Molding and Casting

Molding and Casting

Week 15 Molding and Casting Workshop Note May 14th 2020

Safety - Materials should be stored and used in a warm environment (73° F / 23° C). These products have a limited shelf life and should be used as soon as possible. All liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal, glass or plastic. Mixing should be done in a well-ventilated area. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk.

○ Pot Life : 9 minutes

○ Cure Time : 60 minutes

○ Mixed Viscosity : 100 cps

Work Flow

- Safety gears on and gloves

- Extraction on

// Read 1) safety datasheet, and 2) datasheet for each material/chemical

○ https://www.smooth-on.com/products/smooth-cast-326/

○ https://www.smooth-on.com/msds/files/Smooth-Cast_326_327.pdf

○ https://www.smooth-on.com/tb/files/SMOOTHCAST_325_326_327_COMBO_TB.pdf

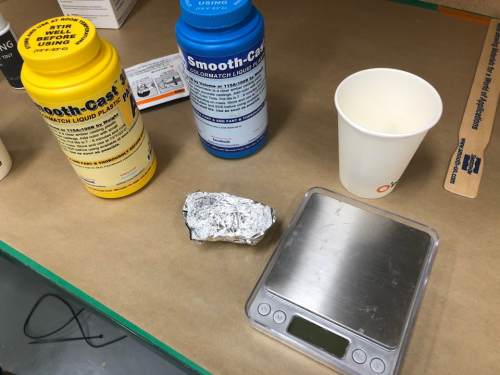

- Measure the two parts (by weight)

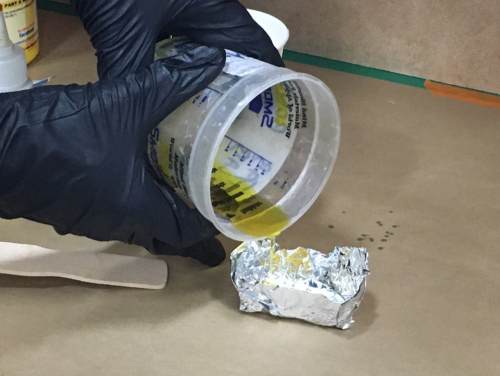

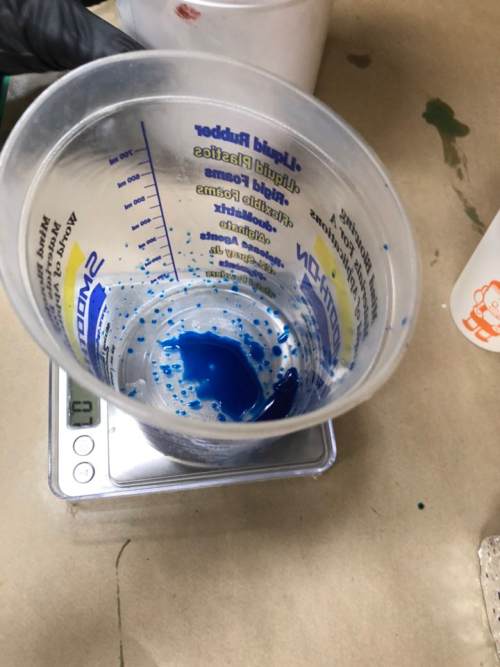

- Mix ‘em (add color before/during this mix process)

- //De-gasing = Remove air bubbles

- Wait

- (alongside the step 6) reset and clean up

○ Mix Ratio_01: 115A : 100B

○ Total: 10g

○ 5.348A : 4.651B

○ Smooth-Cast 326

○ The clock starts after mixing the two materials Not racing the clock until we mix them together.

○ Start_01: 10:30PM Hawaii or 5:30PM Korea

○ Useful to wear two pairs of gloves, one on the top of the other

Smooth cast- 65D

Safety - Materials should be stored and used in a warm environment (73° F/23° C). These products have a limited shelf life and should be used as soon as possible. All liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal, glass or plastic.

○ Pot Life : 2.5minutes

○ Cure Time : 15 minutes

○ Mixed Viscosity : 120 cps

○ Smooth-Cast 65D

○ Smooth-Cast 65D

○ Mix Ratio_02: 100:93

○ Total: 30g

○ 100:93

○ 15.54 : 14.46g

○ Start_02: 10:41PM Hawaii or 5:41PM Korea

Mold max 60

Mold max 60

Safety Preparation - Materials should be stored and used in at room temperature (73°F/23°C). These products have a limited shelf life and should be used as soon as possible. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. Rubber may be inhibited by sulfur base clays resulting in tackiness at the pattern interface or a total lack of cure throughout the mold. If compatibility between the rubber and the surface is a concern, a small-scale test is recommended. Apply a small amount of rubber onto a non-critical area of the pattern. Inhibition has occurred if the rubber is gummy or uncured after the recommended cure time has passed.

○ Pot Life : 2.5minutes

○ Cure Time : 15 minutes

○ Mixed Viscosity : 20000 cps

○ Mold Max 60

○ Mix Ratio_03: 100:3

○ Total: g

○ 100:3

○ 200 : 6g

○ Start_02: 10:41PM Hawaii or 5:41PM Korea

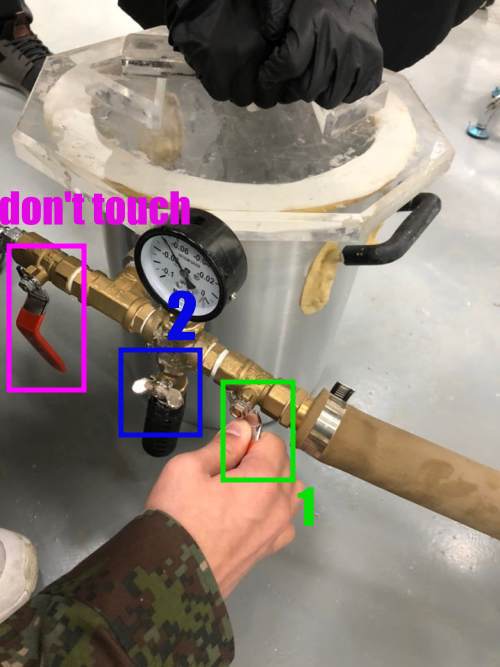

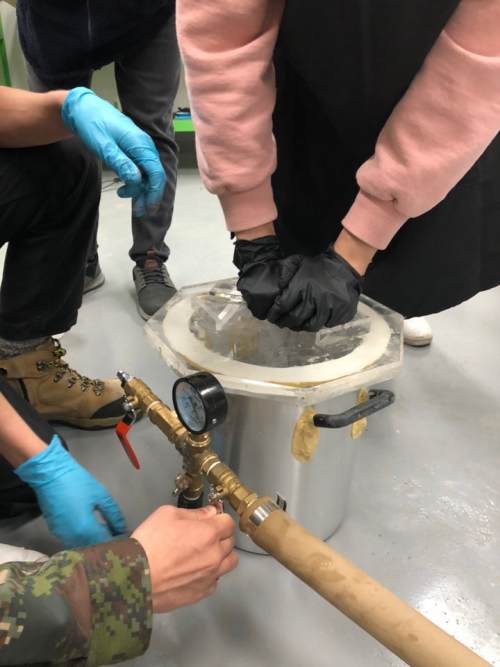

○ Use vacuum chamber

IMPORTANT: Use every velve slowly (Health and Safety).

For this week’s learning process, we should only use velves 1 and 2 and should not touch/use the last one.

The Velve 1 increases air pressure inside the chamber, thus making it vacuum.

The Velve 2 decreases air pressure (usually after using the velve 1) by putting some air inside the chamber.

By giving some weight on the top of the lid, make sure the lid is completely attached to the chamber.

By wisely using both velves (1 and 2), control the pressure inside the chamber in a relatively stable way.

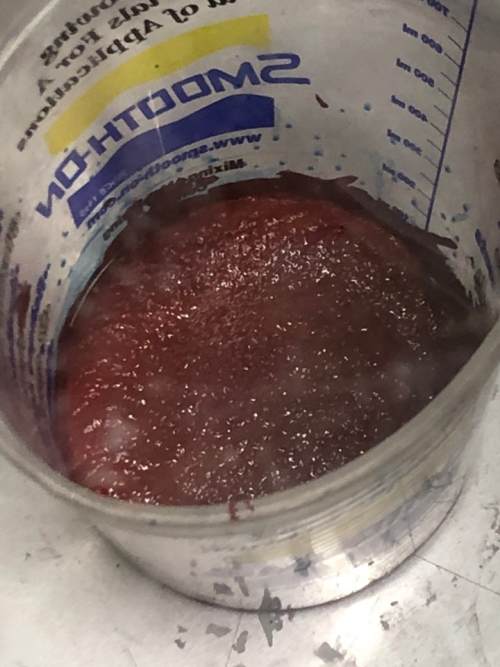

The two photos above show the process of removing air bubbles, which will in turn increase the quality of the final result.

The two photos above show the process of removing air bubbles, which will in turn increase the quality of the final result.

During this process, make sure to tighten the velve 1 up when you see too many air bubbles come up to the surface of the material(liquid), and vise versa.

Question

Q. How do we know how much one chemical goes in?

○ Measure the volume by using water first

Q. How do we know whether or not it is mixed well?

○ Increased viscosity

Q. How much pigment/color/filler do we add?

○ Generally, 0.5% - 1% of the whole thing

Result

○ Smooth cast 326 is the result of a separate yellow dye. It has a very hard material, and is difficult to break or do easily by hand. The amount is small, so it seems light or heavier than other materials. And it’s transparent, so it’s possible to see it.

○ The Smooth cast 65D was very hard and equally light. It was the result of opaque white color and has little flexibility.

○ Mold max 60 First, the smell is a little strong. It’s made of rubber, so it’s flexible and light. The surface is also likely to be colored. It’s not as flexible as silicon, but it feels more robust.