I am a bicycle rider, also I have a smartphone, I see in internet lots of smartphones racks for bicycle. I test a pair of this comercial racks and are awful, so I decide to create my own using composites.

Materials & Equipments

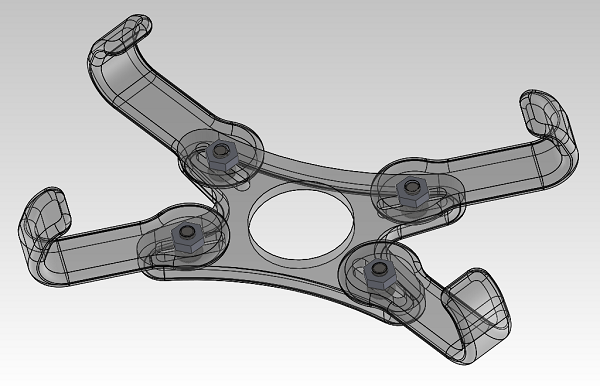

The design

The design consist in a core where four arms will connect to create a claw. The core will be fixed to the fork steerer tube with the fork cap. The dimentions fit the 1 1/8" steer tube (the most common size for mountain bikes).[.STL Files]

The core mold the Modela Player software |

The arm mold the Modela Player software |

The mold

For the mold I used the Roland Modela to mill the negative of the molds. The arm mold has a two half parts. The real mold will make of urethane that normally take 12 to 18 hours to cure in our winter weather.

The two half mold has one hole to fill the resin and other hole to place a M4 bolt that support the nut that will be embedded inside the resine matrix.

The composite

First I made some tests with poliester resin, because it need a pair of hours to cure. Also I made diferent combinations of resin and glass-fiber, and diferent process.

After this first tests with polyester I start the work with Epoxic resin. I notice that the epoxic resin is more viscous, so first I wet the fibers and then I put it in the urethane mold, finally I pour the resin to fill the mold.

Final comparing the results of diferent process the better for the epoxic resin and glass-fiver, is first wet the fiber then put in the mold and final fill the mold with the resin. I don't recomend the polyester resin because it cure too fast for this kind of process.

For the two half part mold, I recomend to fill the two parts with the technic of the last paragraph, then close it, and final inject some resine with the syringe to fill the posible void spaces in the union surface.

|

|

The final parts before and after the deburring

Result & Testing

The rack installed in my bike

The rack and cellphone installed

Test in the street