Mold preparation

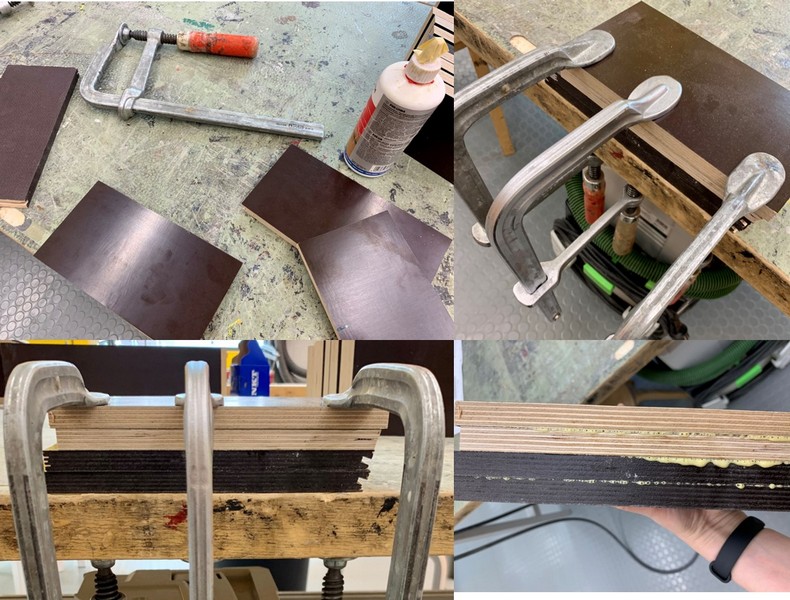

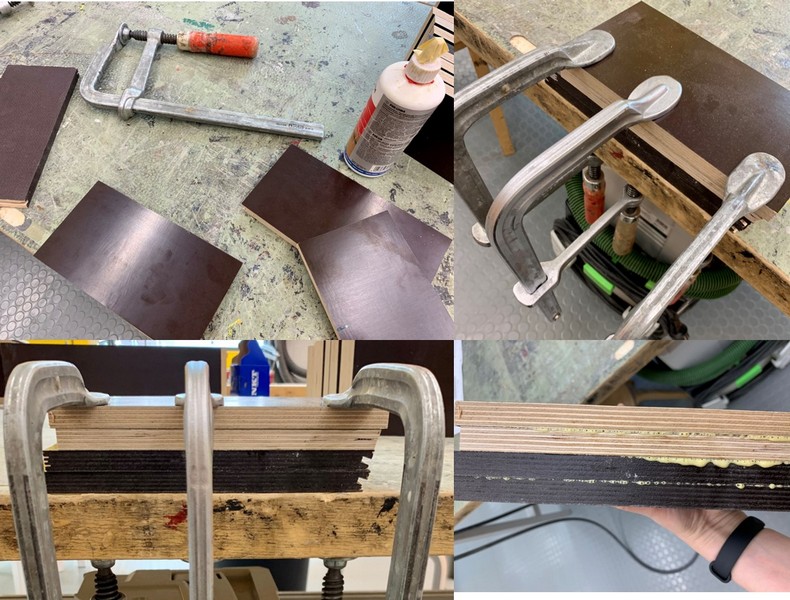

With the help of Ari, I found a couple of fil faced plywood board with around 1.5 cm thickness, while my design height was around 4.5 cm. So, I took four of those board and then, I had to cut two of them to have approximately equal lengths of the boards.

Figure 6. Finding the right size of the material

Then, I used the circular saw for the first time. It is scary but very simple to use:) Just do not forget safety issues (goggles and hearing protection)!

Figure 7. Working with circular saw to cut the boards

Next, I should glue four board together with wood glue and let it dry.

Figure 8. Glue the four board together

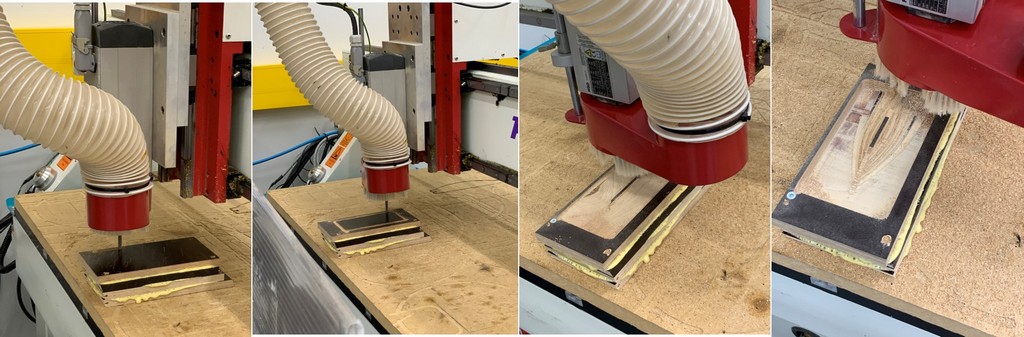

The mold material was ready to mill after one day when the glue completely dried. Then, I needed to screw the board to the CNC Router table.

Figure 9. Fixing the mold material to the to the CNC Router table

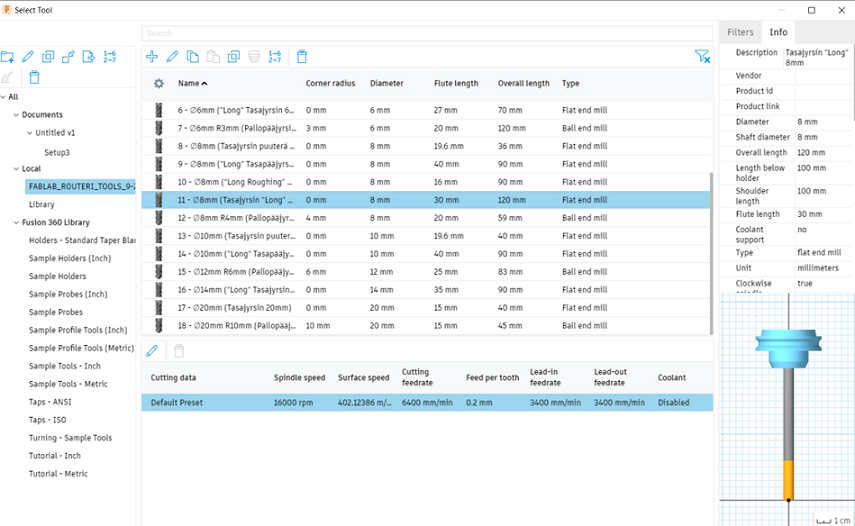

As I had chosen the milling bit as 8 mm flat and mill, I took the right bit to install on the machine jog.

Figure 10. Installing the correct milling bit

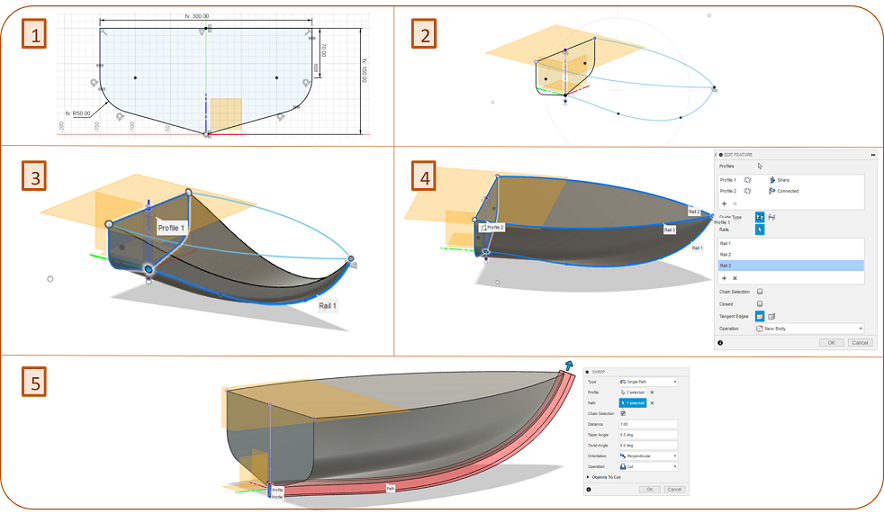

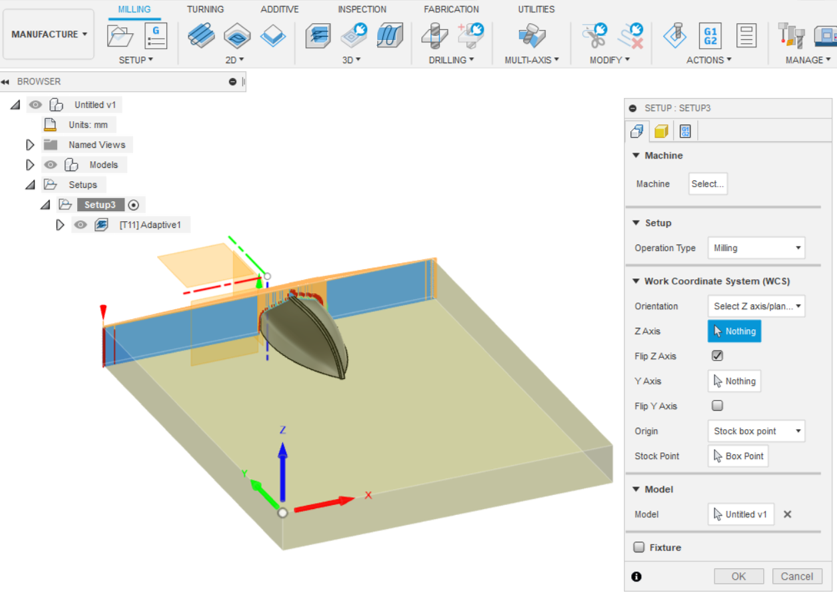

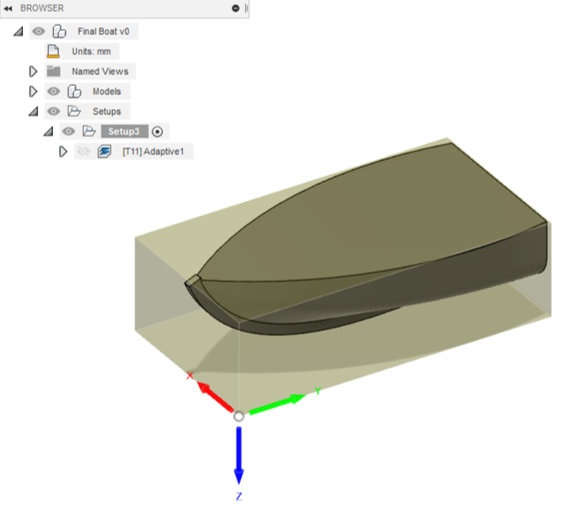

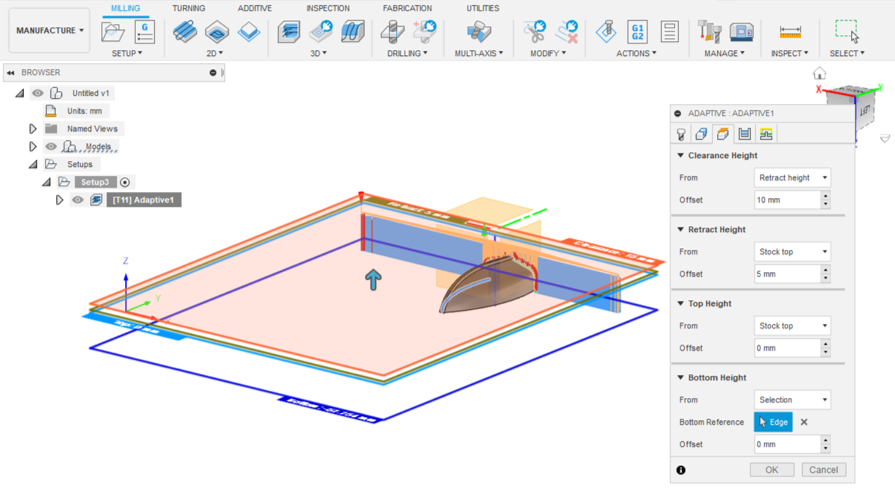

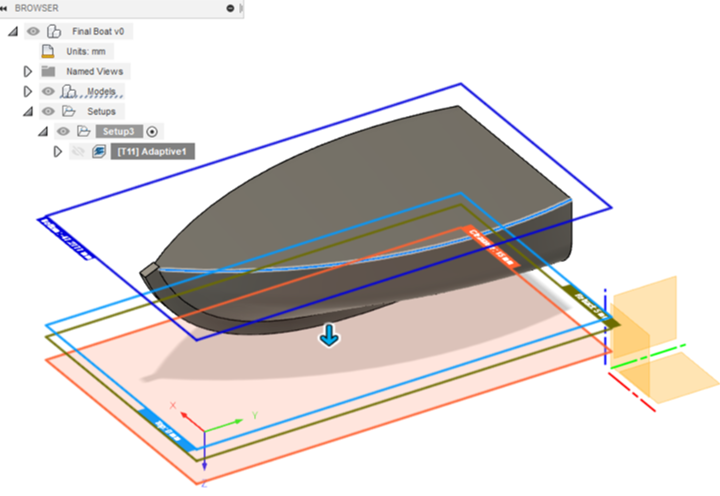

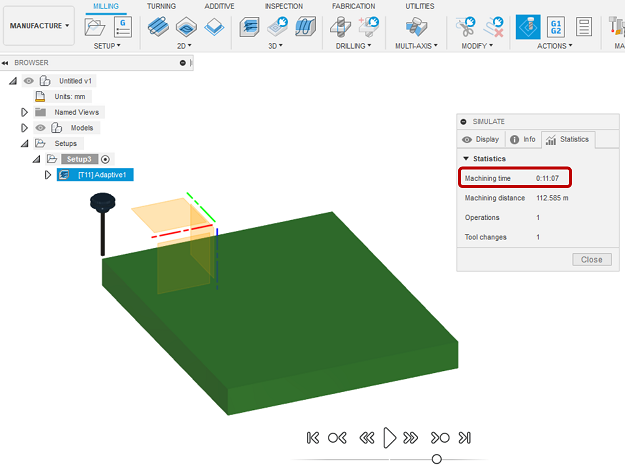

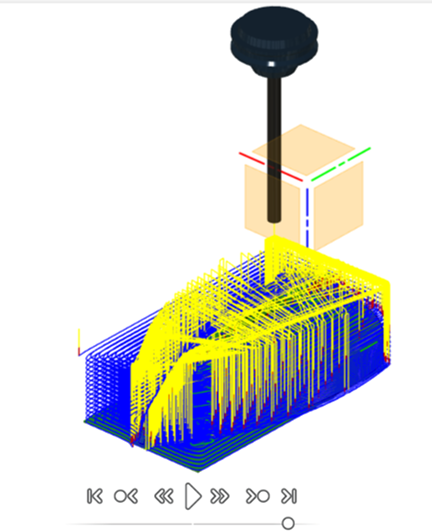

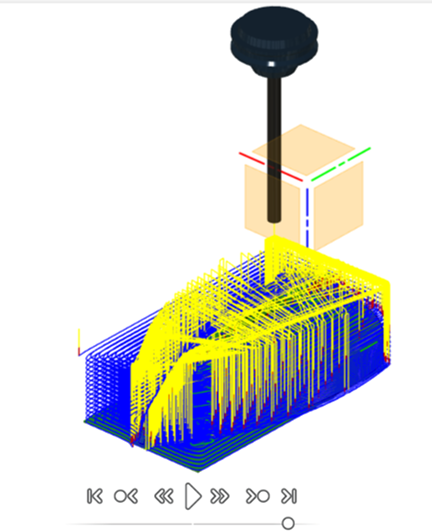

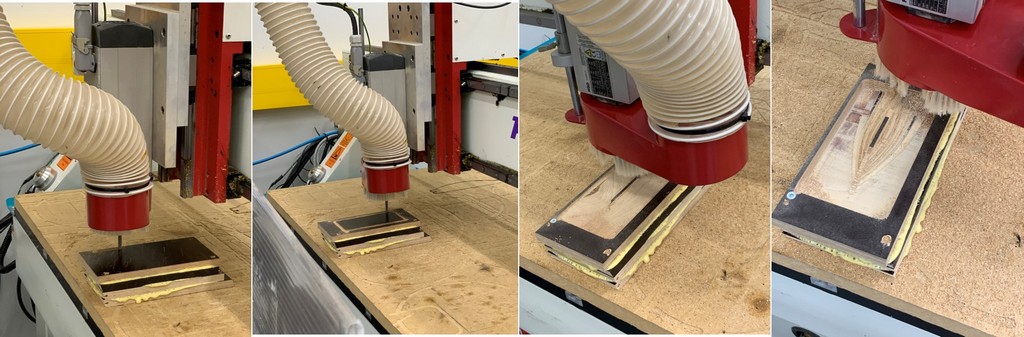

The steps for setting the origin and start the machine were explained in details in Week 7. During this stage, Ari noticed the design dimensions are not correct and it was still big and also, he suggested to remove the bottom board. So, I had to rescale it again and then, start milling.

Figure 11. Final desing simulation after rescaling

Figure 12. Milling the mold with CNC Router

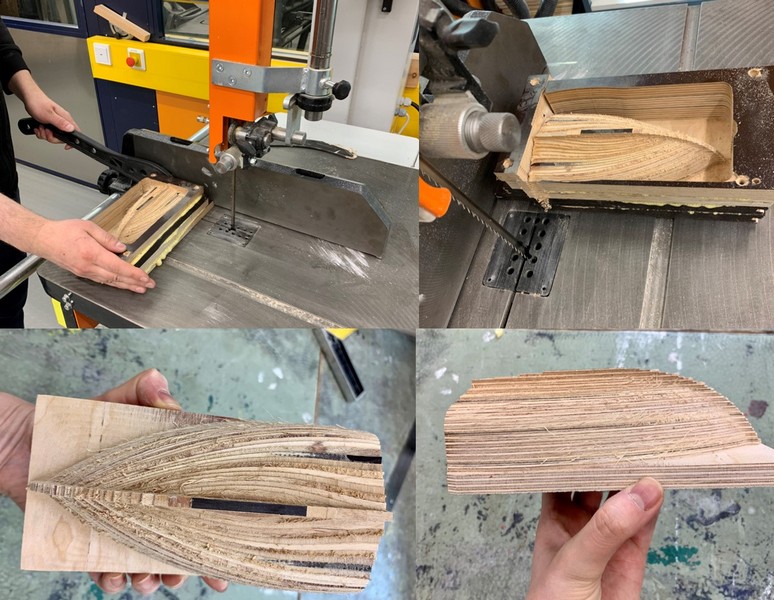

When milling was done, I did a couple of post-processing steps to make it completely ready for vacuum forming machine.

Figure 13. The mold after milling

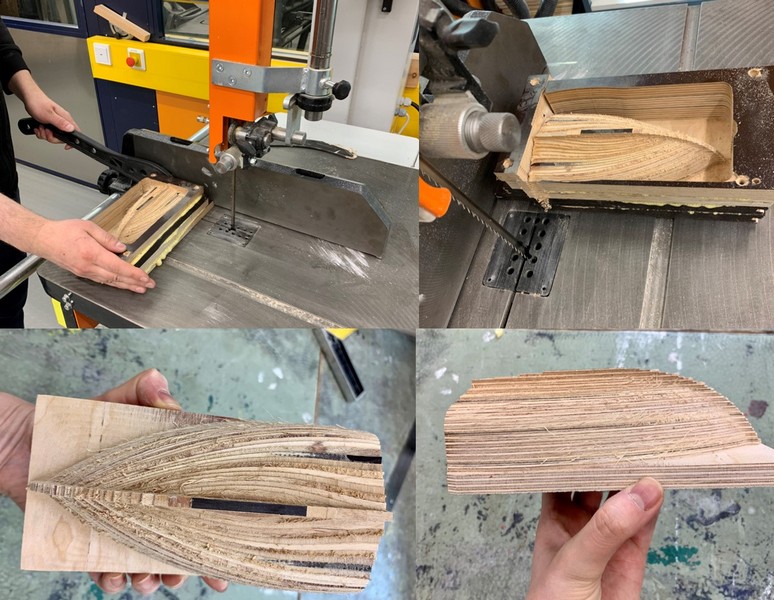

First, I used the band saw to cut extra parts of the mold.

Figure 14. Cutting the extra parts of the mold with saw

Next, I cut another board with the size that fit the machine's plate using circular saw for the mold support and make the vacuum around the desired area and glued it to the bottom of the mold.

Figure 15. Making the support board for the mold

Then, I made holes around the mold for vacuum and Ari suggested to try bench drill machine for that.

Figure 16. Making vacuum holes on the mold

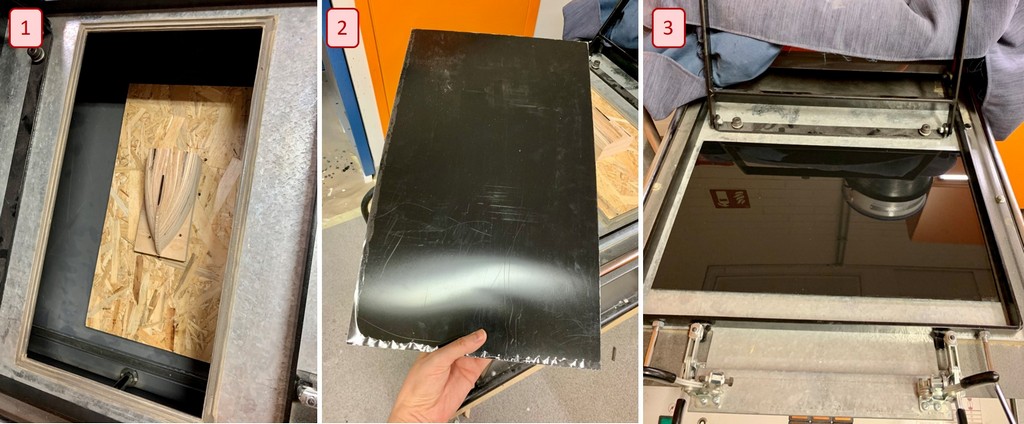

Finally, it perfectly fit inside the machine's plate.