3D SCANNING AND PRINTING

3D SCANNING

3D scanning has a lot of applications in my field. For architecture and design it is a very good tool to develope projects that need reality and virtuality, for example museums, shops, real estate agencies, etc...

Software and hardware

123D-Catch + Iphone

I have had some errors during using this software. First of all I took my pictures with artificial light and not very well iluminated. Also I had the object in my hand while I was taking photos. I should put iT in a table. Finally, all the experimen went wrong. You can see here the process:

.png" width="450" height="321"ALIGN="CENTER"

I tried also with this program making a 3D model with some renders of a chair. It has been impossible, I photos and renders don´t have the same information, you can´t construct 3D from renders in 123D-Catch.

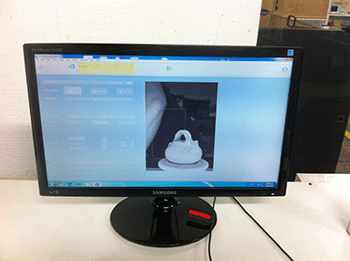

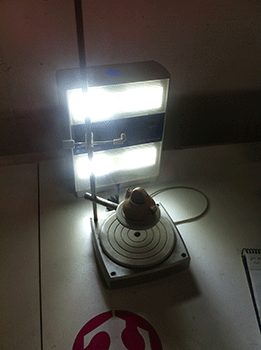

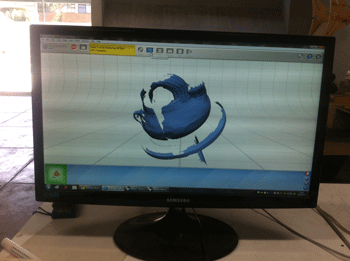

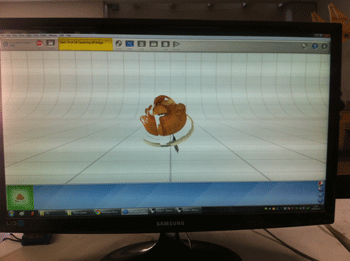

NextEngine software + NextEngine scanner

I think is quite good this scanner. The software is very easy and intuitive. The only step that I think is a little bit complicated is when you have to put all the parts together in the correct position.

3D PRINTING

This Assingment is perfect to prototype my final project. What I want to do is a pneumatic structure that changes its size by the pressure of the air. I have been looking soft robots and my work is based on the article "Elastomeric Origami: Programmable Paper-Elastomer Composites as Pneumatic Actuators" (Martinez, Ramses V., Carina R. Fish, Xin Chen, and George M.Whitesides. 2012. Elastomeric Origami: Programmable Paper-Elastomer Composites as Pneumatic Actuators. Advanced

Functional Materials 22, no. 7: 1376–1384.)

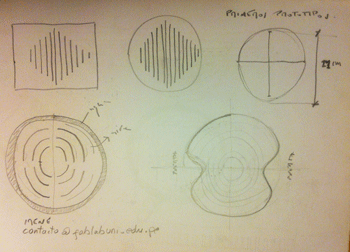

Soft robots can be understood as soft architecture if you change the scale. For me is very interesting the movement of this kind of robots and how can it be applicated to architecture. Dynamics architecture is a good way to explore a future where everything changes very quickly.

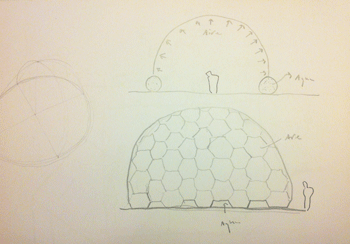

Here is a few drawings with the first idea.

The final prototype is going to be something like this:

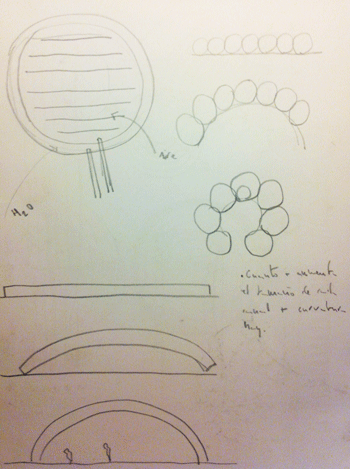

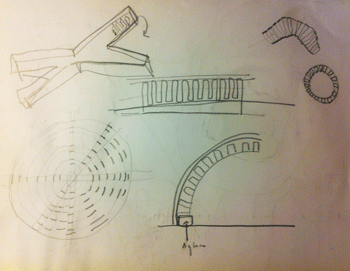

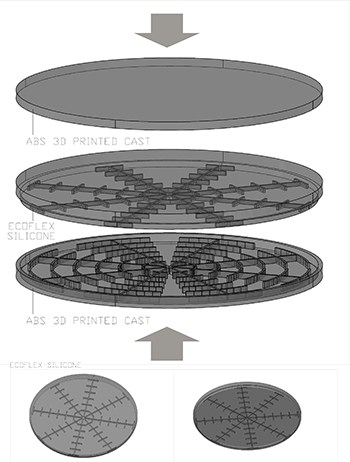

The first step is construct the cast, this assignment is appropriate for it. This is the scheme of the mold:

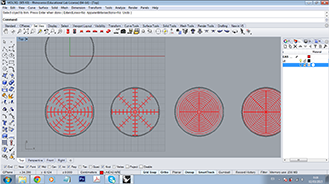

Software

I have use Rhino.

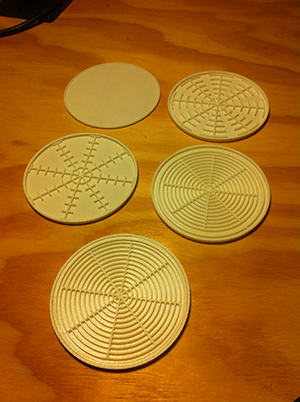

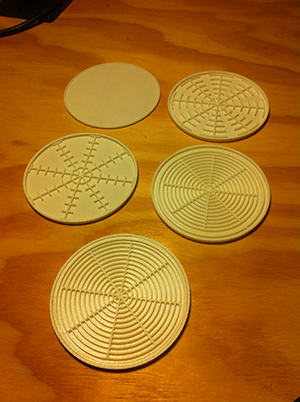

Here is the result of the first casts:

CONCLUSIONS Why I did my cast prototype with 3D printing?

This casts are small, diameter = 9 cm. I could do them with milling but I have realize that with 3D printer the process was easier. First you save time, with small pieces 3D printers are faster than milling machines. Second you save material, because with milling a lot of material is wasted in form of powder. In 3D printers you use all or almost all the material. And third, you save energy because the process is shorter.

For bigger sizes, from 20 cm of side or diameter, I think it is better to use milling machines. In this case they are faster than 3D printers, and so there are savings in energy. The problem is that you still lose a waste a lot of material.