Test the design rules for your 3D printers

Group Assignment 2022 (Raffaele Alone)

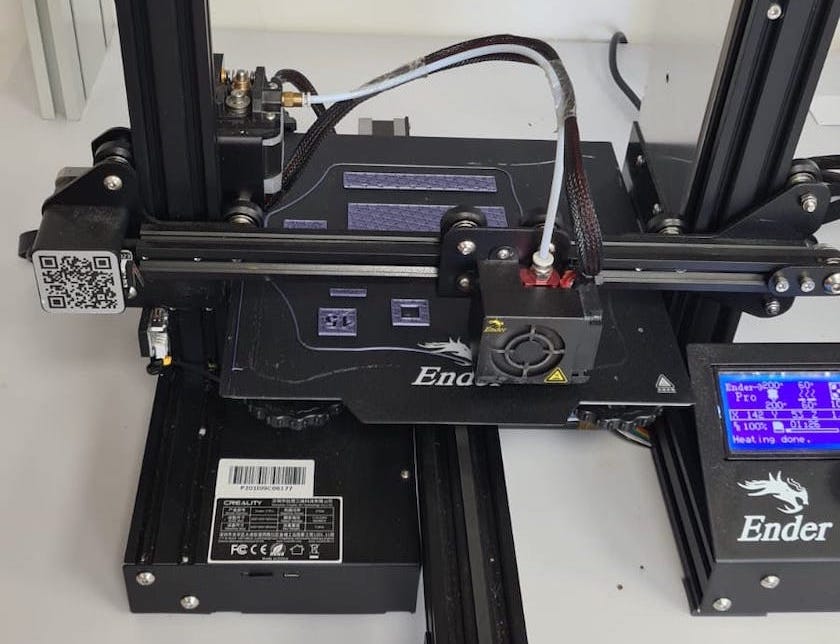

The group work has been carried out with the Creality3D Ender-3 pro

| Modeling Technology: | Power Supply: | Printing Size: | Machine Size: | Package weight: | Max Traveling Speed: | Filament: | Input: | Output: | Layer Thickness: | Nozzle diameter: | Precision: | File Format: | Working Mode: | Max Nozzle Temperature: | Max Hotbed Temperature:: |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FDM | Mean Well UL certified power supply | 220*220*250mm / 8.6x8.6x9.8 inches | 440*410*465mm / 17.3x16.1x18.3 inches | 8.6kg / 19 lbs | 180mm/s | 1.75mm ABS, PLA, WOOD, FLEXIBLE, Carbon firber | AC 100-265V 50-60Hz) | DC 24V 15A 360W | 0.1-0.4mm | 0.4mm | ±0.1mm | OBJ, G-Code, STL(in CURA converted to G-Code) | USB cable (not included) online compatible or micro-SD (offline) | 255℃ | 110℃ |

Creality's Ender 3D printer series is among the strong and popular 3D printers. The Ender 3 is highly appreciated among makers around the world receiving good reviews on specialized websites. The Ender 3 Pro, which can even be found for less than €200, is impressive that anyone can use a 3D printer for so little money. The sensations in the use of the machine are very good and similar to the others.

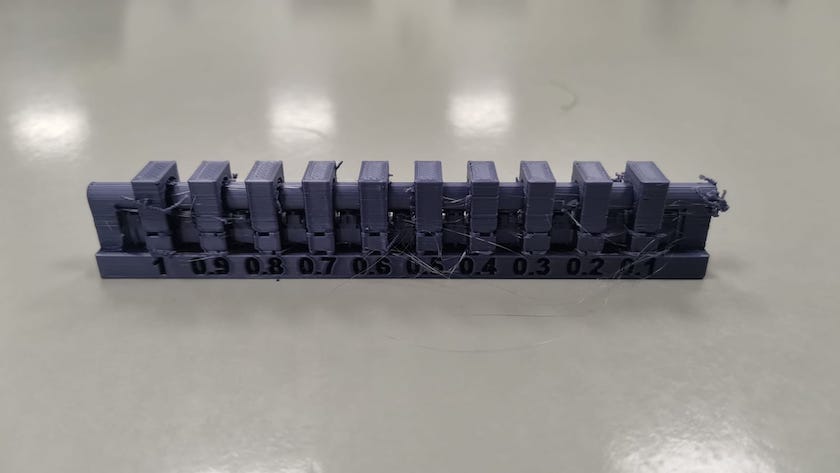

Shooting piece

Shooting piece

Base with suspension bridge

Base with suspension bridge

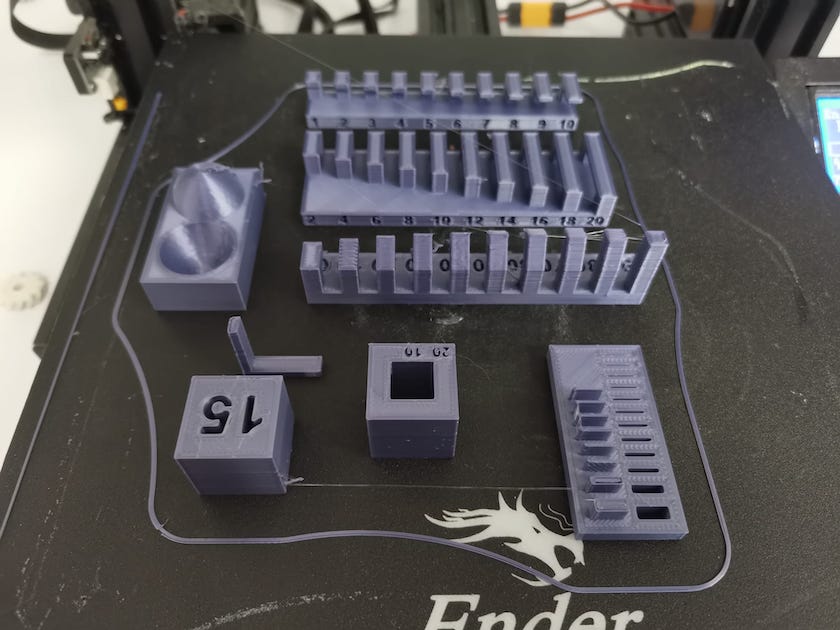

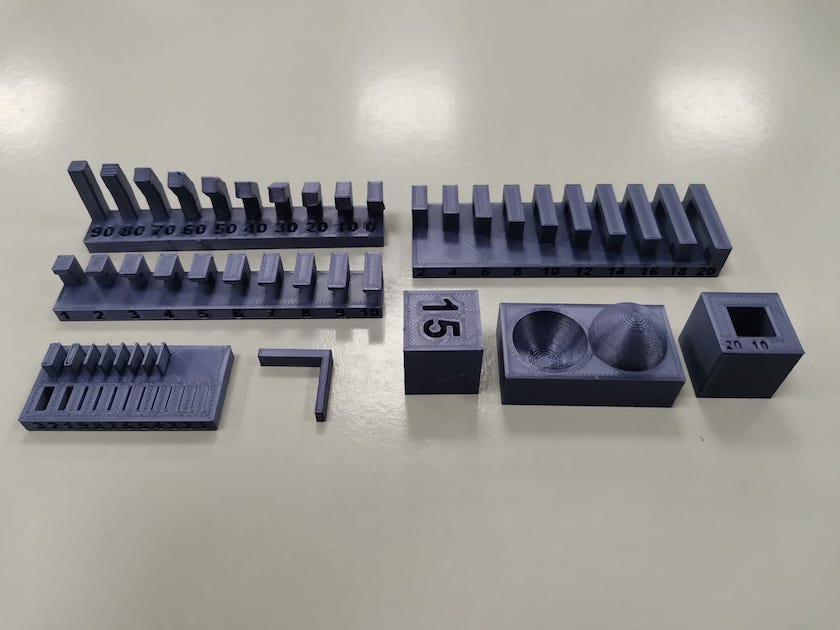

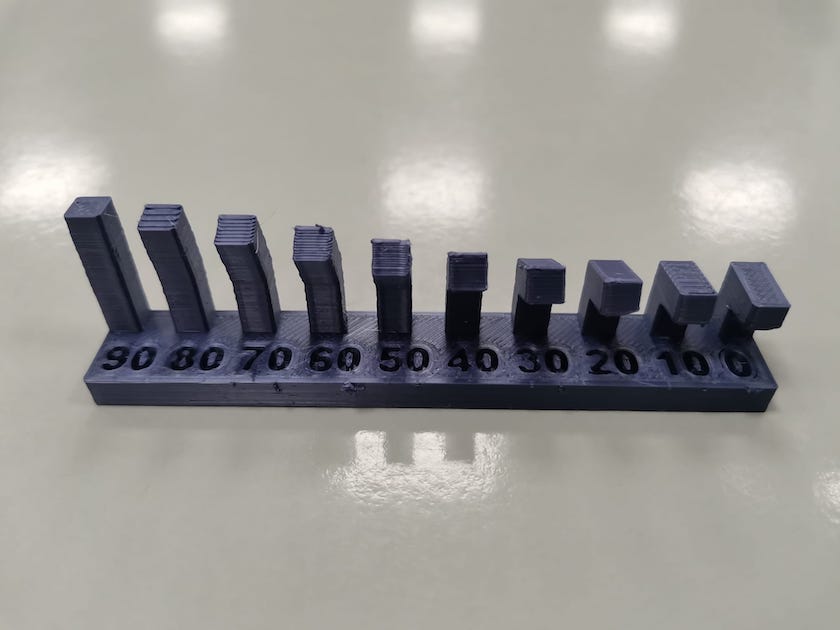

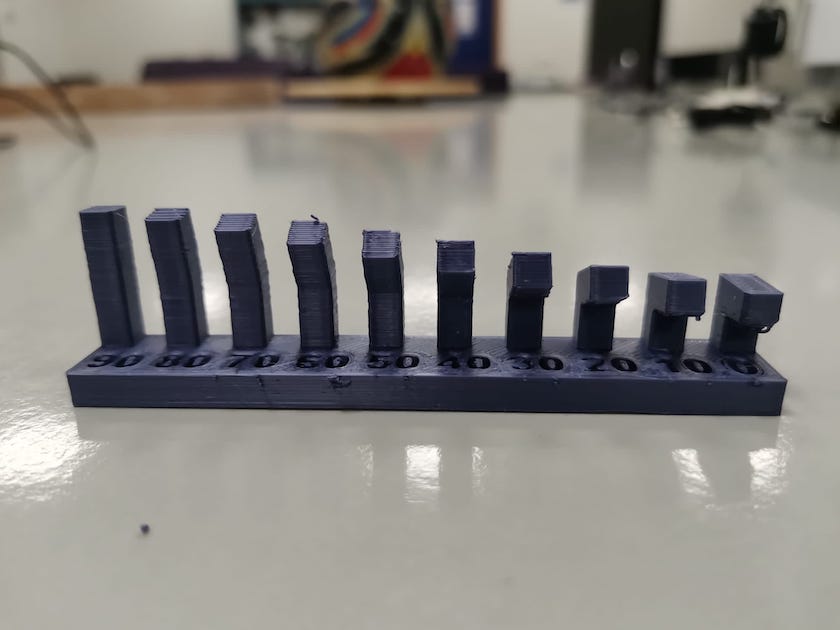

In order to carry out the group work, we downloaded the images from the weekly assignments and launched them to print. The first print job is to make some gauges. This work aims to find the best solution to print knots in one go. It is very interesting to look for the tolerances between the different measures.

Ender printing parts without support

Ender printing parts without support

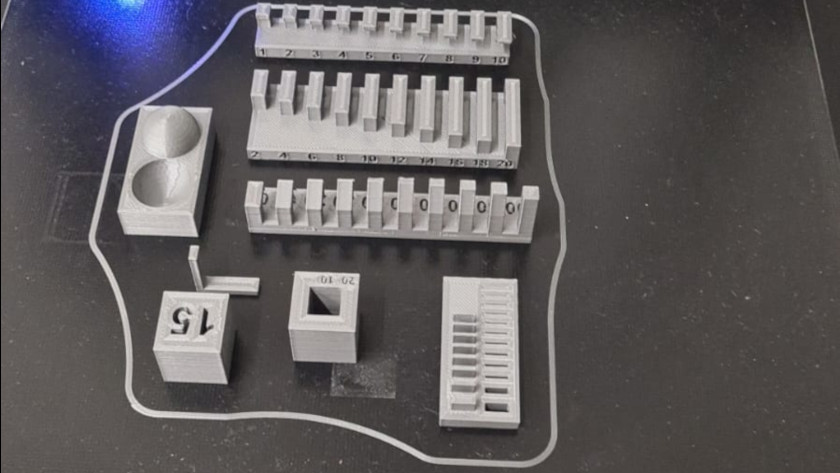

Finished parts

Finished parts

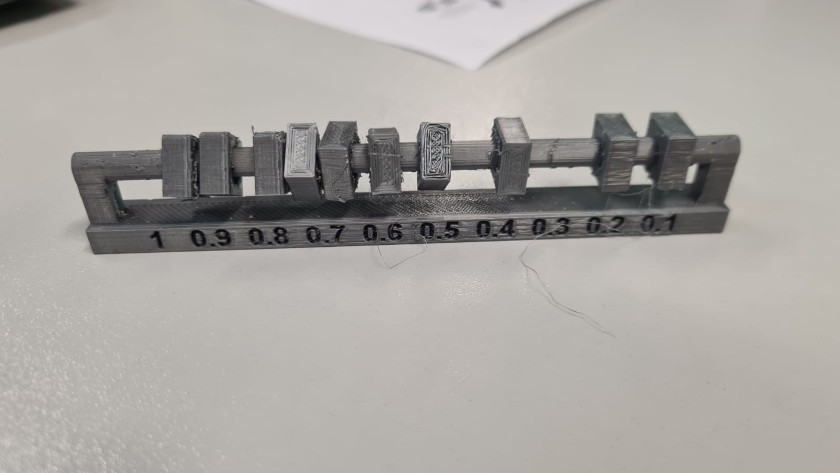

In the print job with support, the ender pro shows limits of verticality of the walls and some problem of compaction of the walls although the files come out quite well. In the measurement of bearing diameters, a good bearing is obtained from 0.6 mm, if I had to use this machine to make a single impression knot, I would probably leave 0.6 mm of distance between wheels.

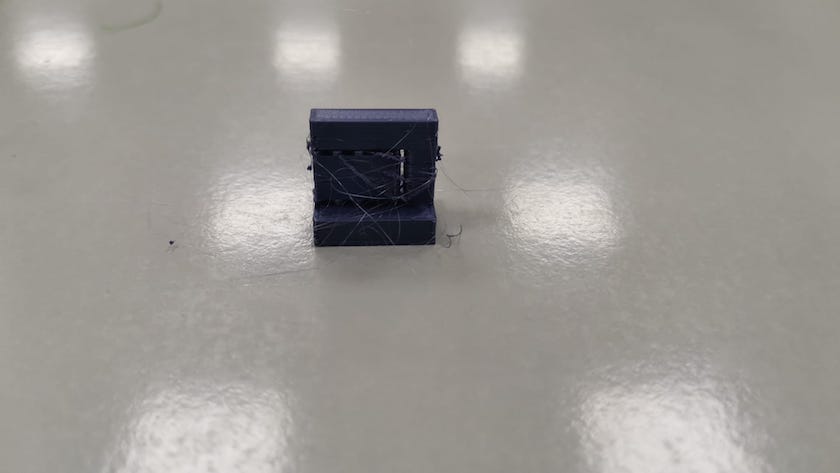

Finished part

Finished part

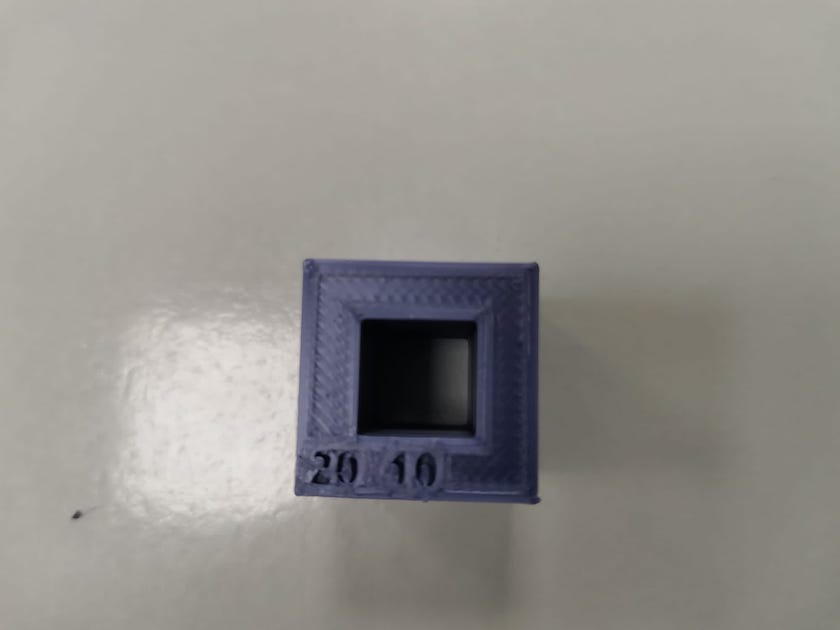

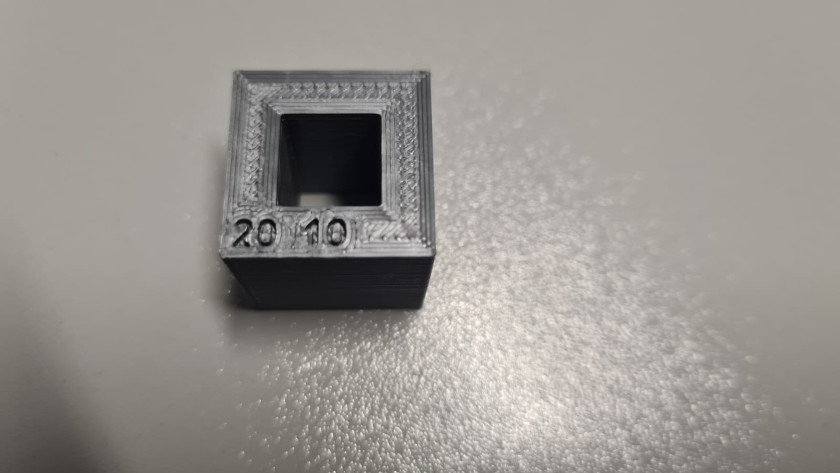

Finished hollow cube

Finished hollow cube

In the photos above you can see a good quality in general of the impressions. The size of the objects has also been measured to see the deviation between the printed part and the actual measurement. There is very little difference, imperceptible.

Printing of suspended bridges

Printing of suspended bridges

Printing of suspended bridges

Printing of suspended bridges

In the bridge tests, the quality is good although the more pronounced, the more the faults are appreciated.

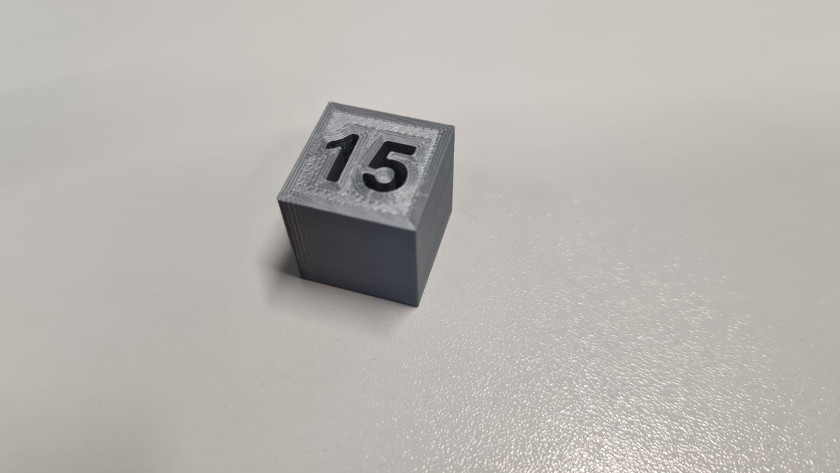

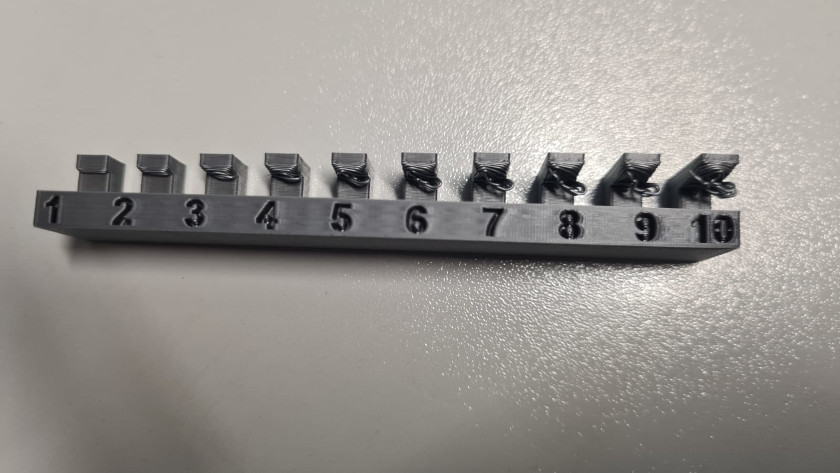

Dice with number

Dice with number

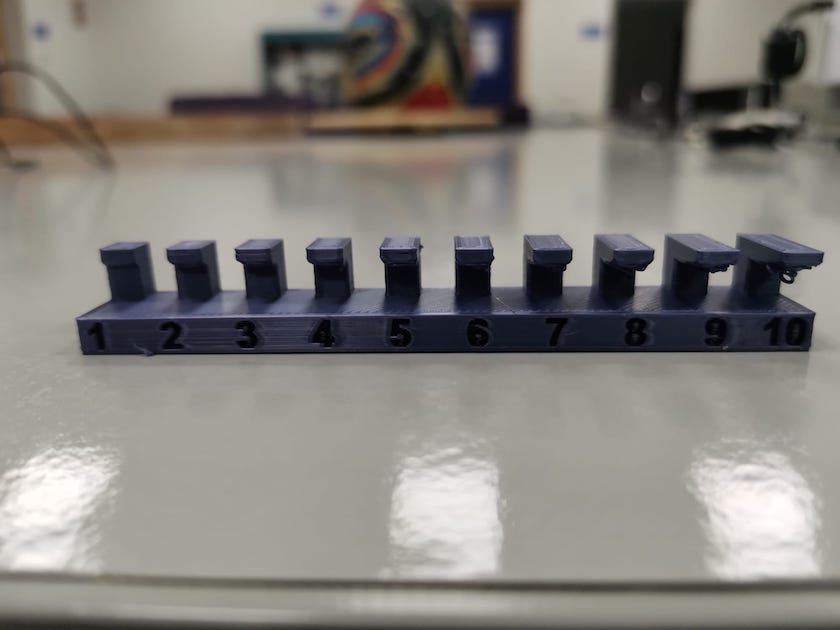

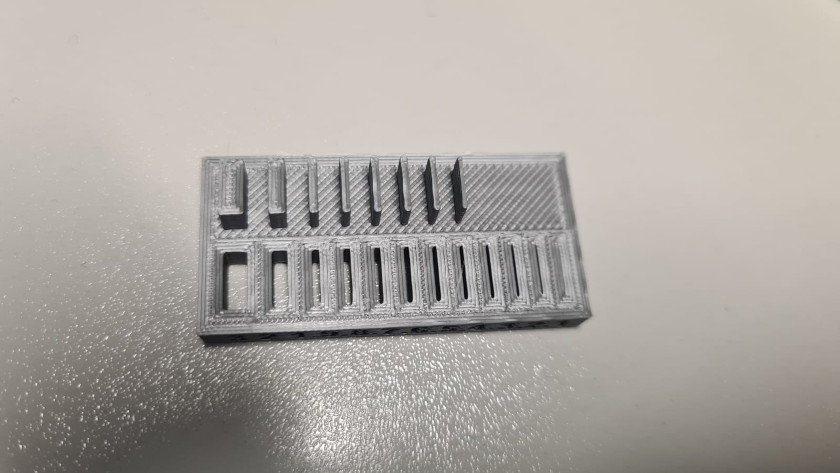

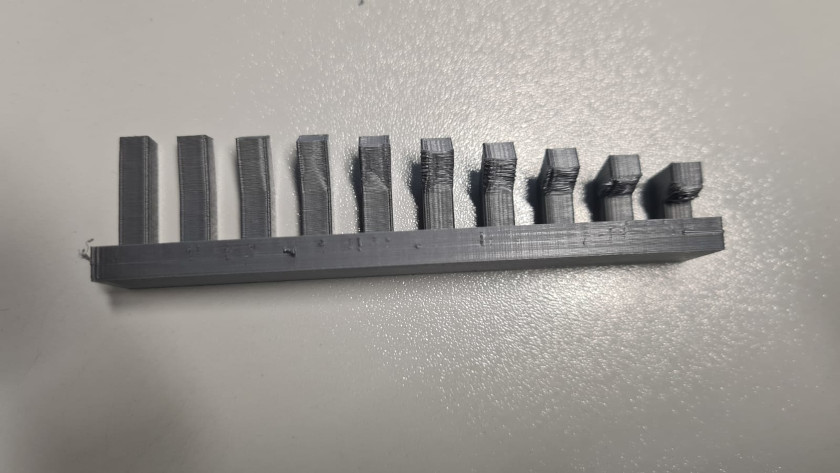

Walls and gaps

Walls and gaps

The walls and the gaps although the printing is finished, not all the printing is of optimal quality. The walls from 0.1 to 0.4 do not exist while the walls 0.5 and 0.6 have misprints.

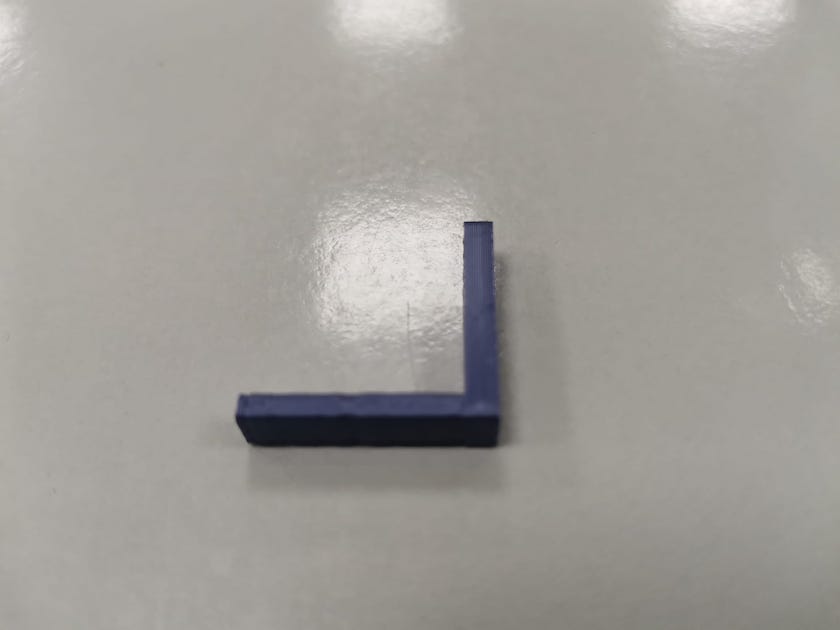

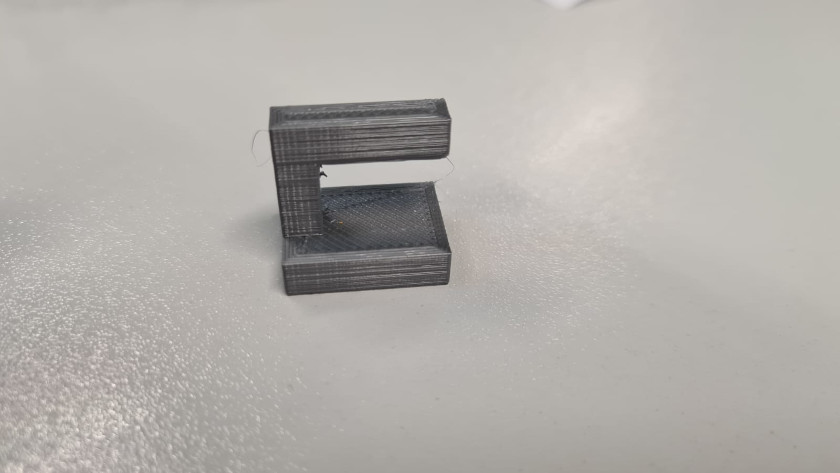

Wall to l

Wall to l

Tilt bridge

Tilt bridge

Bridges 8, 9 and 10. They are not of good quality.

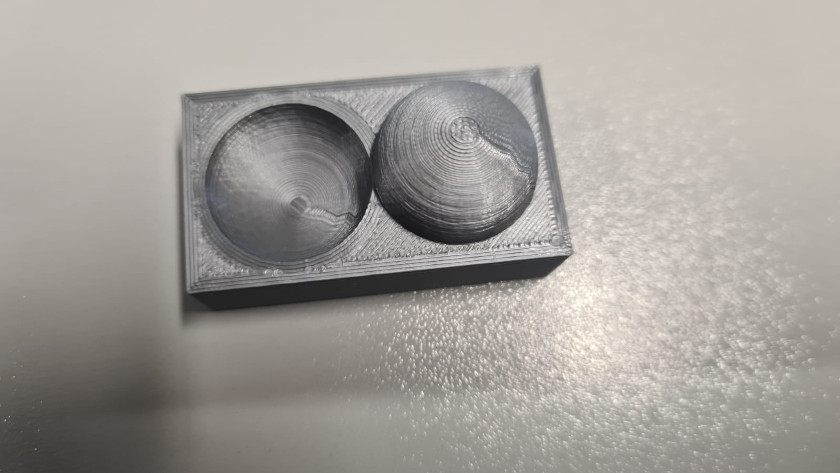

Sphere

Sphere

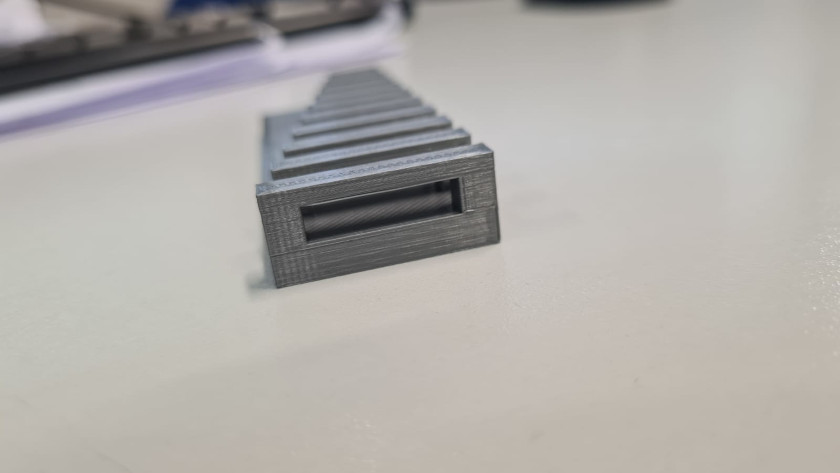

Bridges

Bridges

In the concave and convex impression signs of poor quality are seen when the circles get closer. It is more a software bug, it is seen that the circle is looking like segmented lines. The bridges have no printing problem.

To finish with the characterization, the printing quality of the artillery sidewinder x1 has been studied.

| MBuild Volume: | Layer resolution: | Maximum print speed: | Maximum travel speed: | Print bed: | Heat bed type: | Build plate heat up time: | Filament diameter: | Supported filament: | Bed leveling: | Print technology: | Extruder type: | XYZ resolution: | Nozzle type: | Nozzle diameter: | Nozzle temperature: |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 300 x 300 x 400mm (11.8 x 11.8 x 15.75in) | 0.1mm | 150mm/s | 250mm/s | Glass-ceramic | Rapid heating AC heat bed | 80℃ in less than 2 minutes | 1.75mm | PLA, ABS, Flexible PLA, TPU, Wood, PVA, HIPS | Manual | FFF (Fused Filament Fabrication) | Direct Drive Extruder (Titan type) | 0.05mm, 0.05mm, 0.1mm | Volcano | 0.4mm | up to 240℃ |

Shooting piece

Shooting piece

Base with suspension bridge

Base with suspension bridge

Well, just as the parts for the Ender have been printed, we are going to print a parts with and without support with the Artillery. The results seem better than with the Ender. The pieces have more definition.

Artillery printing parts without support

Artillery printing parts without support

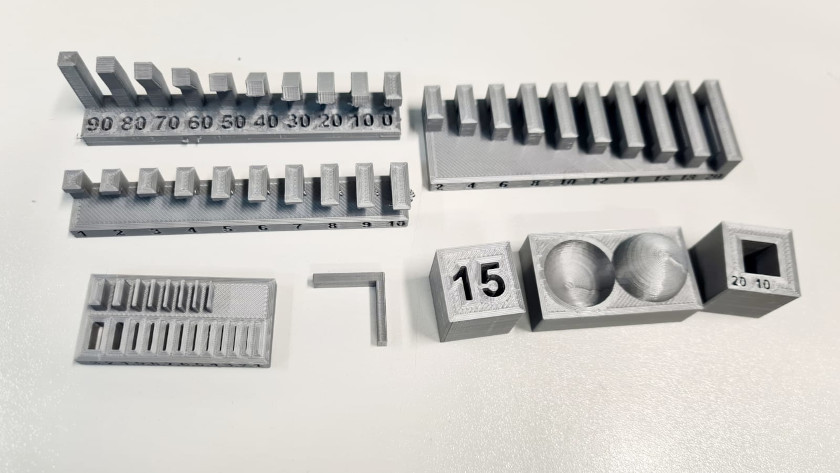

Finished parts

Finished parts

In the unsupported print job, the Artillery shows better wall verticality results than the ender and very few wall compaction issues though the files come out quite well. In measuring bearing diameters you get a good bearing from 0.5mm, if I were to use this machine to make a single impression knot I would probably leave 0.5mm wheelbase.

Finished hollow cube

Finished hollow cube

Sphere

Sphere

In the photos above you can see a good quality in general of the impressions. The size of the objects has also been measured to see the deviation between the printed part and the actual measurement. There is very little difference, imperceptible. The dial has no flaws.

Dice with number

Dice with number

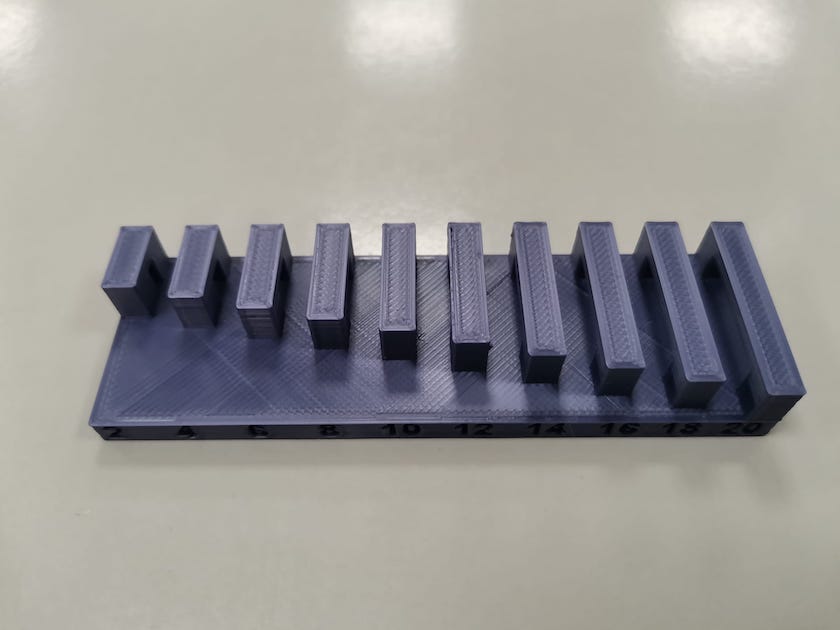

Walls and gaps

Walls and gaps

The number and the walls are of excellent quality. Perfect.

Bridges

Bridges

Tilt bridge

Tilt bridge

The bridge supported on both sides is not of poor quality. The suspended bridge loses quality from the third.

Printing of suspended bridge

Printing of suspended bridge

Printing of suspended bridge

Printing of suspended bridge

The bridge supported on both sides is not of poor quality. The suspension bridge loses quality after forty.