Group Work

The Problem

Recycling is a process whose goal is to convert waste into new products to prevent the disuse of potentially useful materials, reduce the consumption of new raw material, reduce energy use and reduce pollution.

Los recipientes de aluminio son ideales para la conservación de alimentos, ya que son muy ligeros, son impermeables a la humedad, a los gases, a la luz y a los olores. When recovered aluminum is used to manufacture the cans instead of raw materials, a saving of 95% is generated in the amount of energy required. Recycling one ton of aluminium saves 5 tonnes of bauxite (the main element of aluminium)

For the recycling of aluminum cans does not affect that they are in their original form or are introduced crushed into the containers. One of the greatest virtues of aluminum is that it can be used as many times as you want once recycled. Aluminum does not lose any of its characteristics in terms of hardness, ductility, corrosion resistance or high electrical conductivity because it is recycled.

Group members

- Ing. Walter Elias Lenigan Rodríguez

- Ing. Yuri Alejandro Cruz Espinoza

- Ing. Wilson Gomez Hurtado

Process to Perform

1) Group Meetings

To elaborate, our project, we carry out group meetings, making use of programs such as:

- Whatsapp

- Miro

- Zoom

2) Collecting Ideas

We brainstormed to decide which projects could meet the specifications we had been asked for.

After analyzing the possible projects such as:

A) Design a machine that can make picarones

To achieve the assembly of this machine we are guided by the following videos:

- DISPENSER DONUTS MANUAL TECNOCHUFA

- BELSHAW MARK 6 DUAL AUTOMATIC DEPOSITOR

- TRANSFORM CIRCULAR MOTION INTO LINEAR AND CIRCULAR INTO ALTERNATIVE

B) Automatic Electric Can Crusher

To achieve the assembly of this machine we are guided by the following videos:

- PNEUMATIC CAN CRUSHER FROM SCRAP METAL

- AMASSADOR DE LATINHAS ELÉTRICO

- AUTOMATIC ELECTRIC CAN CRUSHER - DIY

After debating the two designs we had, we came to the conclusion of manufacturing option "B"

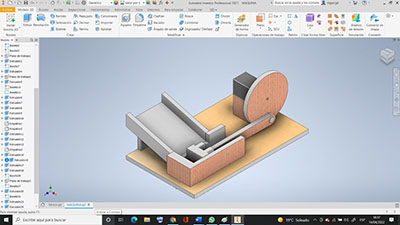

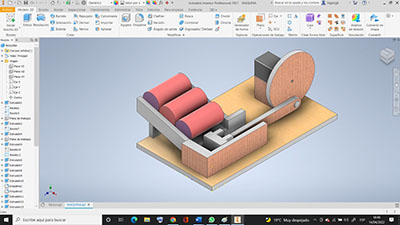

It begins by brainstorming for the selection of mechanisms to apply to compress the aluminum cans, linear, circular, vertical movements, after a wide debate it was agreed to combine movements, use the circular movement of the motor and convert it into a linear movement.

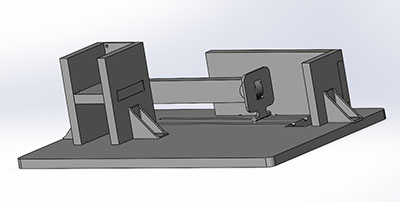

3) Manufacturing

A search was made on the Internet of machines that have this application of compressing containers, where most of the machines are robust and made of metal that make them very heavy, for which their manufacture has a high cost.

Our project tries to design a lightweight and low-cost compactor to be used by small recyclers, using Fab Lab technology such as the application of MDF to perform laser or milling cutting, also consider 3D printing for some parts, as well as electronics for automation such as servo motors and microcontrollers such as Arduino.

MATERIALS

Servomotores 20 kg / 4.8 V a 6.8 V

Fuente de Poder

Motor de paso nema 23

Fuente de Poder

Placa Arduino Mega

MANUFACTURING