Final Project

The Concept 📐

Saliva Panel

Saliva’s presentation video can be found here

Interactive Meditation System

Developed as the final project for “FabAcademy” at Waag - digital fabrication course -, Saliva is a metaphor of personal growth carried out by meditation and reflected by the growth of plants.

The purpose of this design is to explore the symbiotic relationships between Nature, Technology and Individuals. While studying “How to do almost anything” at Waag, I designed and manufactured a press kit rocking chair with a CNC machine. On it, I began to meditate several times a week, which opened the doors to a new lifestyle, generating more interest in it.

Perseverance in meditation generates within few months the development of new structures in the three human brains: Reptilian or Primal Brain (Basal Ganglia), Paleomammalian or Emotional Brain (Limbic System), and Neomammalian or Rational Brain (Neocortex). In Saliva these three brains are represented by flower stands of different heights, shapes, and colors according to their function:

-

Reptilian Brain: The ancestral brain, linked to human instincts and instant response, is centered in the scene with the tallest position. Showing an “alert/protective” role in front of the other two brains. The Reptilian Brain is yellow, representing “caution” by the psychology of colors.

-

Paleomammalian Brain: The irrational brain, takes the lowest position in the scene, as it represents our roots as humans. The pot has multiple faces, which represent the many human feelings. It is awarded the color red for the “passion” it represents attributed to the psychology of colors.

-

Neomammalian Brain: The rational brain, which distinguishes humans from the rest of living animals on planet earth. The plant sits on a medium-sized stand, representing calm and serenity. Intelligence is represented through the use of the color blue.

Saliva has been designed and produced using digital manufacturing methods. It incorporates a PCB designed to allow the user to interact with plants while meditating. When the user meditates on the rocking chair, he/she connects with the plants through a heartbeat sensor. Our BPM’s drop to a rate between 40 and 60 BPM (almost as if we were sleeping) every time we meditate, so, when the sensor detects this frequency, it opens a watering tap for the plants at the same rhythm as our heart.

Everytime the user interacts with the system, he/she will be able to decide which plant needs water. In this way, the plants will have all the water they need (about 3 days a week) as long as the user meditates with perseverance (about 4 times a week).

Why?

It has been considered that most people stop working in the meditation practice due to the perseverance and time required to show long-term results. Especially the young public fails in the practice of this technique, due to the immediate approach that the situation of the current media society entails.

Through experience, Saliva makes the intangible tangible. In the long run, the large and strong growth of the plants becomes the reflection of the inner growth of the users. Thus serving as motivation to continue, and promoting the approach of individuals to nature.

Project Management 🔢

| Task | Time | Day |

|---|---|---|

| Research | 10h | 2 - 8, May |

| Flower Pots 3D Design | 5h | 9 - 10 , May |

| Flower Pots Fabrication | 3 days | 11 - 13, May |

| Flower Stands 3D Design | 6h | 14 - 15, May |

| Flower Stands Fabrication | 10h | 16 - 17, May |

| Electronics research | 8h | 18 - 19, May |

| Coding | 10h | 23 - 25, May |

| Testing - Round 1 | 3h | 26, May |

| Packaging | 6h | 2 - 3, June |

| Testing and Improving - Round 2 | 3h | 4 - 5, May |

| Testing and Improving - Round 3 | 3h | 7 - 9, May |

| Video & Panel | 10h | 8 - 9, May |

Files 📂

| Name | Description | Link |

|---|---|---|

| File 0 | Flower Pot 1 - Draws | Link |

| File 1 | Flower Pot 2 - Draws | Link |

| File 2 | Flower Pot 3 - Draws | Link |

| File 3 | Flower Stand Draws | Link |

| File 4 | Rocking Chair | Link |

| File 5 | PCB - Traces | Link |

| File 6 | PCB - Outlines | Link |

Research 🔍

FabAcademy Student’s references

I did not find any similar project within the Fab Academy context. I did researched as a reference the following agriculture projects when designing the watering system:

I found these pages helpful in order design and watering system and the Saliva PCB board.

Design

What my design should have?

- I want to use as many skills acquired during the Fab Academy as I can.

- I want to experiment with new techniques of possible.

What should my design not have?

- If possible, dot use not sustainable materials.

Sketch

3D Design + Fabrication Flower Pots and Rocking Chair

- The 3D design and fabrication of the flower pots can be found on this page.

- The 3D design and fabrication of the rocking chair can be found on this page.

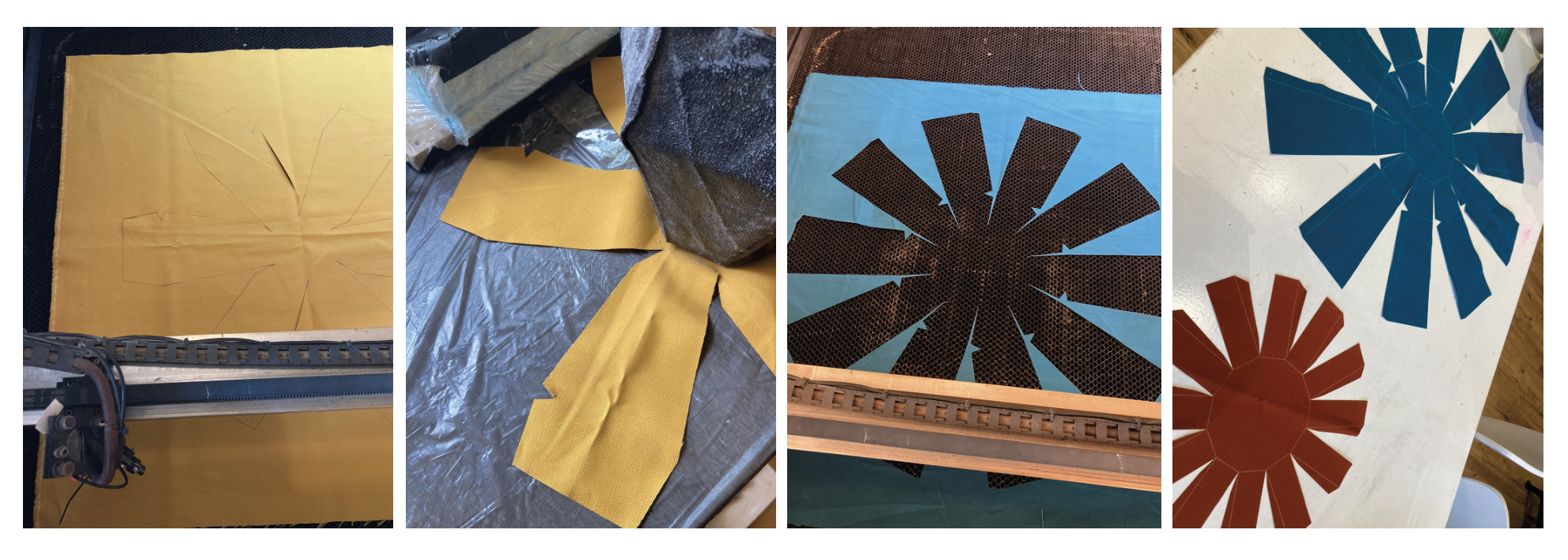

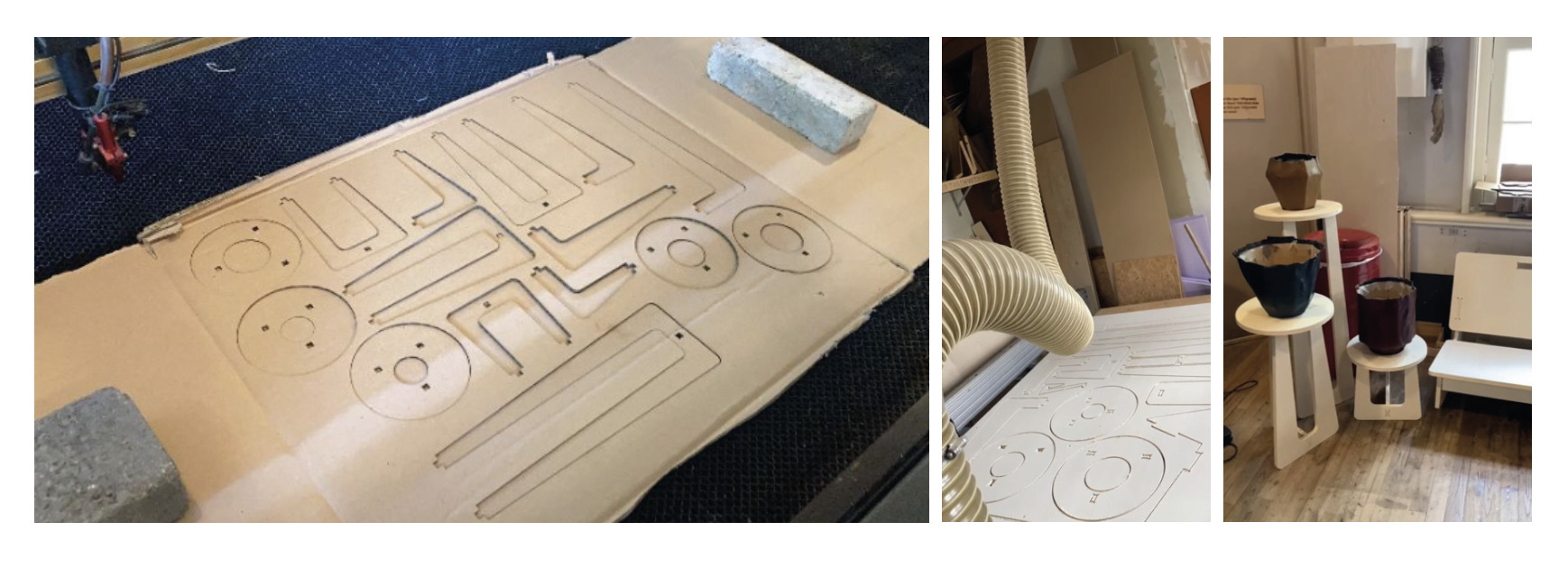

- Pics of the 3D design and fabrication of the flower stands. The process followed to create them has been the same ad the one for the rocking chair explained on this page..

Electronics

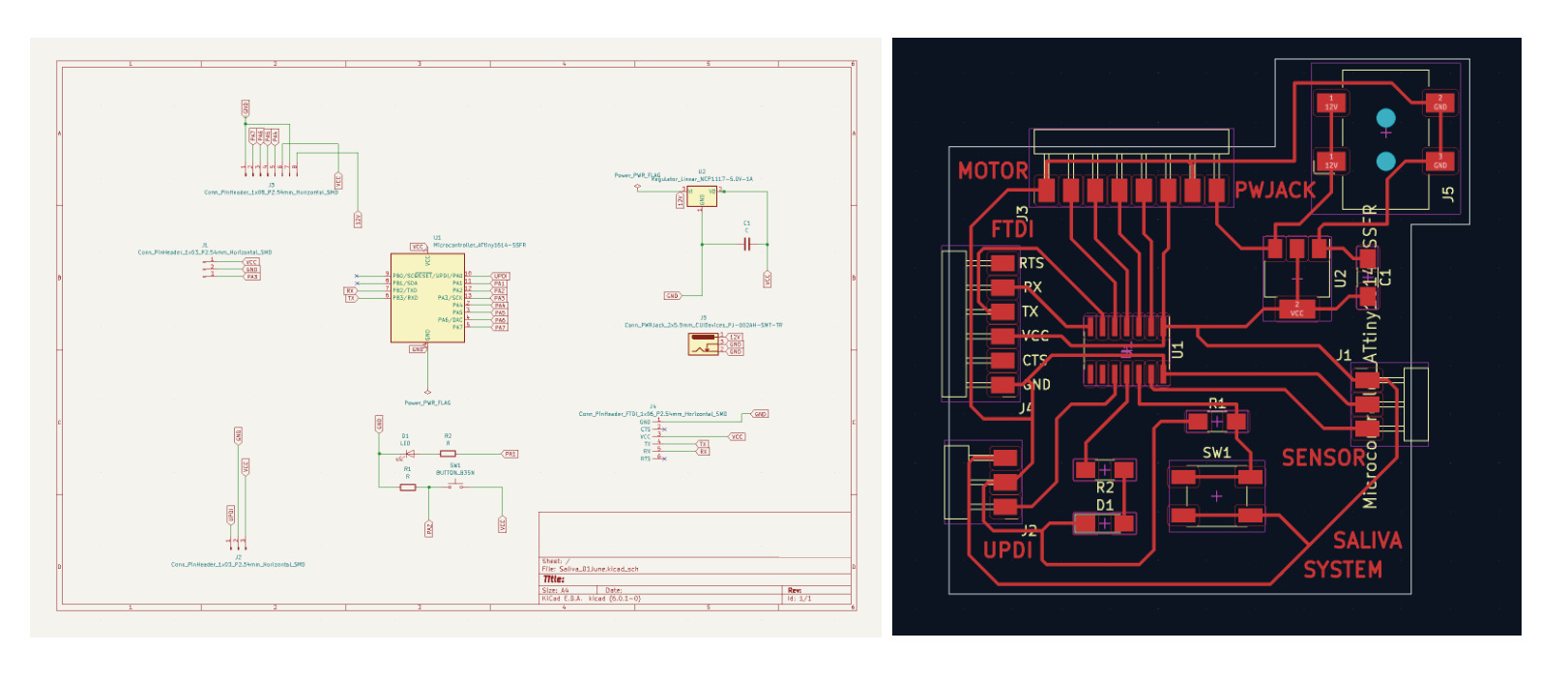

In order to design my own “Saliva” board, the documentation from Adrianino was very helpful.

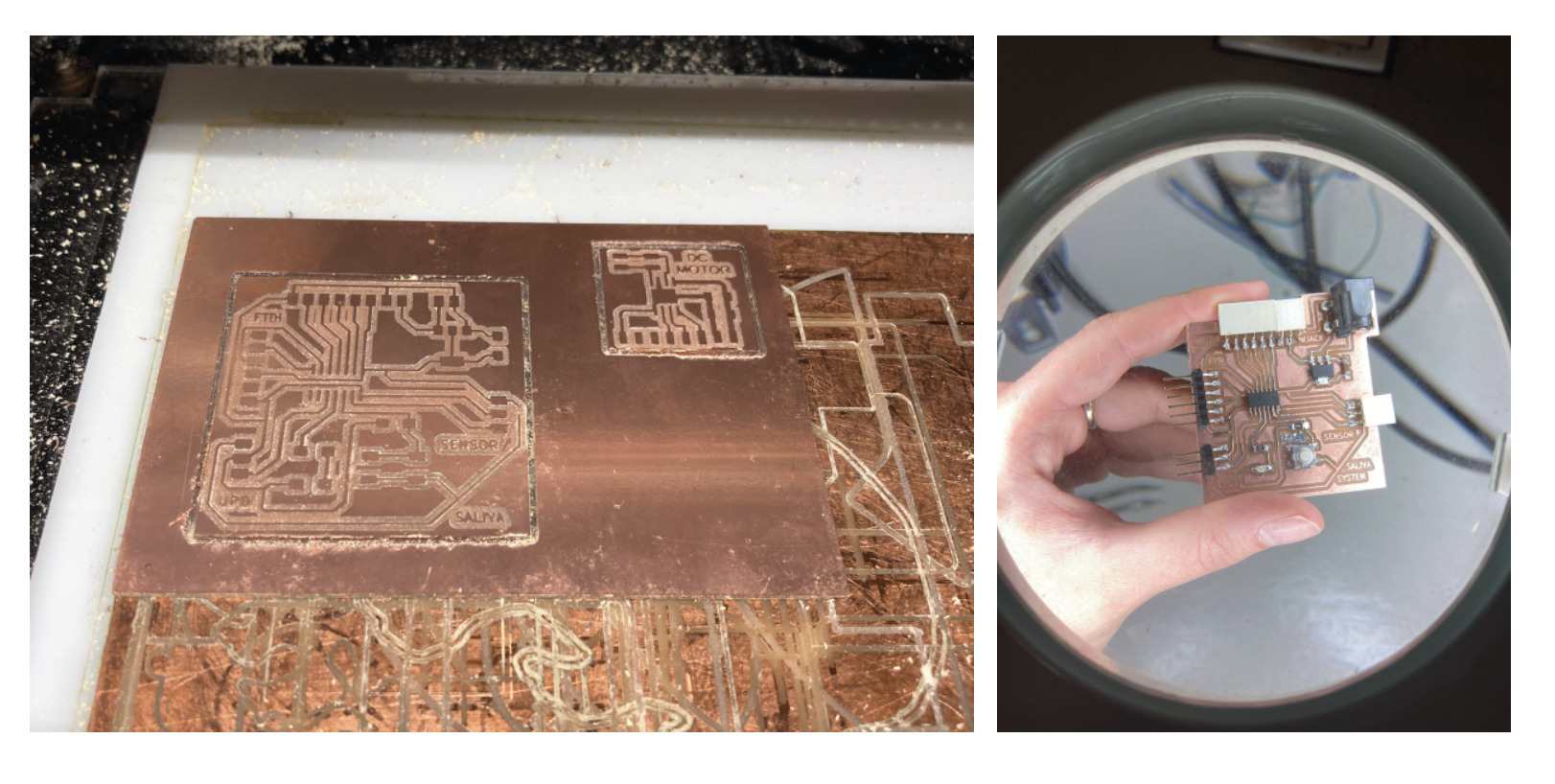

Attached some pics of the Kicad deesign process, the fabrication, soldering and testing.

Code

The code used to make alive the project is the attached:

// "Saliva" code by Paola Zanchetta - 01/06/2022

// Interactive system human-plants

// Heart Beat Sensor + DC Motor Pump

/* Define Pulse Library = FALSE because

the Library is not supported by the Microcontroller */

#define USE_ARDUINO_INTERRUPTS false

#include <PulseSensorPlayground.h>

// Define the format of our output with Arduino

const int OUTPUT_TYPE = SERIAL_PLOTTER;

// Define pinouts

const int PULSE_INPUT = PIN_PA3; // Pulse Sensor

const int PULSE_BLINK = PIN_PA1; // LED Blink

const int THRESHOLD = 550; // Const, limit Threshold

const int RELAY_PIN = PIN_PA4;

byte samplesUntilReport;

const byte SAMPLES_PER_SERIAL_SAMPLE = 10;

// Add Pulse Sensor Library

PulseSensorPlayground pulseSensor;

void setup() {

Serial.begin(115200);

// Configurate motor

pinMode(RELAY_PIN, OUTPUT);

// pinMode(PULSE_INPUT, INPUT);

digitalWrite(RELAY_PIN, HIGH);

delay(100);

// Configure the PulseSensor manager.

pulseSensor.analogInput(PULSE_INPUT);

pulseSensor.blinkOnPulse(PULSE_BLINK);

pulseSensor.setSerial(Serial);

// pulseSensor.setOutputType(OUTPUT_TYPE);

pulseSensor.setThreshold(THRESHOLD);

// Skip the first SAMPLES_PER_SERIAL_SAMPLE in the loop().

samplesUntilReport = SAMPLES_PER_SERIAL_SAMPLE;

}

void loop() {

if (pulseSensor.sawNewSample()) {

if (--samplesUntilReport == (byte) 0) {

samplesUntilReport = SAMPLES_PER_SERIAL_SAMPLE;

// Define Water Pump start when rating 40-60 BPM's

if (pulseSensor.getBeatsPerMinute() > 40 && pulseSensor.getBeatsPerMinute() < 70) {

// pulseSensor.outputBeat();

Serial.println("Detected beat.." + String(pulseSensor.getBeatsPerMinute()));

digitalWrite(RELAY_PIN, LOW); // turn on pump

delay(1000);

digitalWrite(RELAY_PIN, HIGH); // turn off pump

delay(1000);

}

}

}

}

Components

| Nº | Component | Material | Process | Cost |

|---|---|---|---|---|

| 1 | Plants Pots Mold | Cardboard | Laser Cutter | Recycled Cardboard from Amazon Packaging = 0€ |

| 1 | Plants Pots Cover | Mix of Cotton + Polyester Cloth | Laser Cutter + Casting with Epoxy | Cloth = 26€ |

| 3 | Plants Stands | PlyWood | CNC | 0€, material from the fablab |

| 1 | Sensor Touch | PLA | 3D Printing | 0€, material from the fablab |

| 1 | DC Pump Motor | DC Motor | Buy Online | 12€ |

| 1 | Relay | Motor driver | Buy Online | 12€ |

| 1 | 4x2 mm Silicone Tubes | Silicon | Buy Local Shop | 0€, material from the fablab |

| 1 | Microcontroller 1614 | — | — | 0€, material from the fablab |

| 1 | BLUE LED | — | — | 0€, material from the fablab |

| 1 | Resistor | 499K | — | 0€, material from the fablab |

| 1 | Resistor | 1K | — | 0€, material from the fablab |

| 1 | Regulator | LDO 5V 1A | — | 0€, material from the fablab |

| 1 | Button | — | — | 0€, material from the fablab |

| 2 | 3 PIN FEMALE | — | — | 0€, material from the fablab |

| 1 | Button | — | — | 0€, material from the fablab |

| 1 | 8 PIN MALE | — | — | 0€, material from the fablab |

| 1 | Power Supply - 5V | — | — | 0€, material from the fablab |

Total ammount: 50€

Retrospective about “Saliva”

The development of Saliva as the final project has been empowering, resilient and perseverant. I did enjoy very much the development process all around, from the conceptualization to the design, manufacturing, and “making alive” steps.

The concept of Saliva was borns within the context of FabAcademy, as a result of a need when using the rocking chair designed during the CNC Milling week. It has been developed using almost all the new skills acknowledged during this period. Resulting not only in an interactive project but also in a reflection of my intentions within the personal and professional field.

Retrospective about FabAcademy

5 months after the start of Fab Academy, I can say that this full immersion in digital fabrication course, was exactly the experience that I was looking for. Now I feel that I have all the skills needed to make real and prototype almost all my ideas!

As a recap of my fav moments, The CNC milling week was lots of fun! But also, I really enjoyed the last month. Working on my final project development was really exited, especially when feeling that I was mastering all the techniques in use.

Even if is the most dangerous at the Fablab, my favorite machine was the CNC. As an industrial designer, I really love to design furniture, and this machine has endless possibilities to work with different materials. I already have in mind some new projects I would like to try out.

When I enrolled in the FabAcademy, one of the things that attracted me the most is the distributive methodology system that it follows! Having experience working in the Precious Plastic Initiative, I really love the idea of connectivity, globally working on the same tasks, but using the local tools, which brings always really diverse outputs.