Machine Inspiration

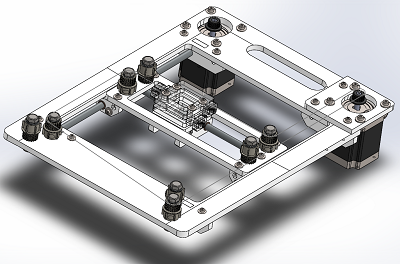

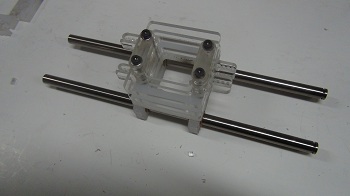

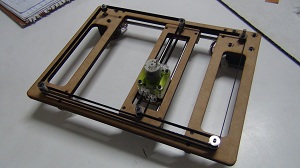

The original machine is the Core XY. This machine is one of the simplest cartesian CNC platforms.

It has two cars that slide in X and Y axis, the Y-car moves inside the X car. The actuators are two stepper motors that moves two belts that are connected to the Y car. A set of pulleys generate the a composition of movements.

How it works?

When the two motors move in the same direction and at the same speed only the cars moves only in Y axis, then if the two motors turns in opposite direction, the cars moves only in X axis. The combination of this two conditions generates all the movements of the machine.

(Re)Design

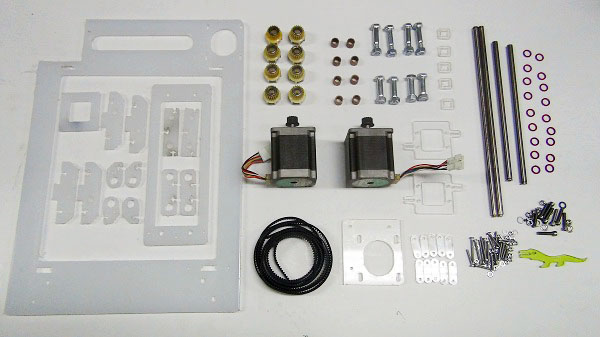

It's easy download the part list from the web site, then make some clicks in the internet and buy online the components.

But here in Peru is almost impossible, because we don't have this kind of services and the import process take too much time. So that, normally we have to go to local markets (sometimes flea markets/yard sales) and look for the components, sometime are from second hand or recycle from trash machines.

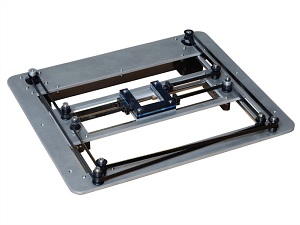

Under this conditions, we normally start the design by looking in local markets, and then with that parts, start the (re)design with the local components. Download CAD Files here.

Materials

All the machine parts are used (second hand). Are recycled from old copy machines

Fabrication process + Assembly

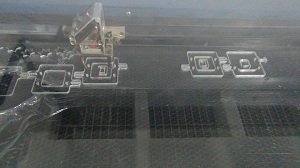

The platform was manufacture using laser-cutter and milling machine.

The laser cut pieces are the machine header (with the belt clamps and spacer), the motor support plate and some washers for the pulleys.

The laser cut pieces are the machine header (with the belt clamps and spacer), the motor support plate and some washers for the pulleys.

Also we use the laser cutter to cut the original pulleys, to remove a lower big gear attached to the upper timing pulley.

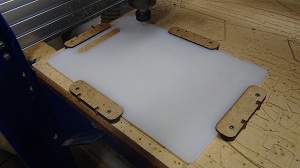

The milling pieces are all the structure of the machine.

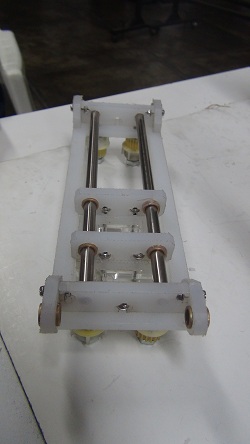

X-Car Assembled

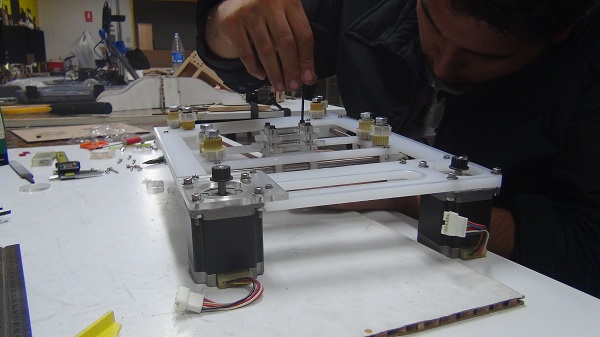

Stepper motors assembled |

The Y-Car Assembled |

We couldn't find the correct bolt length in local market, so we had to cut the bolts to the correct length

Final adjustments before installing the belts

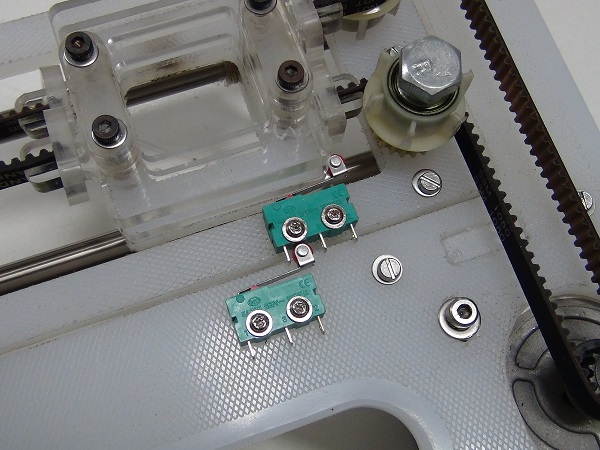

Limit-switch solution

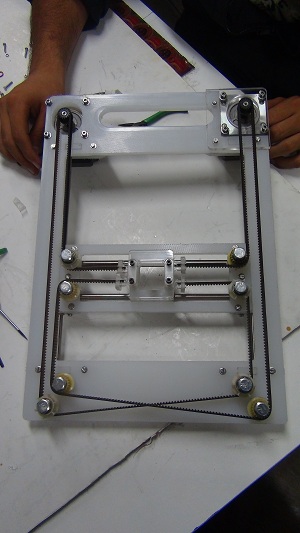

Without timing-belts |

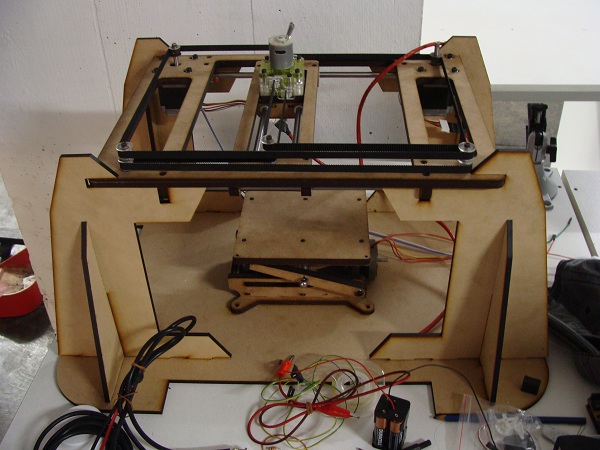

With timing-belts (assembly complete) |

First Testings moving the motor axis by hand.

Testing

Connecting the electronic motor driver to made some test

Testings with electronic control board.

NOTE: We continued developing this machine. More information an pics [here]

The principal upgrade has been the Z-Axis table, with a scissor mechanism that made it collapsible and less bulky if you want to transport it. You can download CAD files here.

For these CAD files you can go to Computer-Aided Design Assignment.