Molding and Casting¶

Group assignment¶

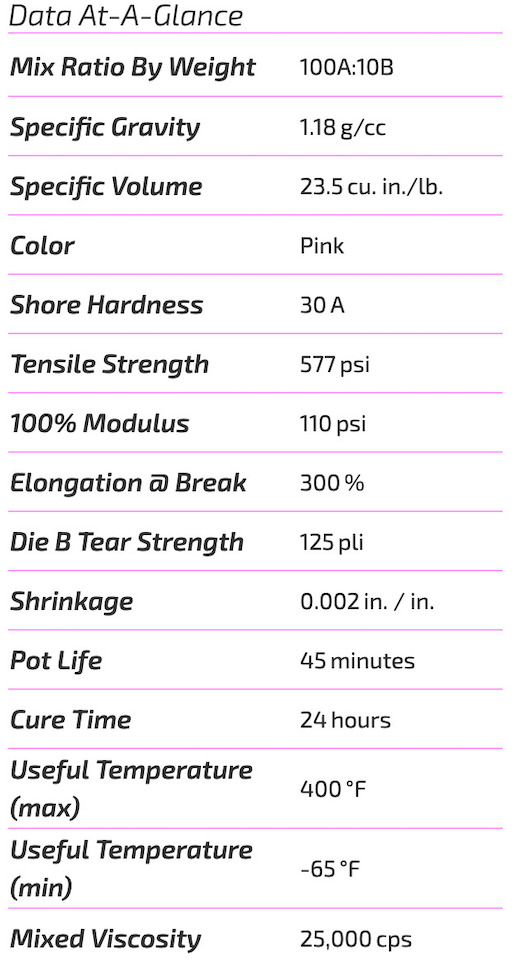

To make the mold we used Mold Max 30 silicone. The page has the essencial set of instructions/guidelines to use the material.

Safety

Use in a properly ventilated area (“room size” ventilation). Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. Wear vinyl gloves only. Latex gloves will inhibit the cure of the rubber.

We check the Technical Bulletin and the Safety Data Sheet, reading carefully the “Section 2 – Hazard(s) Identification” and “Section 4 - First Aid Measures”.

For the casting material, it was used the Smooth-Cast 300 resin.

Safety

Materials should be stored and used in a warm environment (23° C). These products have a limited shelf life and should be used as soon as possible. All liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal, glass or plastic. Mixing should be done in a well-ventilated area. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk.

We checked the Smooth-Cast 30 Technical Bulletin and also the Safety Data Sheet.

Made several casts of the individual assignment, but not with different materials because for molding and casting we used the only materials available. Differences between casts were mainly in mold alignment. In terms of resin curing results, were always the same because didn’t mix with different A/B ratios.

Note: For the group assignment we didn’t do any molding and casting test. This was done in group but along our individual assignment.