6. 3D Scanning and printing¶

6.a. 3D Scanning¶

For 3D Scanning we use SENSE 3D Scanner to scan offset pipe reducer¶

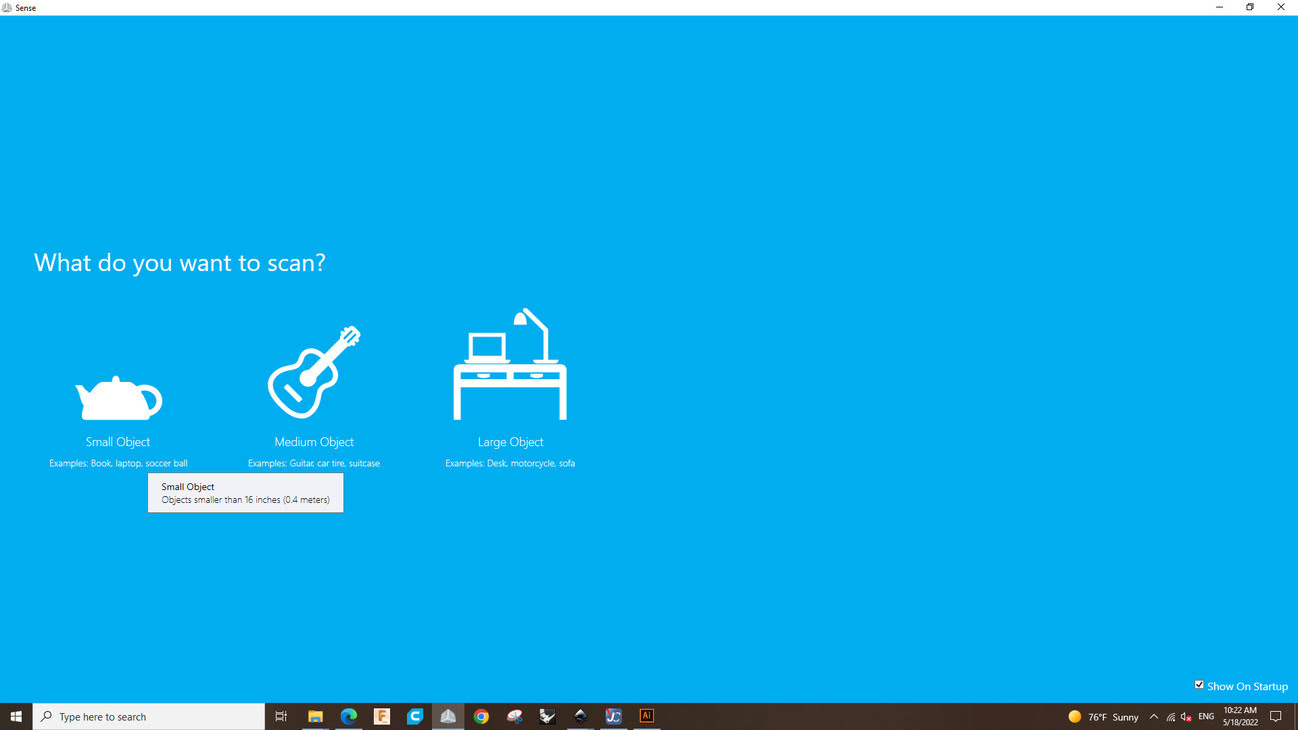

Opening Scanning software and choosing Small Object to start scanning object

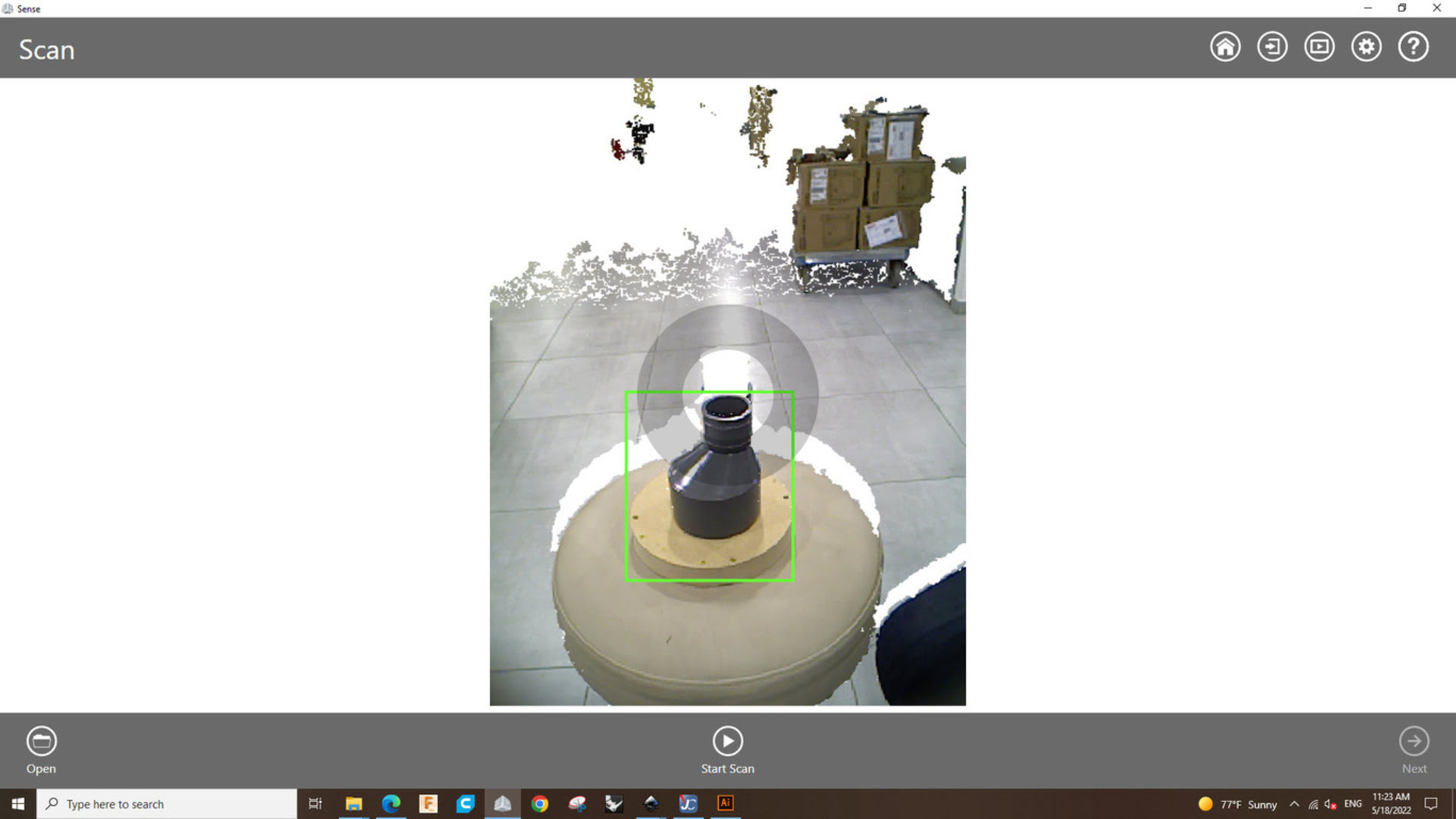

The scanner is verifying the part and we try to focus the part within the green rectangle

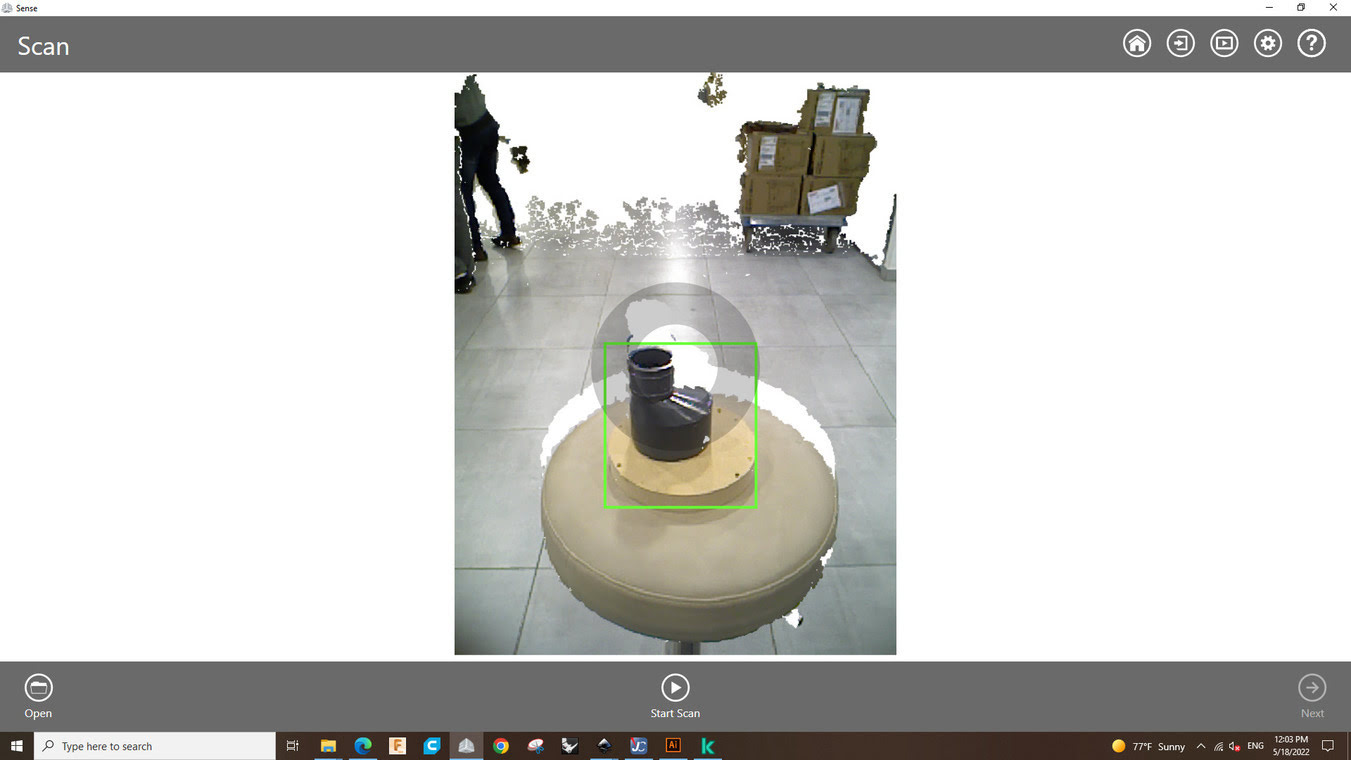

Scanning the part by rotating the part during the scanning process to cover all part sides

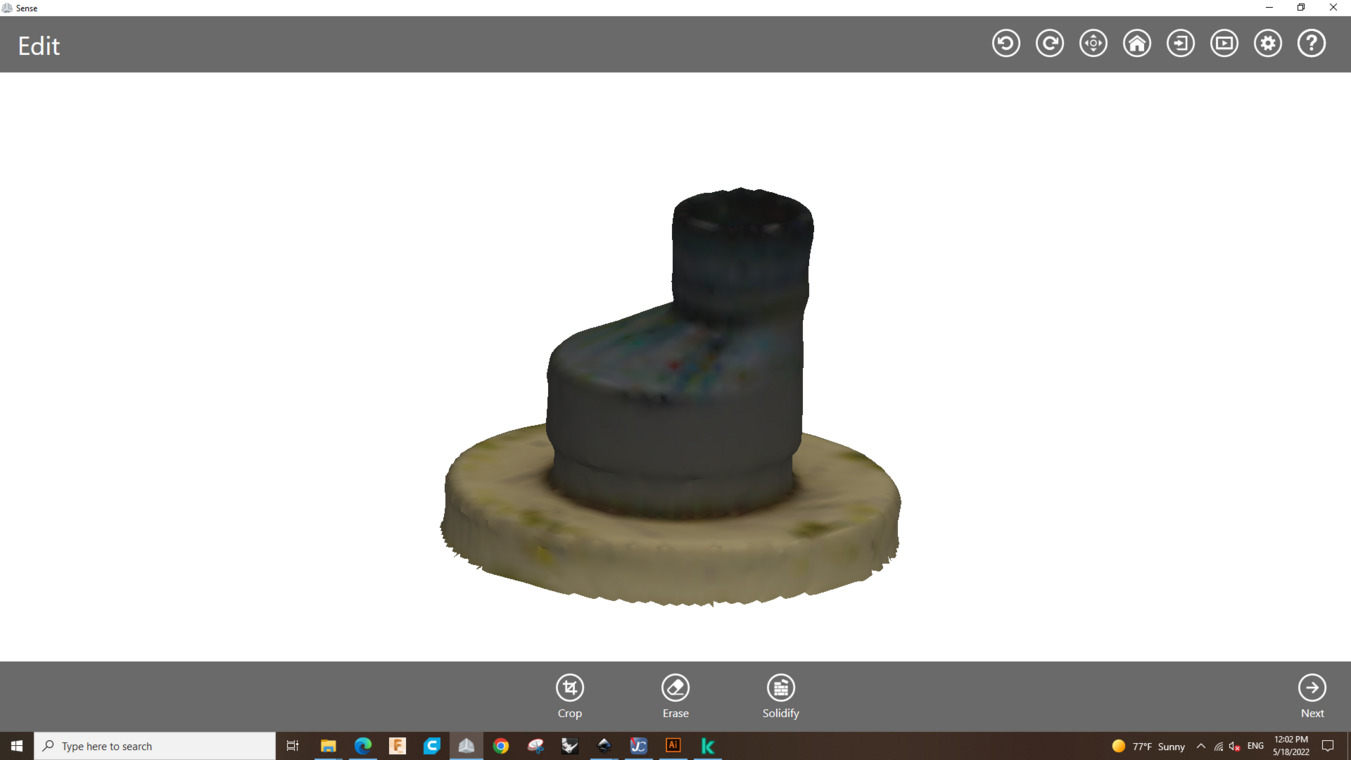

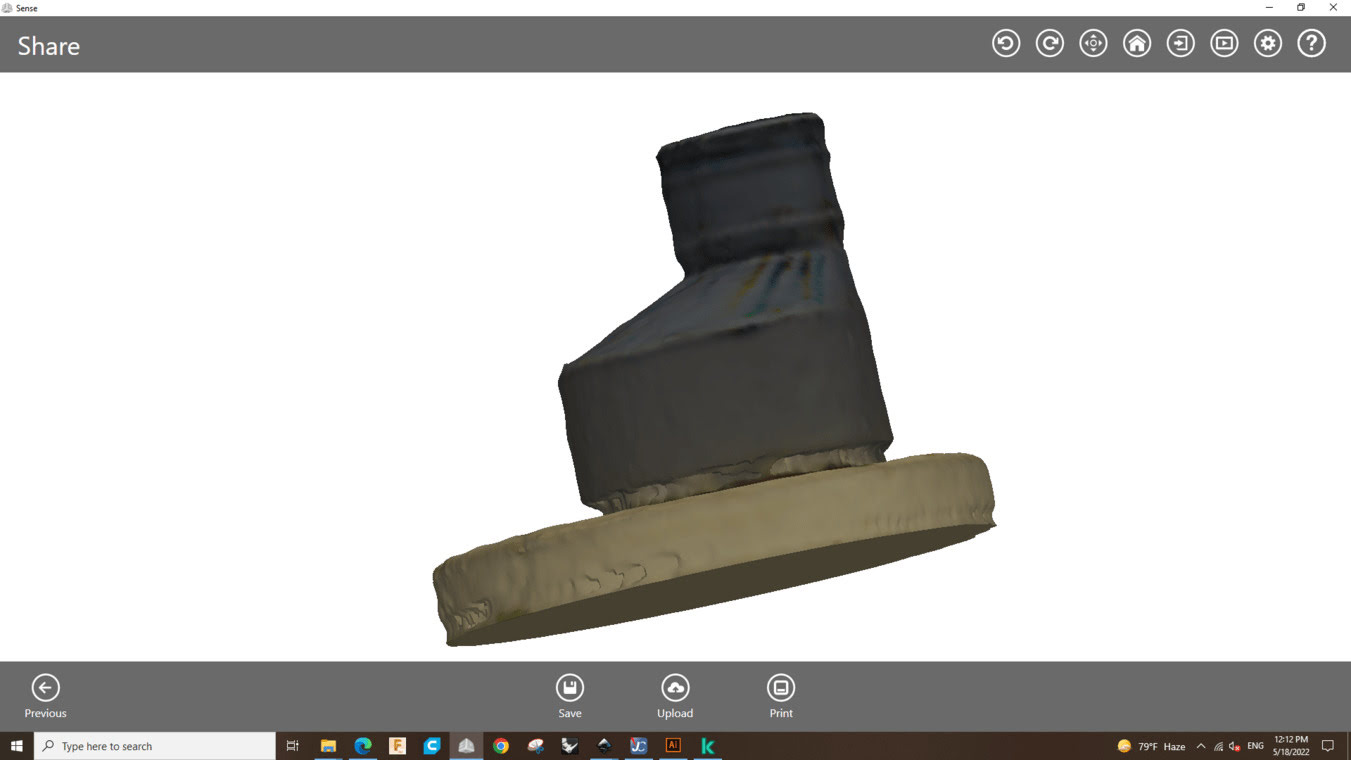

Scanned part render on software

Scanned part render on software

Scanner setup using tri pod and rotating stool to maintain constant distance between scanner and part and eliminate any variances in distance or angle

6.b. 3D Printing:¶

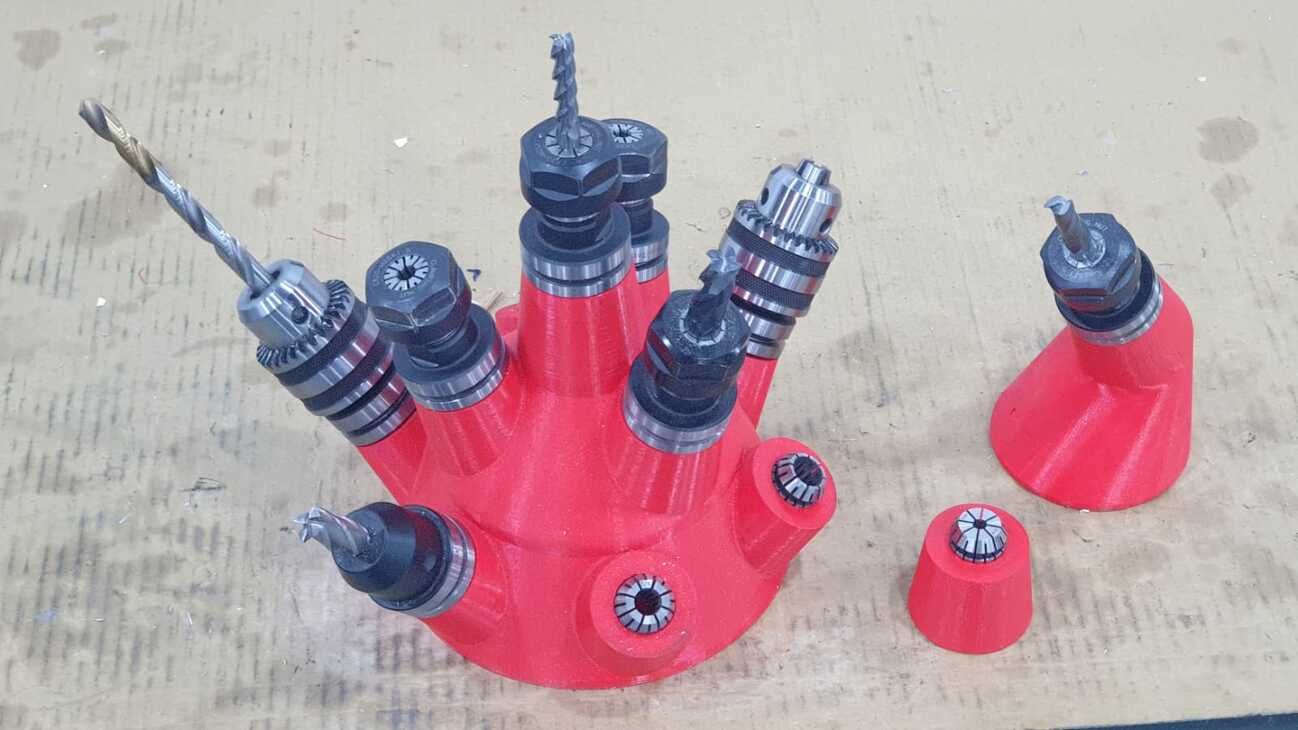

Working on 3Dprinter to make my Final Project Adapter and to print my own design for Tool Holder & Collet Fountain¶

Machine:¶

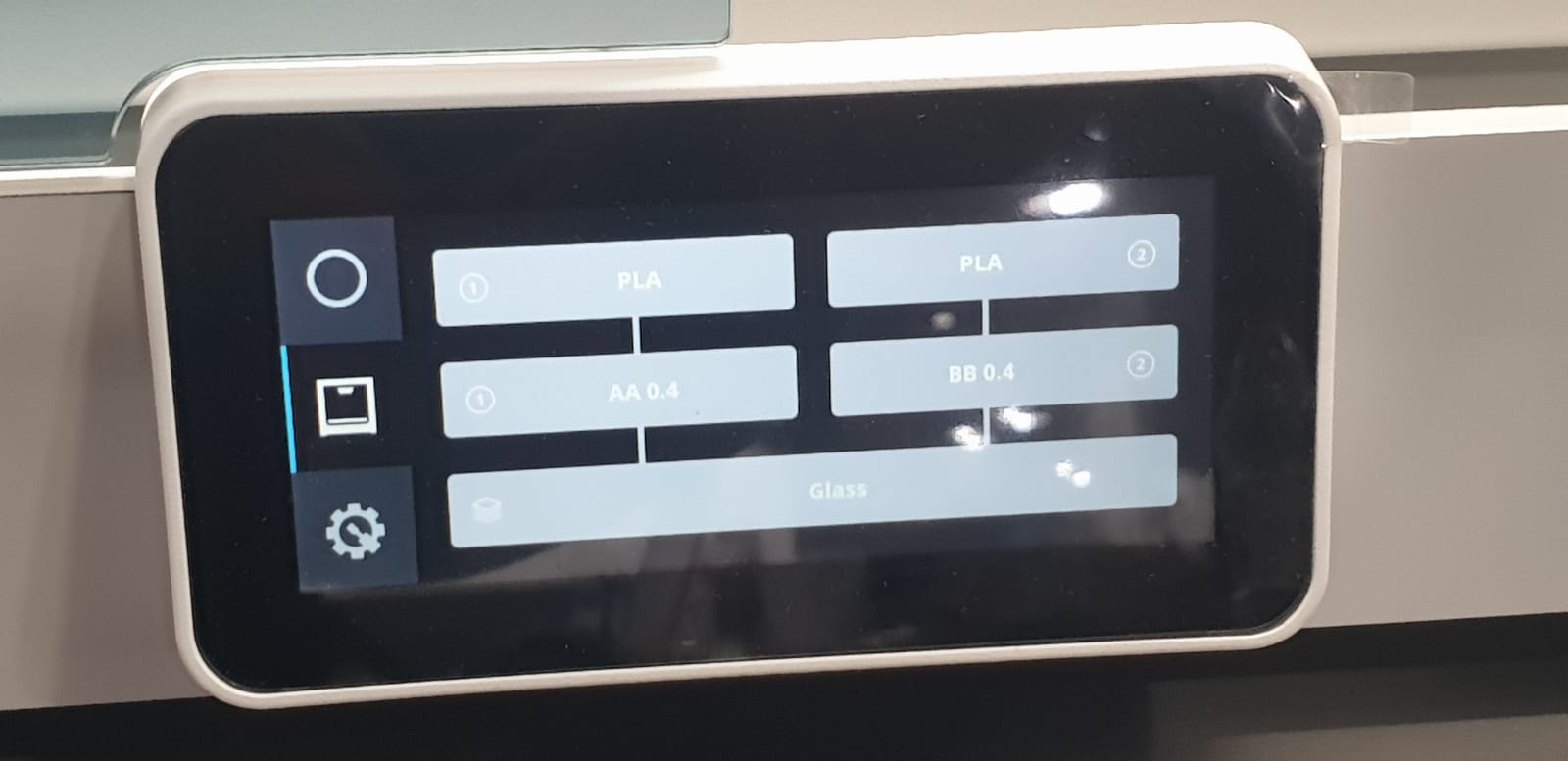

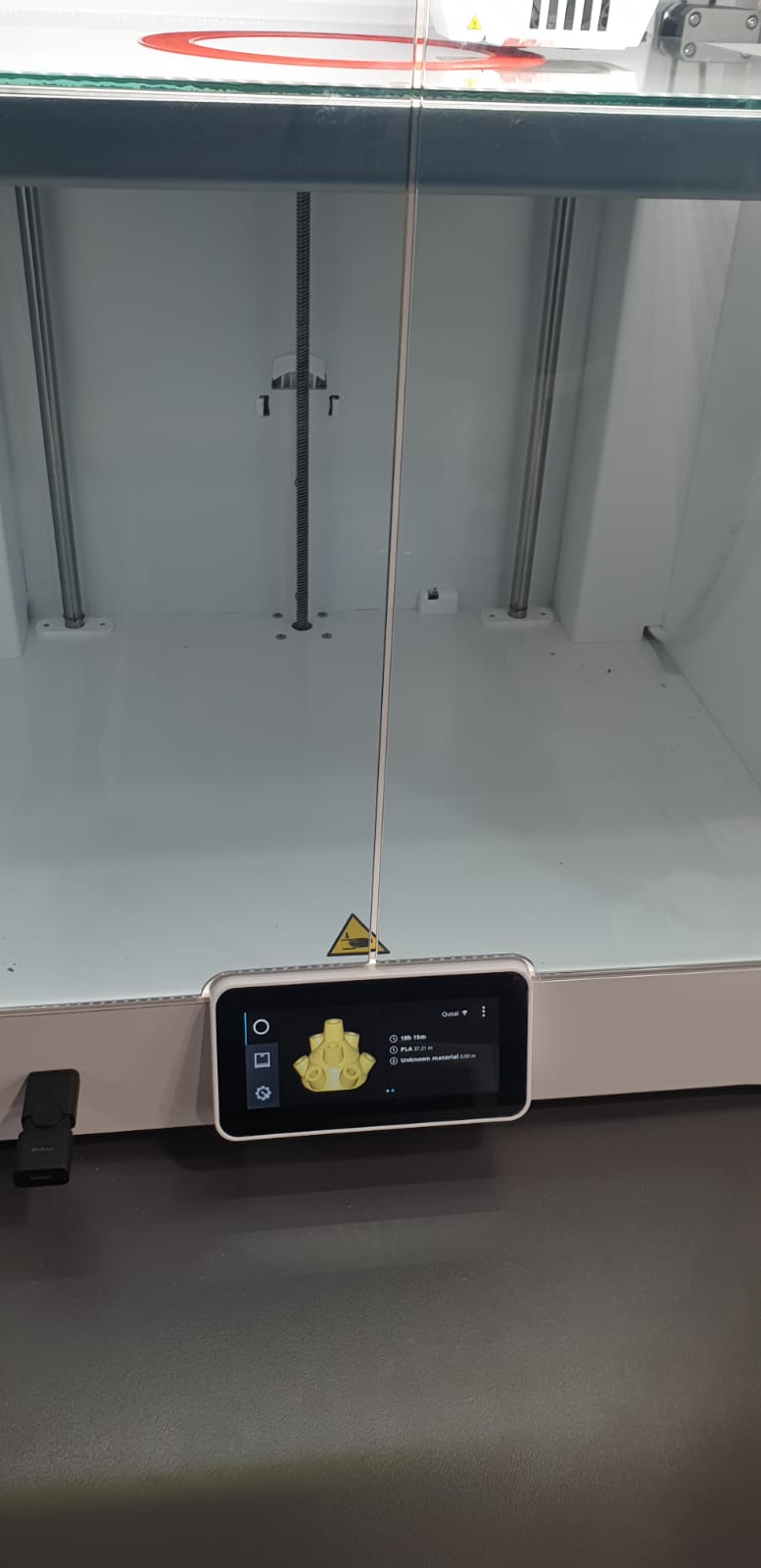

The 3Dprinting Machine in Techworks-Amman is Ultimaker S5¶

Main machine specs:

Build volume: 330 (X) x 240 (Y) x 300 (Z) mm, Printing technology: Fused Filament Fabrication (FFF), Dual extrusion head

Layer resolution:

0.25 mm nozzle: 150 - 60 micron

0.4 mm nozzle: 200 - 20 micron

0.6 mm nozzle: 300 - 20 micron

0.8 mm nozzle: 600 - 20 micron

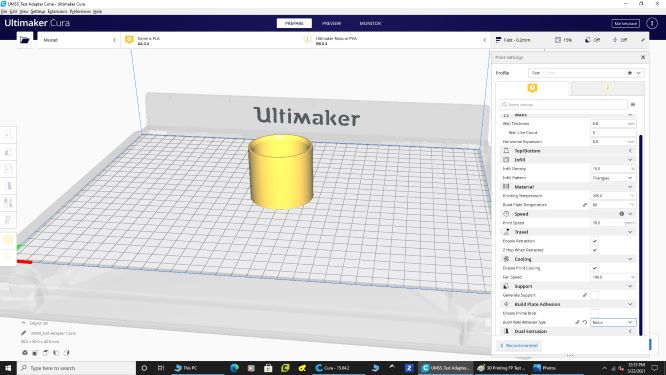

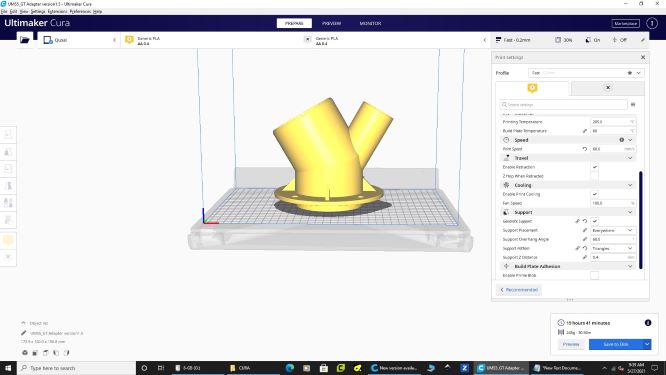

3D printing Test Hose connector with Cura Software¶

3D printing Test Hose connector with Cura Software¶

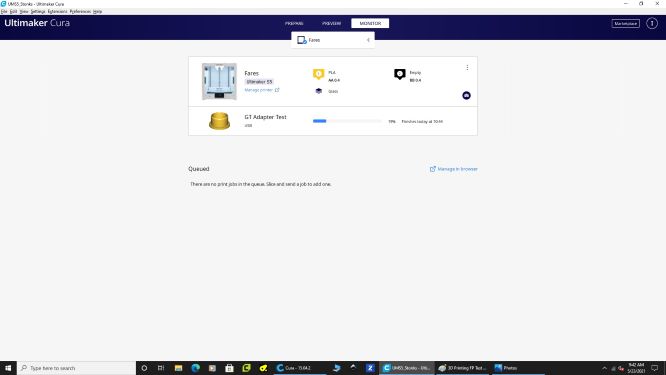

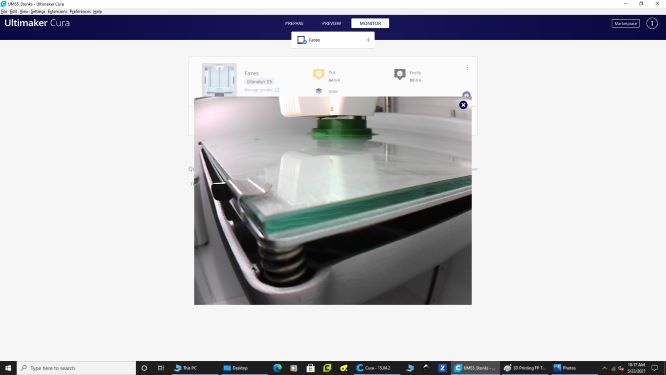

3D printing Test on Ultimaker S5¶

3D printing Adapter with Cura Software¶

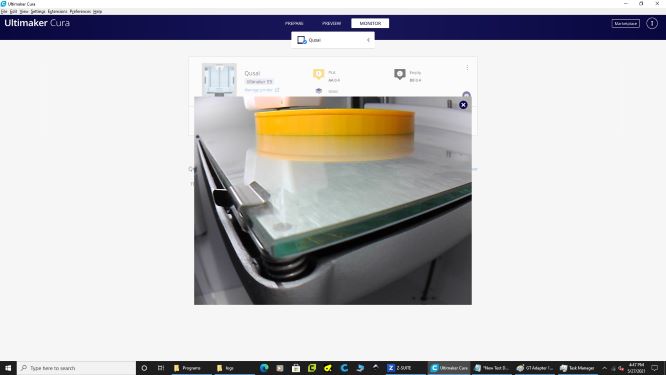

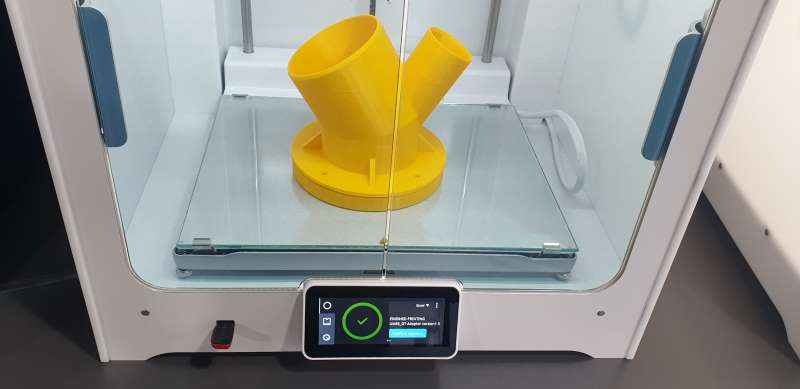

3D printing Adapter on Ultimaker S5¶

3D printing Adapter on Ultimaker S5¶

Removing Support Structure¶

3D printed part¶

Inspecting 3Dprinted Adapter with Dust Collector Hose¶

Inspecting 3Dprinted Adapter with ShopVac Hose¶

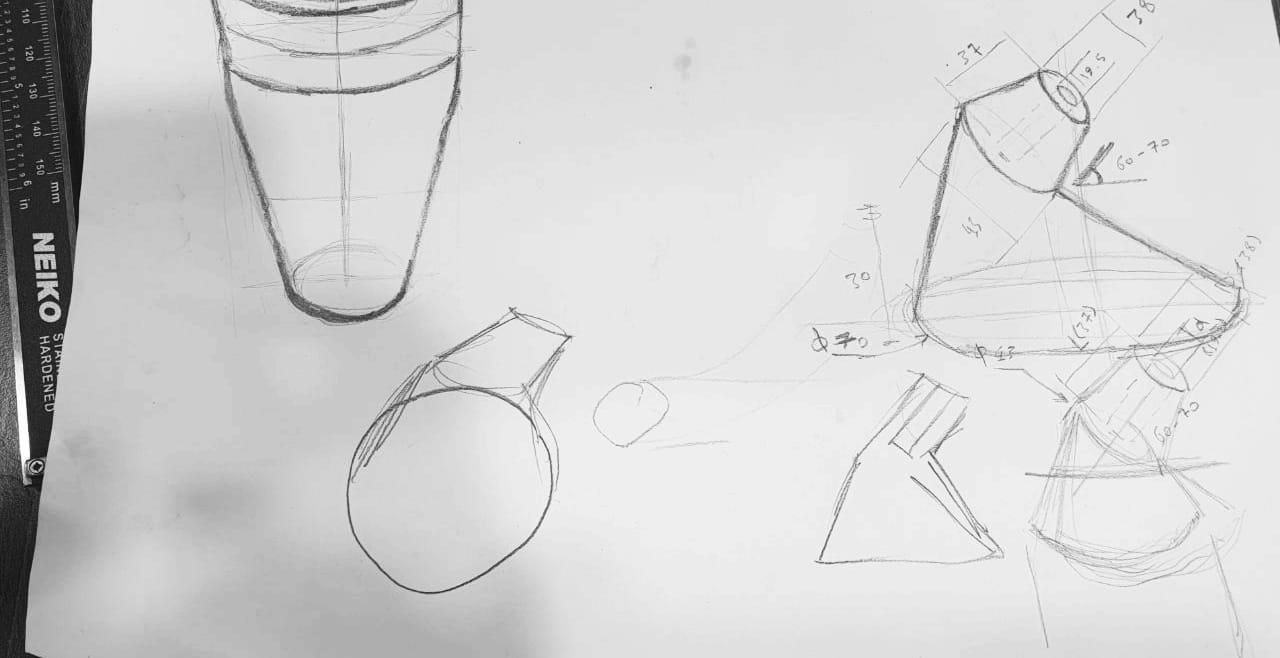

Designing Collet fountain¶

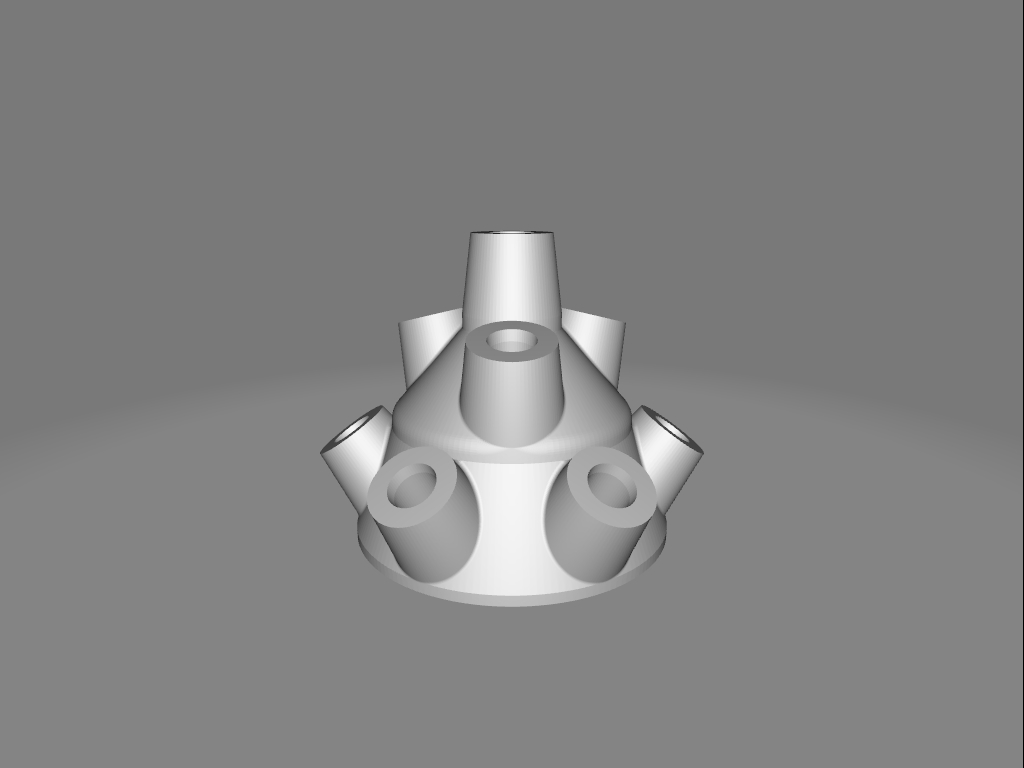

Collet Fountain final 3D model¶

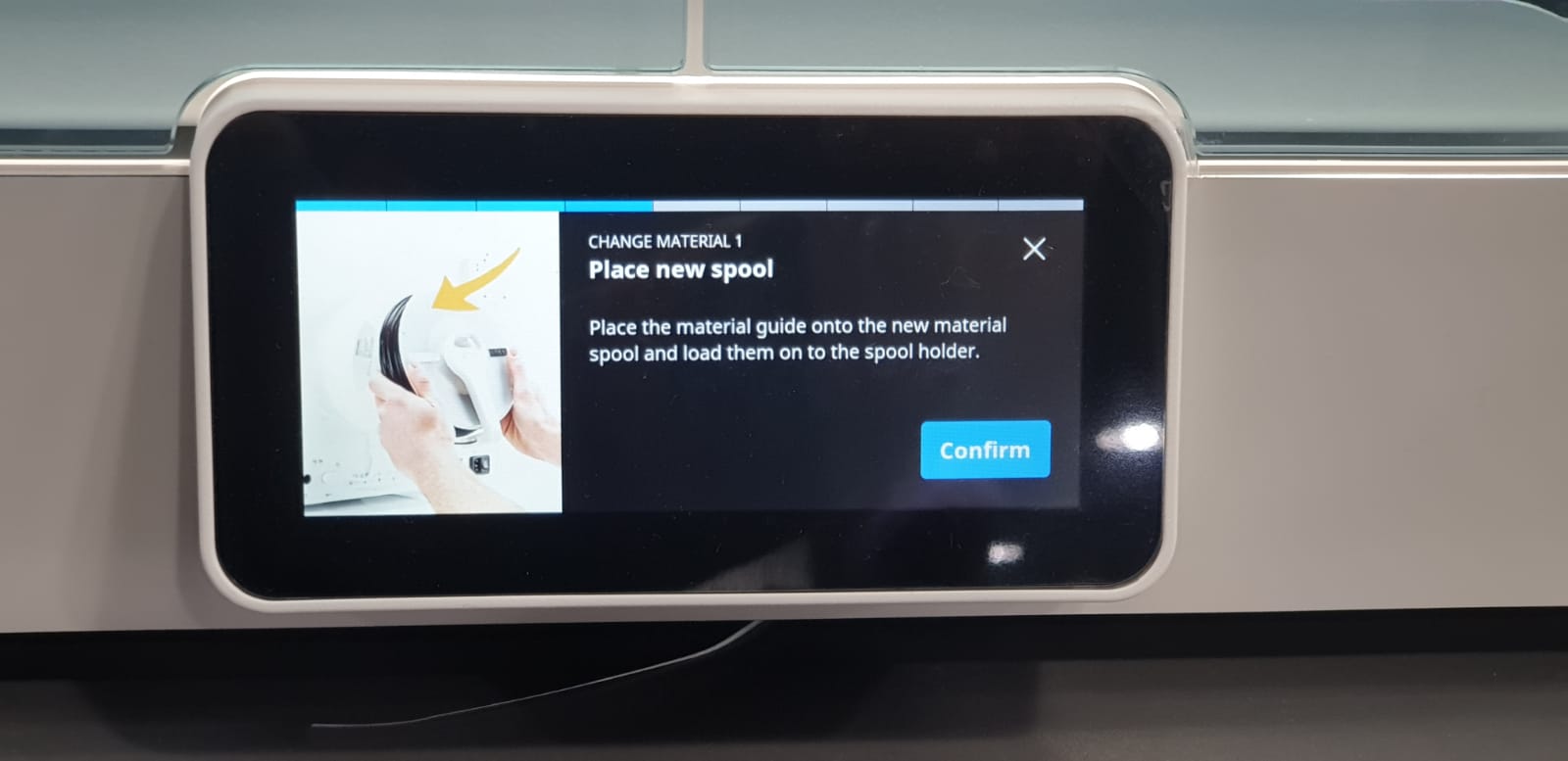

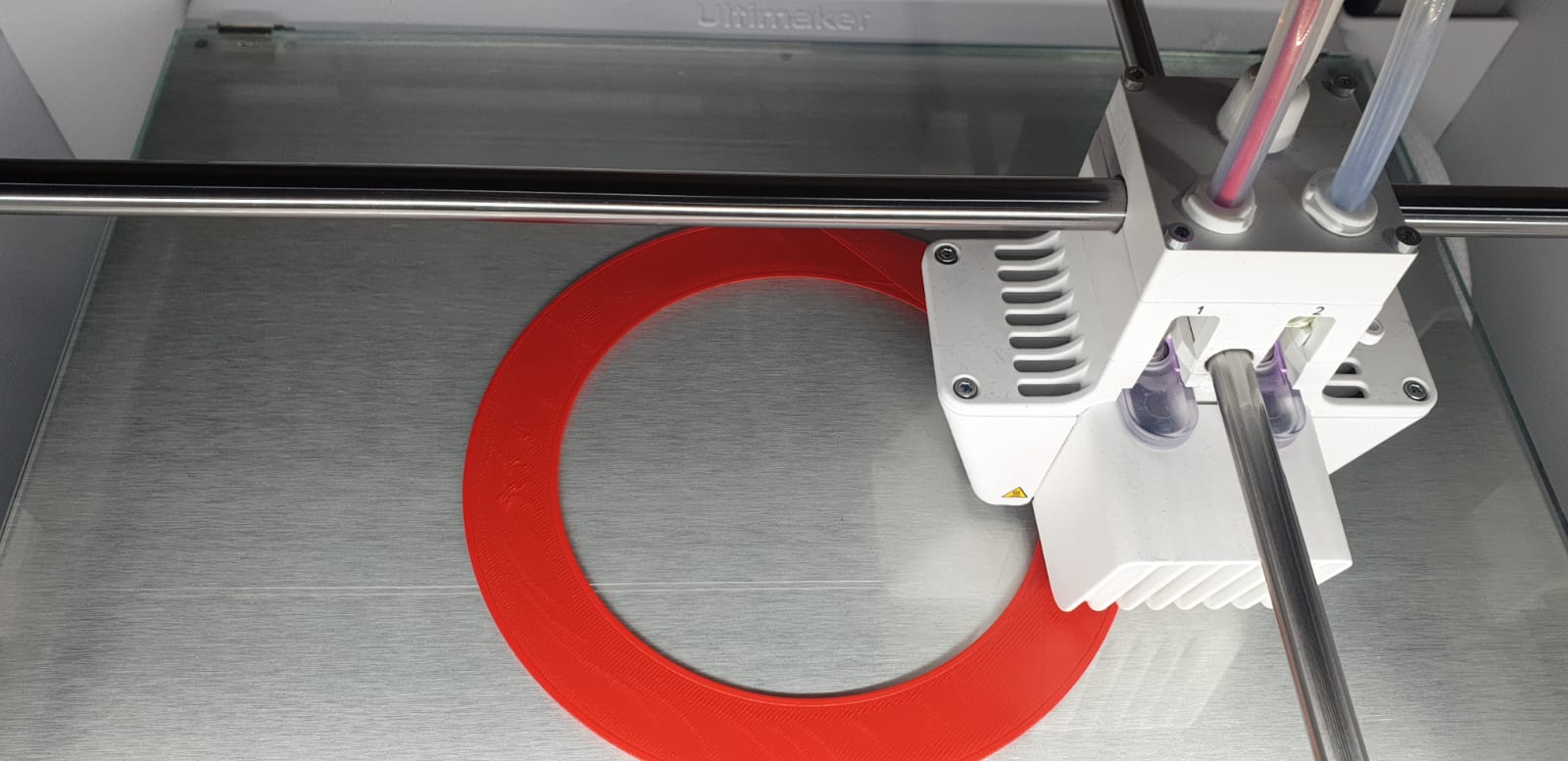

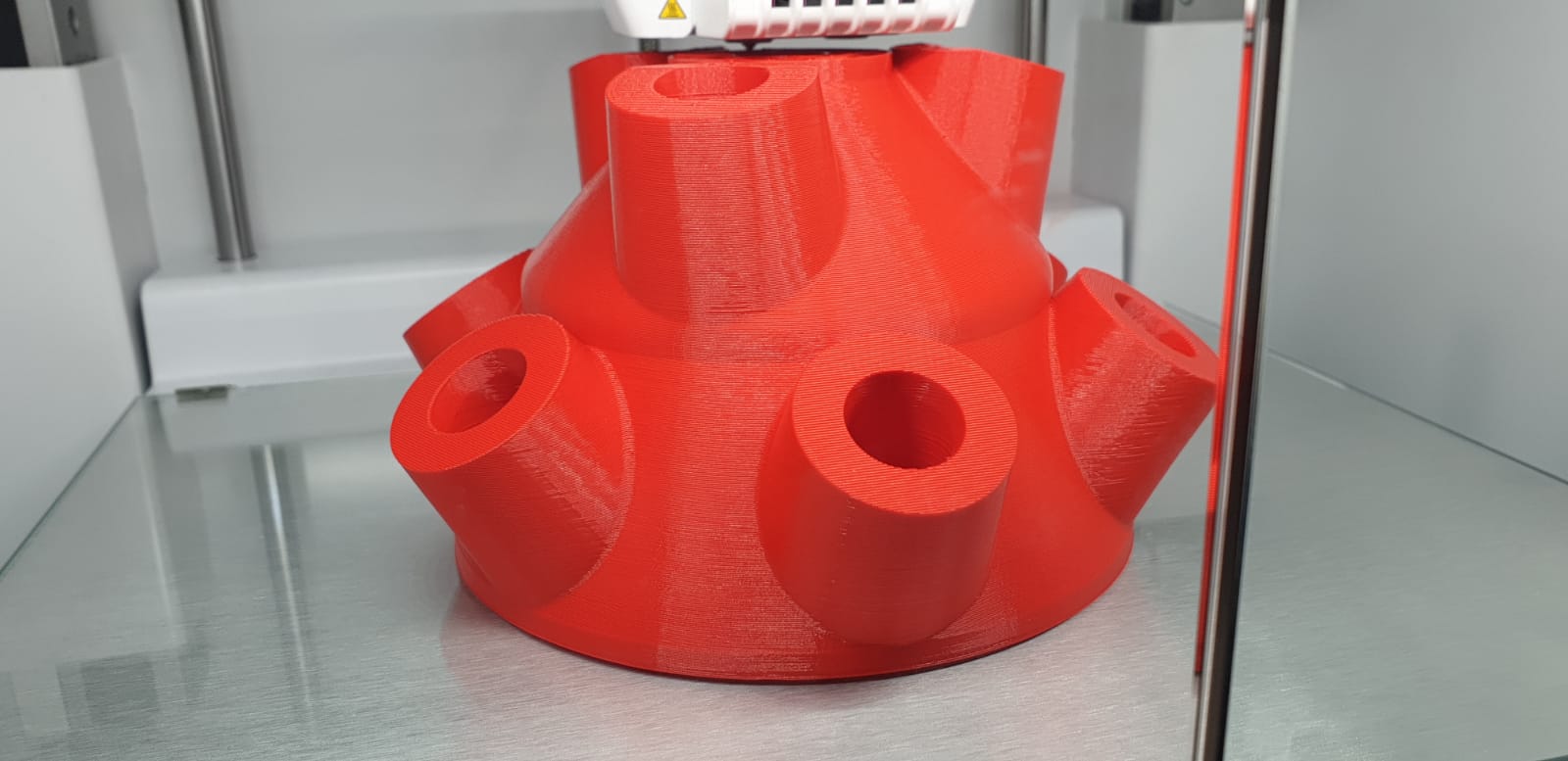

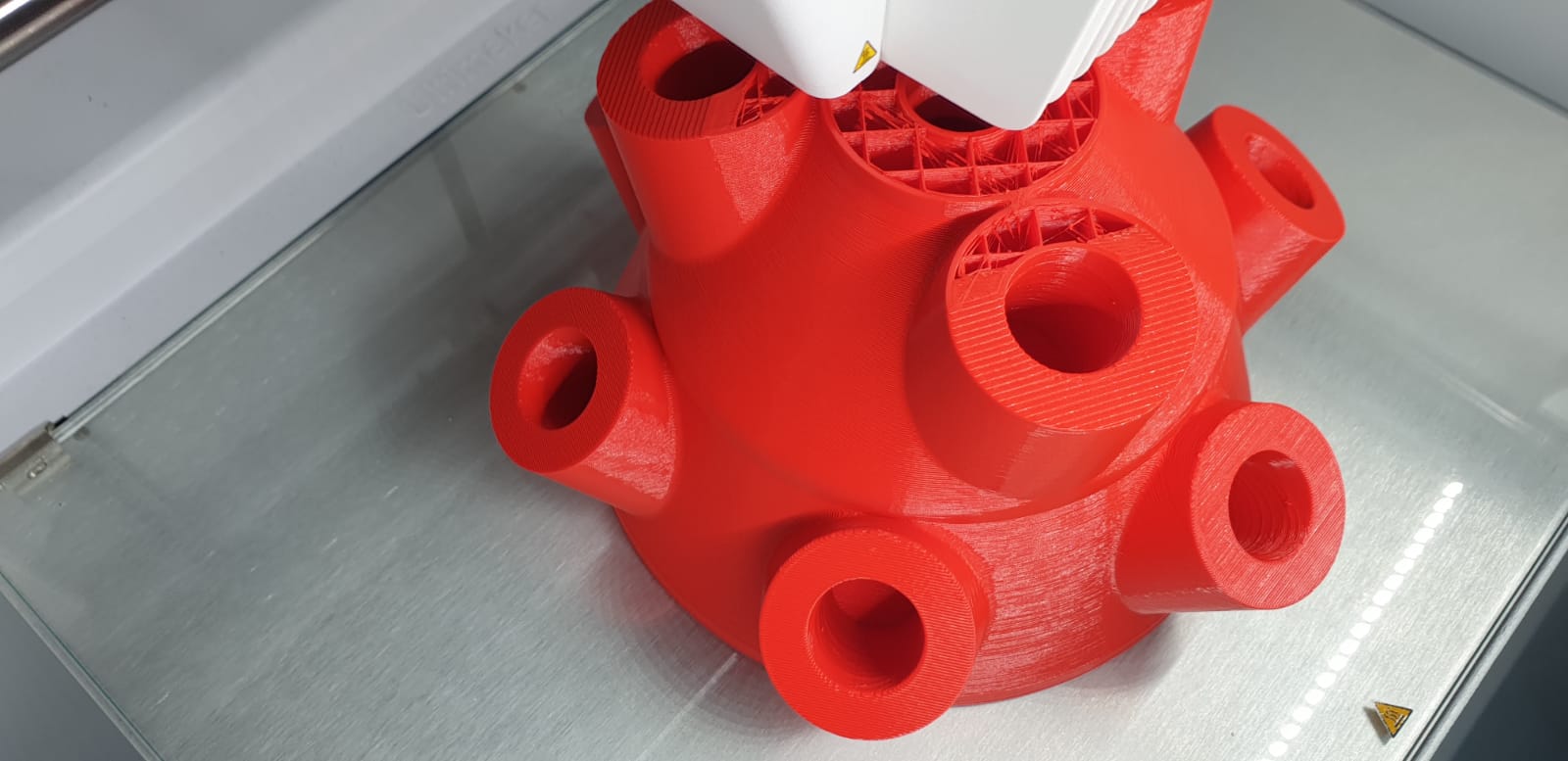

3D printing Collet Fountain on Ultimaker S5¶

3D printing Collet Fountain on Ultimaker S5¶

3D printing Collet Fountain on Ultimaker S5¶

3D printing Collet Fountain on Ultimaker S5¶

3D printing Collet Fountain on Ultimaker S5¶

3D printing Collet Fountain on Ultimaker S5¶

3D printing Collet Fountain on Ultimaker S5¶

Collet Fountain in use¶