Making the circuit board

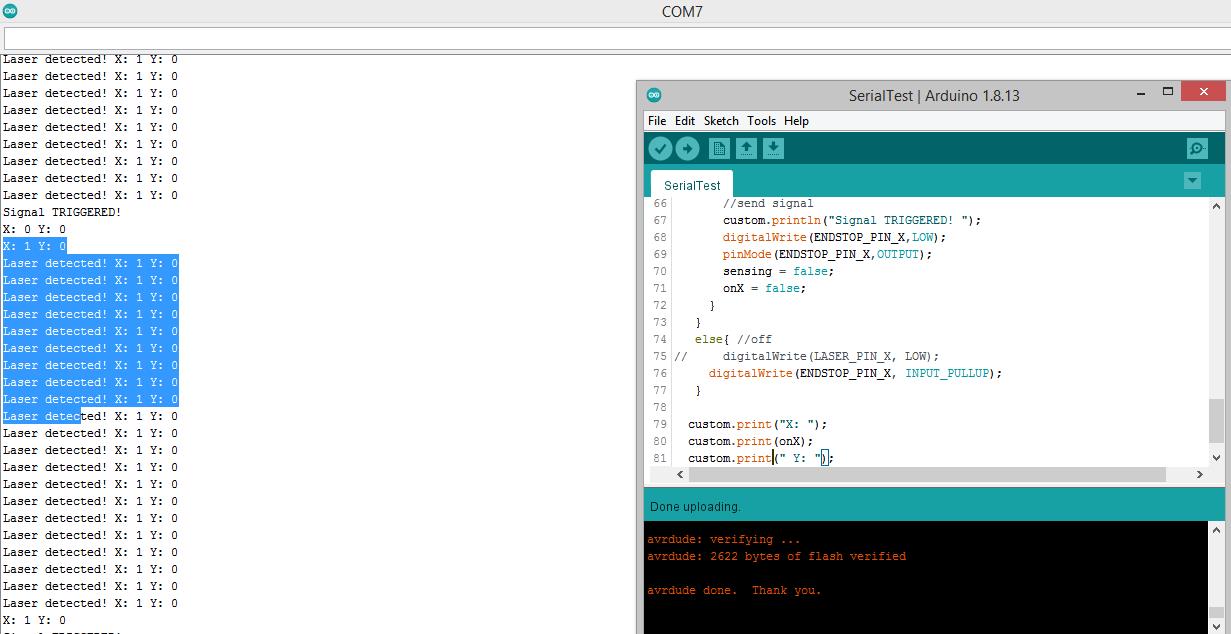

As our machine was centered around laser-zeroing we need to 'hack' the limit switches, as we hope that the laser can add precision on top of the physical switches by eliminating the bounce effect issues.

The board has to be capable of sensing when the limit switch is pressed and turn on the laser and then sense the interruption and act as a limit switch.

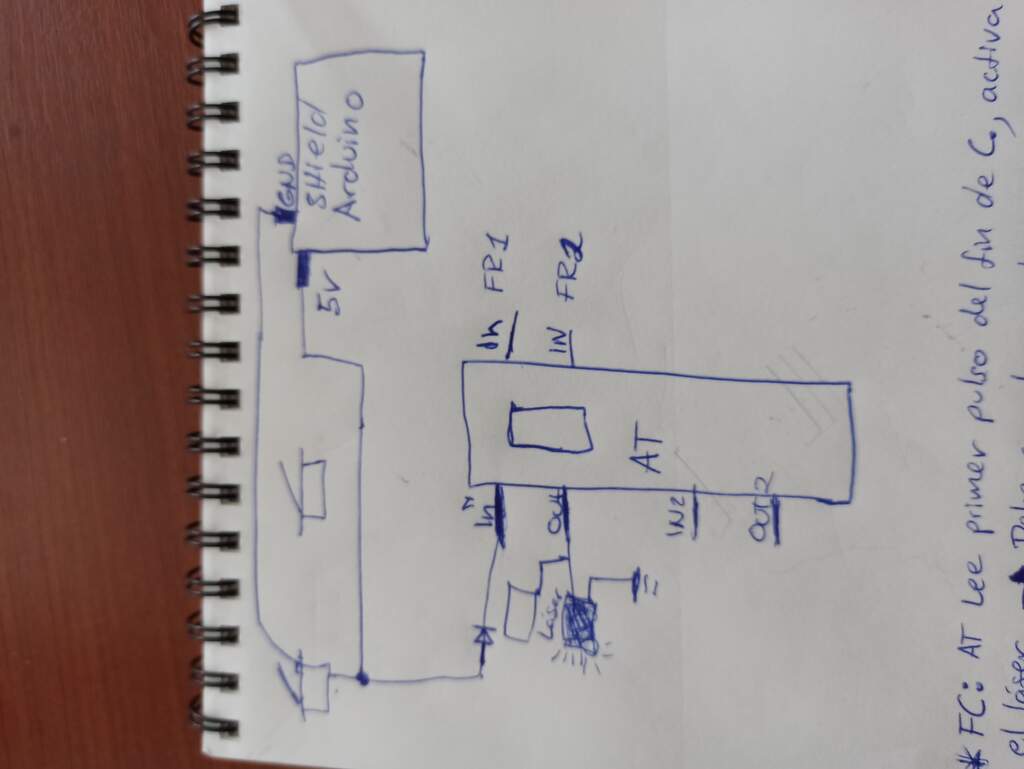

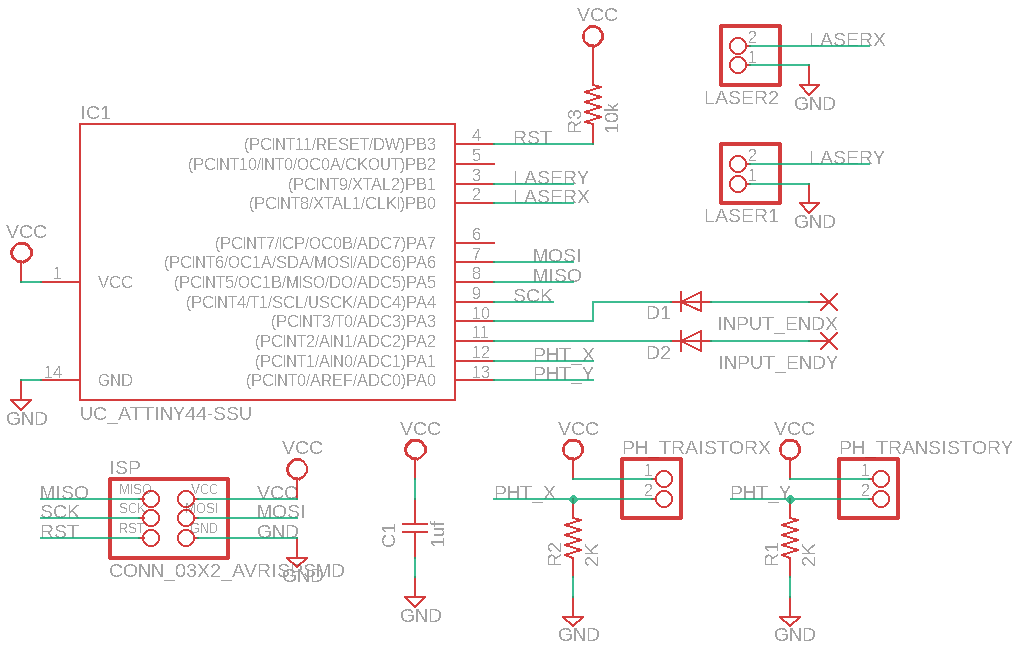

With Camilo we sketch a simple diagram that uses the ATtiny44 as source of logic some pulldown resistors for the phototransistors and some diodes to make sure the board does not interfere too much with the sensing from the Arduino UNO.

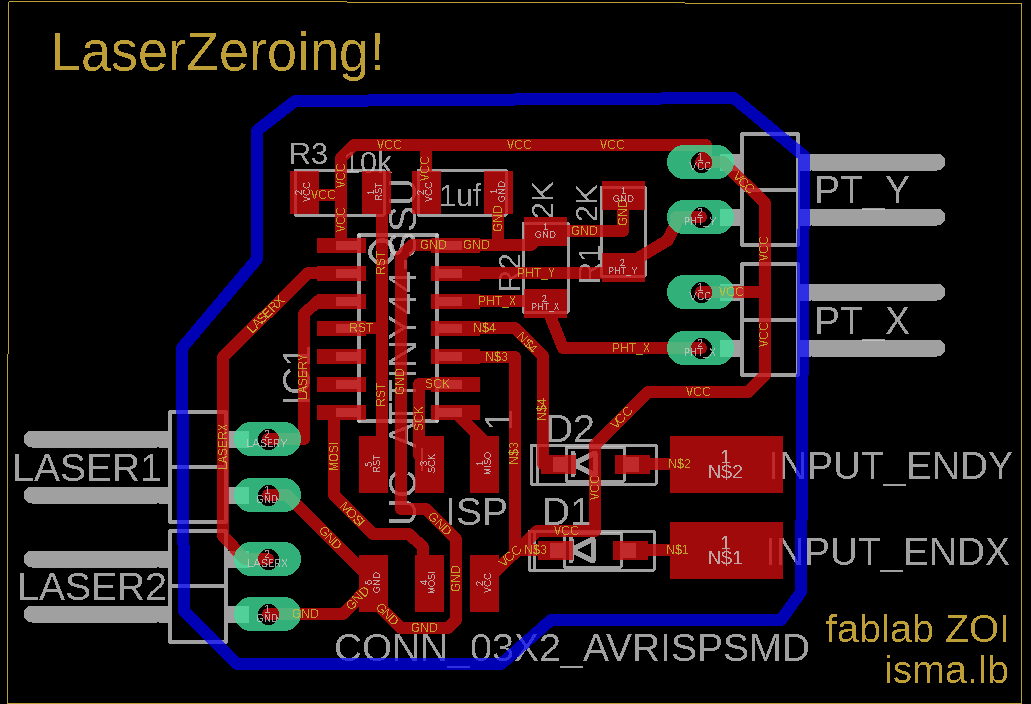

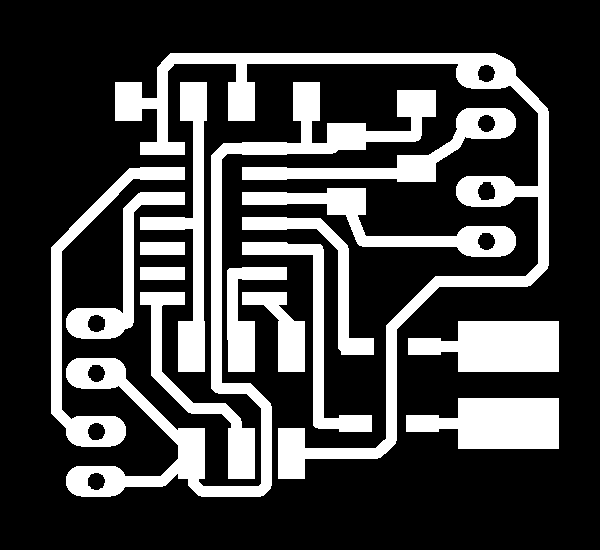

Using Eagle we place the required components and start routing the traces. This process takes me always a while, figuring out the best way to make the traces is difficult.

After this was done I exported the outline and the traces as a png image. I use Microsoft Paint to fill the outline shape and fix some details as well as inverting the colors of the traces.

Using Mods we generate the G-code needed for the traces and start milling, our first attempt was a failure because we were using wrong the auto-level on the bCNC (software that controls the CNC milling machine). But after some research on the internet, we manage to use a new workflow and use the auto-level properly. The result was that the mill bit only engrave the surfaces of the copper layer and did not crate the traces.

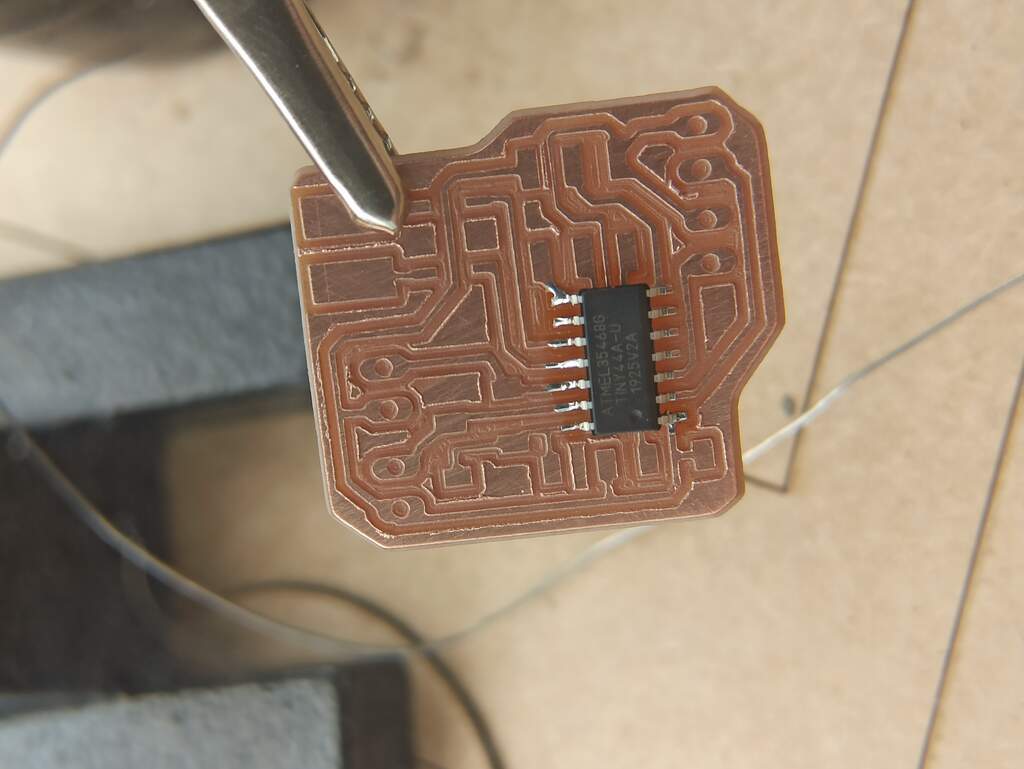

After adjusting the cut depth on the g-code using the same workflow we finally make a good looking circuit board.

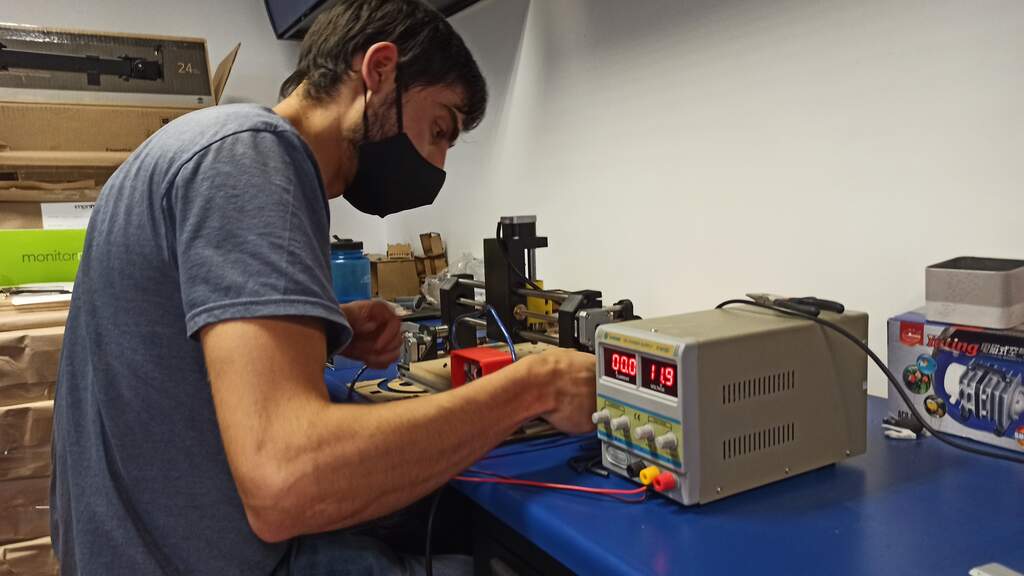

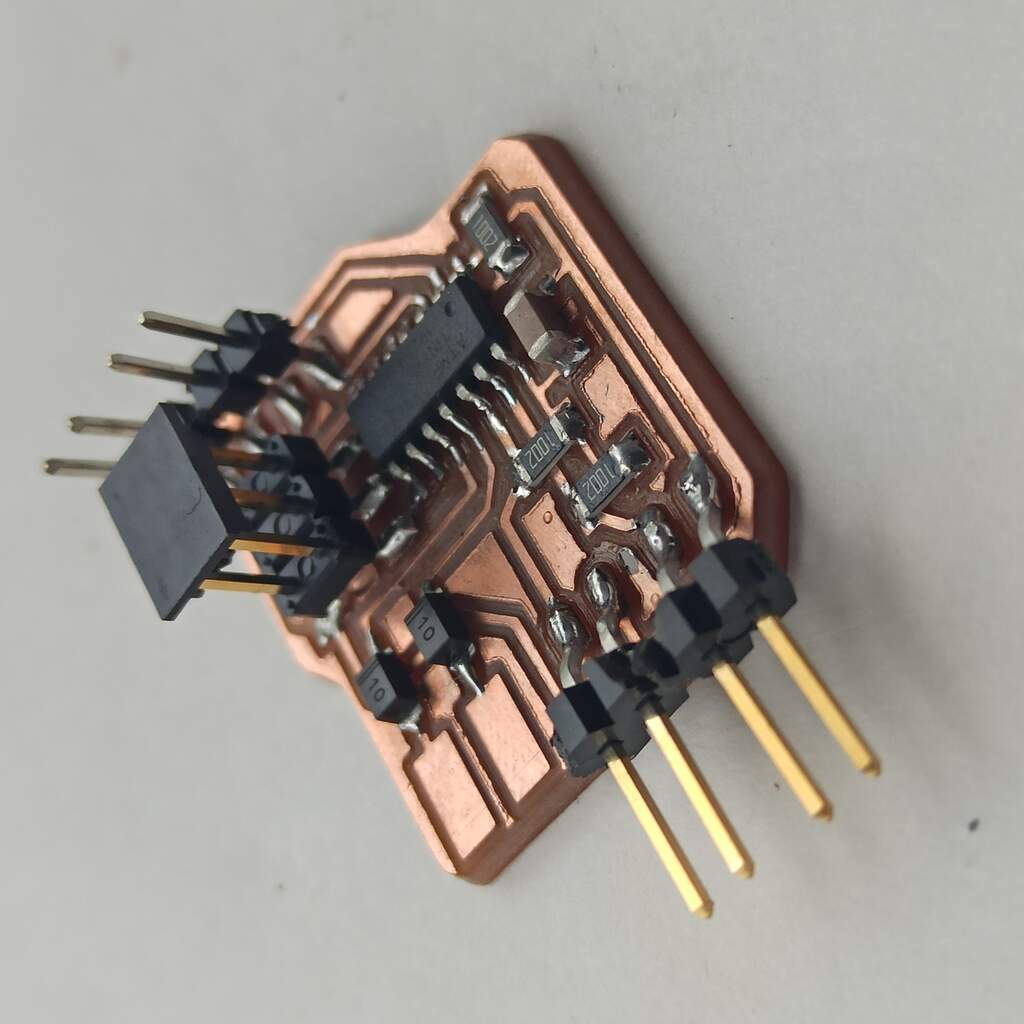

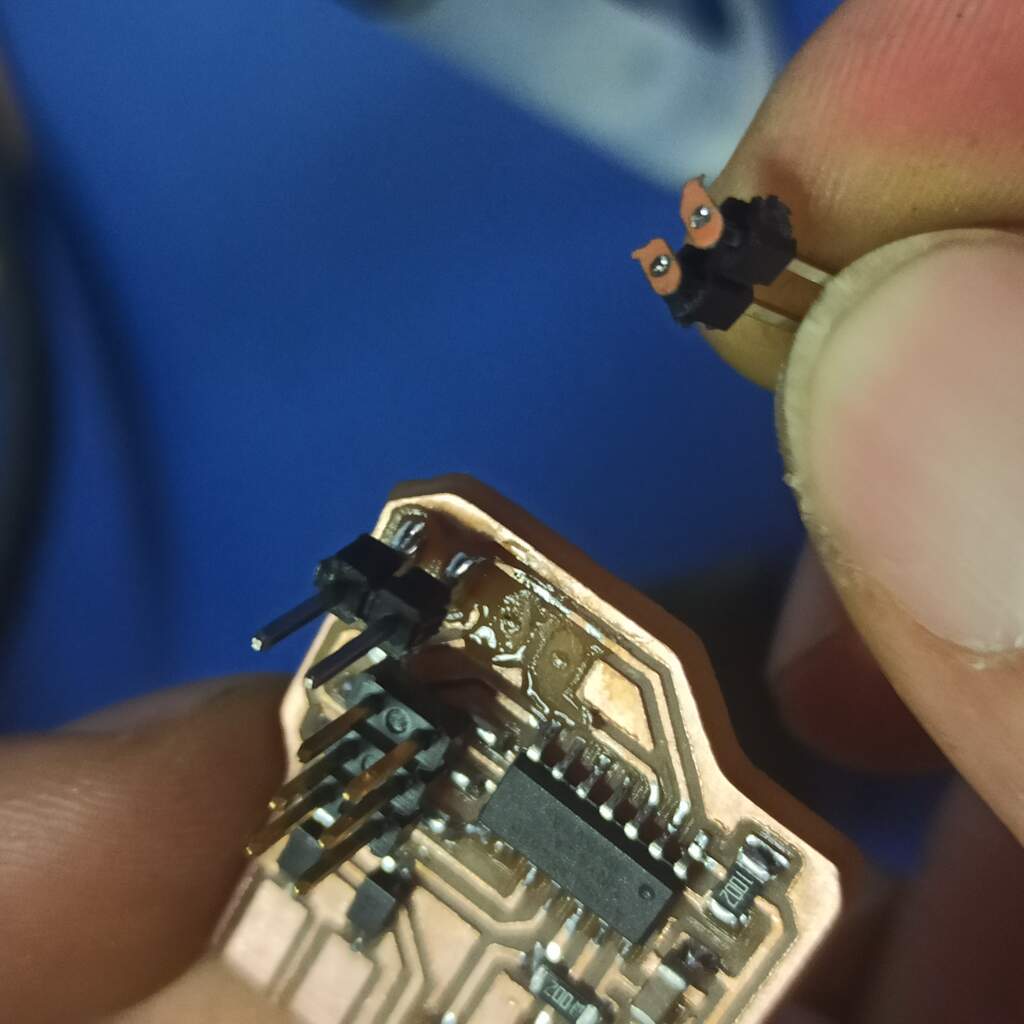

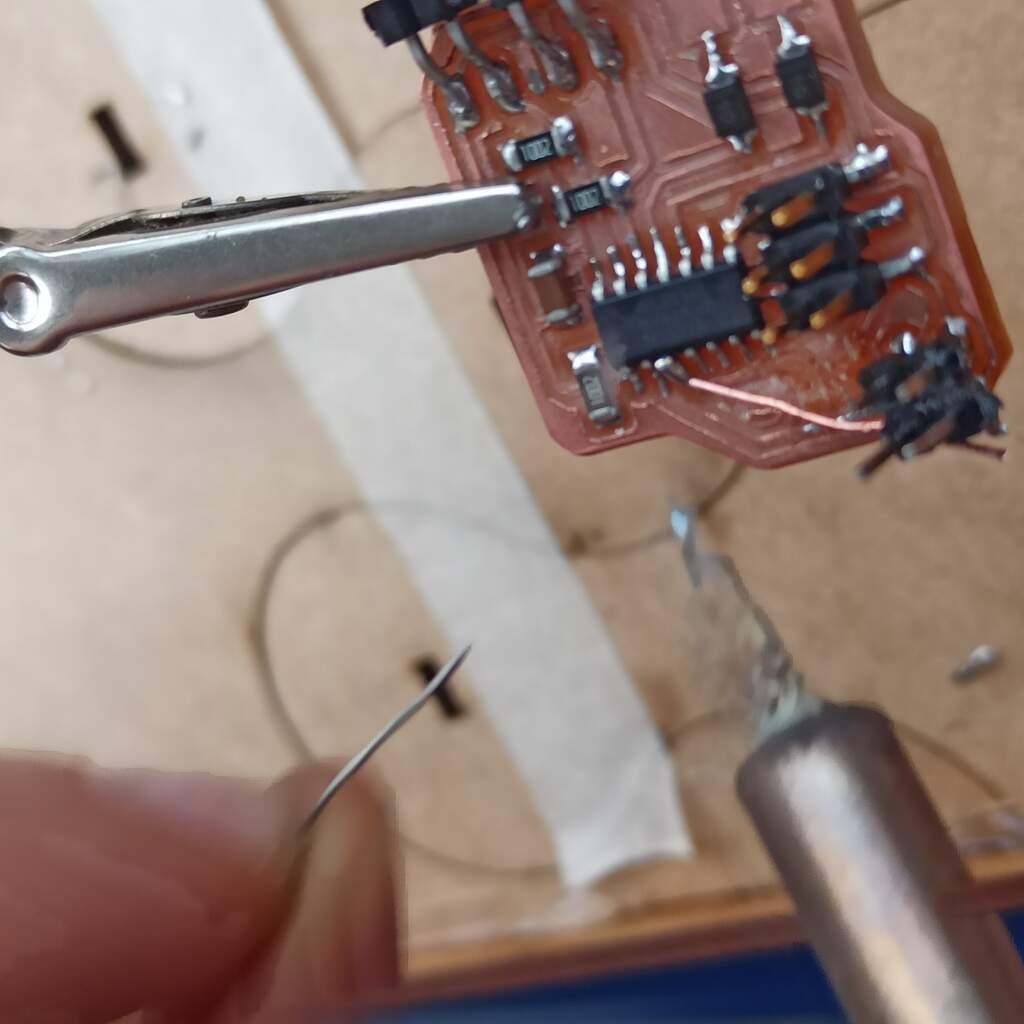

Then the next step was to solder all the components, I started by the micro controller unit, followed by the capacitor, the resistors, diodes and finally the pin headers for the ISP connections.

While programming and testing the board we have and inconvenience, one of the pin headers to connect the phototransistor broke, peeling off some traces. Luckily Camilo managed to solder the header again and using super glue we secure everything in places again.