Week 5. It's time for 3D scanning, printing and modelling. The task of the week was to 3D-print something that couldn't have been done subtractively. My idea is to make the impossible and push toothpaste back in the tube. For this I need a tube with two different inner diameters and two different threads. These custom threads would require two custom thread bits or CNC lathe. It wouldn't make any sense to manufacture these other than molding or 3D-printing.

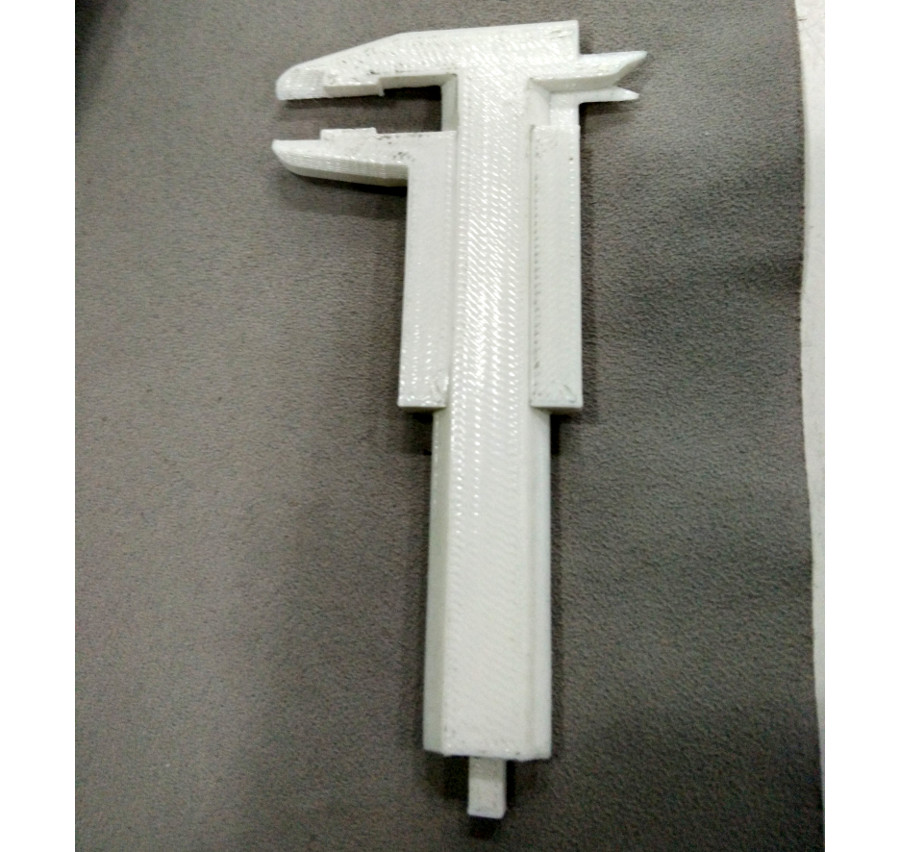

I couldn't find a Caliper, so first I downloaded one from Thingiverse and printed it. It came out really well! With a little fine tuning with a miniature file the fitting and functionality was perfect. The measured value in caliper must be compared with the ruler until I can figure out the way to add scale into the caliper.

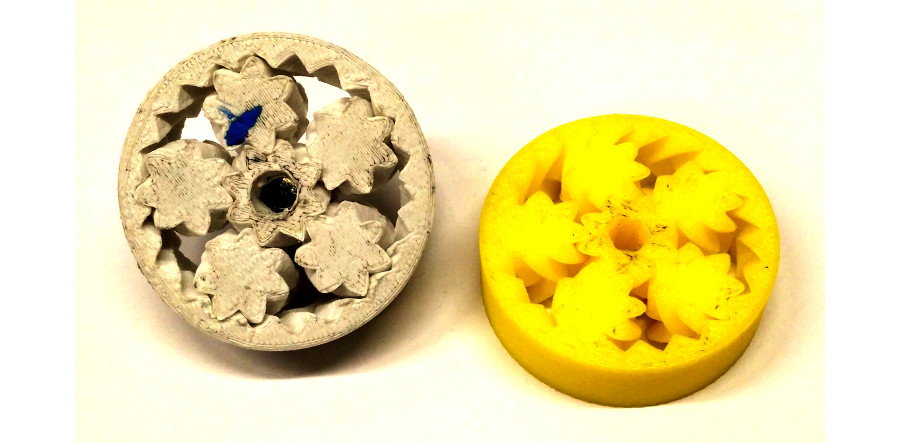

Also these herring bone bearings come from Thingiverse. The one on the left is the one I test printed with Makerbot. It barely moves. With adjusting the parameters just a bit, it would work. The yellow print on the left is done with Leapfrog earlier. It runs totally smoothly.

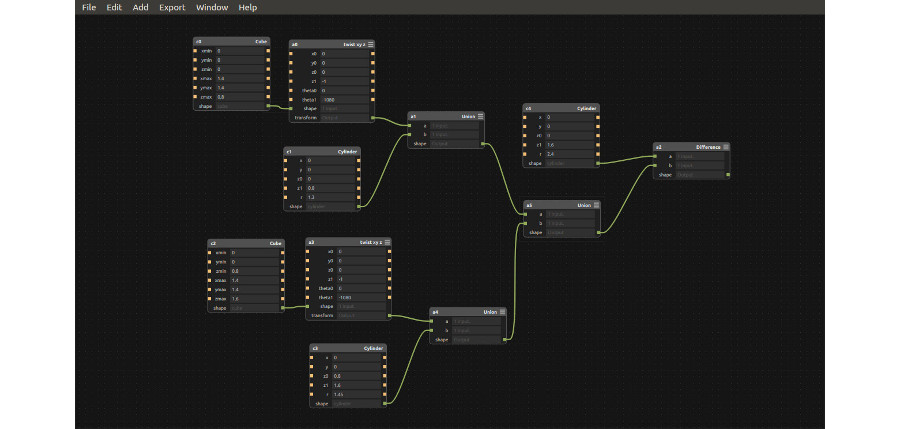

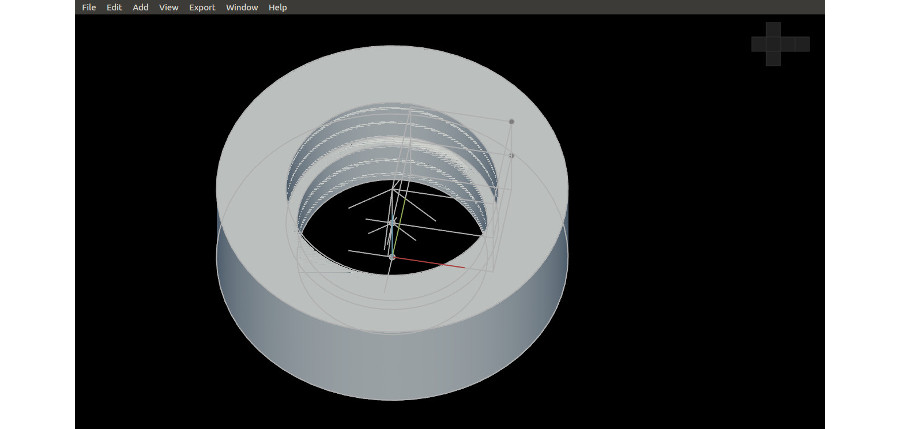

I decided to draw two sided cork with Antimony. The structure is shown in the picture below. I made the threads twisting two cubes and uniforming them with two cylinders. Finally, this object is subtracted from a bigger cylinder leaving a tube with two different ends. The lower picture shows the image in Antimony.

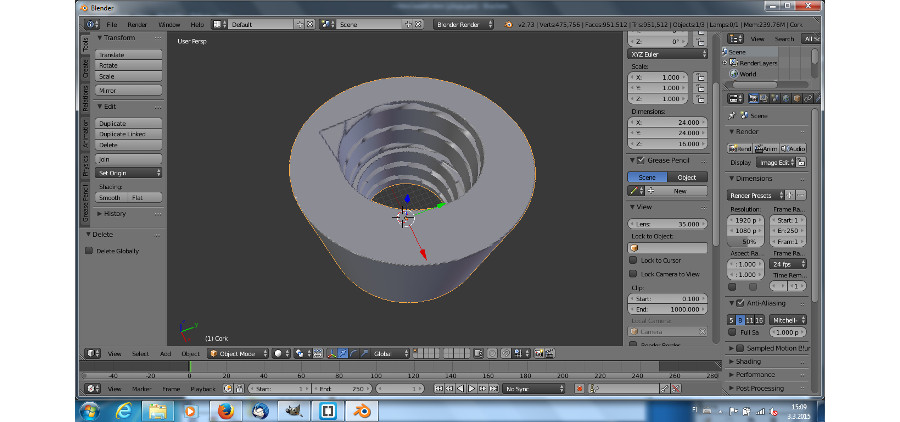

I checked the exported stl file in Blender just to be sure. It turns out, the drawing must be scaled. Generally, it would be scaled by ten, but since I made an error in Antimony mixing the diameter and radius, I had to scale x and y only by five.

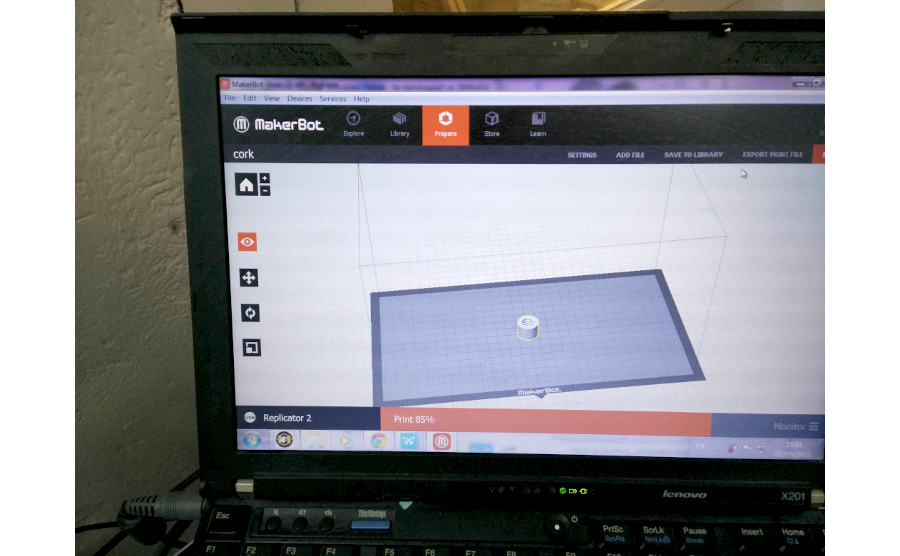

The stl file is sliced for printing with MakerBot Desktop -software No raft, no support, full fill, 230 degree temperature for PLA and basic speed.

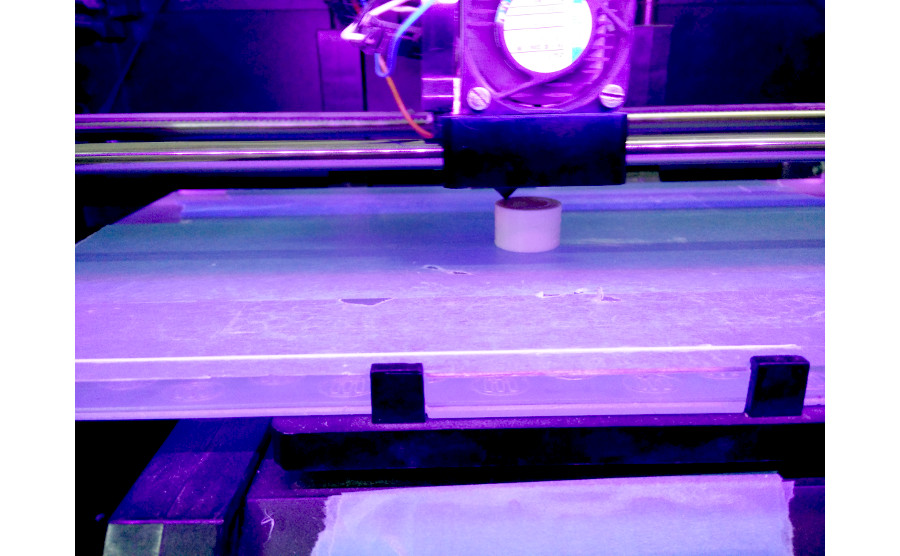

The printing is going on. The printer works amazingly well again.

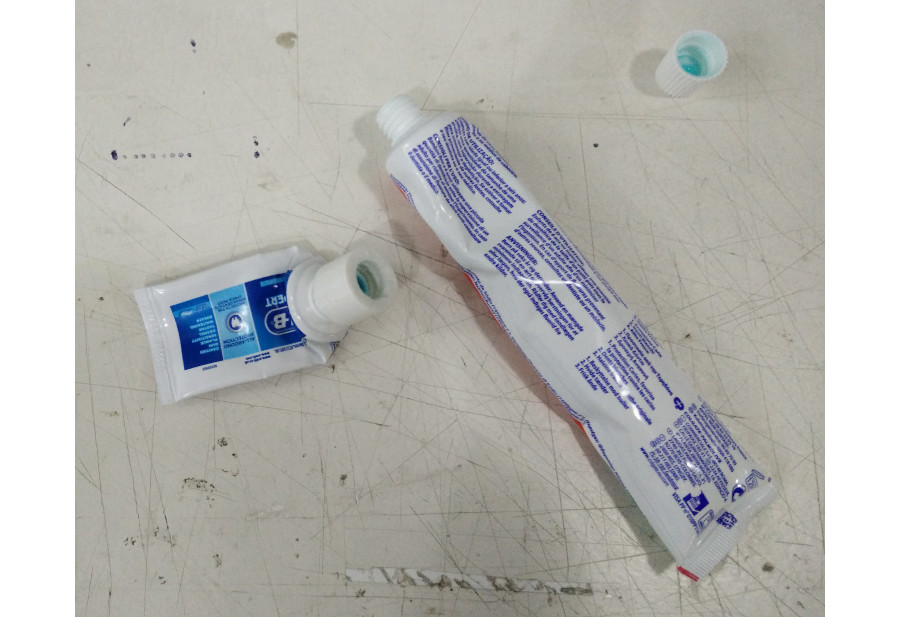

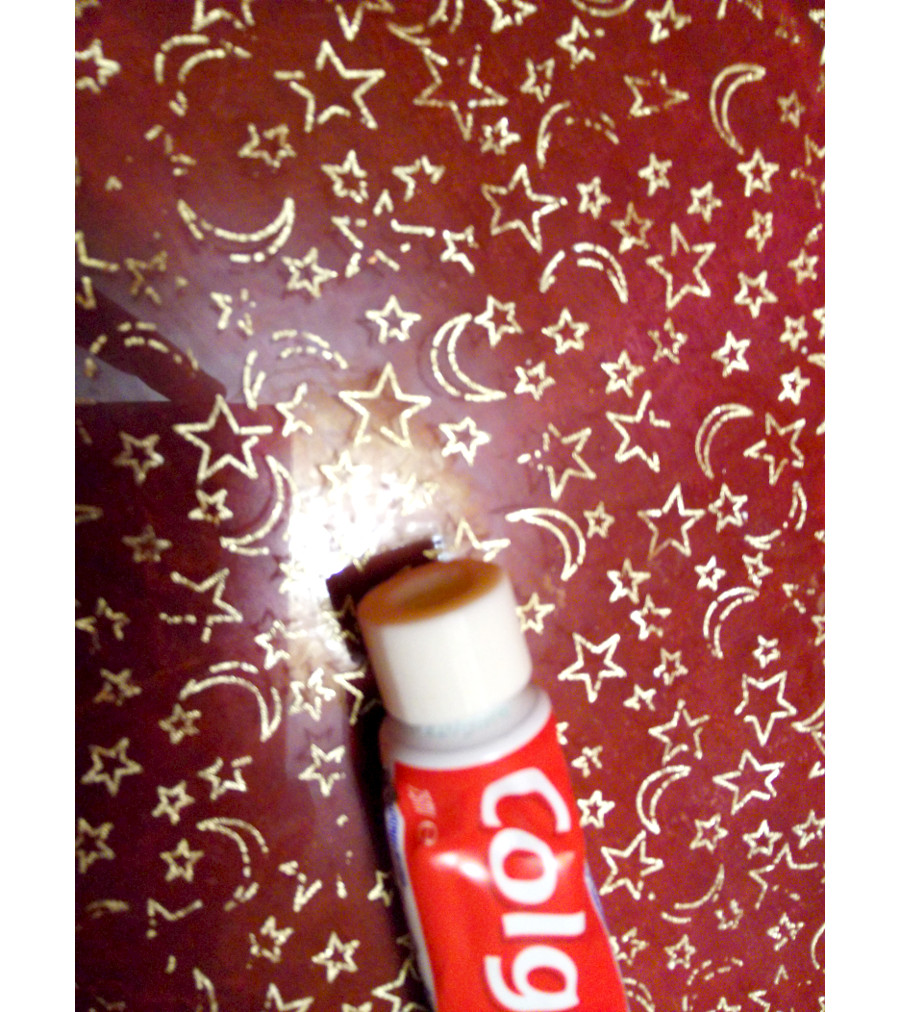

It turns out, I first printed a wrong file. Fitting a small tube of toothpaste by force broke the tube. I was still able to refill it from a bigger tube.

After printing the right file, the cork fits perfectly!

I also 3D-printed a couple objects for the surf board. First I downloaded a model from thingiverse of a thing I thought was a fin box for FCS. I printed it with Makerbot and realized it was probably an adapter for attaching the FCS fin to the long board. So I took the measurements for FCS and draw my own version of FCS Fusion fin box. This one I printed with Ultimaker. The measurements were incorrect. The distance between pockets is faulty. I also draw and printed a leash box. I have added a fillet to the leash box and screw holes to the fin box after printing.

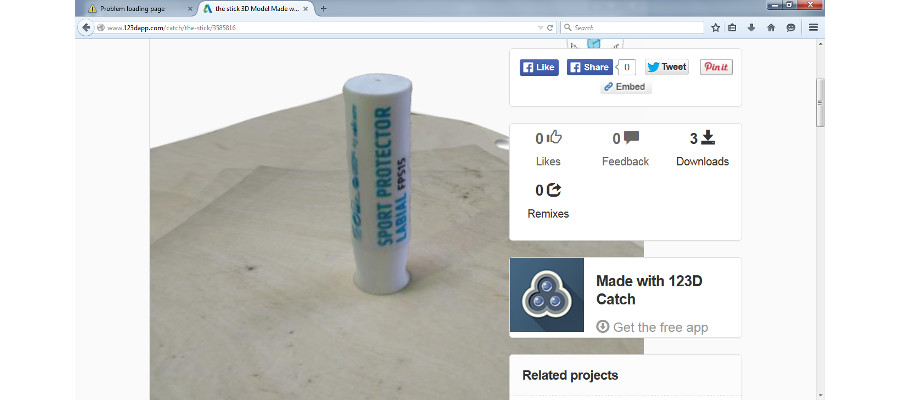

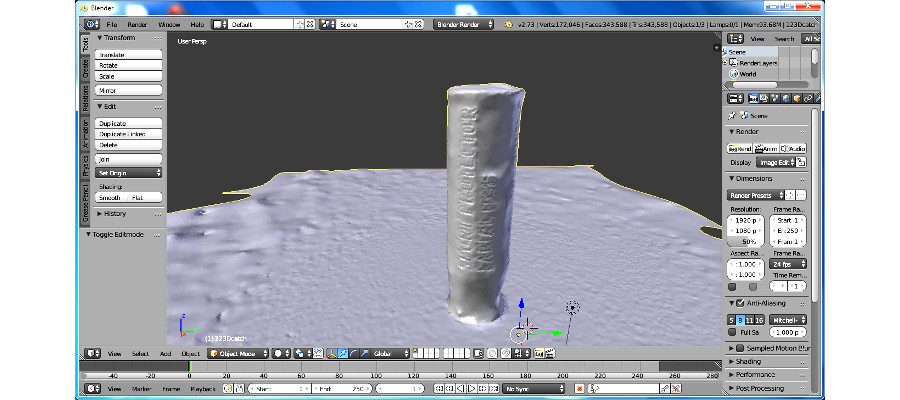

I made a 3D-scan using 123D Catch for android, but first attempt failed after processing a few hours. The second one with a smaller and simpler object worked well and formed a very nice 3D picture.

It also opens in Blender when imported as stl. There is no reason to print this though.

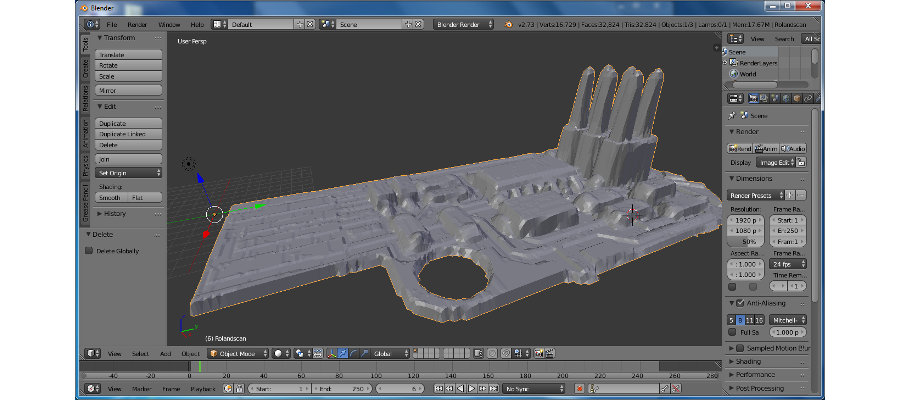

Last, but not least I learned to scan with Roland Modela

And scanned whole body with KUKA robot and Kinect, but unfortunately after scanning the computer crashed. I had opportunity to drive a huge industrial robot scanning Taichi though!