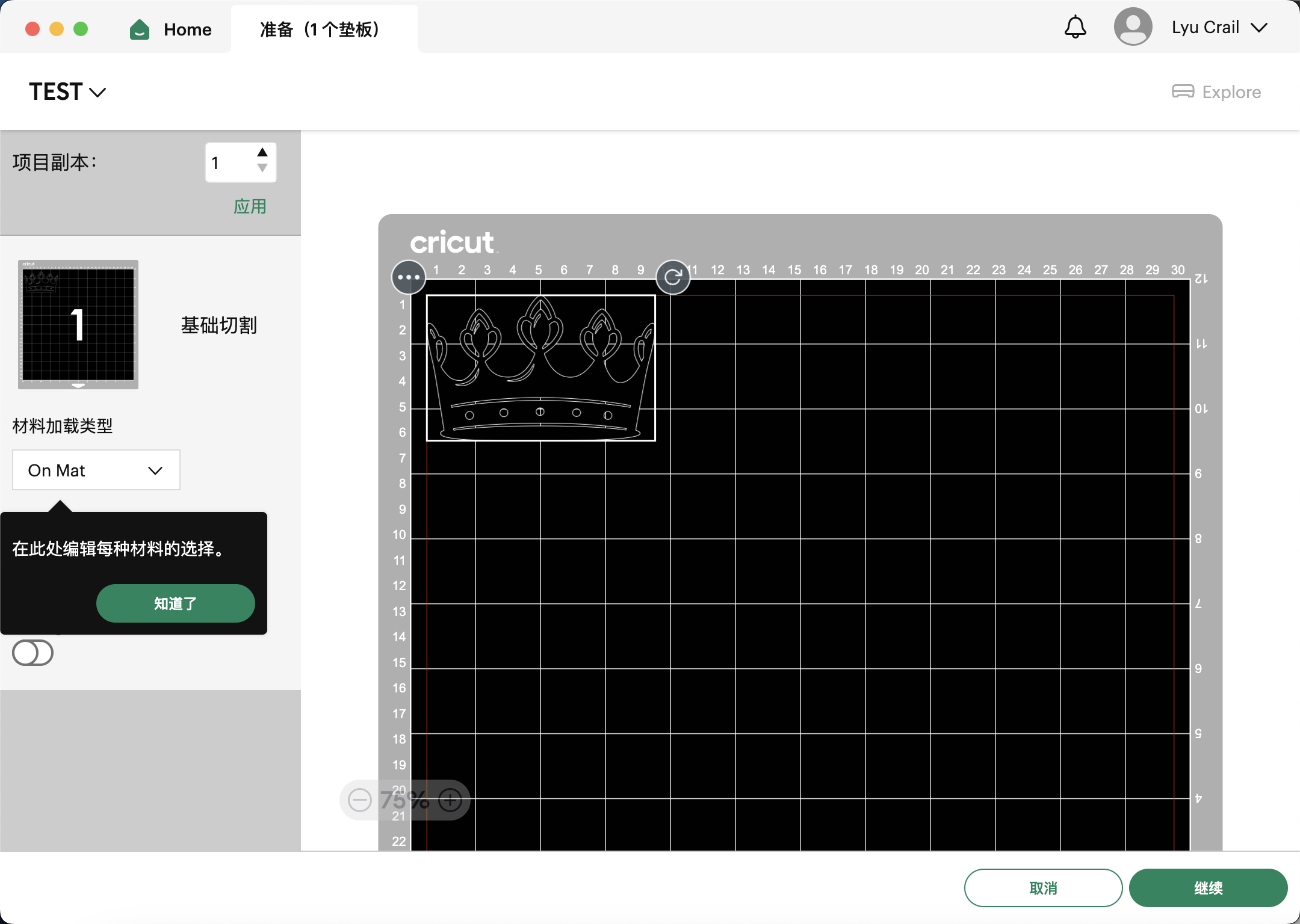

- Follow the instrunction: Setting >> Get to know >> Testing >> Making.

There are sevral clear steps that we can follow and good for beginners.

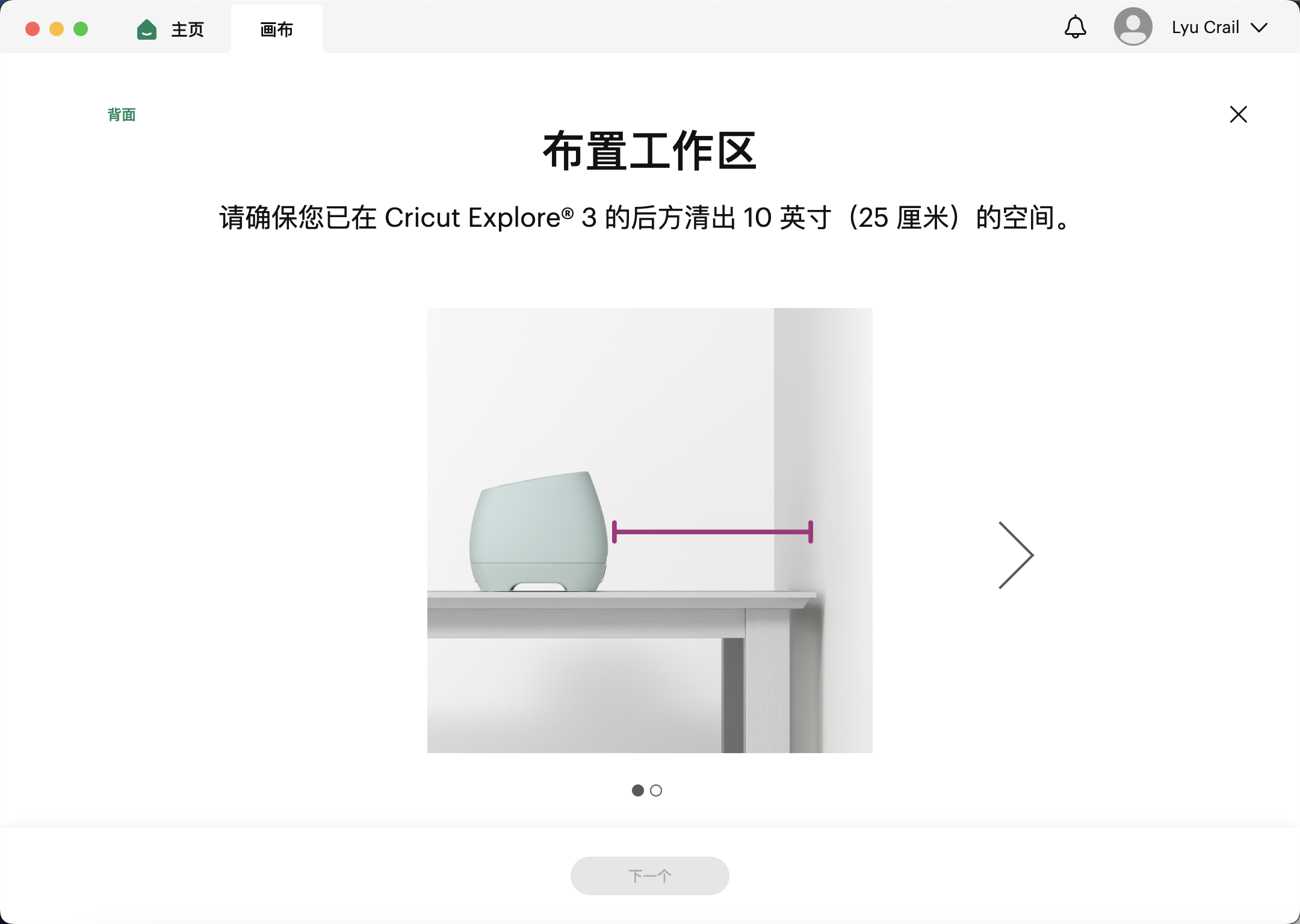

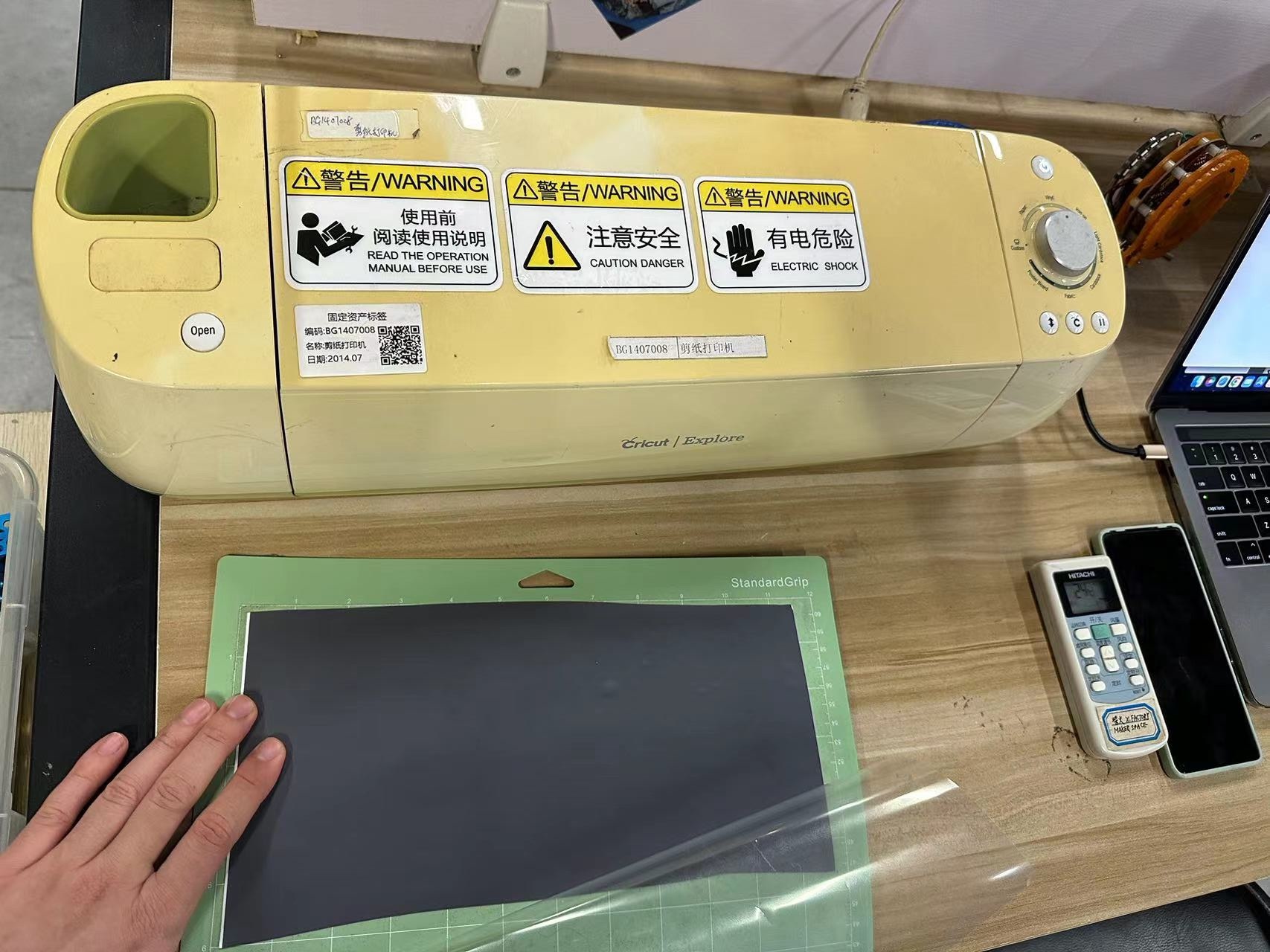

- Setting the machine and leave min 25cm for back. Because if we make larger stickers, the board will come over the machine and shows up on the back of the machine.

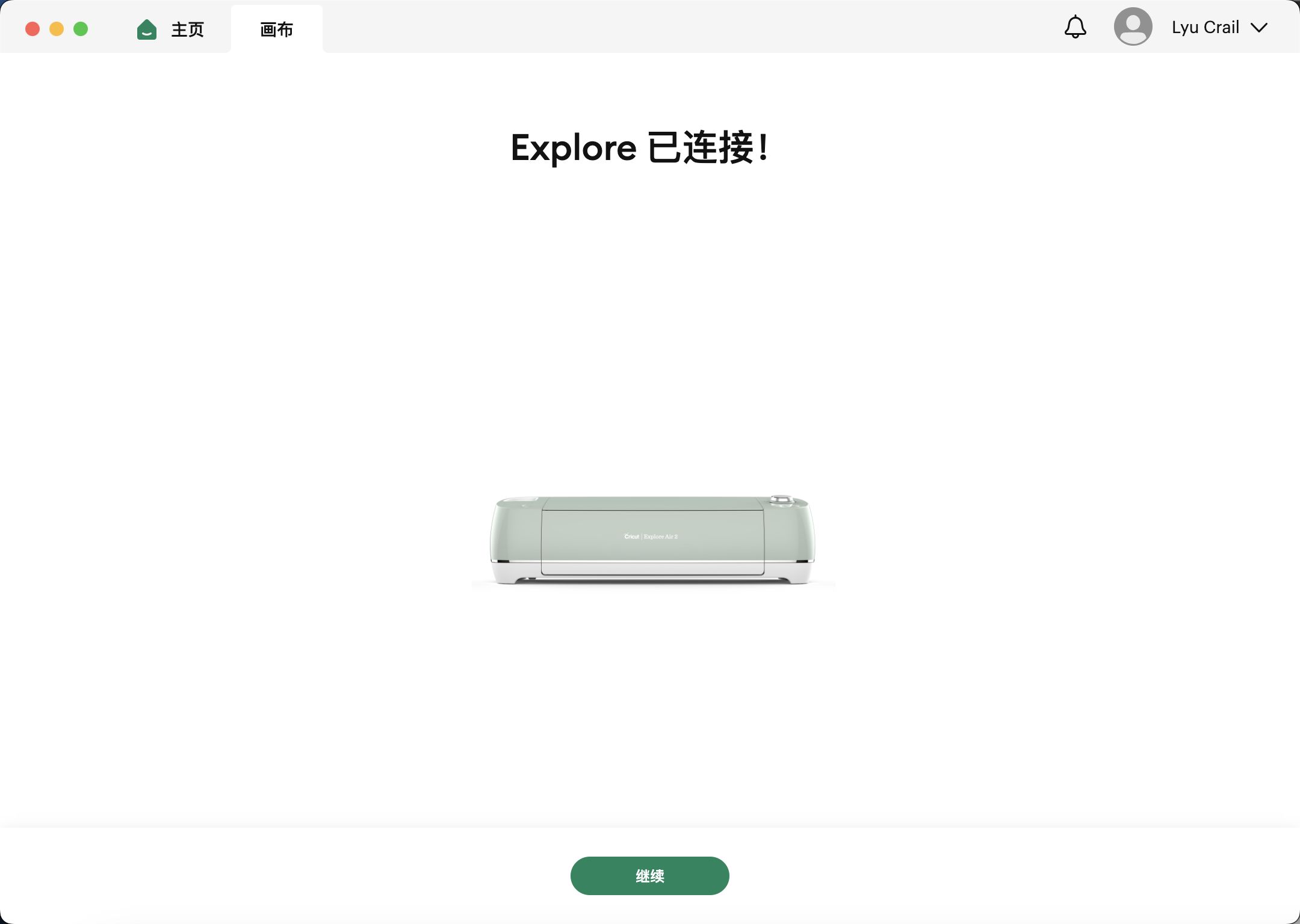

- After we connect the computer and the machine with a data cable, after the setup is completed, it will show that the device has been successfully connected.

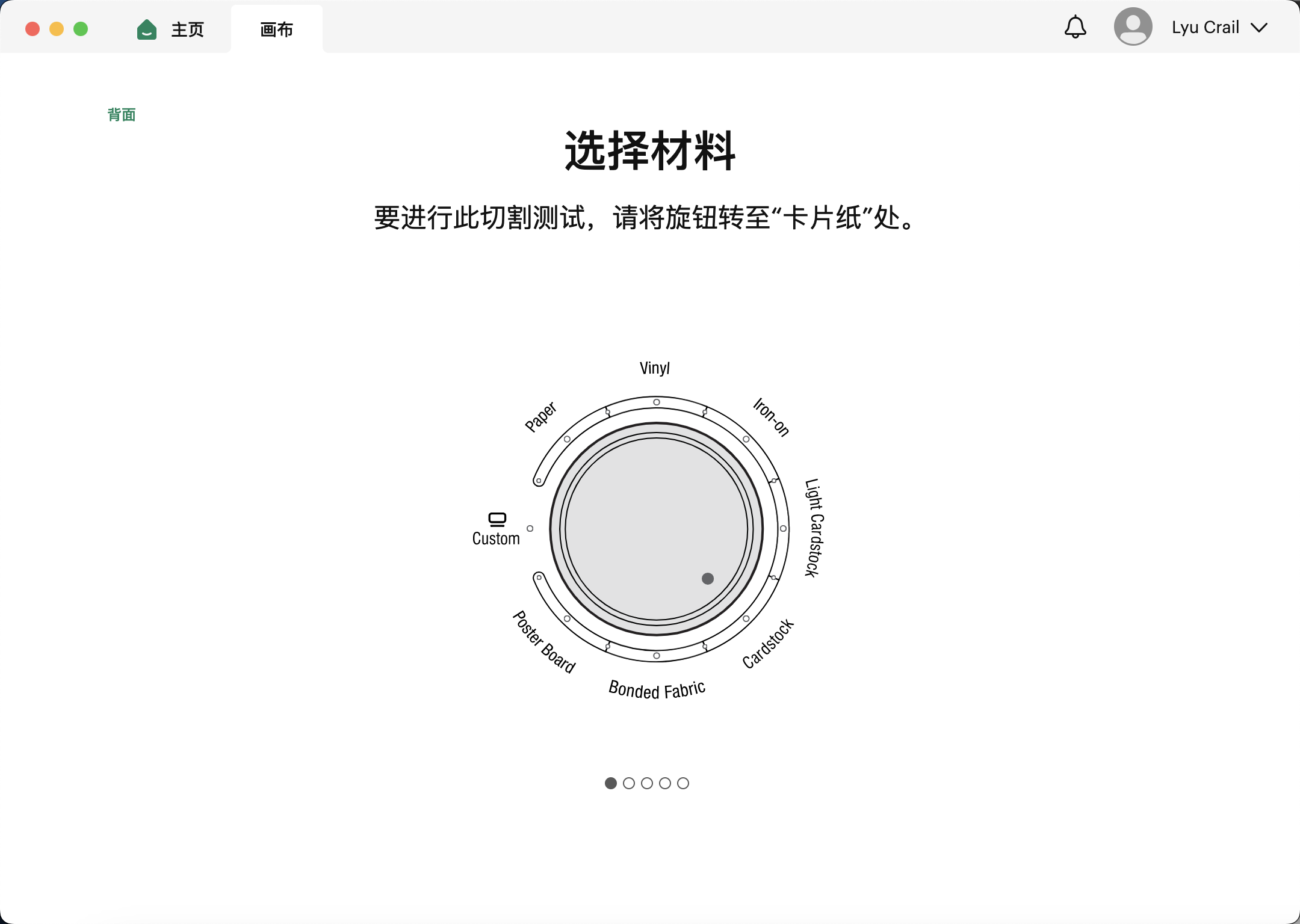

- Then we choose by turning the knob on the machine, using vinyl processing materials, of course there will be more choices on this, such as paper, vinyl, iron-on, light cardstock, cardstock, bonded fabric, poster board and a custom option.

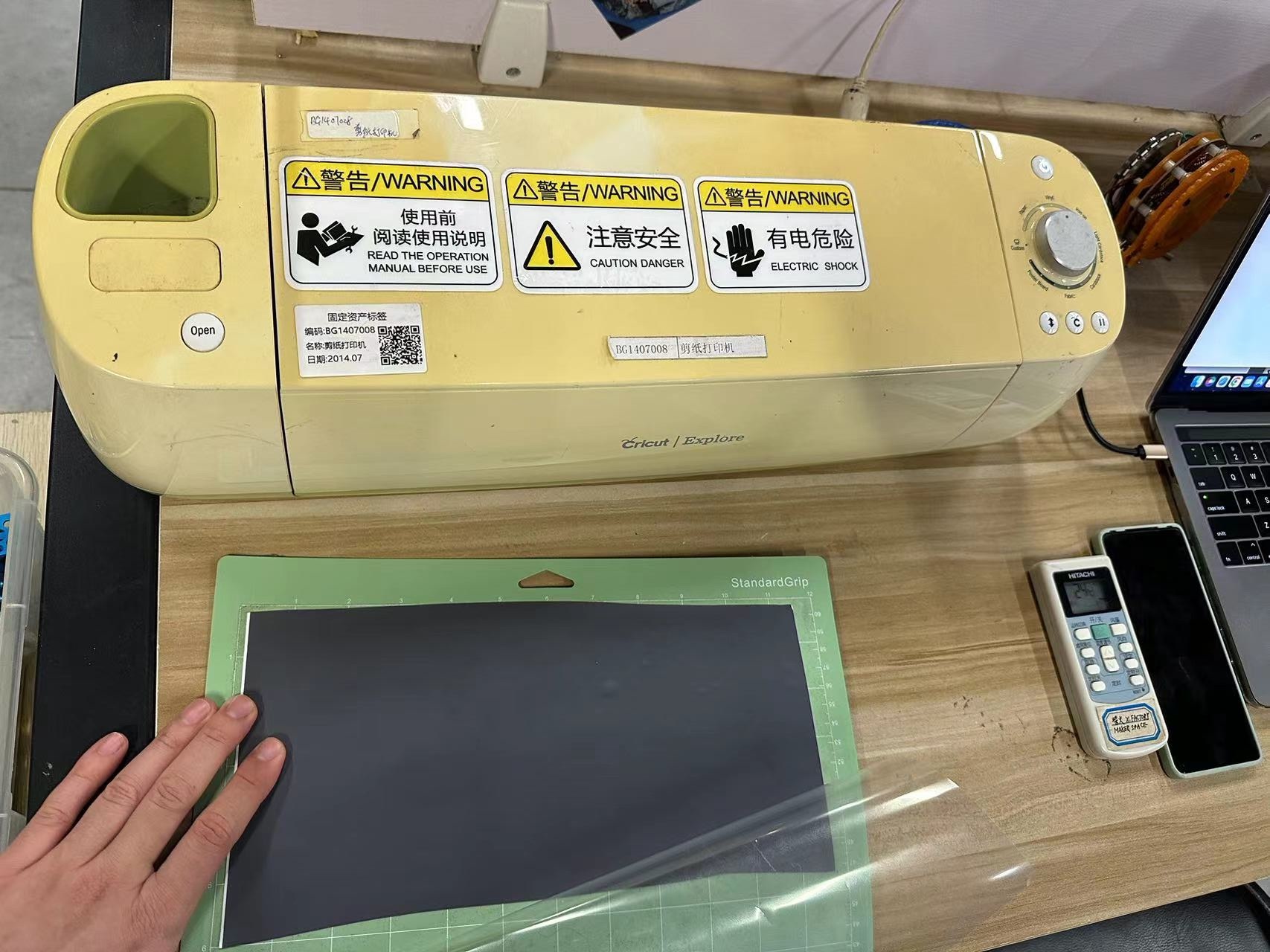

7.Next, we need to glue the stickers that need to be cut onto the cut fixing plate. The fixed board has its own adhesive, so we need to peel off the adhesive protective paper when cutting. Do not insert the protective paper into the machine for cutting.

- Pick up images and insert it into sketches.

- Put the vinyl material on the hardboard and click the “insert” button. Please notice that the cutting materials should be stick on the hard board. It will also need to set the cutting presures.

- Press the button”C” to start cutting.

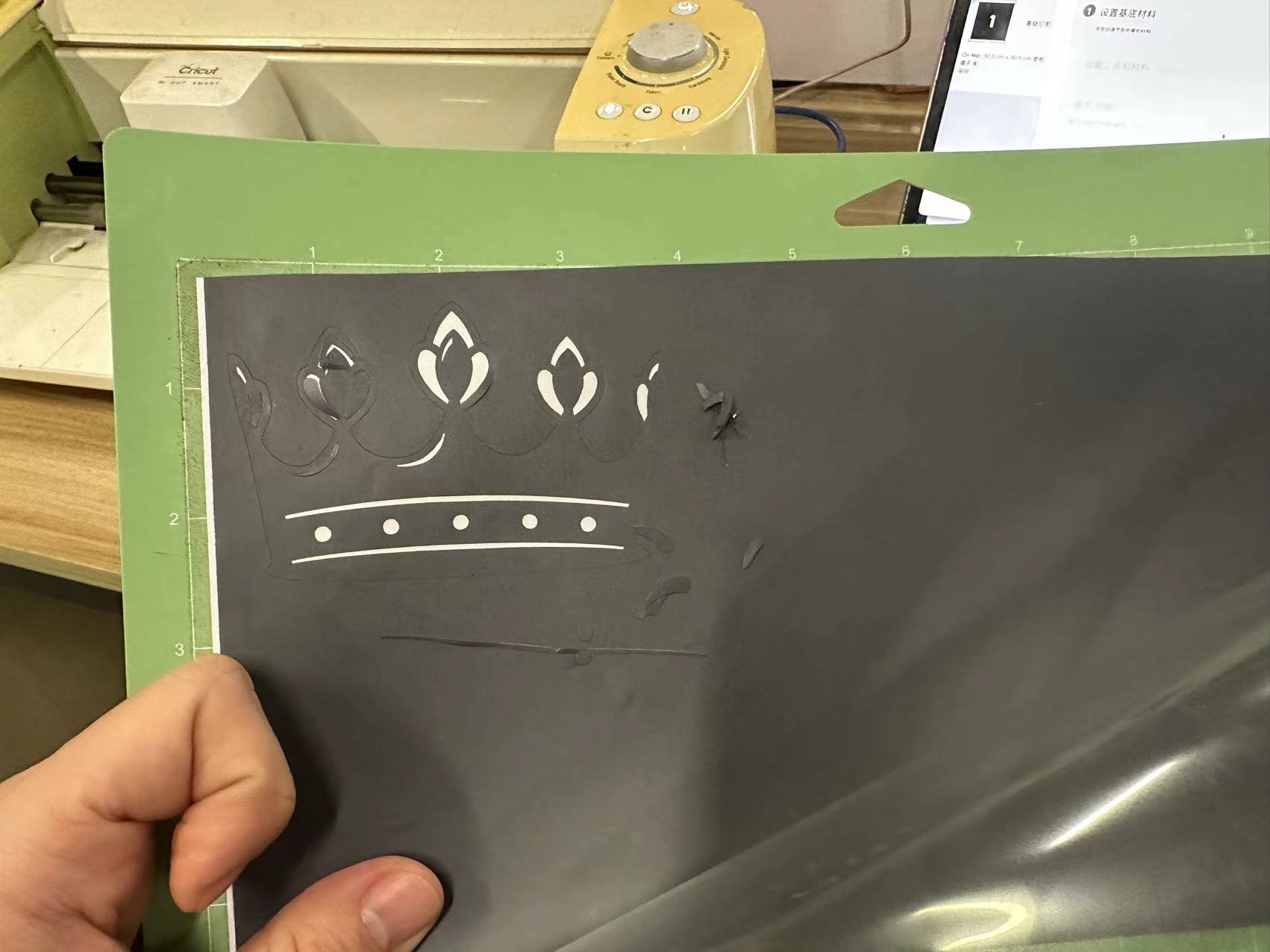

- When the vinyl cutting is completed, we can take the sticker off the cutting board and take it off gently.

- Since the part I cut is relatively small and easy to handle, I can remove the sticker with my hands. For normal operation, I should use small tweezers to remove it.

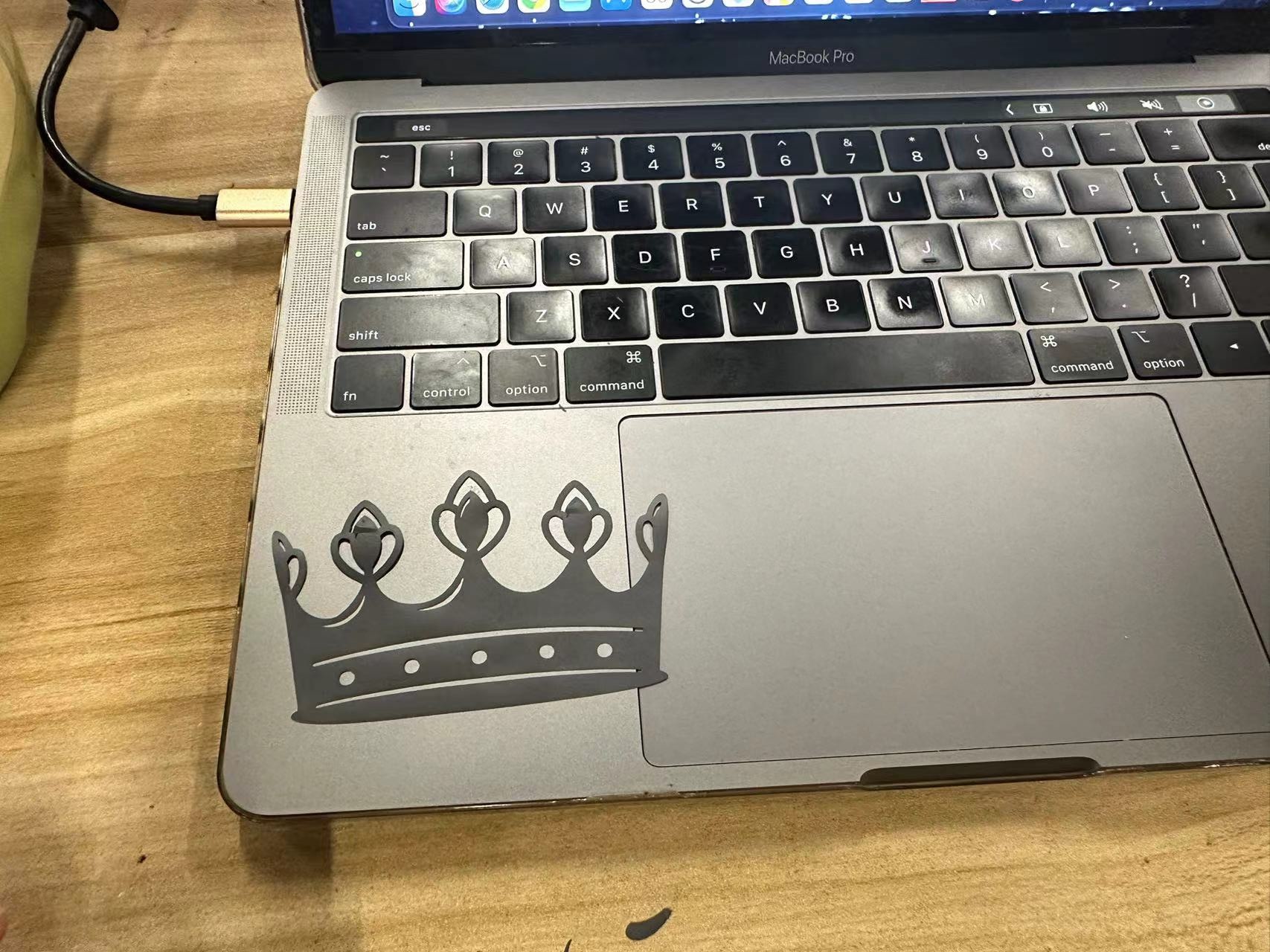

- I will paste the cut pattern directly on my computer for display.

Summary:This vinyl cutter is considerably easier than laser cutting. However, the cutting pressure still needs to be set. Otherwise the cut won’t be as perfect as the cat image above. There are still some places where the cutting is not very good, which will result in some small parts not being cut off, making it impossible to remove that part, such as the cat’s mouth and nose that I cut above. Because the details are too small, the cutting pressure is too high. Not enough, resulting in the inability to remove the unwanted parts of the cut. I tried using tweezers to remove it but it couldn’t be done.

Cut something on the laser cutter¶

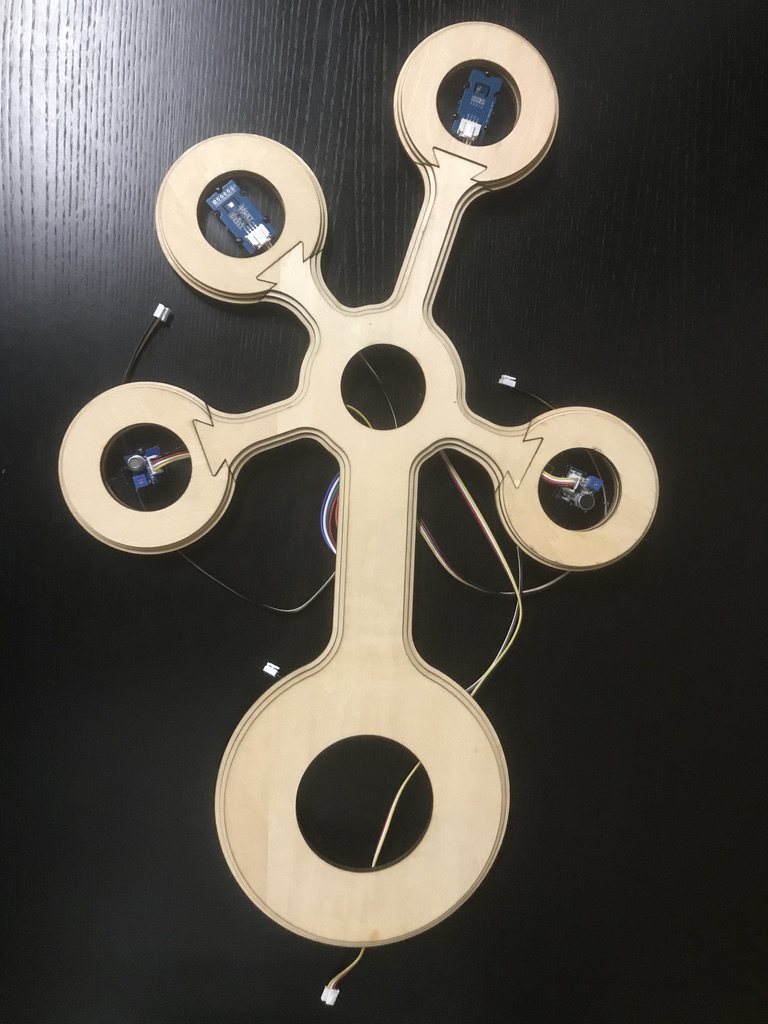

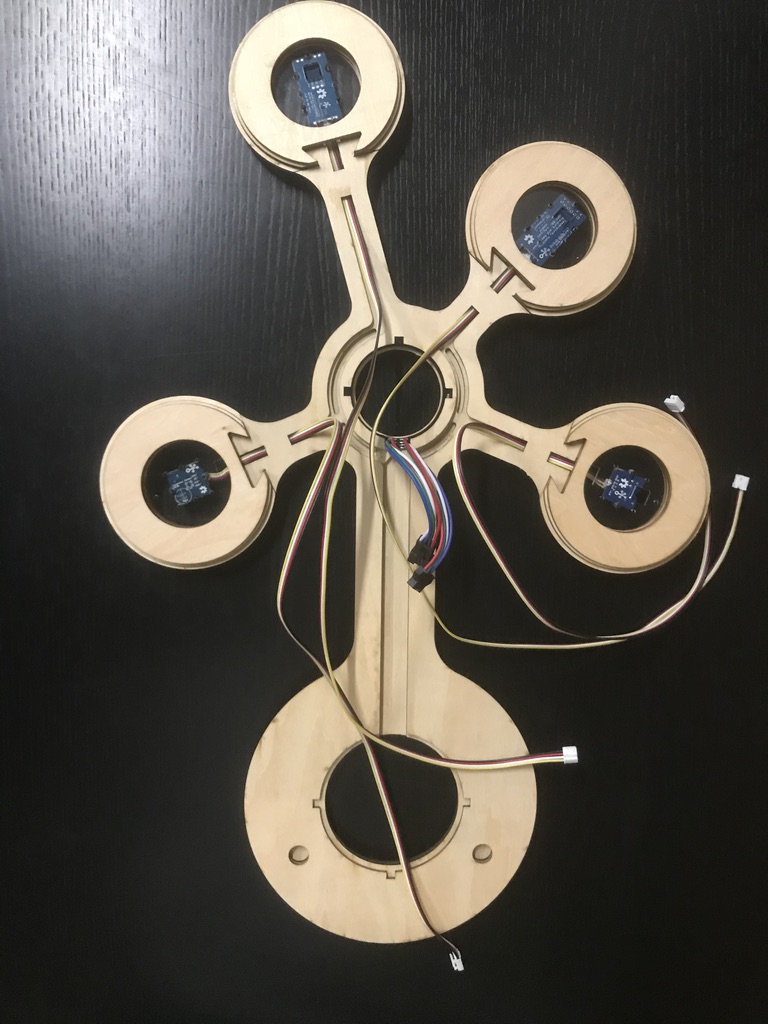

I made the final project design on laser cutting machine.

In fact, when I was working on the final project, I did not use parametric design. Because when I was using onshape, due to network reasons, I had no way to verify the combination effect of the designed accessories.

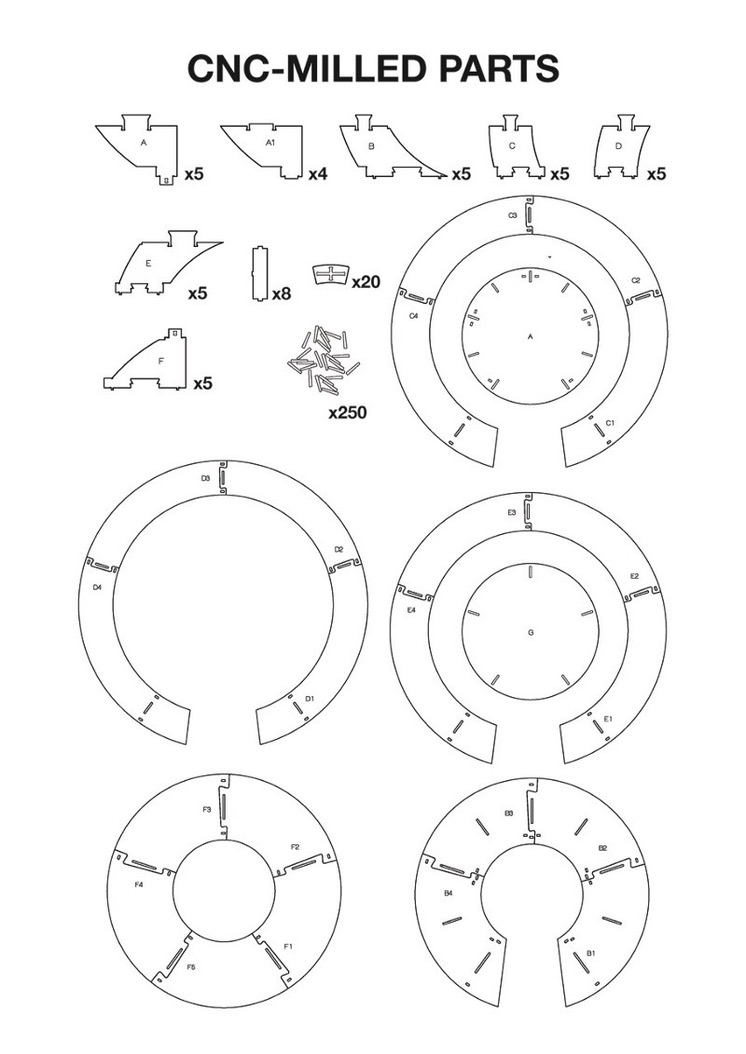

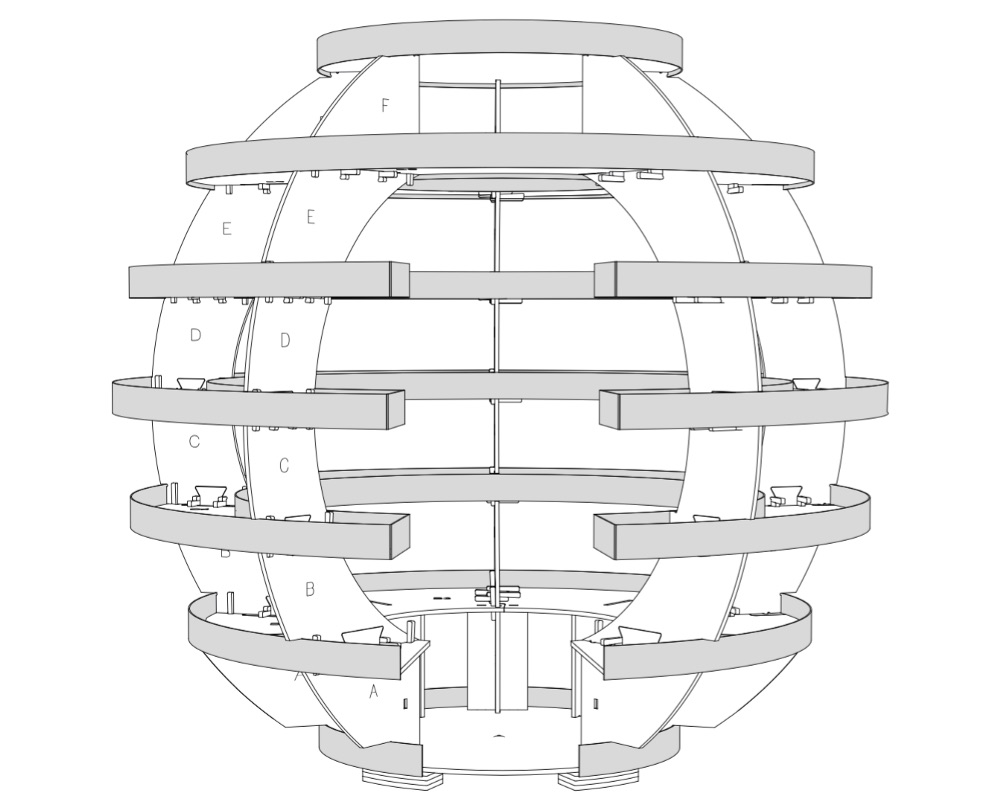

So I moved back to my previous window computer and used solid works to design graphics again. After all parts were checked and matched, I directly exported the planar projection of the 3D parts to a dxf file and directly imported it into the laser cutting machine for processing.

Because the motion axis of the laboratory laser cutting machine is not regularly maintained and lubricated, when the processing speed is too fast or too slow, more noise caused by mechanical movement will be generated, and the corresponding processing accuracy will also be affected. , so I chose constant processing speed. In fact, our laser cutting machine software will also adjust the processing speed adaptively when processing some complex curved surfaces.

Because my final project required the production of a rotating opening and closing device, I finally chose to use laser cutting to process my design.

1. Regarding material selection: I tried 3mm basswood board, 3.2mm bamboo board, 2.8mm/2.5mm acrylic board of different colors and other different materials for test cutting. Because the entire designed structure needs to be rotated, opened and closed, and the fixed bolt holes need to be rotated by friction. At this time, the friction of the wood board was too great, resulting in unsmooth sliding. I finally chose acrylic for cutting.

2. Regarding the choice of material thickness: Because it was difficult for me to find suitable fixing bolts, after various choices, I chose push-type fixed plastic fixing rivets. Since the length of the rivets is fixed, in order to match, I chose We experimented with acrylic boards of different thicknesses and finally chose a 2.8mm orange acrylic board.

3. Regarding the choice of material color: Mainly because of its beauty, I chose the final orange acrylic as my final project material.

In the end, the thickness of the orange acrylic I processed was 2.8mm, the laser power was 90, and the laser intensity was 75%. Because the thickness of this board is a little thinner than the recommended processing thickness of 3mm, I still set the processing speed to 20mm/s.

Previous works on Laser cutting.¶

Before Fab academy, I learned how to use CNC and Laser cutting when I was in school and last job. Here is some samples which I made before.

a. Laser cutting - Mr.Sun toys.

Aryclic Cases and buckle details

b. Laser cutting - Start War ships

c. Grove environment monitor

Previous works on CNC cutting.¶

This is a project that i’ve learned from Google in 2016 which is comes from IKEA project with a Secret Innovation Lab called Space10.

I made this for our revious company garnden by only using the sketch image from internet.

Practice on laser cutting.

¶

Design via Inkscape >> Save as Laser cutting file format(svg, dxf) >> Set the Laser Frequency then calibrate the laser zero point >> Test the laser then place the boards