MECHANICAL DESIGN, MACHINE DESIGN

For this week we have to design, fabricate, assemble and automate a machine. This week we have to work in groups. Our group is formed by two industrial designers (Wilhem Schütze and Luis Sierra) and an architect (Lucía Lucas). We have decided to make a CNC milling machine because Luis and Wilhem have special interest in this item.

Design

The authors of the machine are Wilhem and Luis. Lucía has

designed the box for the electronics and has done the documentation and the video.

The design is based in different DIY projects about CNC

milling machines. It is easy to find all the components used

in this project in anyone hardware store. The structure has

been made in MDF boards with digital fabrication. We have used also aluminum profiles to make the x y movement easier and softer. The working area of the machine is a standard size of 600x900

mm. This size has been chosen because is the right area to

fabricate guitars (body and mastil, separately).

The chuck system is ER11 and the motors are stepped motors

DEMA 23.

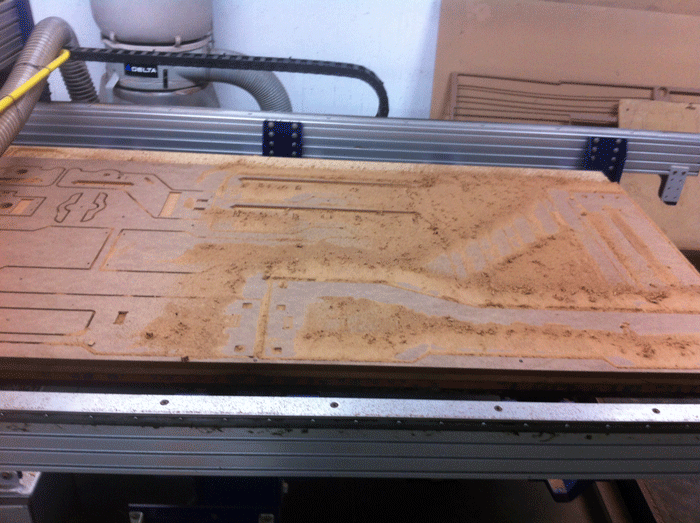

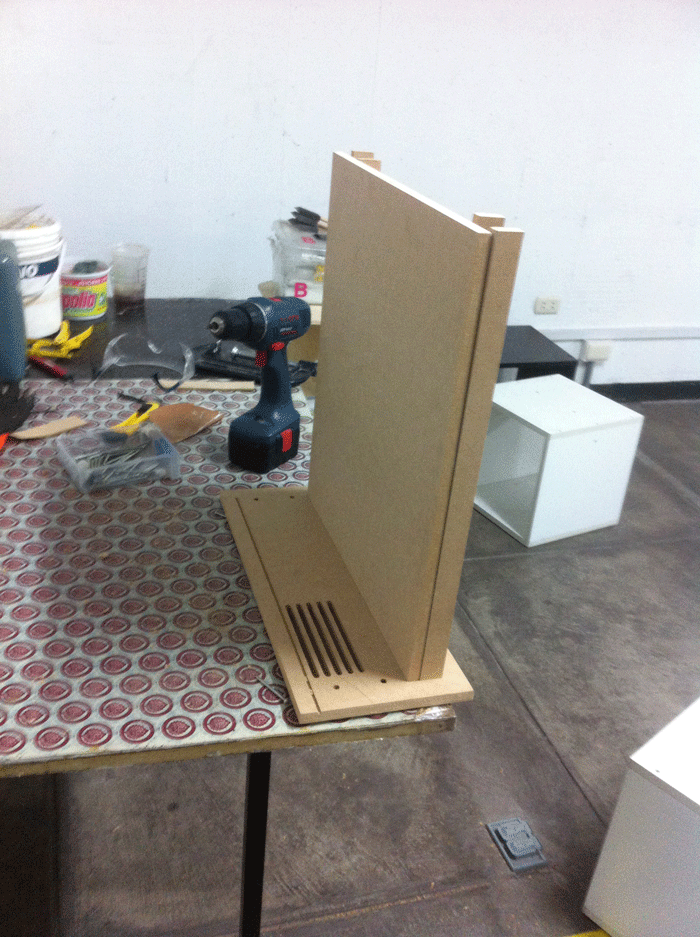

Fabrication

For fabrication we have used a ShopBot and MDF boards of

2,44 x 1.22 m. For all the pieces the machine has took 7

hours aproximately.

We had to make 9 different toolpaths for the ShopBot because

we had different ways to cut. The problem of that has been

that some holes weren´t cut. Finally we fixed it ordering

again the machine to cut the holes.

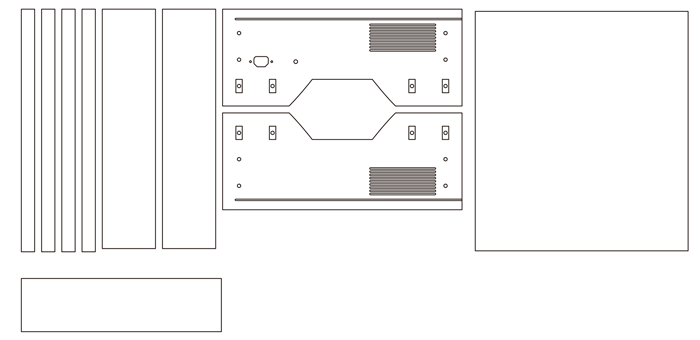

Machine drawings:

Electronics box drawings:

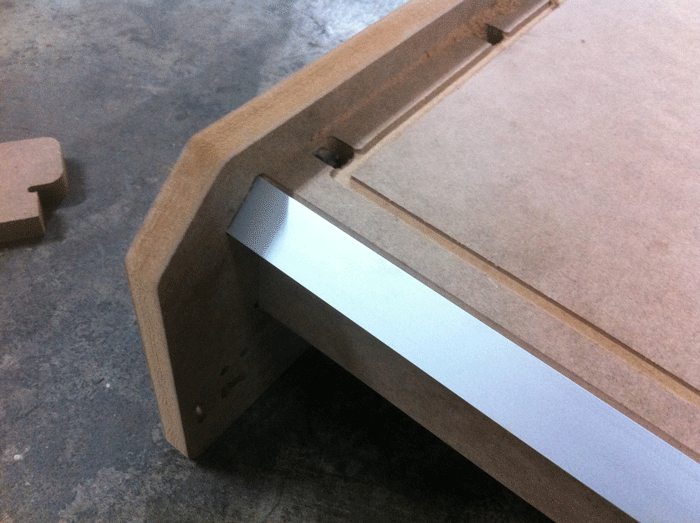

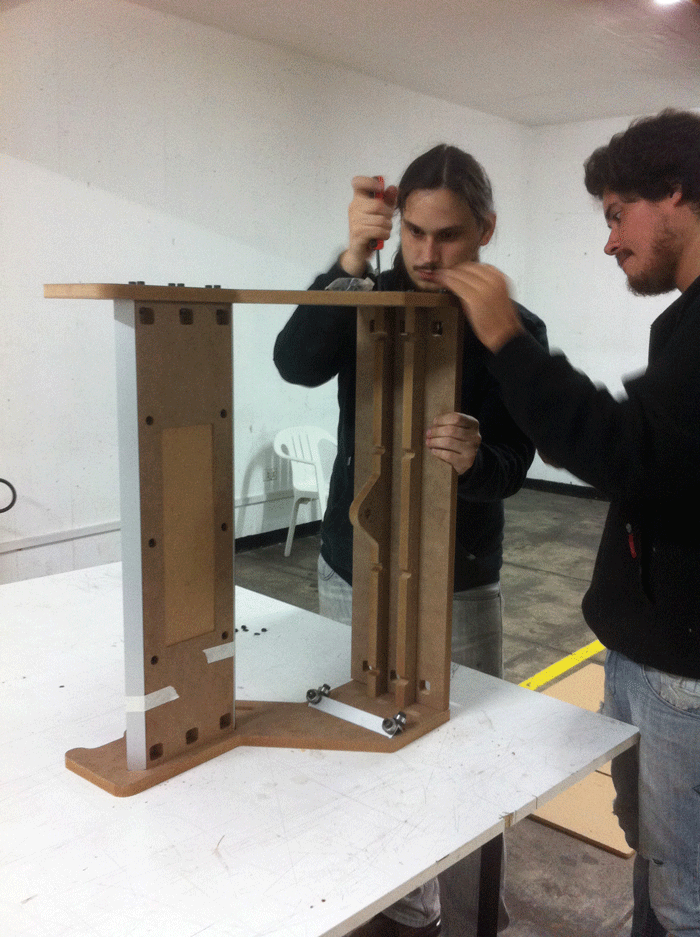

Assembly

The assembly between mdf pieces has been ok. We have

hadproblems assemmbling mdf pieces with aluminum profiles.

This union had to be almost perfect because the aluminium

profiles are the basis for the movement in X and Y. Other

problem has been the insert of other mechanical pieces for

the movement. Finally we could solve all issues as you can

see below.

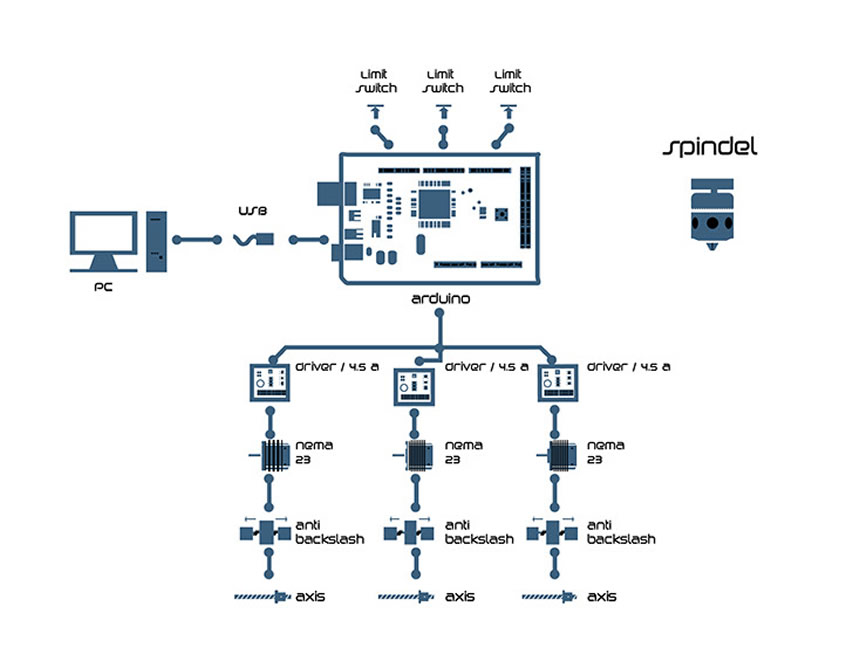

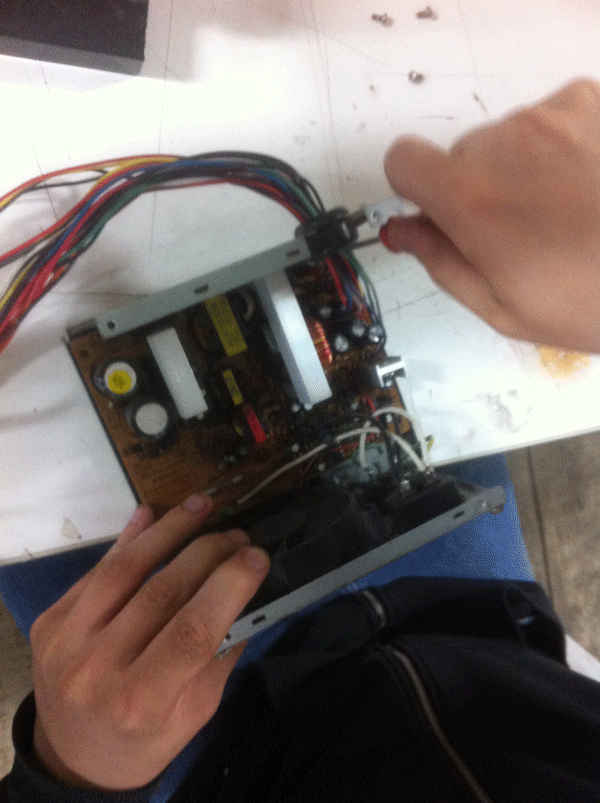

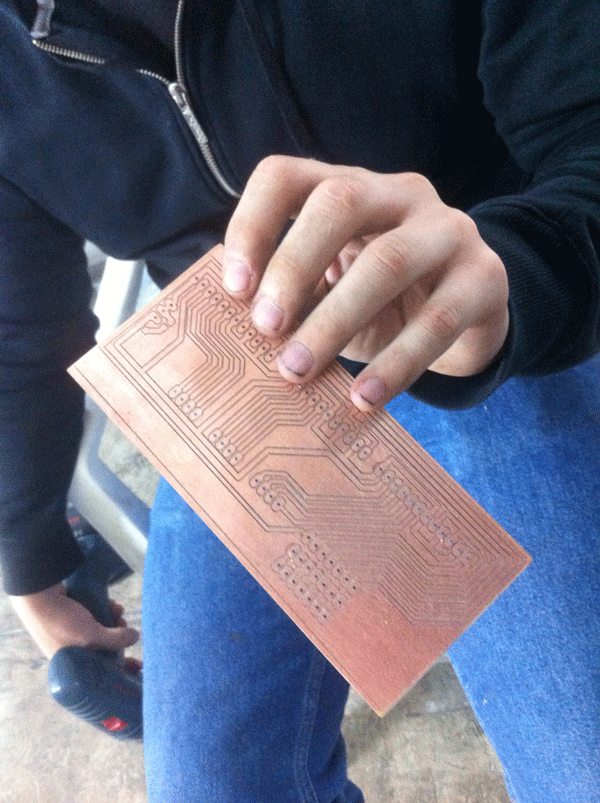

Electronics

We're using an Arduino board loaded with firmware GRBL, this is connected to 3 drivers TB6600, which control 3 motors NEMA23. We designed anf fabricated a distribution board, to facilitate and order the wiring. As a source of power we are using a computer ATX switching power supply 12v for the drivers, the feeding for the arduino is via USB, and the feed of the head, that is a spindel 300w is apart with a 31v source

G-Code Software We Used GRBL Universal Code sender, here is the project's site

Final result

You can see in this video all the process and the final result milling a block of wood.