18. Wildcard week¶

I have chosen to do Plastic injection molding as my Wildcard. For this assignment I’m using an existing mold for an electronic device housing and I will use available injection molding machine at TECHWORKS - Amman.

Machine¶

The machine I used is xxx and have following specs:

Manufacturer --------------- Medium Machinery, LLC

Model ---------------------- Benchtop Injection Molding Machine

Max Shot Capacity --------- 2oz(56g)

Min Power ------------------ 10A @ 120V

Max Temperature ----------- 600F(315C)

Min Air Flow ---------------- 4.5cfm(128lm)

Max Mold Size -------------- 8x10x4.5in(200x250x110mm)

Max Clamping Force ------- 12tons

Max Pressure --------------- 13,500psi(9490tons/m2) @ 90psi(6.2bar) air

Machine Dimensions ------- 16x22x50in(410x560x1270mm)

Machine Weight ------------ 170lb(77kg)

Origin of Manufacture ------ United States of America

Useful links¶

Injection Molding Machine¶

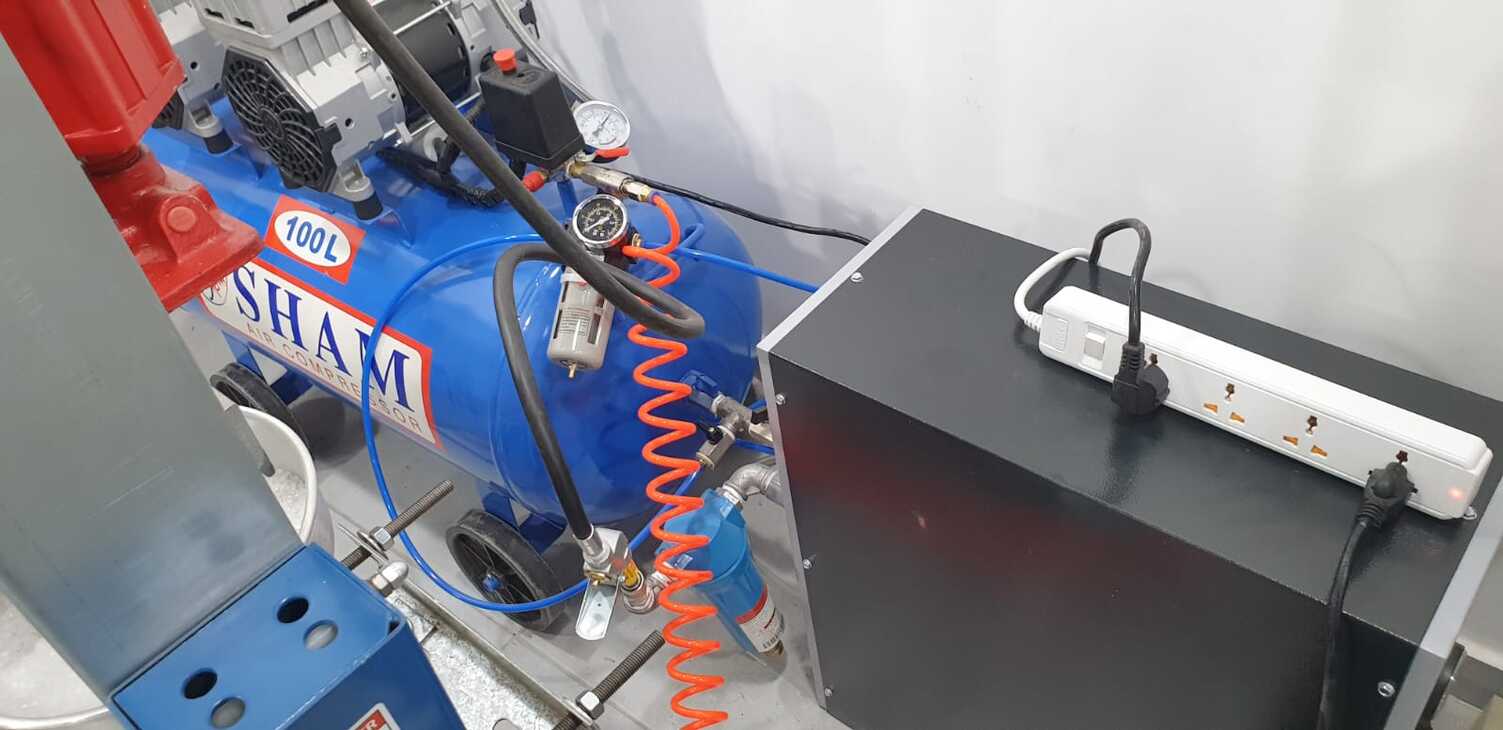

Injection Molding Machine connected to Air Compressor & Air Dryer¶

Electronic Temperature Controller for the Injection Molding Machine¶

Setting Plastic melting temperature on The Injection Molding Machine¶

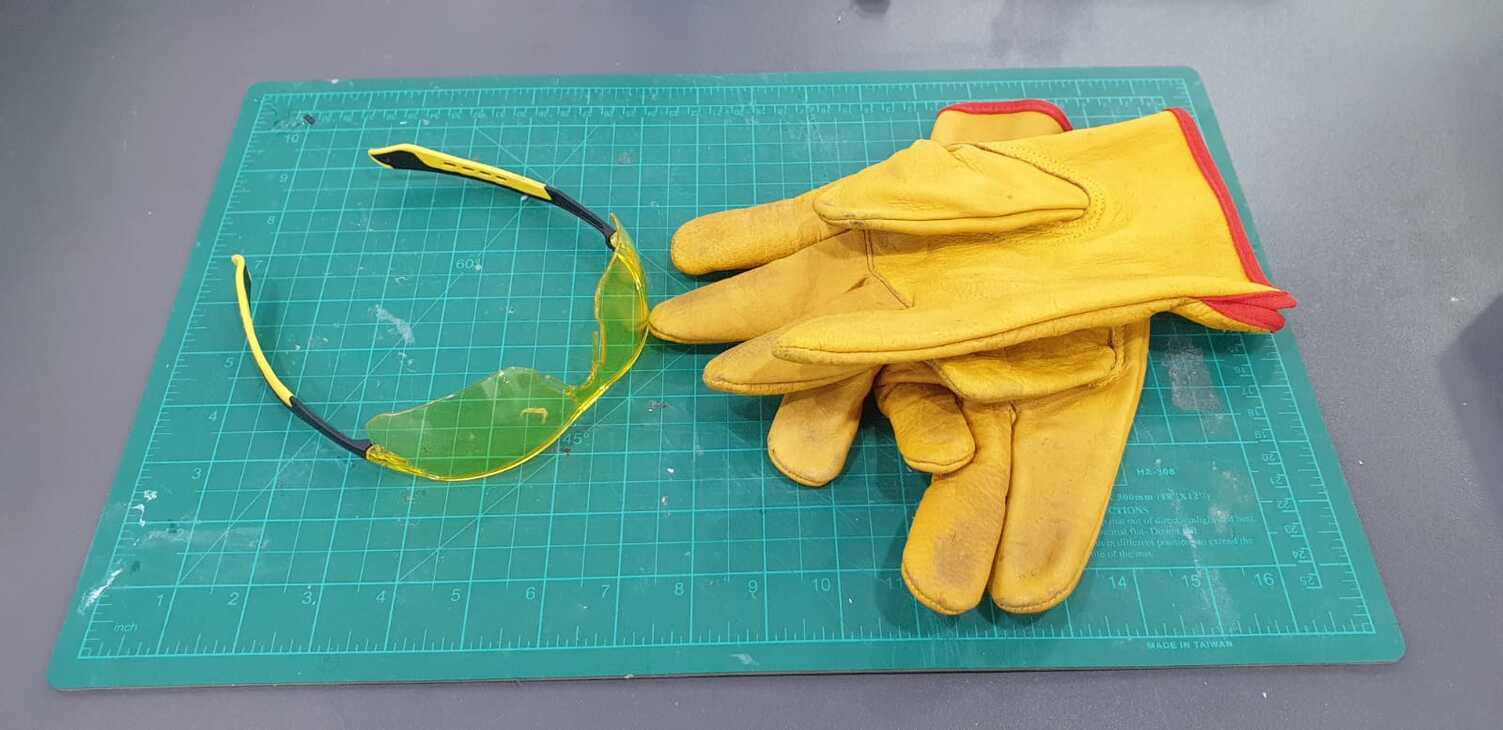

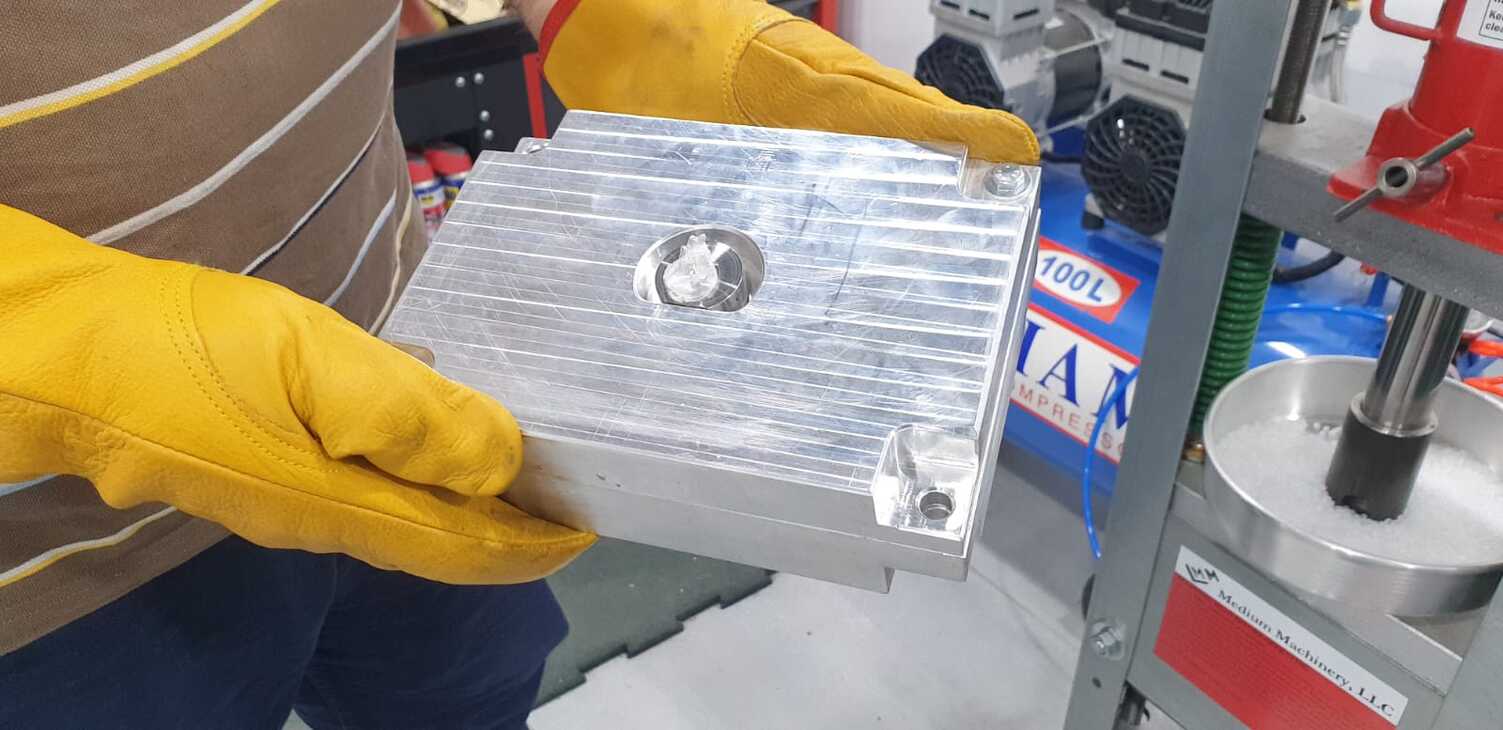

PPE needed when operating The Injection Molding Machine are Safety Glasses and Leather Gloves¶

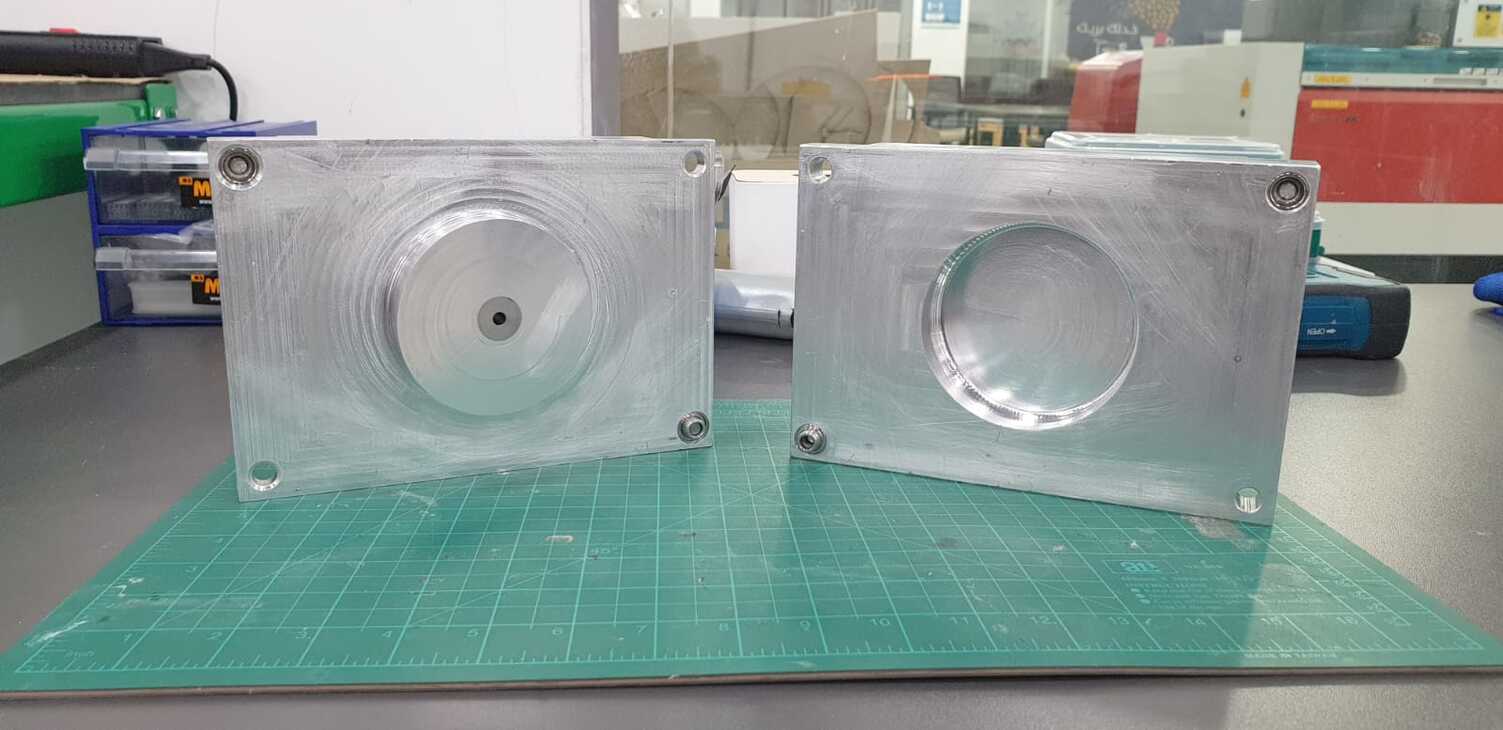

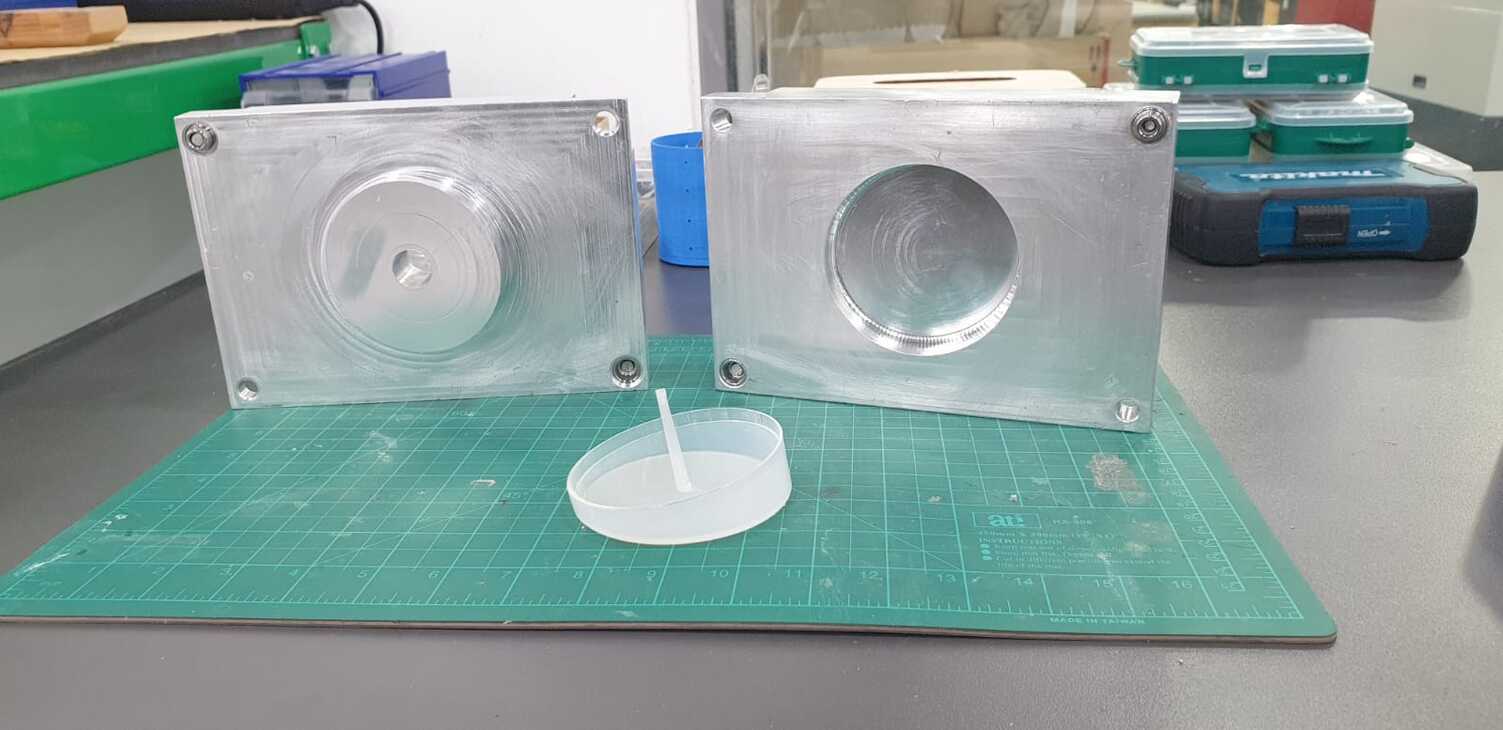

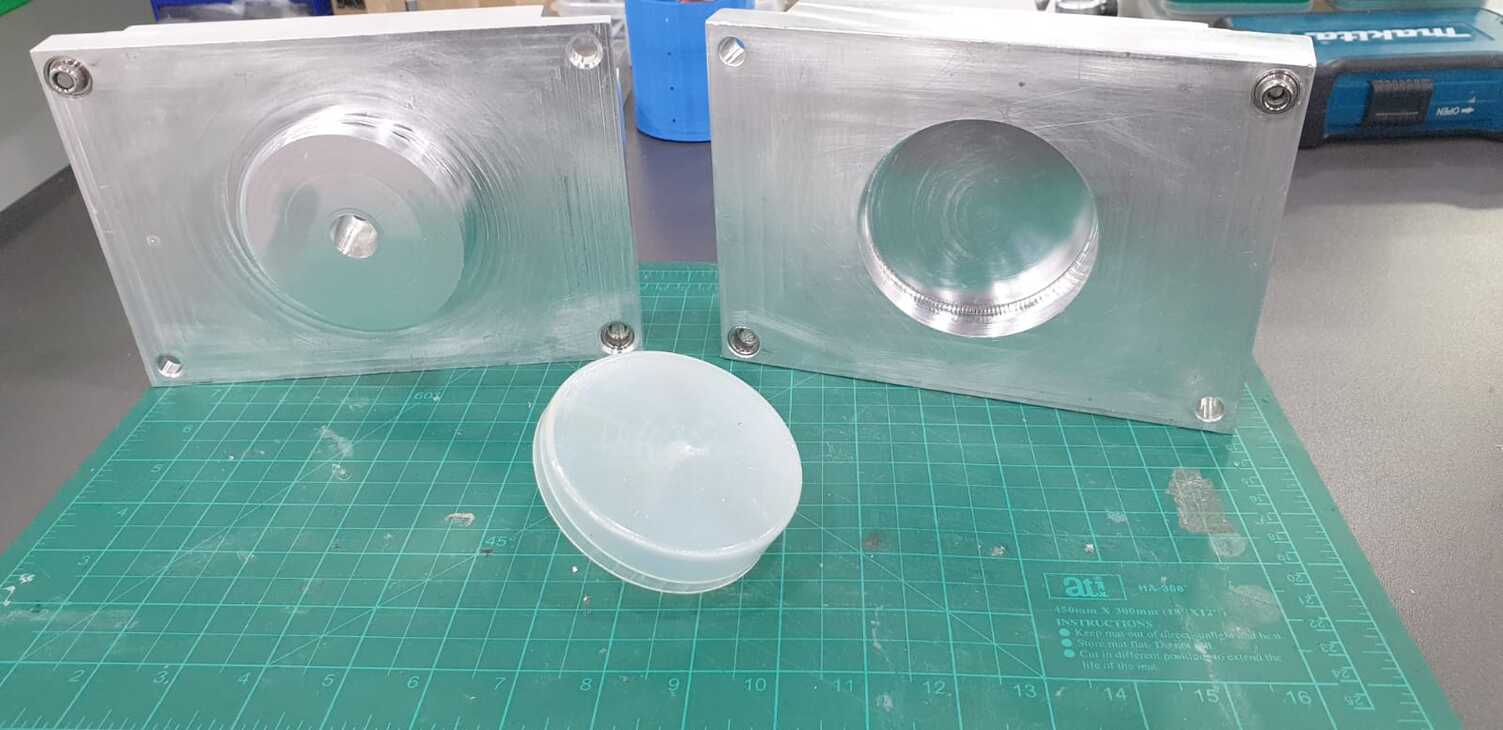

Injection Mold Core & Cavity for molding Electronic device Housing¶

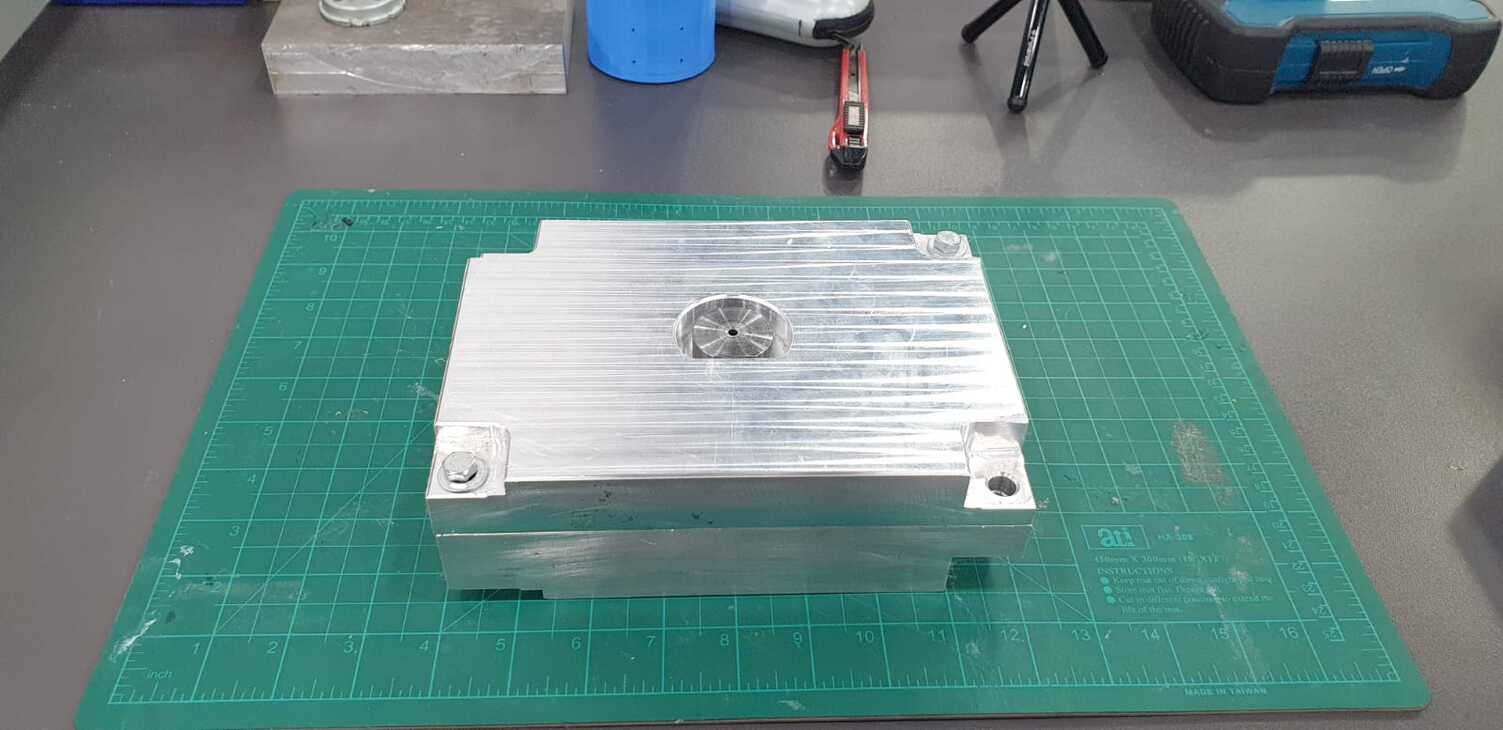

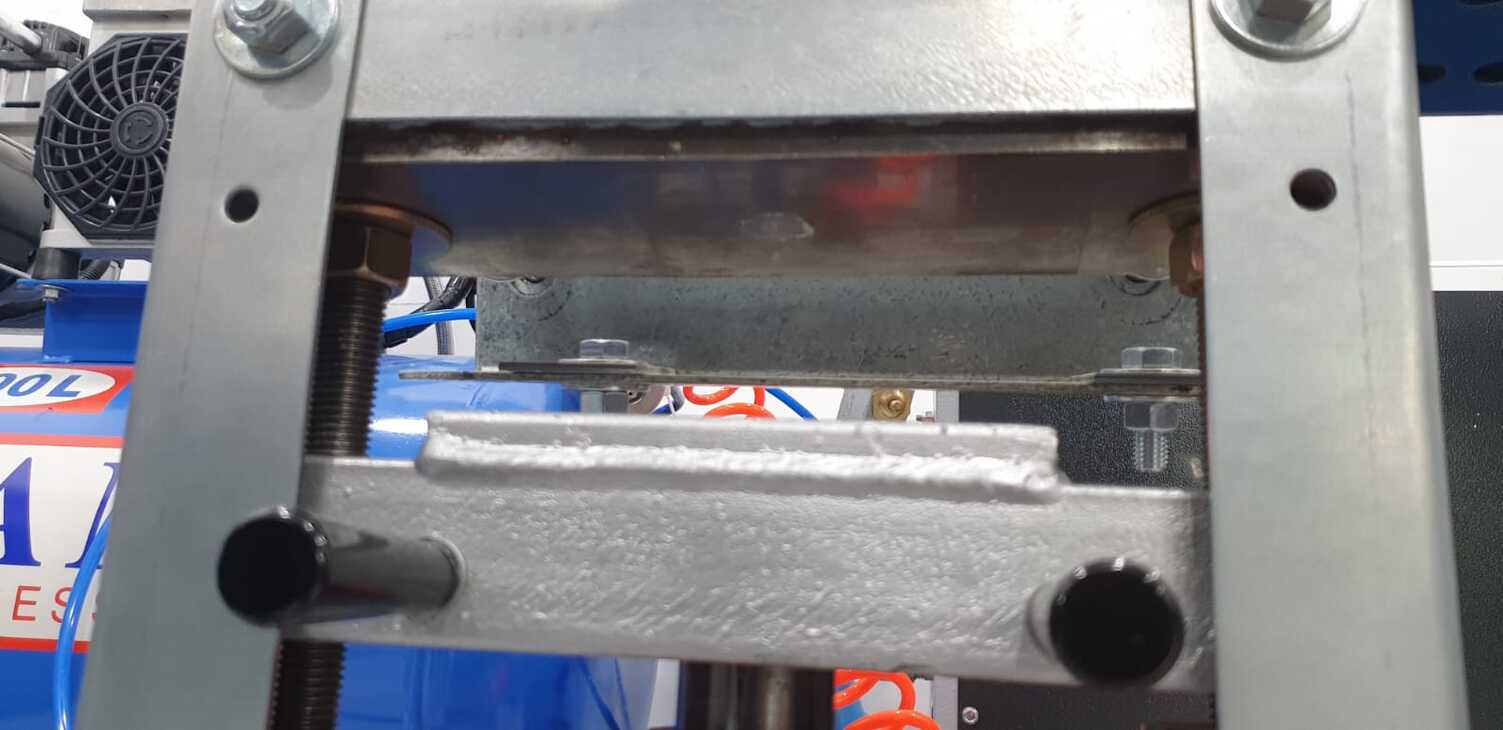

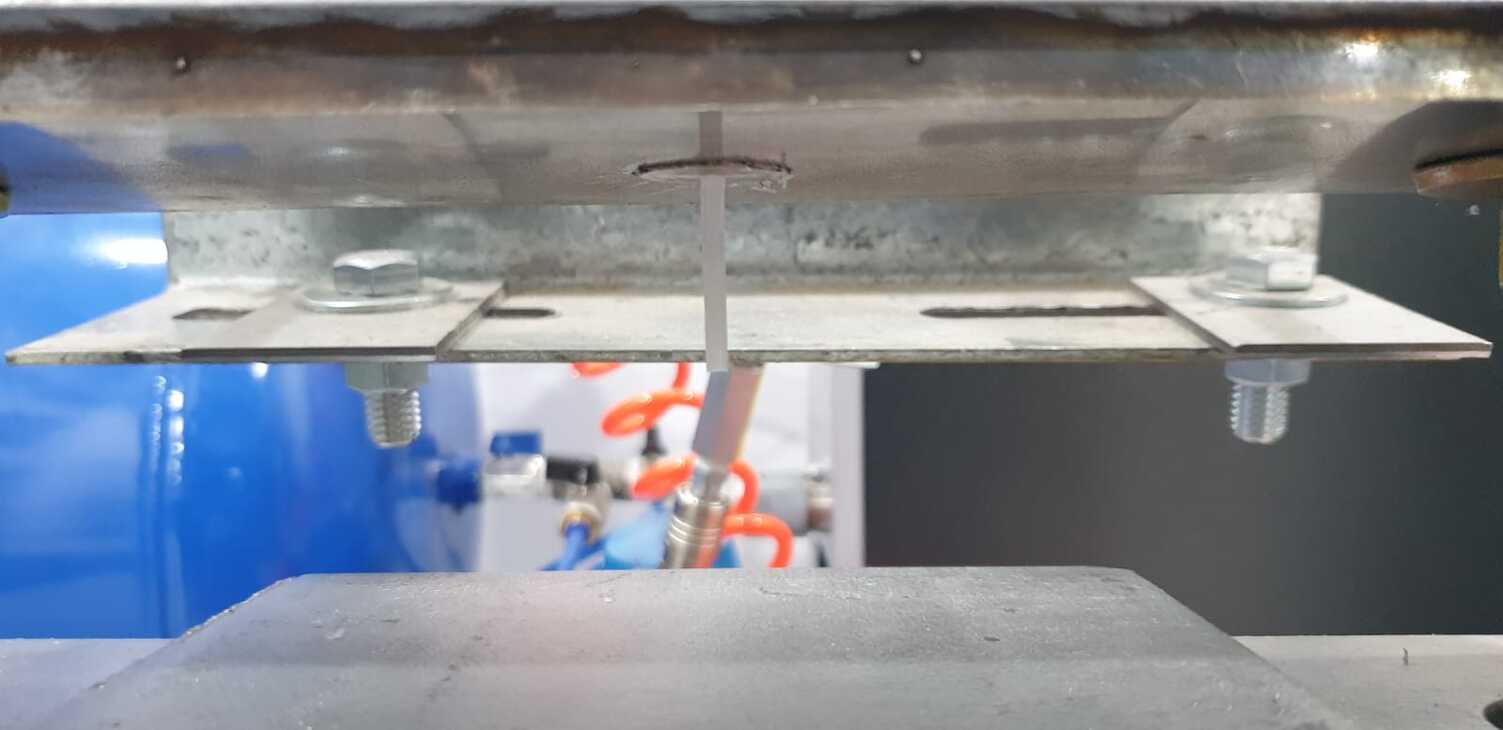

When mold is closed, we can see the Sprue Bush where molten plastic will pass throu and fill the gap between Core and Cavity and soldifies after cooling down and taking the shape of Core & Cavity¶

Here we can see The Injection Nozzel where molten plastic is released from the Injection Molding Machine into The Mold¶

Injection Molding Machine Plastic Nozzle close up¶

When set temperature is reacheded¶

We release a small amount of plastic to help with centering the plastic mold¶

Loading the plastic mold into The Injection Molding Machine¶

Now we clamp the mold after centering the Sprue bush with the injection nozzle¶

And now we can start plastic injection process¶

We first check the air connection between injection machine and air dryer while inspecting the air pressure in the air cmopressor tank is more than 6bar¶

Then we press air switch to start injecting plastic into the mold¶

After injecting plastic into the mold we remove from the injection machine after releasing the hydraulic pressure from upper cylinder first then releasing the hydraulic pressure from lower cylinder¶

Mold to be opened and plastic parts removed from the mold¶

Process to be repeated to reach required number of parts¶

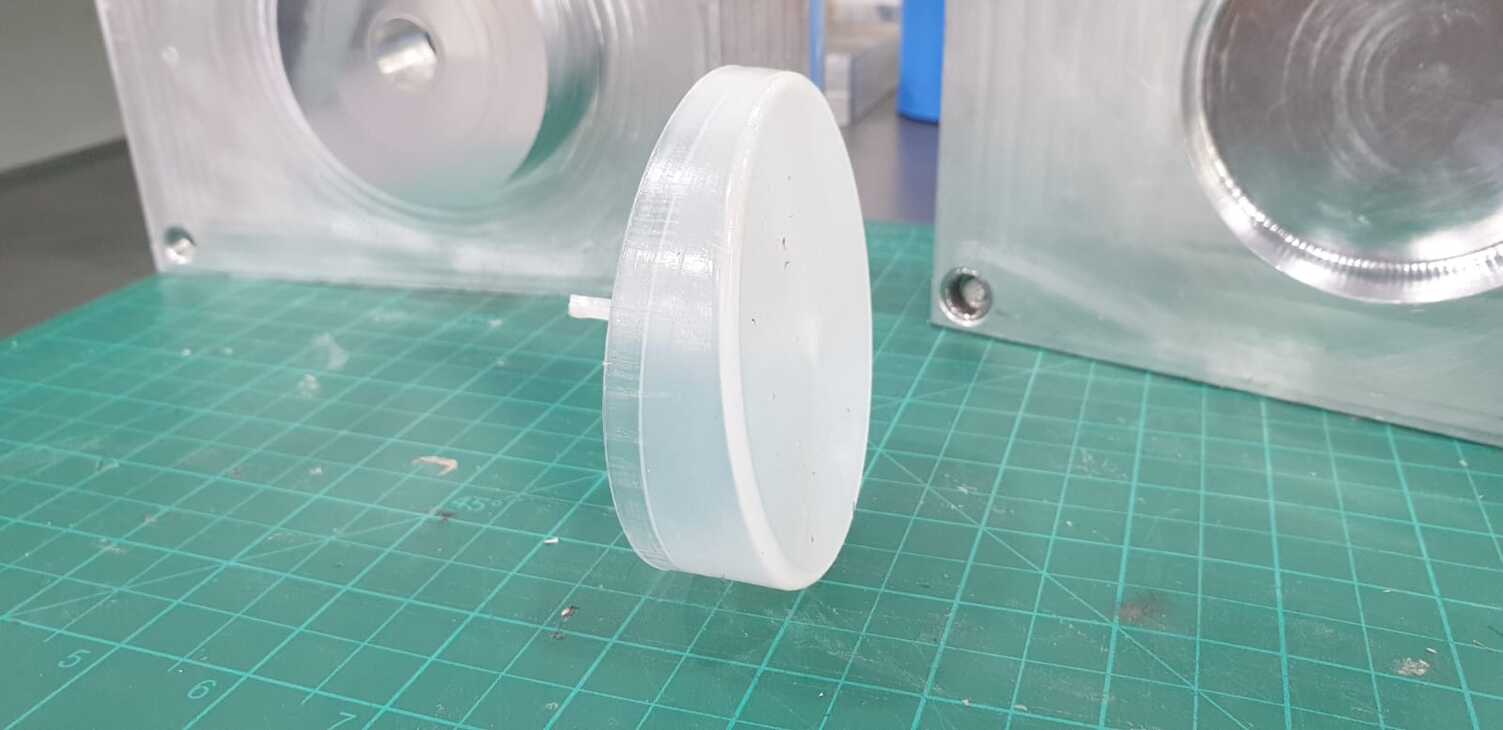

Final injected plastic part¶