4. Computer controlled cutting¶

Worked this week on Vinyl Cutting and Laser Cutting Machines

Vinyl cutting¶

For Vinyl cutting I looked for an abstract pattern to apply on glass door at TECHWORKS-Amman in the CNC shop.

Machine:¶

The Vinyl Cutting Machine in TECHWORKS-Amman is:¶

-

Roland CAMM-1 GS-24¶

The Roland machine can accommodate material up to 700mm in width and it uses a diamond cutting head to cut through material.

Abstract Pattern Proposal #1 for Cutting on Vinyl Cutting Machine¶

Abstract Pattern Proposal #2 for Cutting on Vinyl Cutting Machine¶

Abstract Pattern Proposal #3 for Cutting on Vinyl Cutting Machine¶

Abstract Pattern Proposal #4 for Cutting on Vinyl Cutting Machine¶

Abstract Pattern #5 Proposal for Cutting on Vinyl Cutting Machine¶

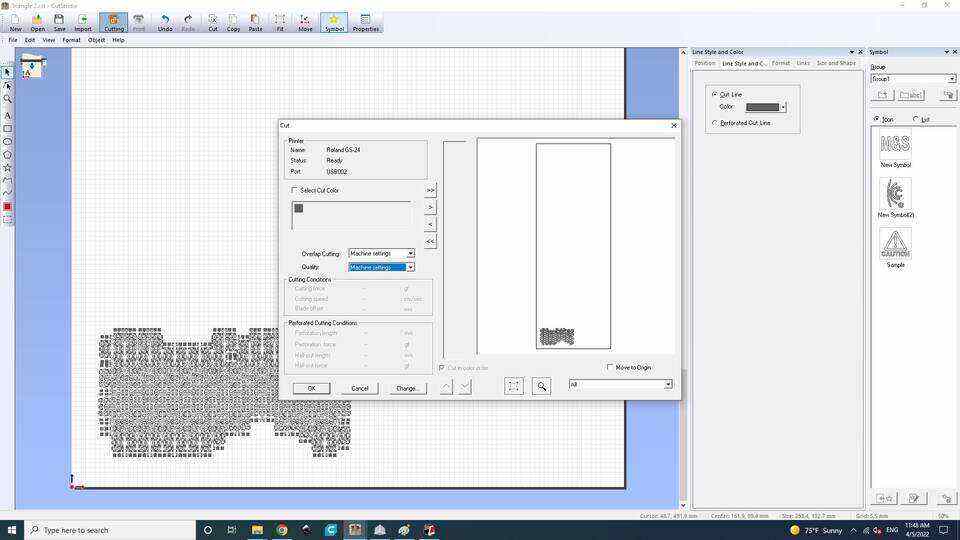

Vinyl Cutting Machine Roland CAMM-1 GS-24¶

Vinyl Cutting Machine cutting head with diamond cutter¶

Cutting head mounted on holder at the machine¶

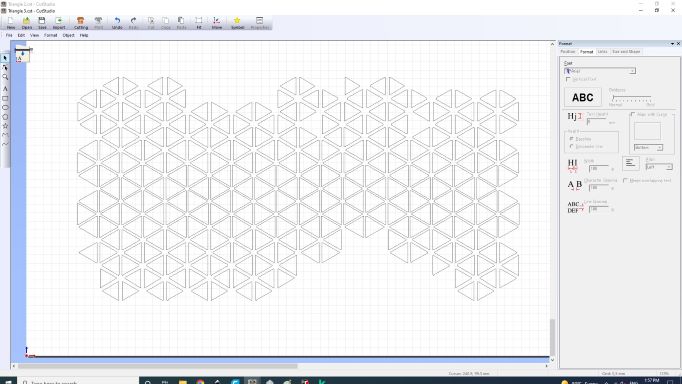

Abstract image chosen and imported to P-cut software¶

Abstract image exported to vectors and sending it to cut on Vinyl Cutting Machine by P-cut software¶

Loading Vinyl roll to Cutting Machine and adjusting rollers position¶

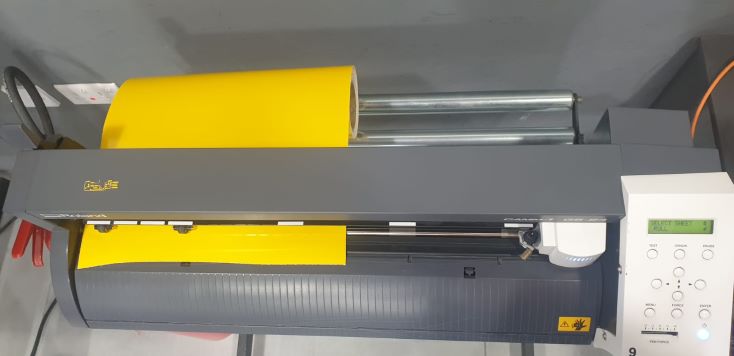

Abstract Pattern Cutting on Vinyl Cutting Machine¶

Abstract Pattern applying to Glass Door by cleaning the pattern area first¶

Using masking tape as transfer tape on cut pattern and applying the pattern to Glass Door and removing any wrinkles and air bubbles using flexible squeegee¶

Removing transfer tape carefully without removing the vinyl Abstract Pattern from the Glass Door¶

Final Abstract Pattern after removing old label and making the Glass Door more visible¶

Abstract Pattern File¶

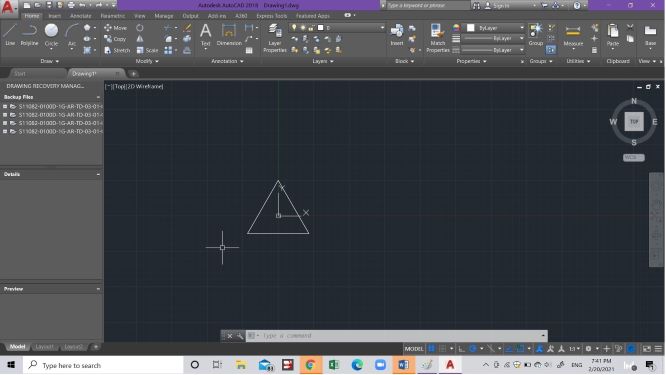

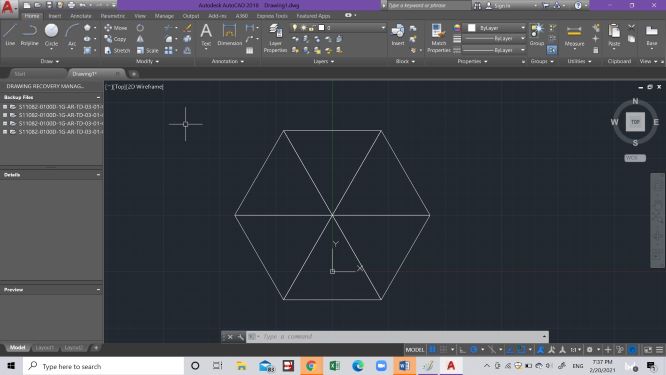

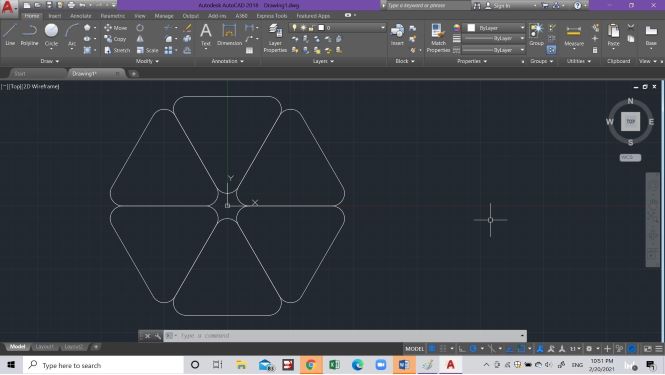

AUTOCAD¶

I used AUTOCAD software for designing 2D parts that I will use in Laser cutting my modular parts, where Modular Parts and Joints are designed parameterically to keep the same function of fit between parts.

AUTOCAD Drawing Triangle using Triangle function¶

AUTOCAD Drawing Rotating using Rotate function¶

AUTOCAD Drawing Filleting using fillet function¶

AUTOCAD Drawing Trimming using Trim function¶

Above illustrations are for commands I used AUTOCAD software in making my 2D design for modular parts.

Laser cutting¶

Machine:¶

The Laser Cutting Machine in Techworks-Amman is:¶

-

trotec Speedy 400 CO2 Laser¶

The trotec machine can accommodate material size 900mm x 600mm and has 80 watt CO2 laser source.

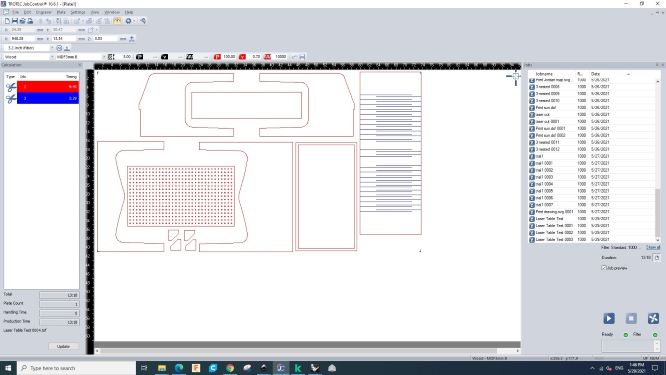

Importing dxf file for Grinding Table Prototype to cut on Laser machine¶

Mounting focus tool on Laser machine head to adjust machine table height to correct material thickness¶

Nested table parts after cutting on Laser machine¶

Waiting for the cutting fumes to clear from inside the machine before opening machine cover¶

Grinding Table Prototype assembled after Laser cutting¶

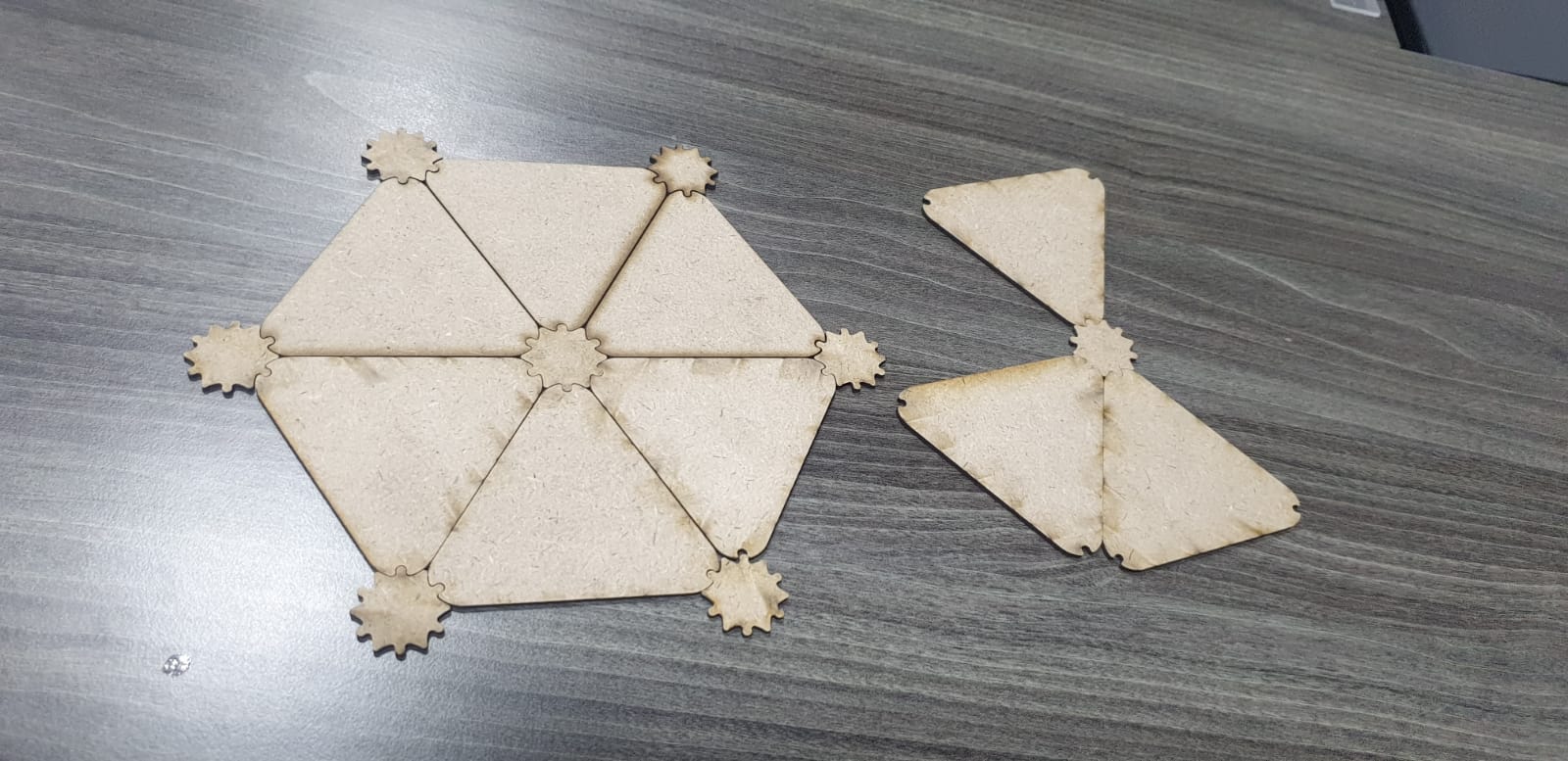

Laser cut test for Modular Parts from MDF board before cutting on acrylic sheet¶

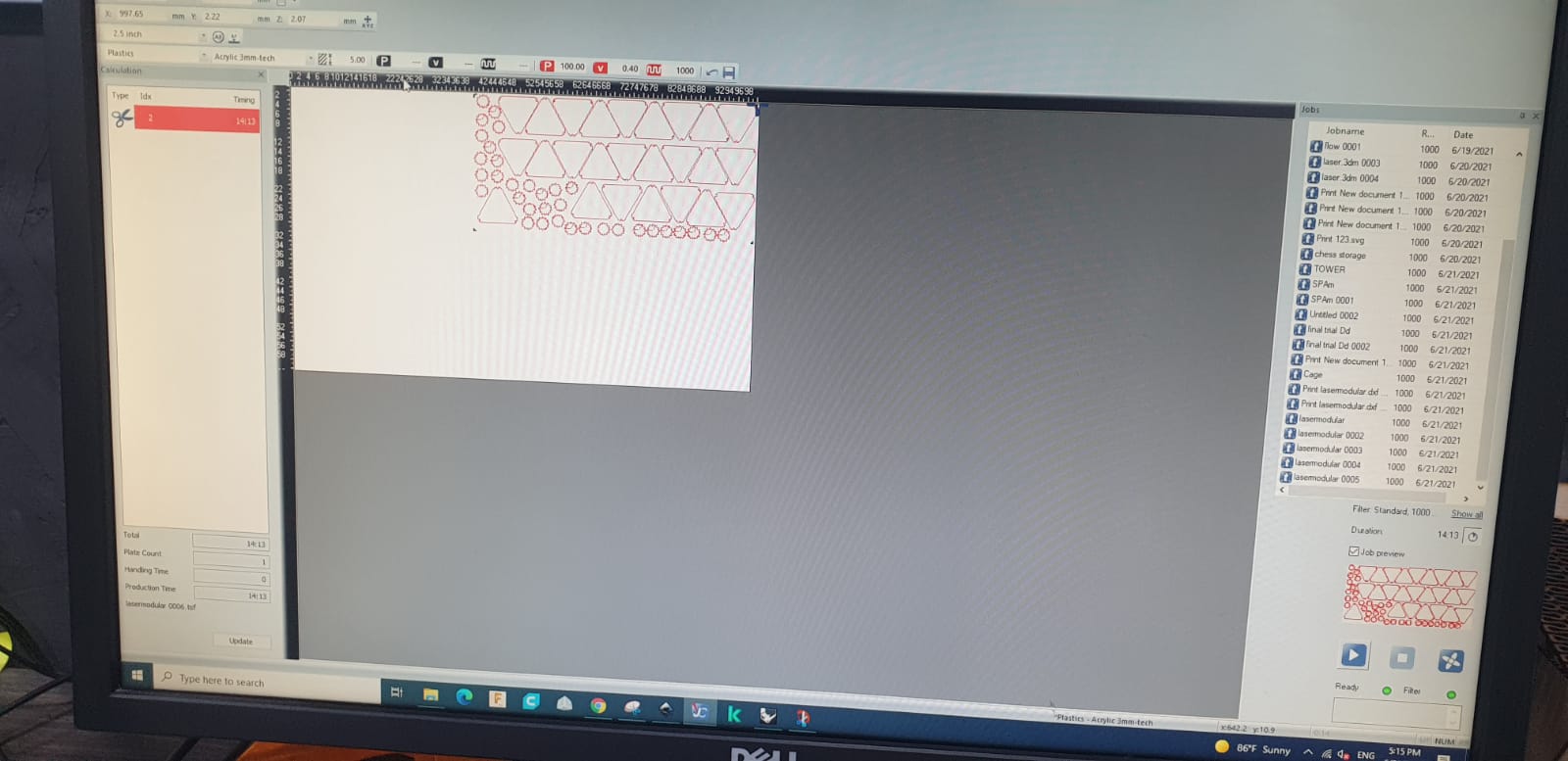

Importing nested Modular parts to Laser software for cutting¶

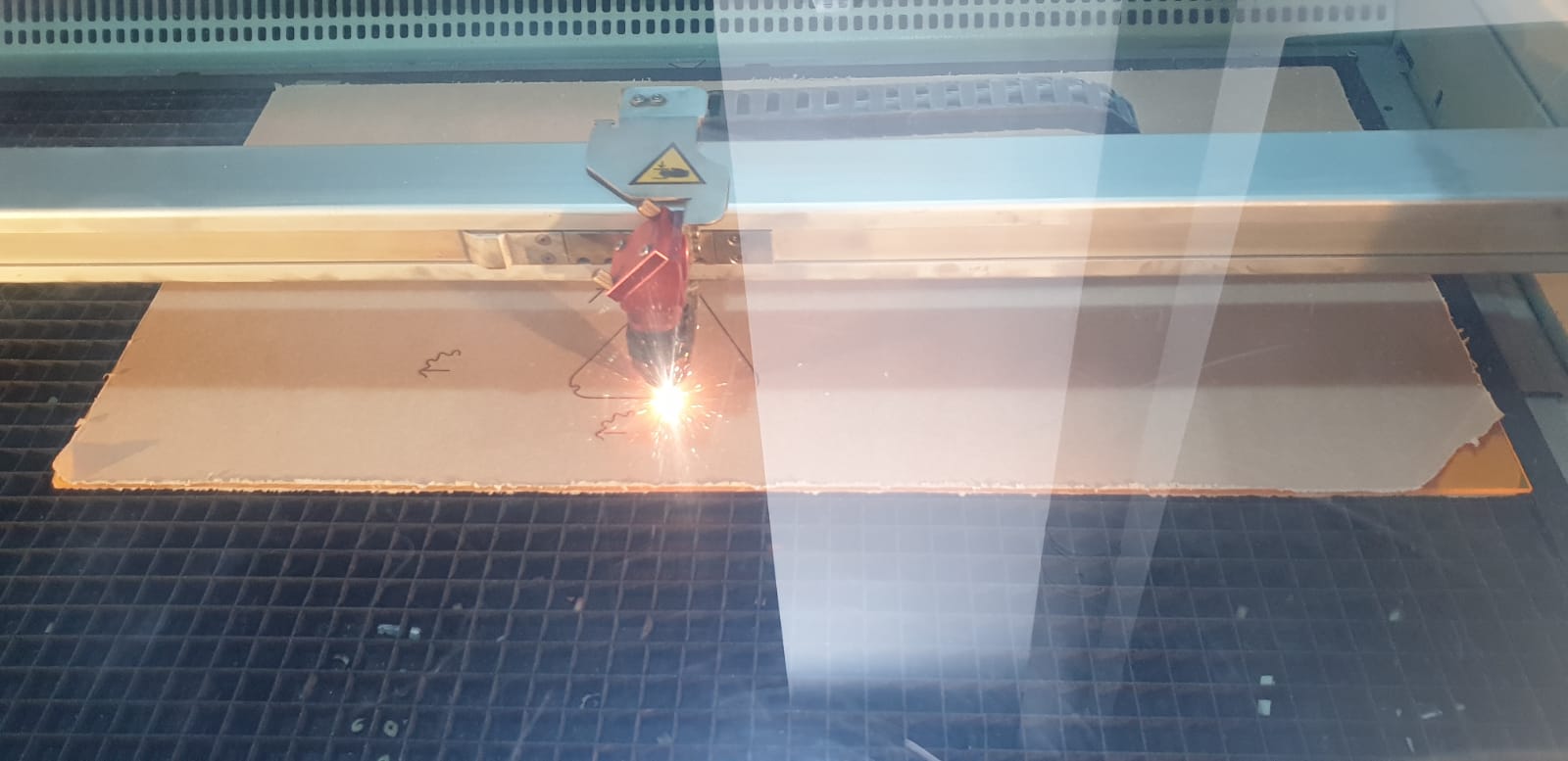

Laser cutting Modular Parts on acrylic sheet¶

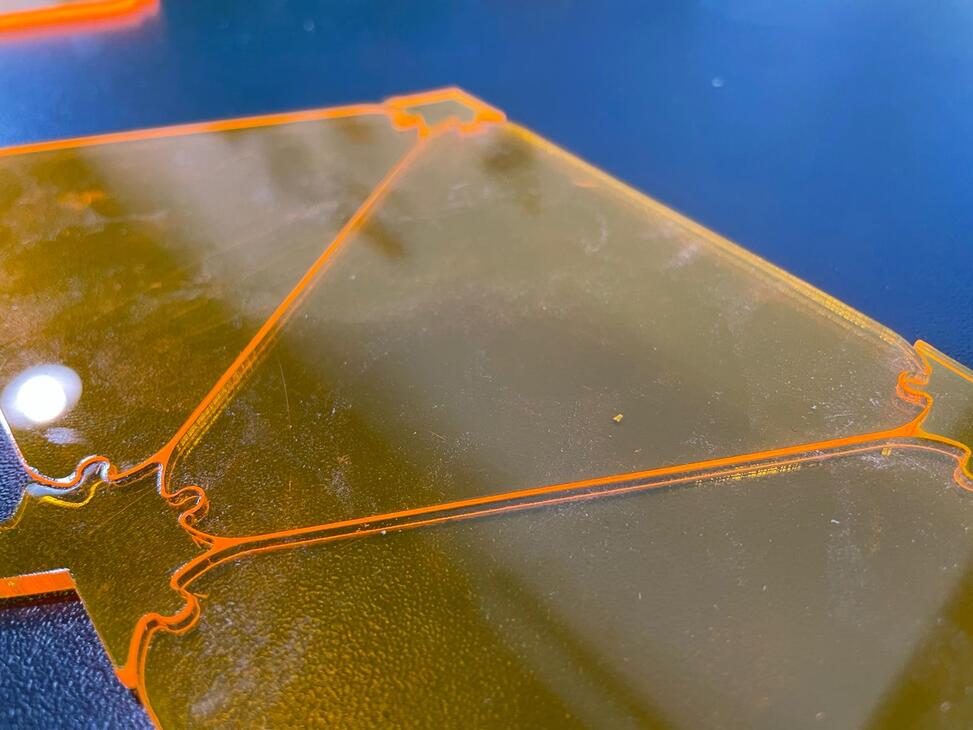

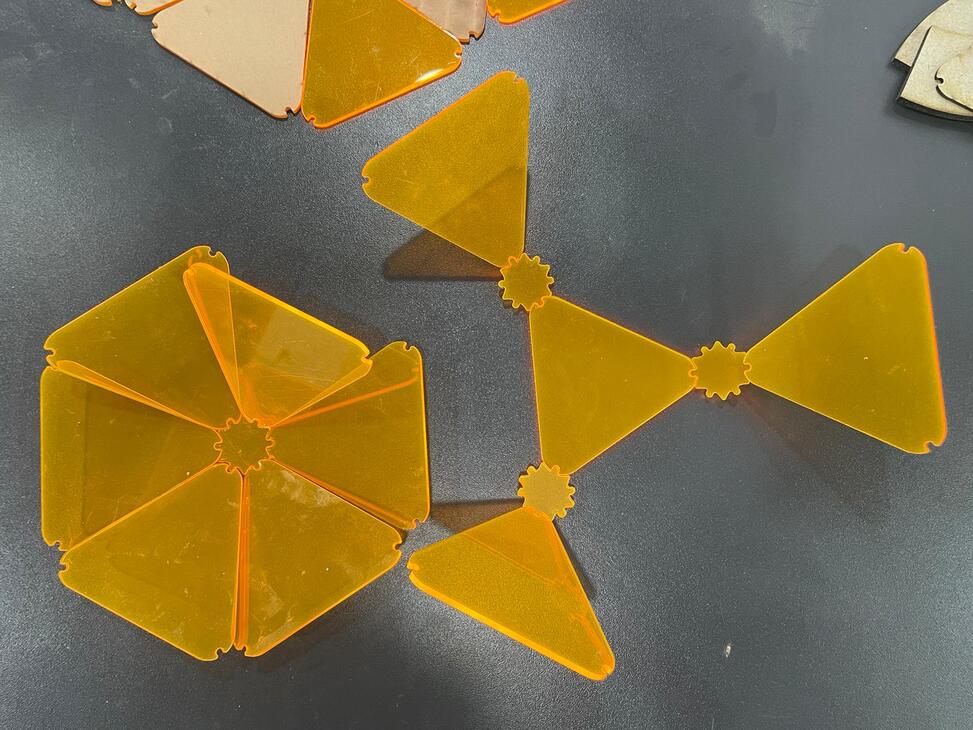

Laser cut Modular Part and joints¶

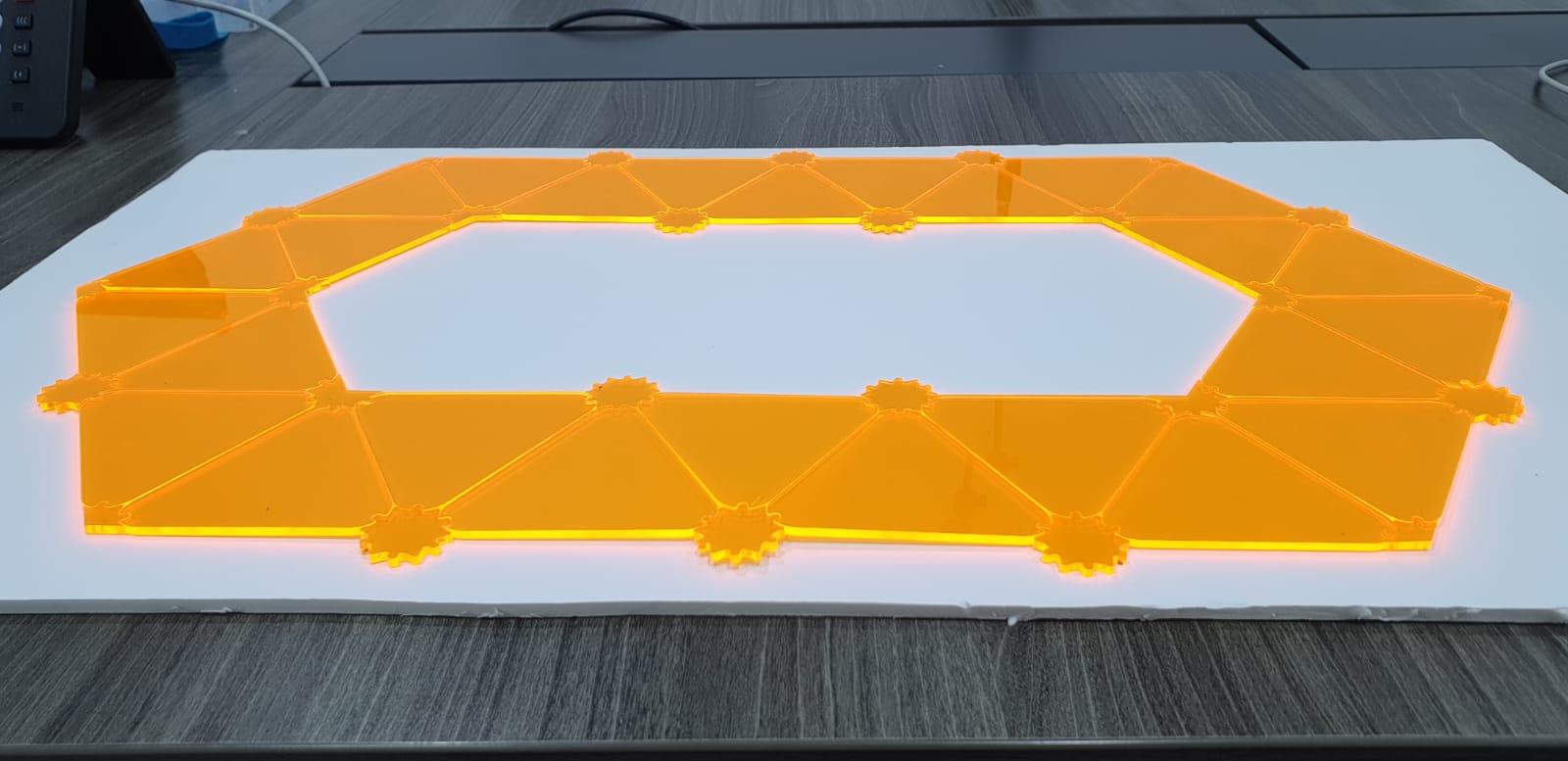

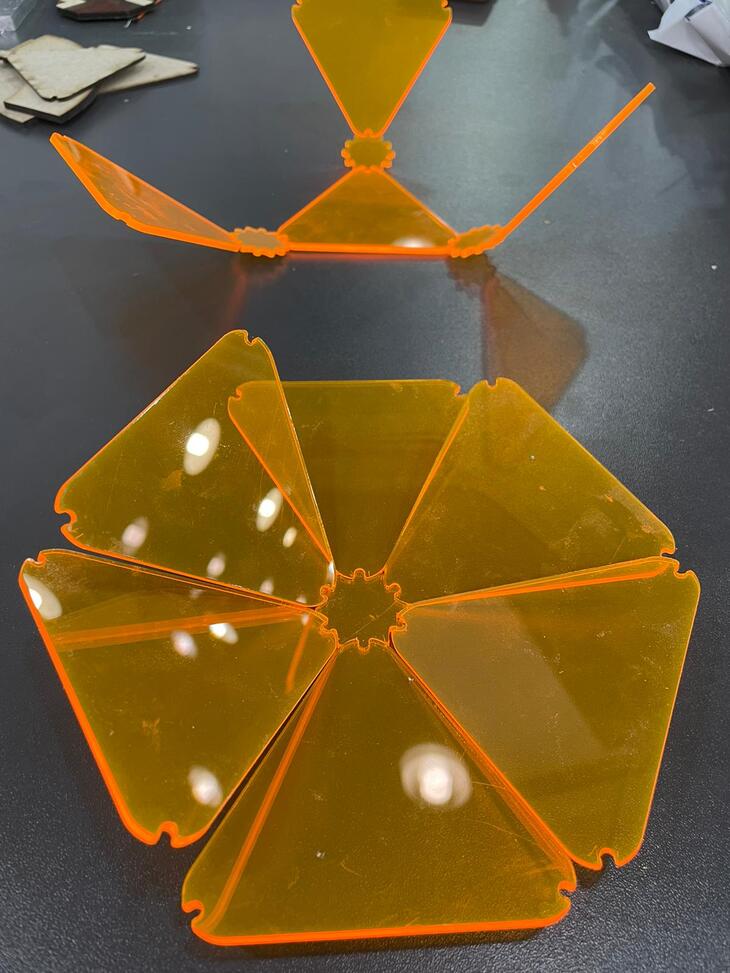

Laser cut Modular Parts assembled as frame¶

Laser cut Modular Parts assembled as shield¶

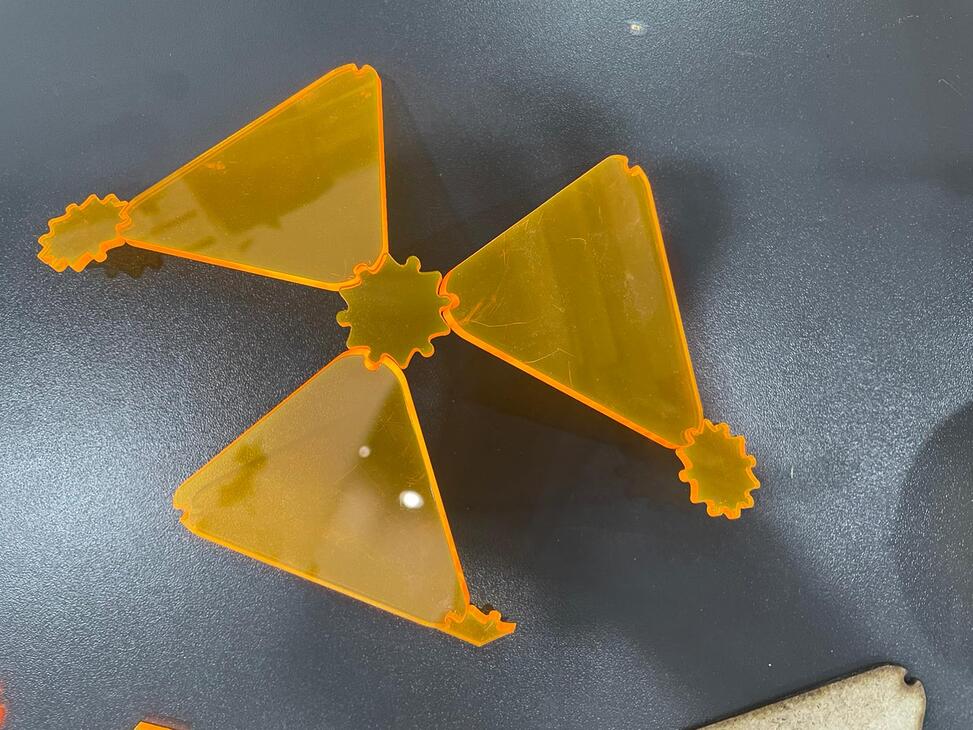

Laser cutting Modular Parts connected with joints¶

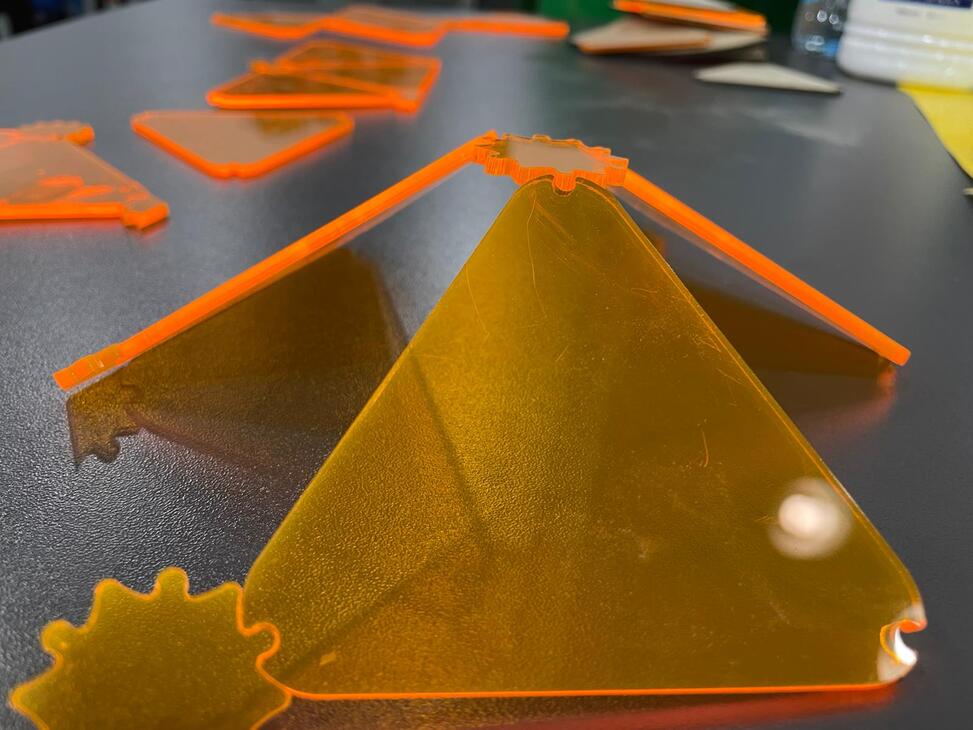

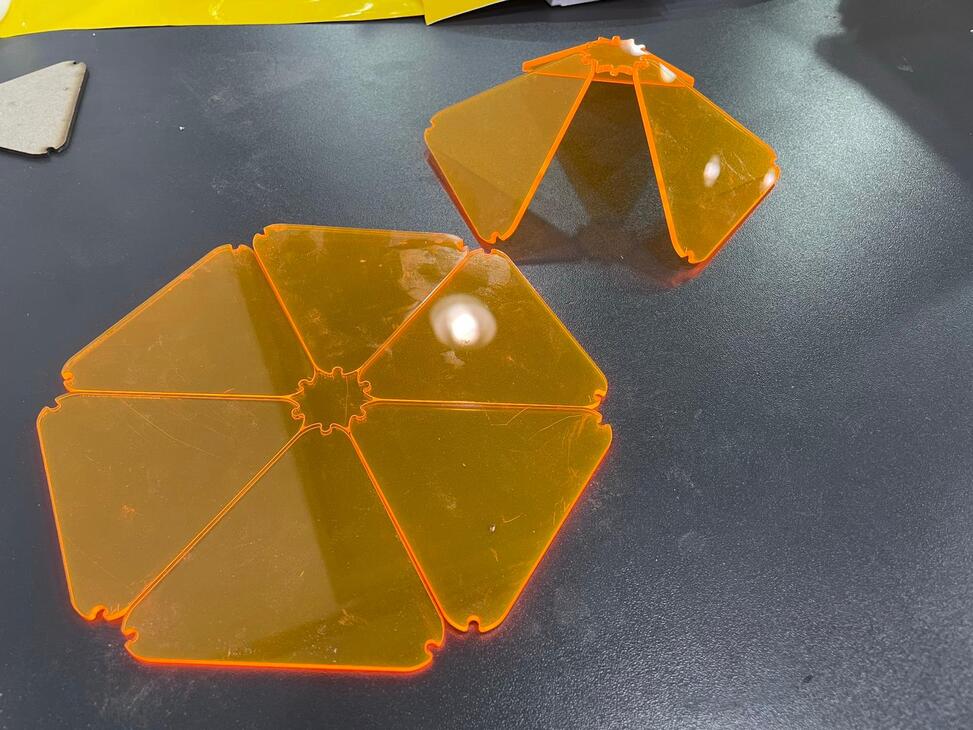

Laser cut Modular Part assembled as pyramid¶

Laser cut Modular Part assembled as pyramid¶

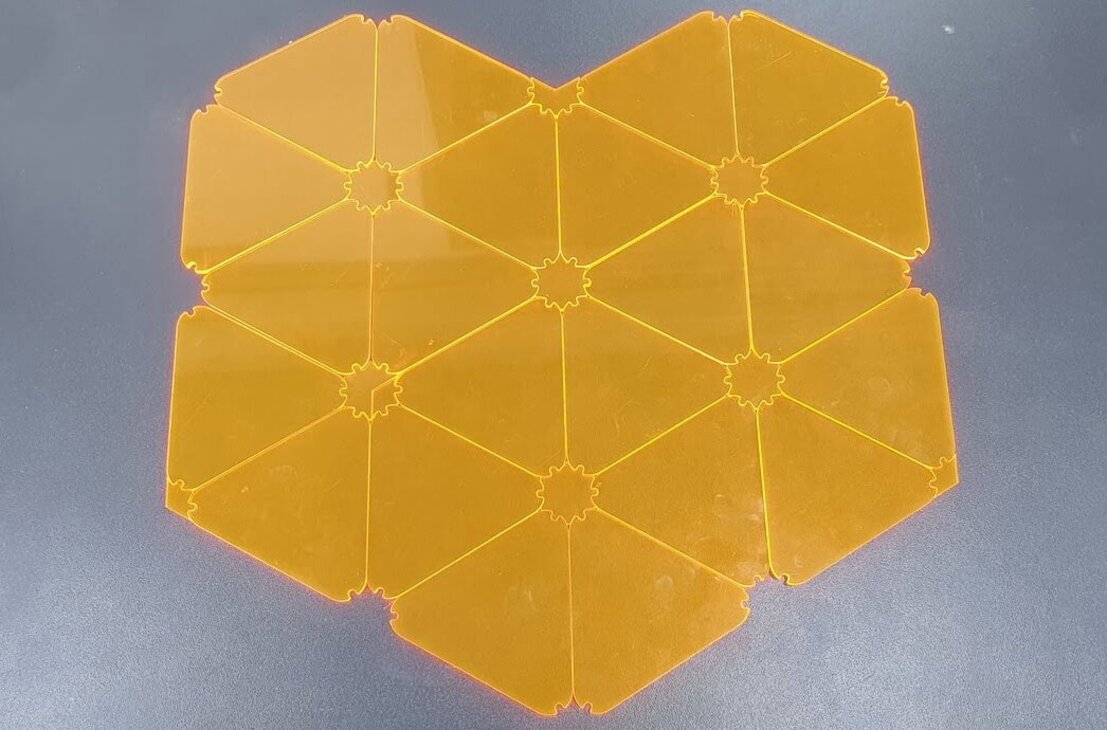

Laser cut Modular Part assembled as hexagon¶

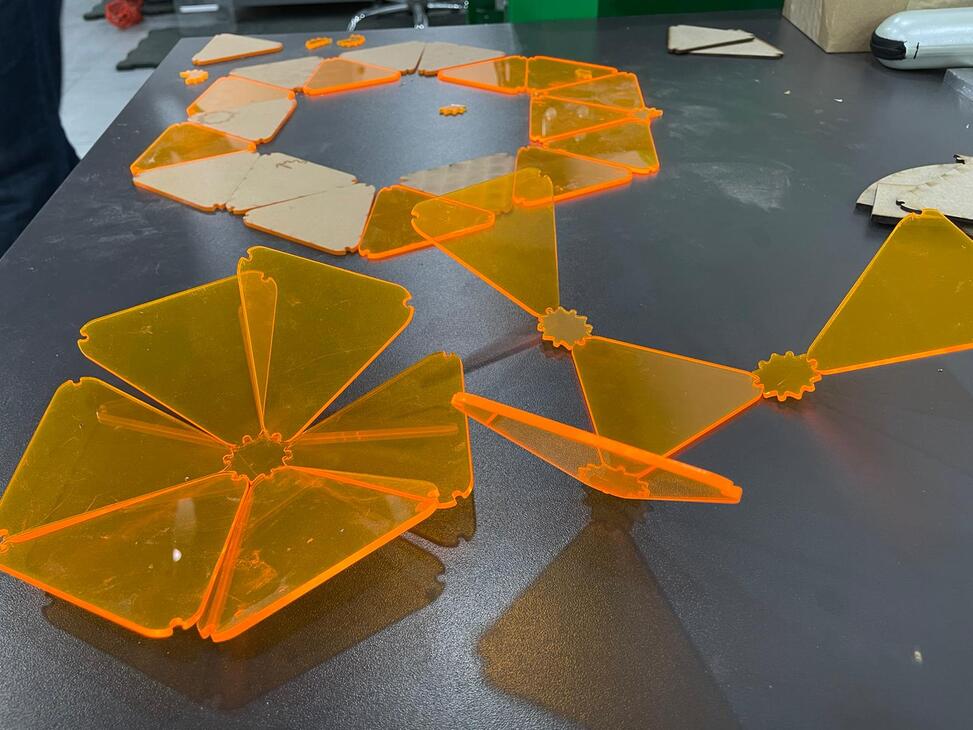

Laser cut Modular Part assembled as different 2D & 3D shapes¶

Laser cut Modular Part assembled as different 2D & 3D shapes¶

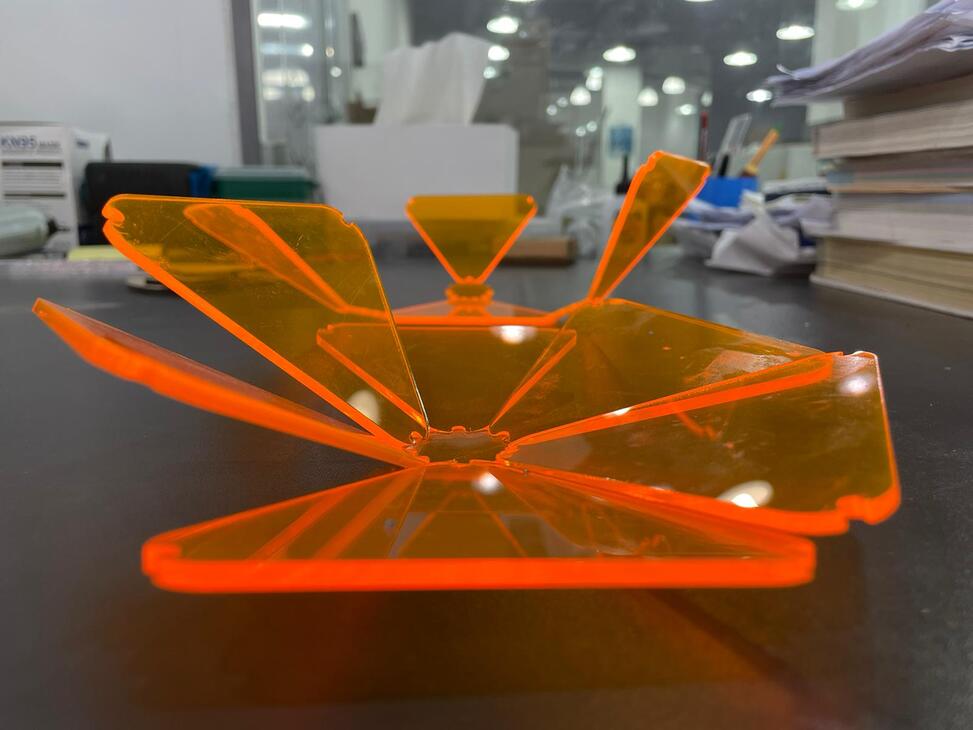

Laser cut Modular Part assembled as 3D flower¶

Laser cut Modular Part assembled as 3D flower¶

Laser cut Modular Part assembled as 3D flower¶

Laser cut Modular Part assembled as 3D flower¶

Video¶

Laser cutting Modular Parts¶

Laser cutting Modular Parts¶

Laser cutting Modular Parts¶

Files¶

Grinding Table Laser Test 2D DXF File¶

Laser Modular 2D DXF File¶

Last update: July 20, 2022