Computer-controlled machining

BACK TO WEELY ASSIGNMENTS

Making Something Big in the FabLab.

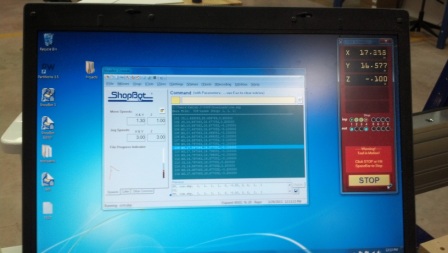

The main idea for this week Was to make something big Using any of the Machines in the lab. It sounded fun. this Assignment brought me to the cross road, across road due to the fact that it was going to be first using the Shopbot in doing a project from scratch. The first few steps such as: (1) Developping the idea, (thinking of what to design), 2) Sketchin the the idea. 3) Drawing the idea using the CAD program such as AutoCAD 4) Modeling the idea and 5) Saving the idea as a DXF file) was not that much of a problem. But thinking the machining would be a problem turned out to be such a false thinkking. I cam to know this after taking a few moment with the machine; going through the CAM software (pathworks) and then fameliarizing myself with the coordinates.

All the same, It did not take me more than 30min. to get to a total understand the Shopbot. So I decided to make a Table that can easily be folded. This table I called, (the flat pack table).

Blow are the various steps I went through to get the assignment done.

1. I make the 2D sketch with using the AutoCAD

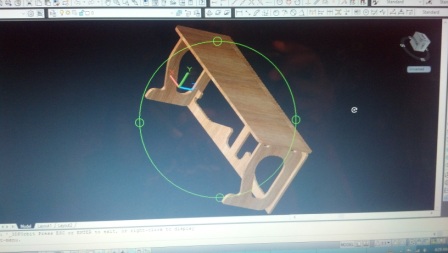

2. I converted the 2D sketch to 3D and then made a vertual modle to make sure everything fits.

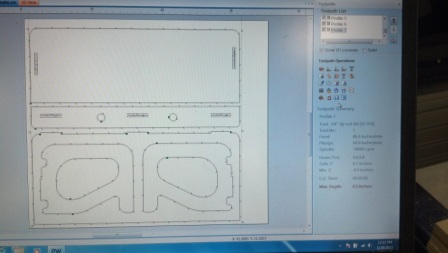

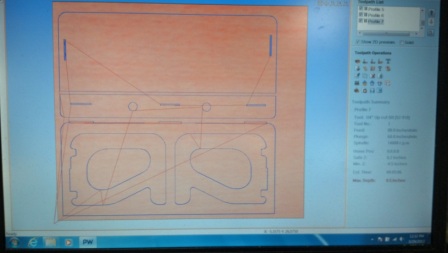

3. I imported my dxf file into partworks for the shopbot and generated the tool paths

4. I the previewed the tool paths to make sure I am on the right track.

5. I saved the tool paths and the openned it with the CAM processor, set all my zero's

6. I started the cutting with my work sheet (wood) in place.

7. After cutting, I took all my parts out and the sanded the parts

8. I then put it all together and I got my final object which I call the flat pack table.

BACK TO WEELY ASSIGNMENTS