20. Project development¶

My final project¶

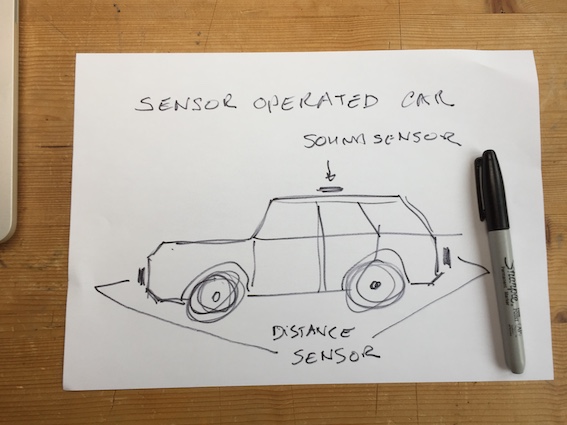

For my final project I would like to make a sensor operated bump-and-go car. But with a difference. The traditional bump-and-go car has to bump against a wall or an object to change direction. Mine will be sensor operated. So it will not bump against an object but change directions at a certain distance from the object.

This toy car will be for playful people from 8 till 88

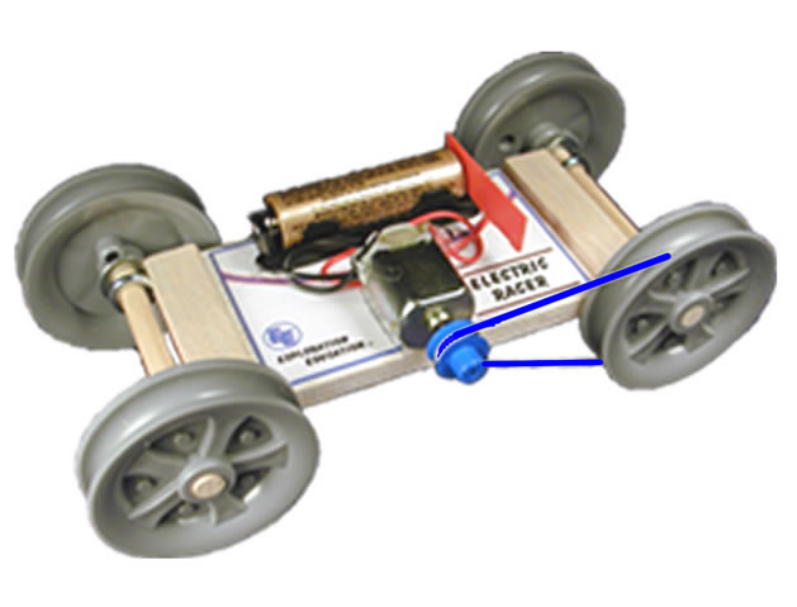

View from the side, although this looks to car’ish. I would like to give it a more abstract shape.

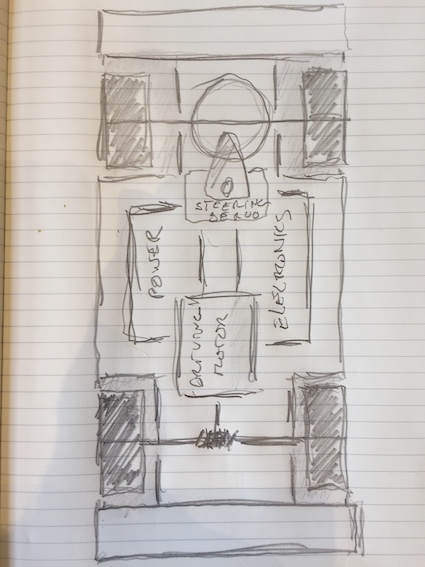

View at the bottom. This is how I think I should organize the driving, steering, power and electronics.

What do I have to research for this project?¶

- Material for the car, wheels, and axes

- Gearing from motor to ax

- Steering mechanism

- Servo motor for steering

- Micro USB rechargeable battery

- Electronics such as distance sensor

And off course all the machines to make it.

Update 20 February¶

New Look¶

Plan is to give the car the looks of a Renault 4

New sensor idea¶

In the initial idea the car interacts with the wall by a distance sensor. To make it interactive with the user the steering should be sound based. The user claps hands or shouts.

Material¶

Plan is to build the car from several layers of 18 mm birch plywood

To Do¶

Buy a RC car to figure out driving and steering

Update 25 February¶

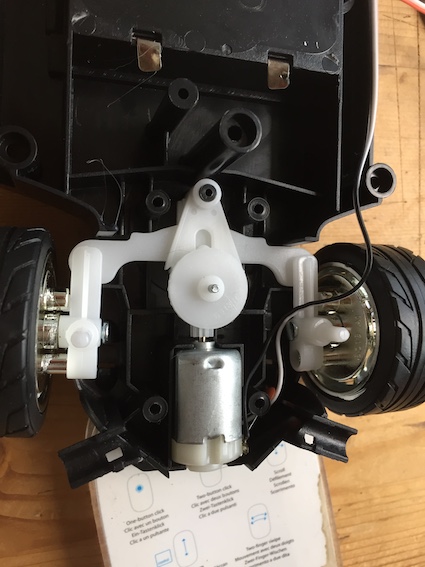

I bought a RC car and took it apart. The driving is quite simple: the moter is directly connected to the axel by gears. One on the motor one on the axel.

The speed of the motor (the car) is very high. The control has only 2 positions: drive (fast) & stop

• In stead of gears I could use pulley and a rubber band.

• I have to gear the speed down.

Someting like this

The steering has a seperate motor. The control has three positions: left, middle, right. When the wheels are in the upmost left or right position the motor stops.

Update 1 March¶

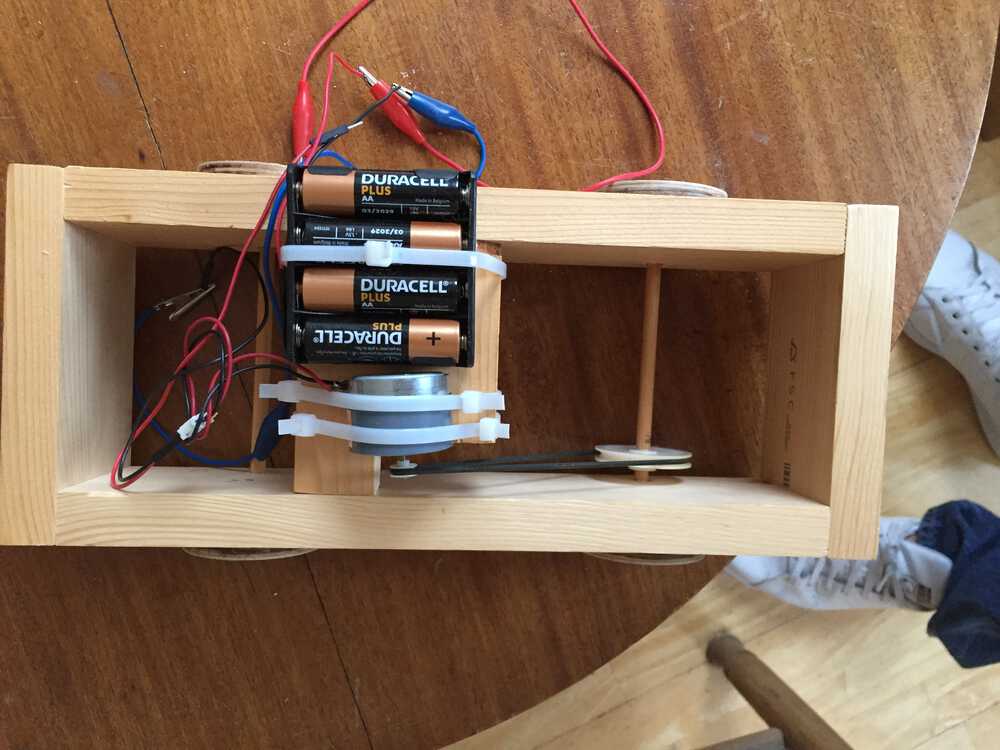

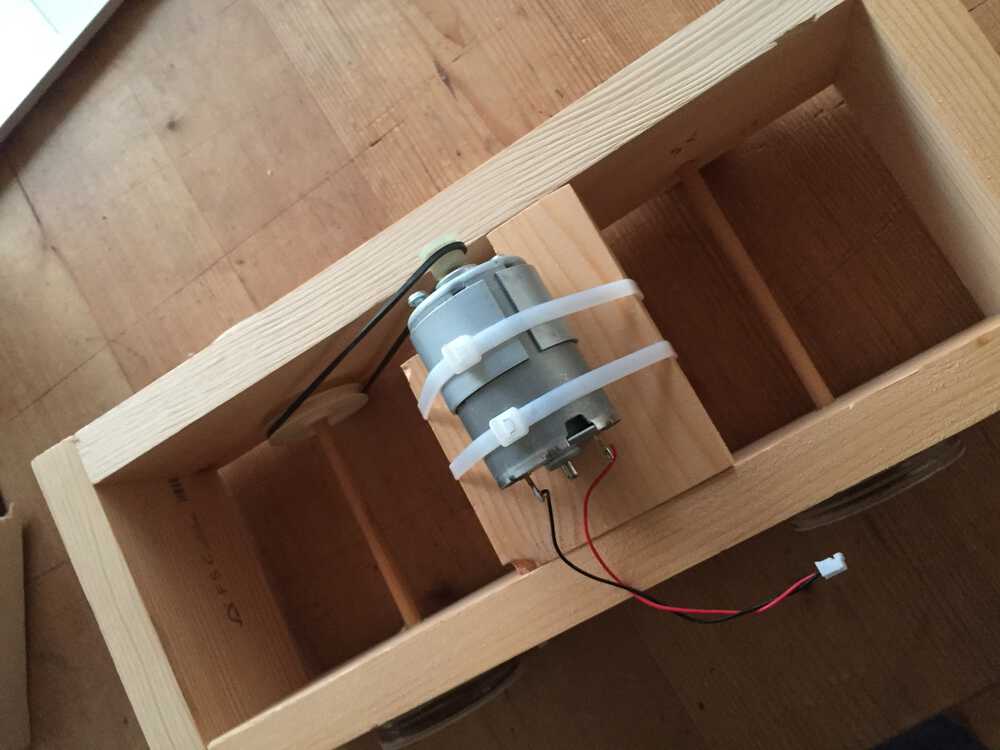

I tinkered a car. With a hole saw I sawed out 4 wheels out og 9 mm plywood. For the body work I used 18 mm pinewood. I was especialy interested if the drive would work.

I used a motor I took out of a printer. On the axel I put a pulley, also from a printer. To connect them I used a rubber band. For 12 V power I used 8 AA batteries.

The rubber band drive worked okay. I replaced the motor by a smaller one with a better pulley. I think 12 V is a little bit too much for the motor (salvaged from a record player) so I have to test is with 6 V.