9. Mechanical Design, Machine Design¶

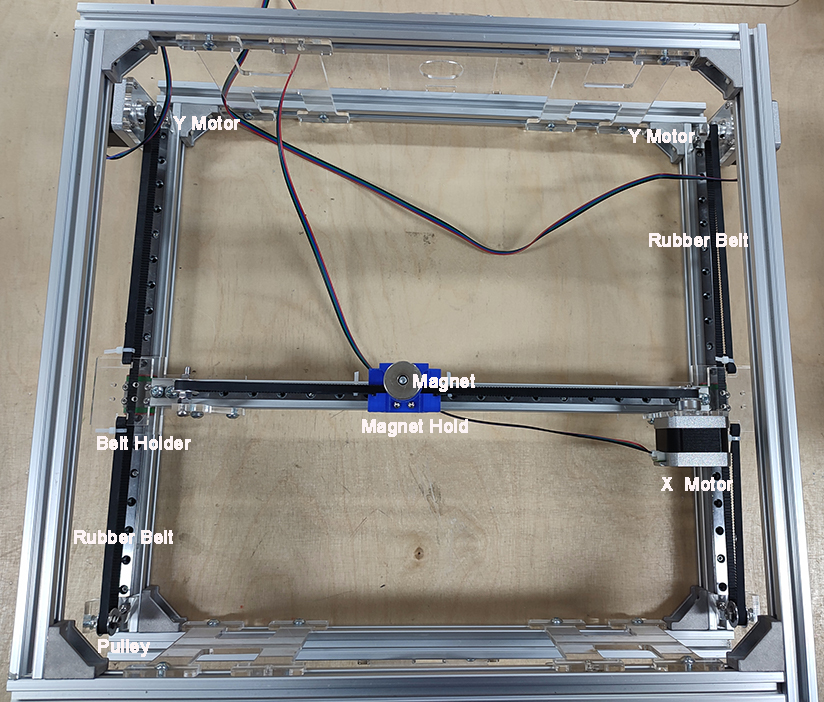

The topic of this two weeks for my group is to design one machine that includes mechanism, actuation and automation. After brainstorm, Chloe and I decide to design and make a machine that could draw in the sand.

Group Assignment¶

We spent half day on brainstorm. There’s so many interesting ideas, however considering our time and skills, we decide to make a machine that draw in the sand. Then we assembly the basic frame of the machine together. Chloe test and program the machine. And I was responsible to design the support for the motor and magnets.

Challenges & Problems that we met¶

At first we want to design one box to put the sand. Considering our machine basic frame and how far apart are the strong magnet and the iron ball meanwhile the magnetic force works, we just put the acrylic on the top and the magnets works very well.

Future development¶

We want to add the support for the sand box. We also want to try how many kinds of materials that the machine can draw on.

Group Assignment Reference:¶

https://fabacademy.org/2021/labs/oshanghai/students/chloe-huang/assignments/week09/

Individual Contribution¶

The support for the motor.¶

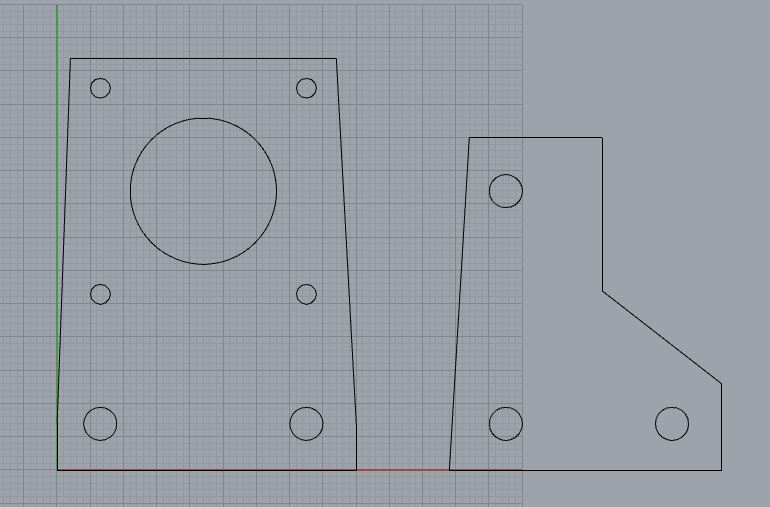

The material for motor & pulley supports is the acrylic in 6 mm thickness. We use the laser cutting machine. The support uses black stroke line without filling, 0.05 pt widthdeth. The speed is 0.7, the power is 88 %, and the PPI is 1000.

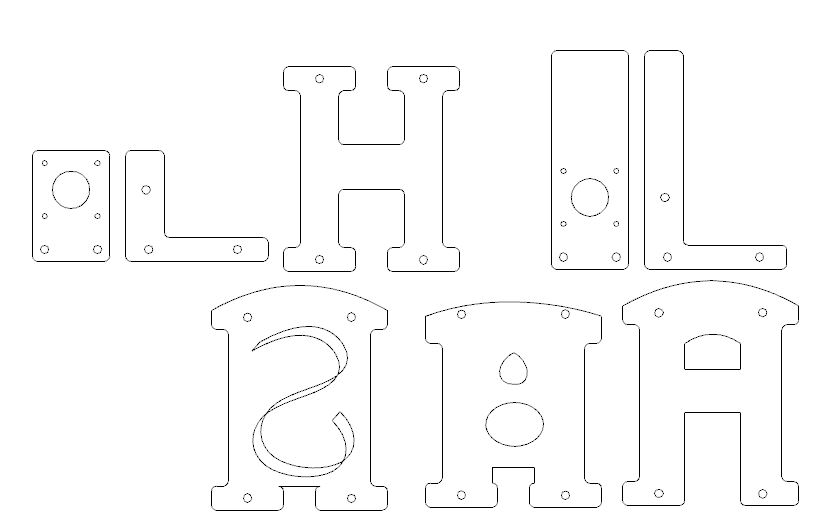

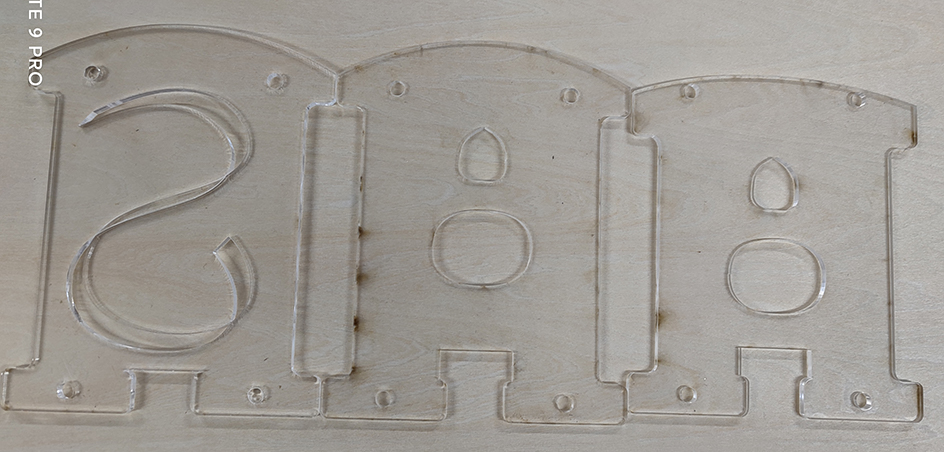

We design the two shapes as the support for the motor at first. Then I decide to use our name Chloe and Alisa to draw the support shapes in Rhino.

A and I are from Alisa, H and L are from Chloe. For the first version A, I merge S with A characters and found it is fragile and couldn’t hold the second layers of the machine. And the 2nd A version is too high that the top Acrylic couldn’t stay in horizon. And the third verison works very well.

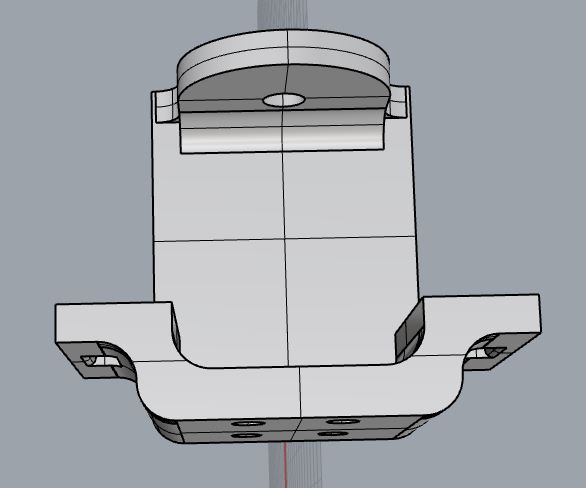

The magnet Holder¶

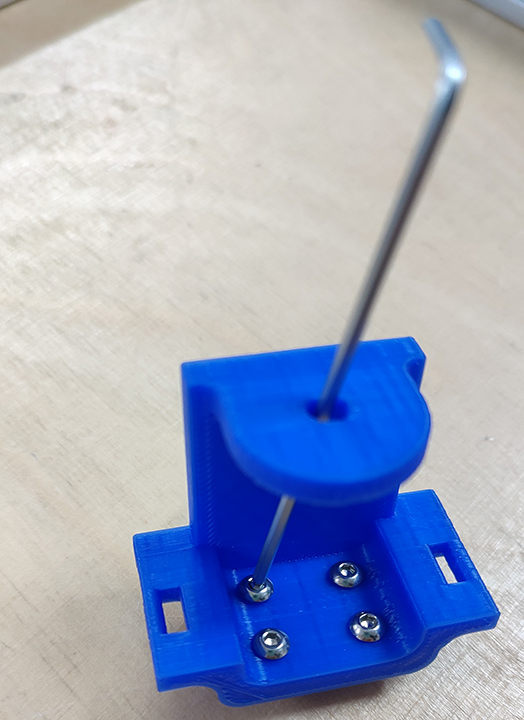

I design the holder in Rhino and slice in Cura .The hole in the half circle is to put the magnets and the right part is to connect the rubber belt. Considering the magnetic force, the height of the holder is designed a little smaller (around 0.3 mm), which will give a little space between the top Acrylic and the magnet and allow the magnet move freely without friction.

The top half circle may be not print well without support, I rotate the holder and print it in FDM printer.

Challenge and Problems¶

- When I design the magnet holder, I don’t consider how to fix the holder to the machine until I fix it. So I fix the screws by hands firstly and then put the tool through the hole on the top to tighten the screws.

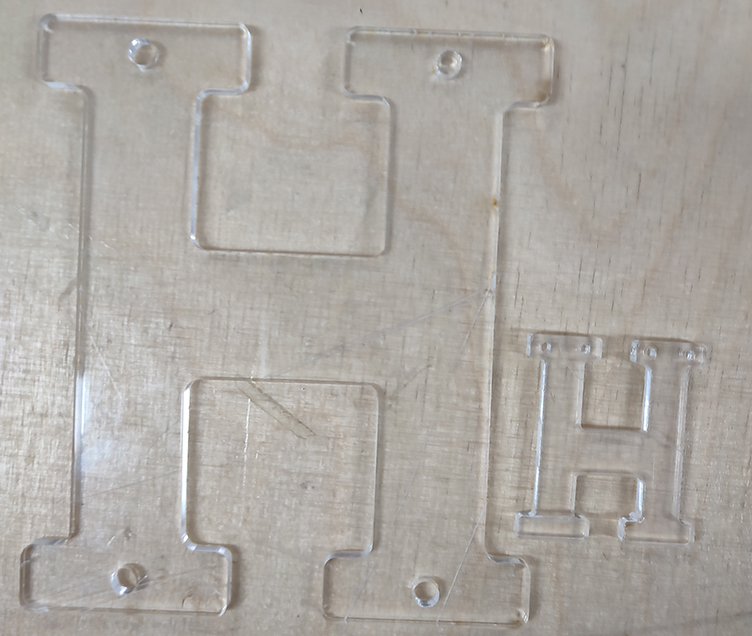

- I forget checking the size of the shapes in the Adobe Illustrator software before cutting it, and get one cute “H”.

File: motor support magnet support