We can fabricate Machinable Wax in our kitchens, mixing only paraffin wax (used to fabricate candles) and low density polyethylene (LDPE) in my case I used food wrap film.

Considerations:

The high density polyethylene (HDPE) used in plastic hose or liquid vessels are bad for our purpose. There are more dificult to melt.

The temperature to melt the paraffin is 47-64°C aproximately, but to melt the LDPE film you will need more, near the 110 to 120°C. Personally to acelerate te melt down process I heat up to 160-170°C. I used a thermometre (thermocouple) to monitor the temperature, but a cooking-thermometre are enough.

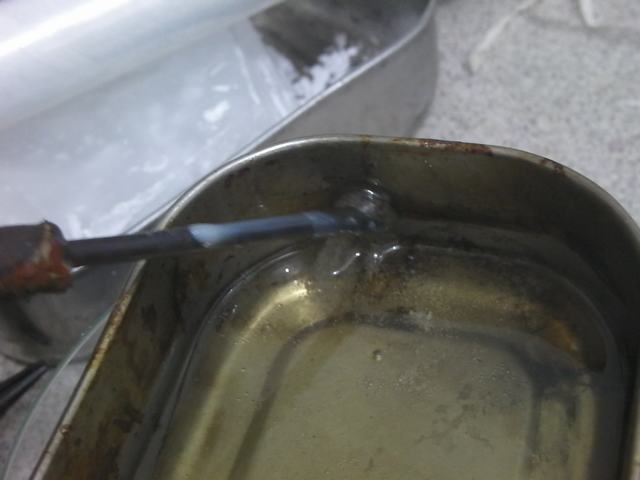

If you notice that the film it don't melt, don't heat up, you only will burn it (see pictures bellow), see the photos. In the market are two kinds of food wrap films. Not all are made of LPDE, some films are made of PVC, Do some test with diferent tipes of wrap films; the LDPE films are stretch least than the PVC films.

If you have a scale (if is digital better) use it to weigh the paraffin and the polietilen film. If you don't have one you have to pay atention when the liquid parafine is saturated with the melted polyethylene; you will notice that the plastic film don't melt (see pictures bellow), the proportion is aprox. 80% of paraffin and 20% of LDPE.

Precautions:

The wax will reach the flame point with the boiling, so it's posible get in fire when you are mixing, NEVER USE WATER TO FIRE OFF THE HOT WAX. Cover the recipient with board or something fireproof to cut the oxigen supply of fire.

Do that in a ventilated ambient, because the wax vapors are inflamable.

The process: Is very simple

| 1.First weigh the paraffin, I used 50g for testing. |  |

| 2. Weigh the LDPE, in my case I was testing the proportion, so that I first weigh all the LPDE film, and in the end weigh it again. |   |

| 3. Melt down the paraffin inside a metal resipient. I put over the oven covered with copper layer to distribute the heat (If you prepare more you don't need these copper layers) |  |

| 4. Add the LDPE when all the paraffin is liquid. I do it in pieces to notice when the paraffin was satured with LDPE. |  |

| 5. Wait coll down the mix. Now you have cheap Machinable Wax. |  |

Cost: Is really cheap

Considering that my paraffin wax (500g) cost S/.5.00 ($1.75).

For 50g of paraffin y use 13g of wrap film and 1Kg of LDPE in roll cost aproximately S/.10.00 ($3.50). So for 500g I will need 125g, doing a simple proportion calc S/.1.30 ($0.45)..

Considering the gas used to heat in S/.1.00 ($0.35), the total cost of 625g (aprox. 830cm3) of Machinable Wax is S/.7.30 ($2.56).

In the internet we found 860cm3 of Machinable Wax in $25 [link], so it's too cheap fabricate our own wax

*Special Thanks to Carlos_Pedreros and Luis_Sanchez for their experiments "How not to do Machinable Wax", that served me to complete this manual.