|

Week11: Composites

Lets take a break this week making some composites materials. Some creativity and a vacuum and thats all we need :)

What is a composite

Composite materials (also called composition materials or shortened to composites) are materials made from two or more constituent materials with significantly different physical or chemical properties, that when combined, produce a material with characteristics different from the individual components.The three ingredients necessary for cure are heat, pressure, and

vacuum. All three are mandatory for prepreg layups; only heat is

required for wet layups, but pressure and vacuum always result in a

better laminate.

Materials

I choose the LINEN as the fiber and RESOLTECH 1040T (from a spanish vendor)

as the matrix, a high temperature epoxy. This epoxy is conformed by two

products, which allow to get different working time. In Fab Lab Leon

we used 1040T + 1048N, mixing it in a 100 x 30 g of respective

component. With this mixture, as the instructions says, we have 20

minutes working time (tiempo de gel) until the product get to his

higher temperature (more than 90º).This was the

first time the Fab Lab Leon works with composites, and we have to make

a test to see the correct parameters, how to get a vacuum bag and how

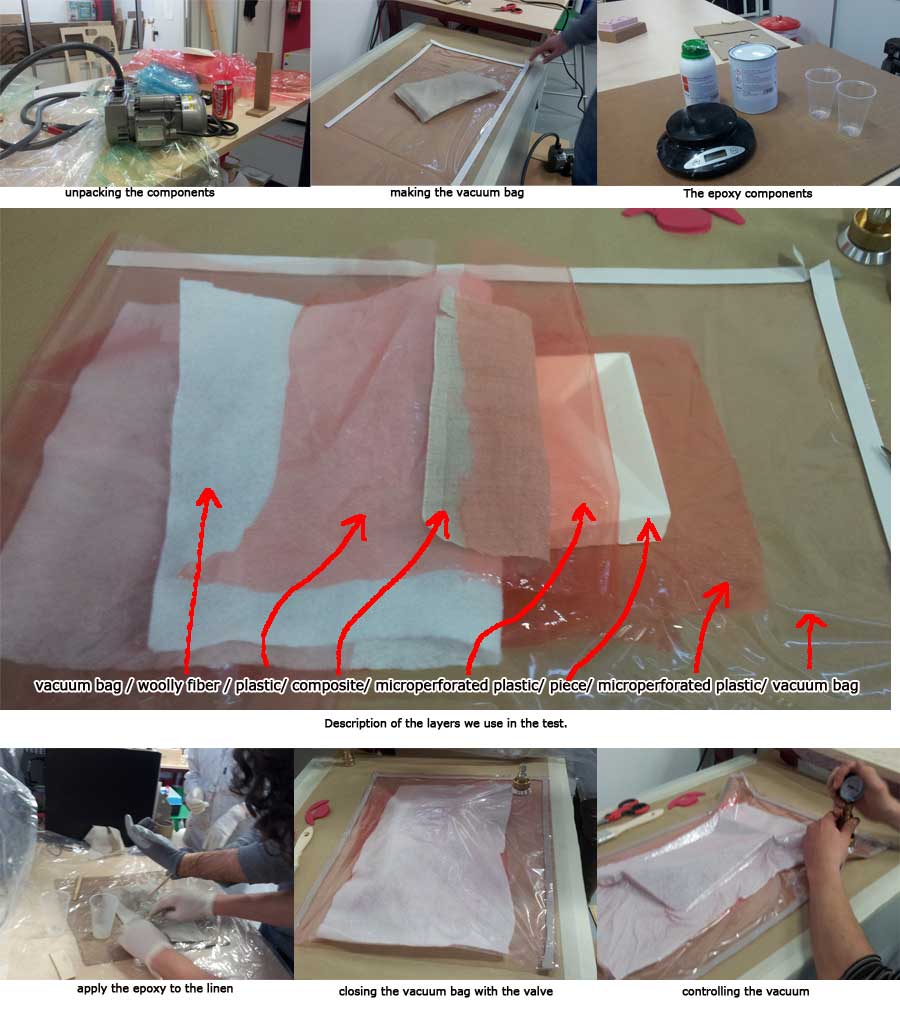

many time to leave the pieces until it was completely cured.As the especifications says, the Resoltech 1040 could be used with or without post-cure time. Doing our first test To help us in the testing time, we have a great friend of the Fab Lab Leon, Alejandro (watch his fabulous hand-made creations), which help us in all the process:

After

all this process we have the vacuum machine several minutes, until the

preassure was stable. But we realice that the vacuum bag wasnt really

well closed, and some air goes inside the bag. The bag has sticky

rubber in all the edge, and we press again all the perimeter of the

bag. After this the tressure still going down...so we repeat the

process until we have a lower loss of pressure. Finally we can stablish

the pressure in 15 inHG, which are about 7psi.

1inHG = 0.49115 psi14,7 psi = 1013 mBar

We

left the bag all night with the manometer, and at the next day, after

about 12 hours, we apen the bag and have a resistent film of composite

with the form of the piece.

Making my own piece of composite

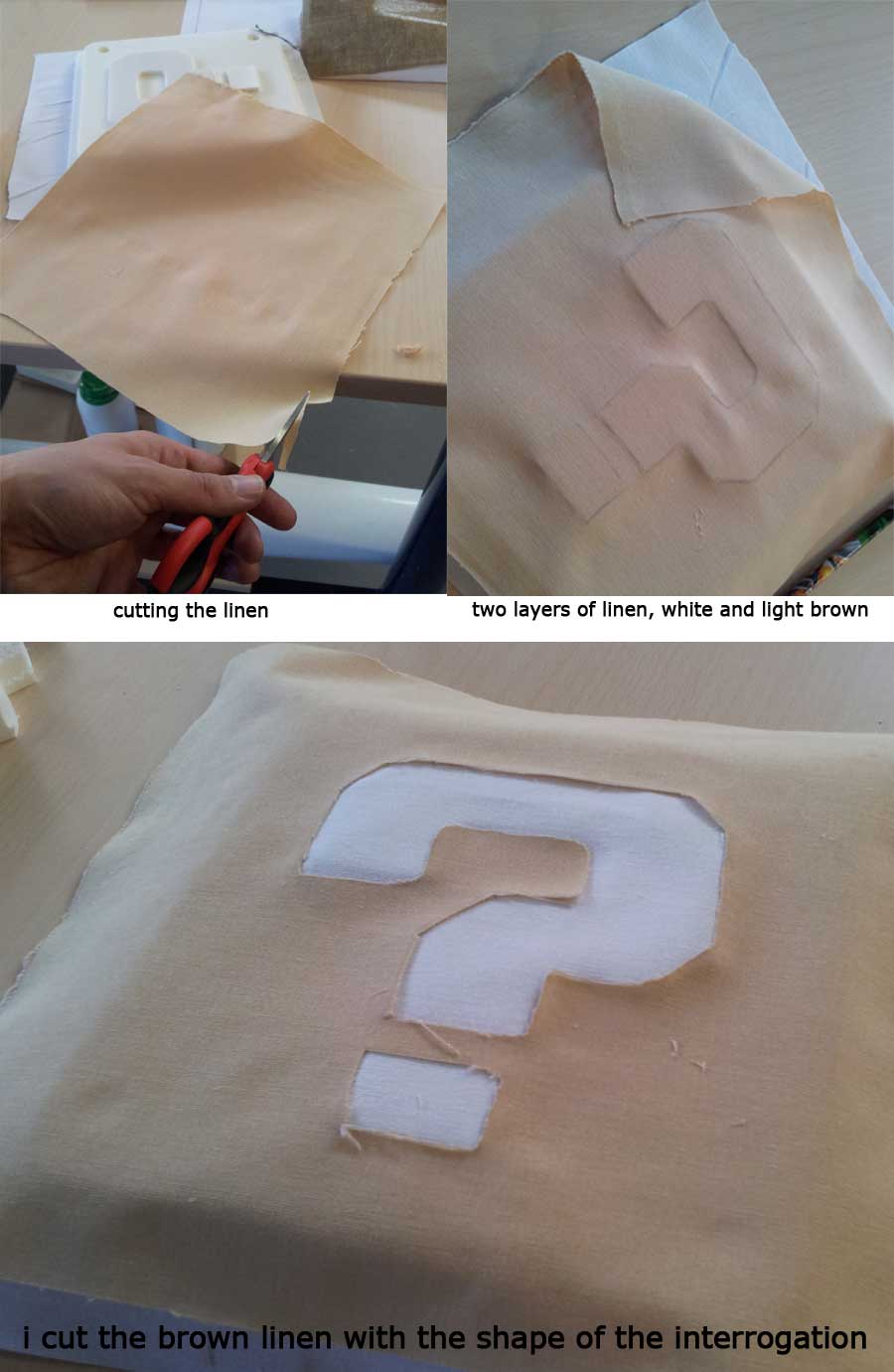

After

this test i started to do my own piece of composite. For this time we

have to design a 3D model and make a composite, so the first step was

to design and mill a 3D form. I use the Super Mario coin box as

inspiration.

Then i do the model in Rhinoceros and mill it with the CNC machine.

I mill a piece of foam of 3 cm width. I just do a desbaste pass, with a 6mm plain foam end mill.  Now

that i have the piece, i cut the linen to fit the piece. I want to do

this piece with tho linen colour. The white linen will cover the whole

piece, and the light brown linen will only cover the box, so i

have to cut the linen with the form of the interrogation. Our laser

machine is being repaired, so i must do this with scissors.

Now we prepared the vacuum bag to get the components. Javier Contonente, Ruber Ferrero and I used the same vacuum bag.

Presenting the pieces with all the layers...

Making the mixture of Resoltech 1040T + 1048N ( with a proportion of 100g/30g ) and applying in the linen.

Making the vacuum.

The

final result: the composite on the left and the piece on the right. The

composite had some striations, due to the bad cut of the linen (that

don fit in the interrogation) and the plastic over the composite, which

dont fit exactly over the piece. A bad vacuum bag seal could be the

cause.

The composite in its final position, covering a led light (the photo dont catch how good it looks in my childs bedroom)

PROBLEMSThe

main problem was the vacuum bag. It always loose the pressure after

20-30 minutes. The Bag Sealant Tape dont seems to fit perfet with the

vacuum bag, and it make some little canals of air which allow air to

come inside the bad. Maybe a best sealing with two pieces of BST (one

in each side of the vacuum bag) could solve the problem.

|