Molding and casting

This weeks assignment was to create a mold and make a cast out of the mold

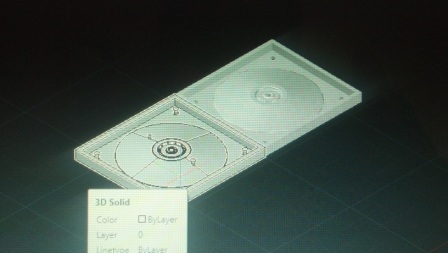

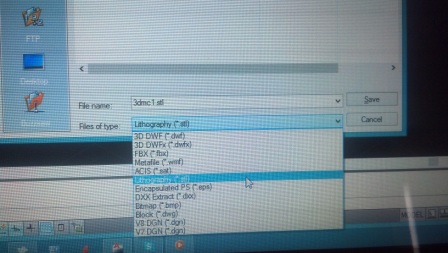

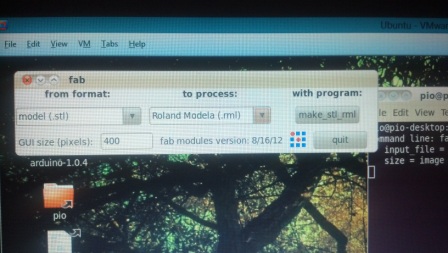

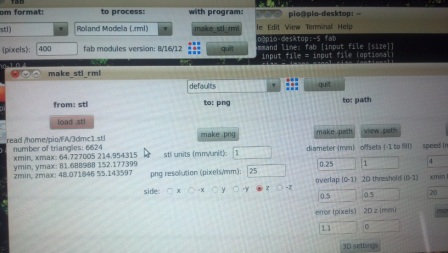

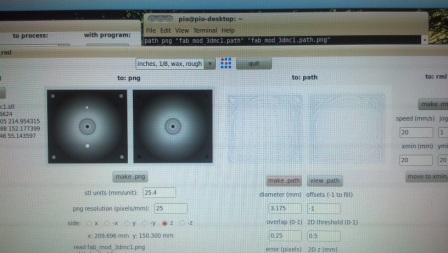

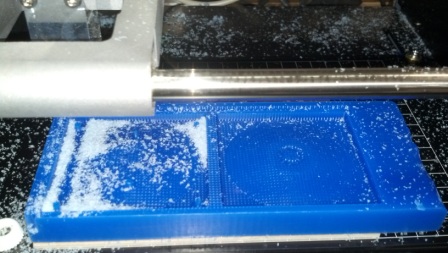

I started this by making simple 3D sketch using the AutoCAD program. After getting my 3D drawing, I saved it as an STL file and then using the fab module in the STL to RML mode. I openned my STL file, checked the size to make sure it is the rigth size and then made a PNG. From the PNG, I then made the part by first sellecting the tool path parameters for rough cutting after which I made tool path for smoot cauuting. I then calculated the tool path and then with my material (wax) in place, I sent the command for the catting process for each face.

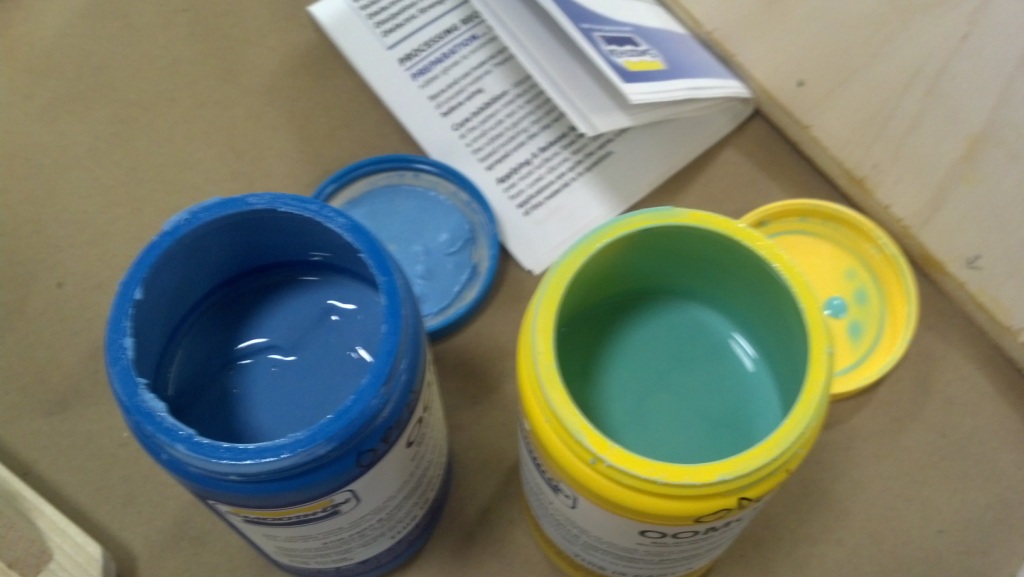

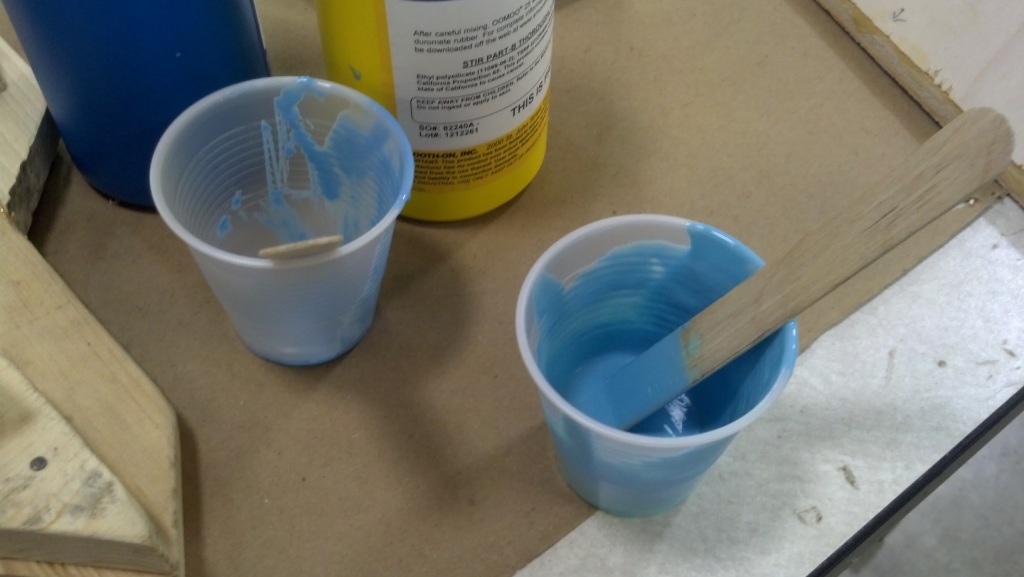

I then use the wax mold to create a flex mold which is then used to cast my odject.

Below are screen shots showing the precesses

1) AutoCAD drawing:

2) Saving as STL file

3) Opening STL to RML mode in FabMoudle

4) Opening STL file in FabModule

5) Generating Tool path

6) Milling object on modela

7) compound used

8) Mixing compounds

9)compound into mold

10) comleted flex mold