NINTH WEEK ASSIGNMENT

|

|

|

|

Molding

and

Casting

Assignment

- Design a 3D mold, machine it, and cast parts from it.

- The first step is to create the 3D object for molding.

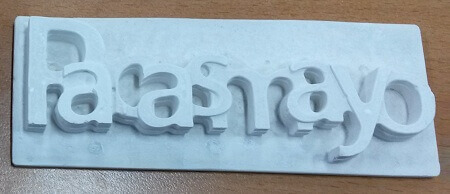

- The second step is to made a positive mold using industrial millable wax.

- The thirth step is to made the negative mold of the created object.

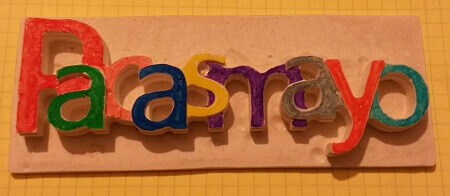

- The fourth step is to reproduce the initial 3D object in different materials.

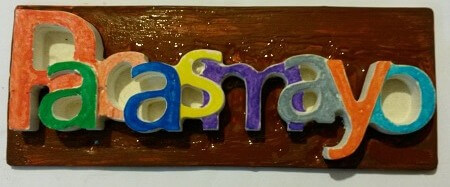

Pacasmayo, my hometown, is a touristic place, and the souvenirs that tourist can buy are mostly made out of pumice stone and soapstone. I have not seen any ornament with the harbor's name, thus my project will be to make a mold of the word "Pacasmayo" to create an ornament that you can place a magnet on and being able to put it up on the refrigerator's door.

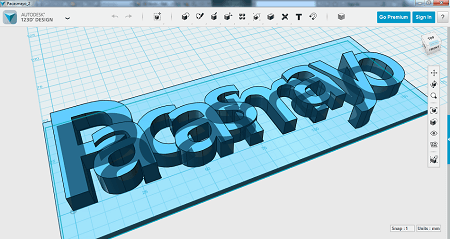

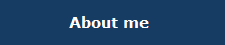

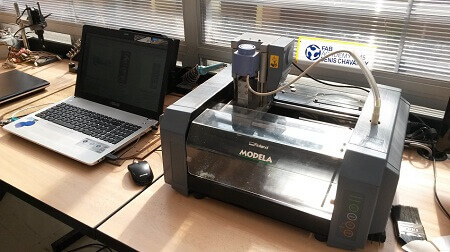

For this task I initially used the 123D Design program, exported the file in STL, and tried to work on MODELA, but it did not work properly. Following the recommendation of the instructor Jose de los Rios, I opened the file using RHINOCEROS. I missed to join all the meshes in the design.

When exporting in RHINO It is necessary to export files as Binary and not as ASCII.

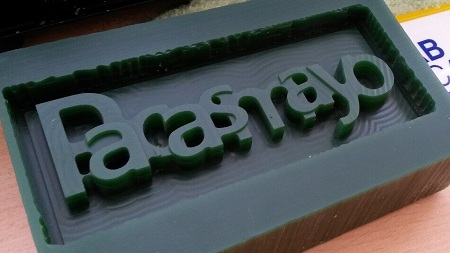

Here I show a screenshot of my design " PACASMAYO ".

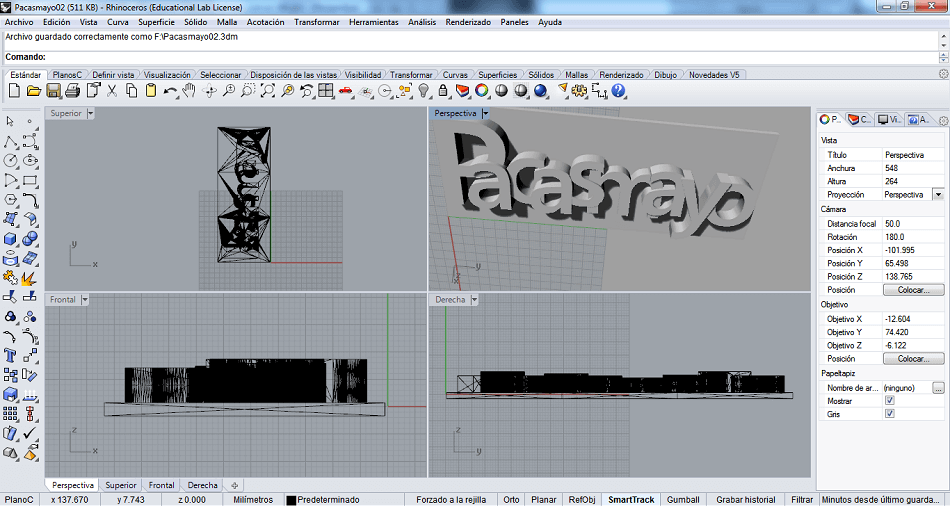

SECOND STEP. Make a positive mold using industrial wax. (Precision carving waxes)

As shown in the picture of the industrial wax KERR box, the specifications are:

"AccuCarve precision carving waxes are designed for the discriminating wax designer.

- Green - Hardest

- Purple - Medium hardness

- Blue - Regular Flexible Most)"

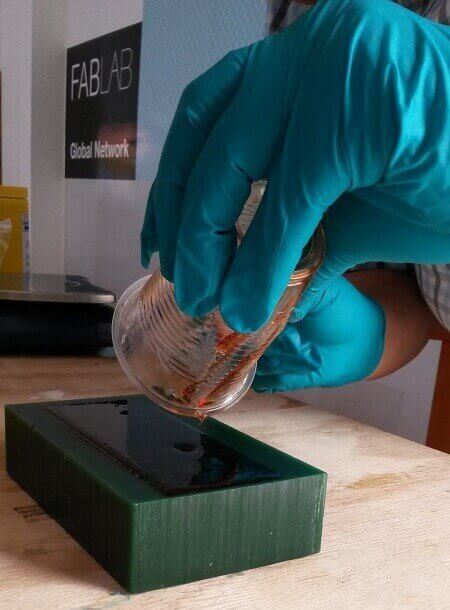

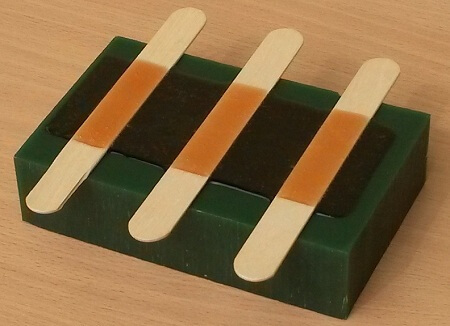

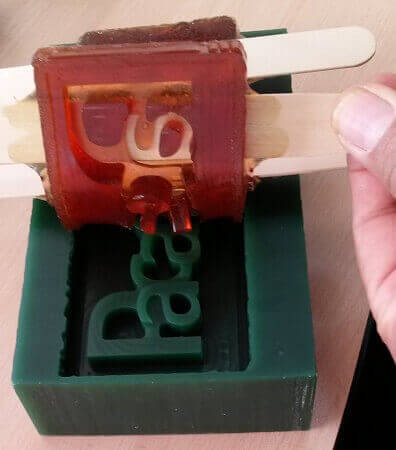

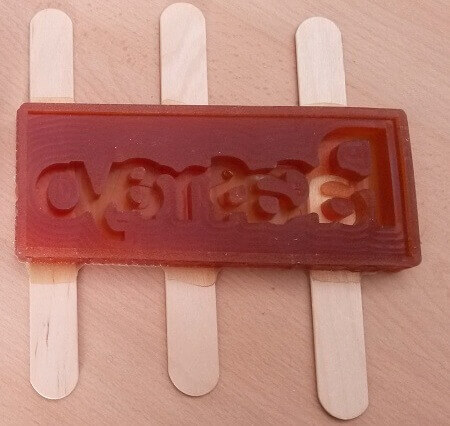

THIRTH STEP. Made the negative mold of the created object .

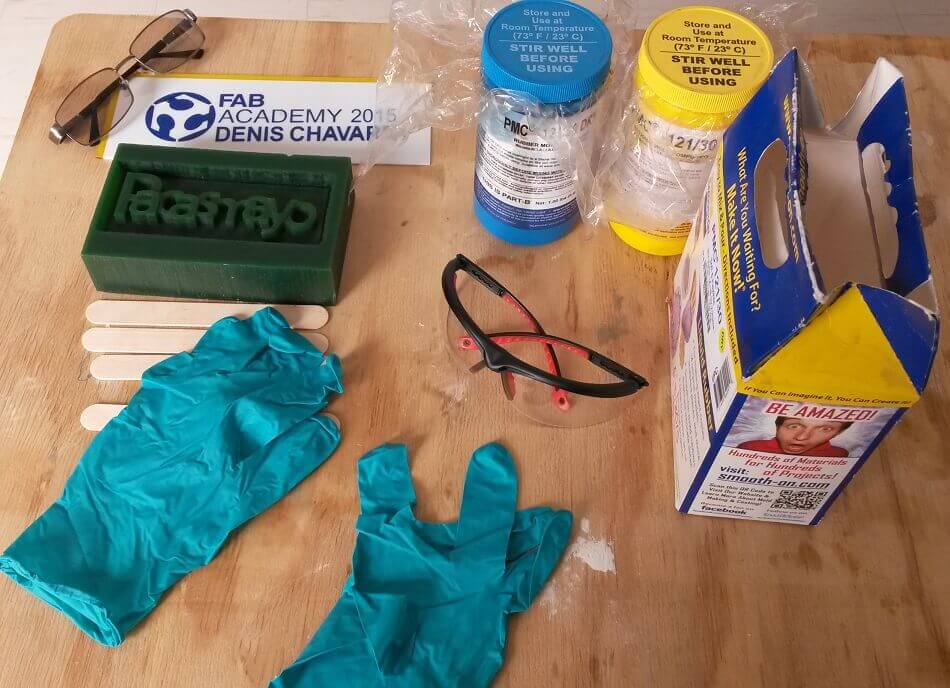

Tools and materials

One must have the right tools, and the appropriate safety equipment.FabLab TECSUP has in stock, PMC-121/30 (dry Urethane rubber), to make the negative flexible mold.

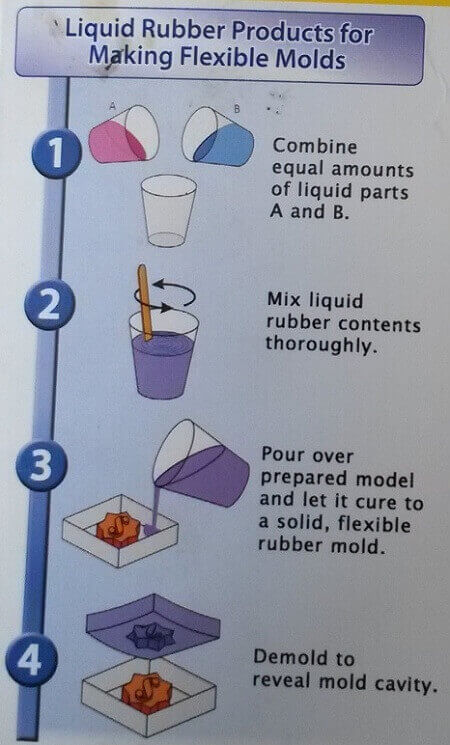

PMC-121/30. FLEXIBLE MOLDS

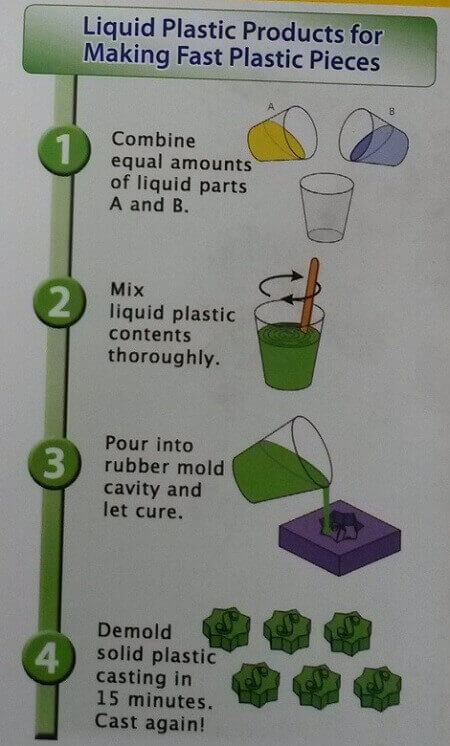

The product box details the steps to achieve a flexible mold.

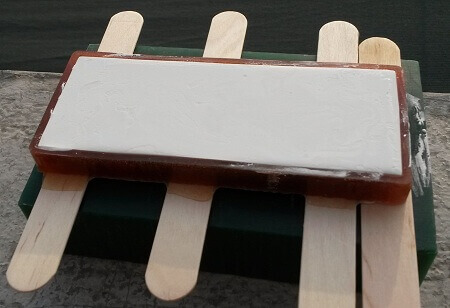

FOURTH STEP. Create the final object.

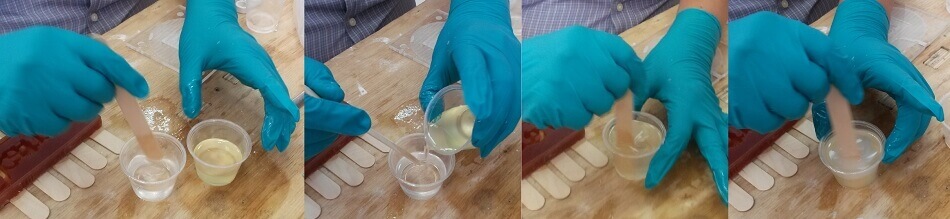

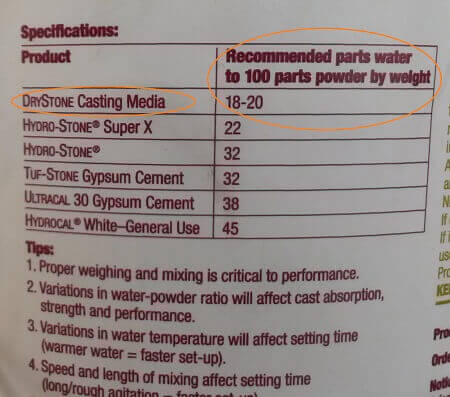

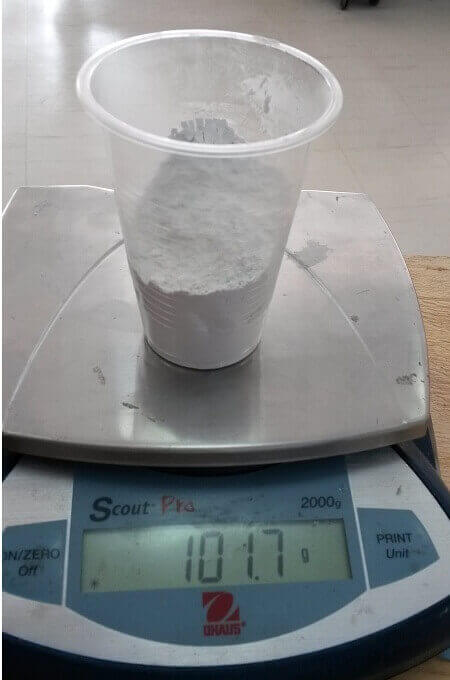

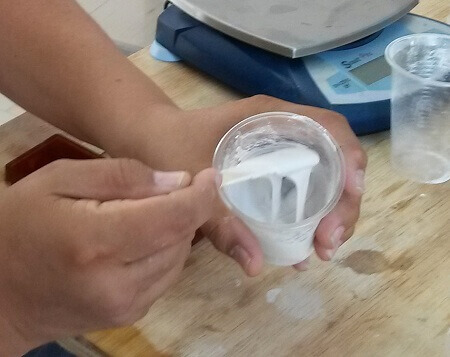

At this stage I worked with two different materials, one is the DryStone Casting Media, which is a very fine powder, and the other is Colomatch, liquid plastic Smooth-Cast 326.

DRY STONE CASTING MEDIA.

Smooth-Cast 326

The liquid plastic Colormatch SMOOTH_CAST 326,