Week 7- Computer Controlled Machine

Overview

For this week we have two assignments:

- Group assignment

- Individual assignment

Test runout, alignment, speeds, feeds, and toolpaths for our machine

Make (design+mill+assemble) something big

My Assignment Steps:

Step (1):Get the idea.

Step (2):The design process.

Step (3):The Milling and assembly.

The Process

Get the idea !

I volunteer as a kid coach in Ihyaa academy in which I help kids explore the field of media production especially the filmmaking and designing process.

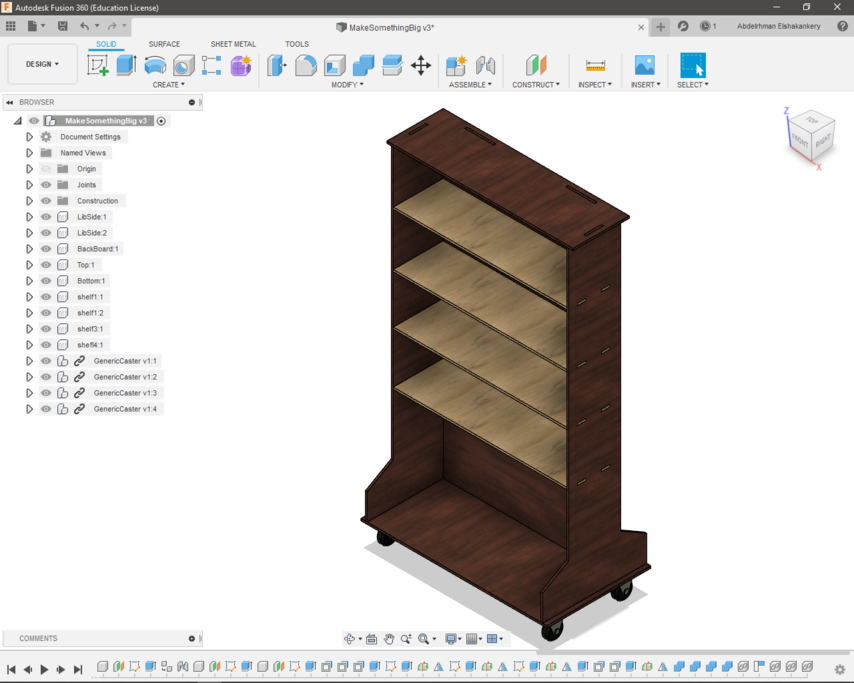

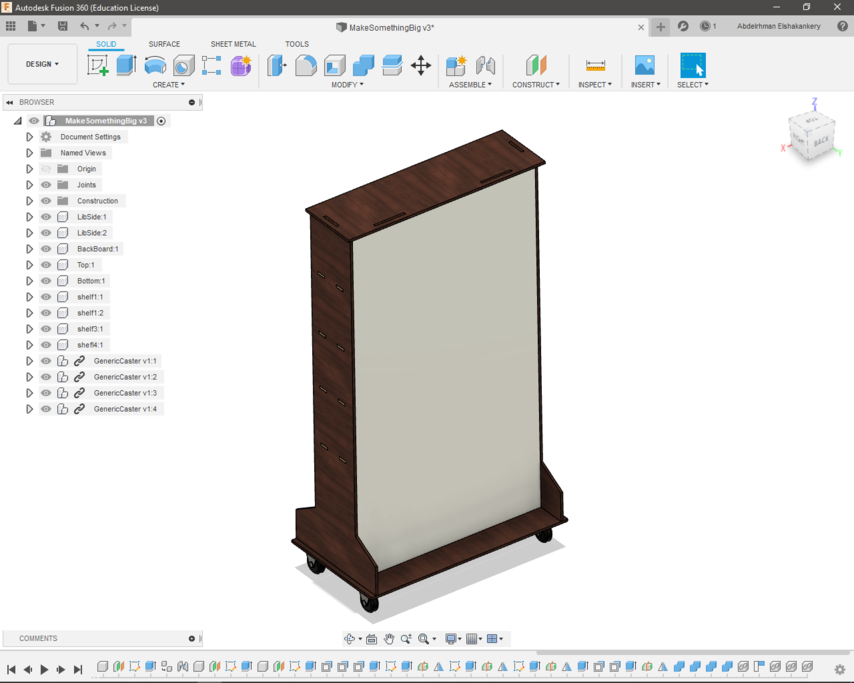

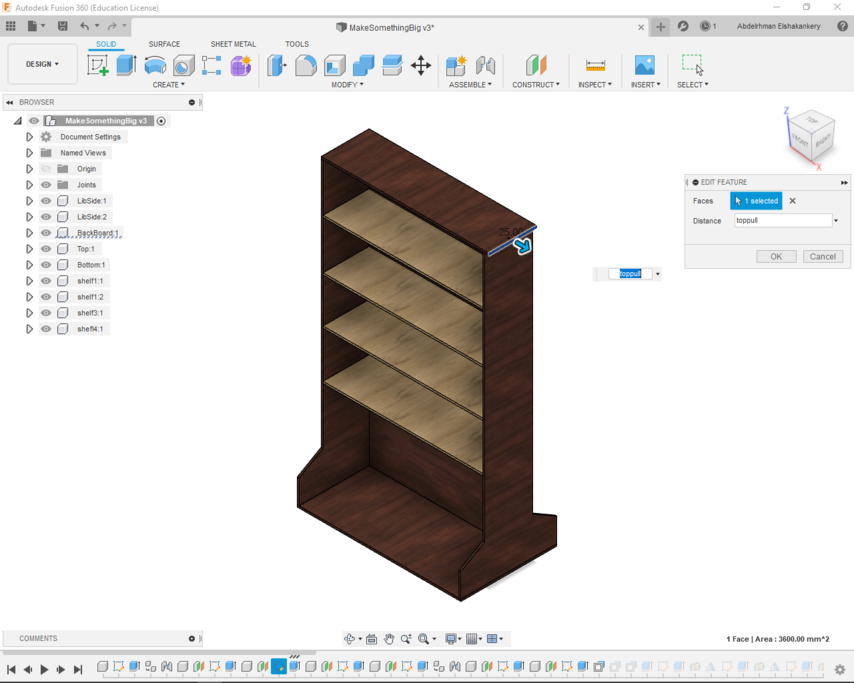

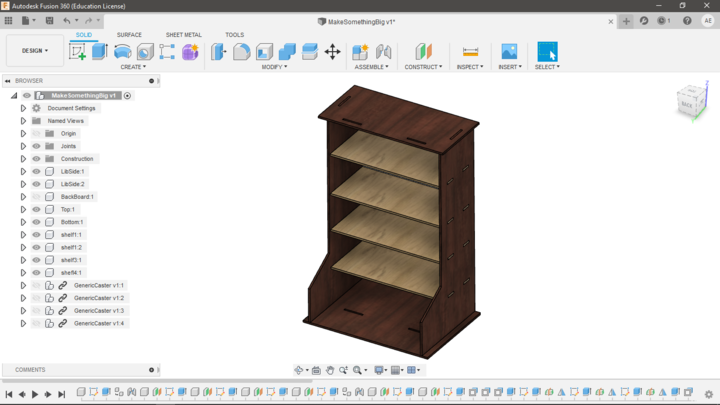

Revers studio is the name my kids choose for our team and somehow we started to build an actual small studio within the academy for them. So as you can see in the picture to the right we have number of shelves organized together to be used as a storage unit. Therfore, my idea is to create a double-edge shelves/whiteboard in order to make a good use of the small area we have.

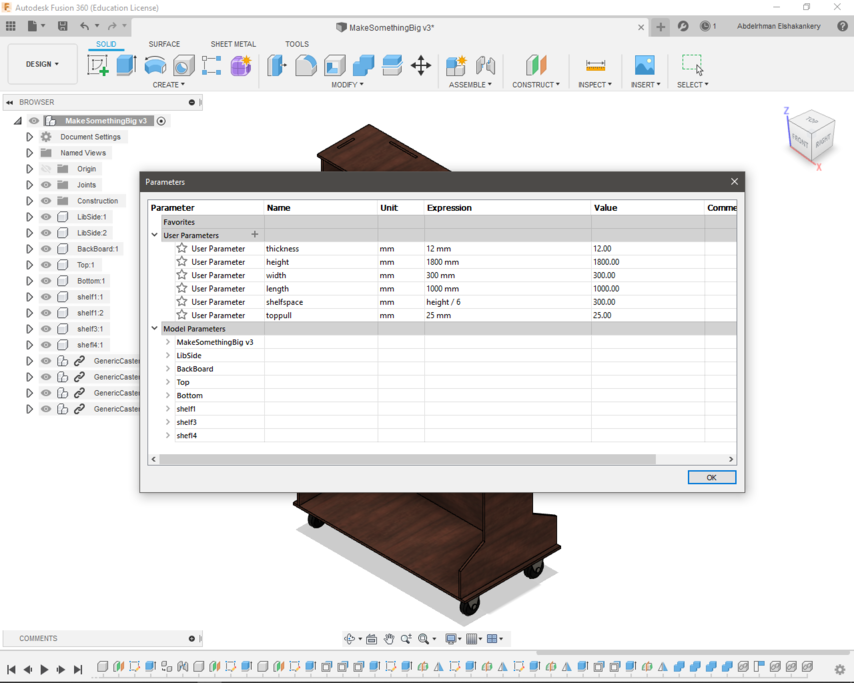

The design process

Edits due to Covid-19

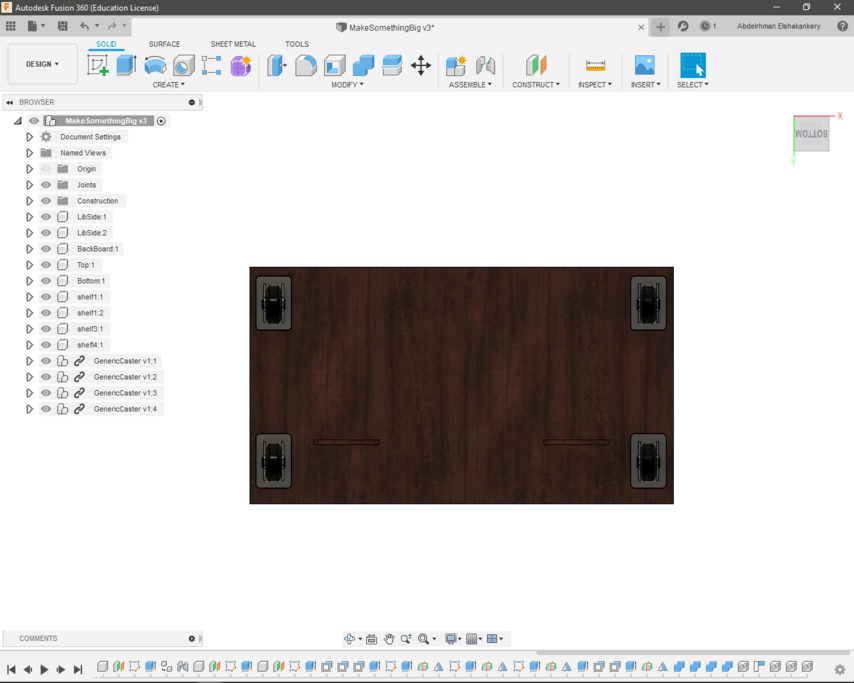

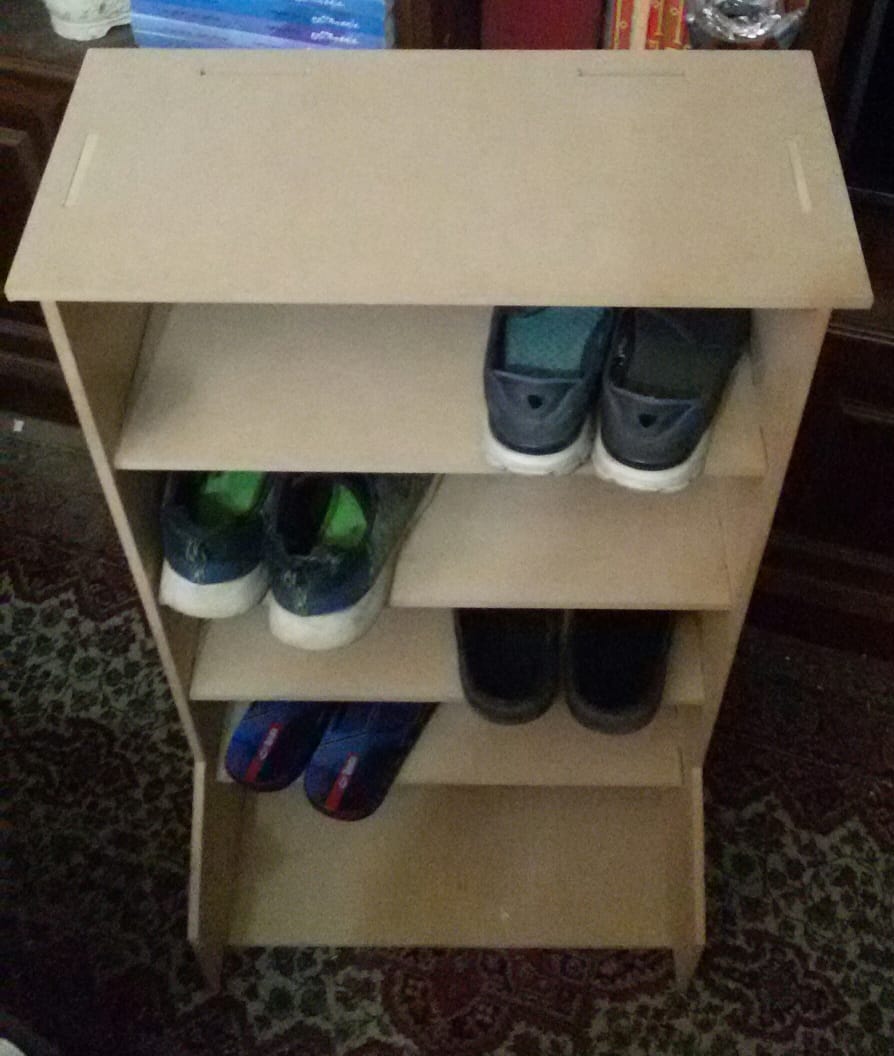

Due to the circumstance of Covid-19 we weren't able to access the our Router machine till October and we have a limited size of wood sheet that my storage unit wouldn't fit, So I edit my design parameters and change my storage units to a Shoes cabinet

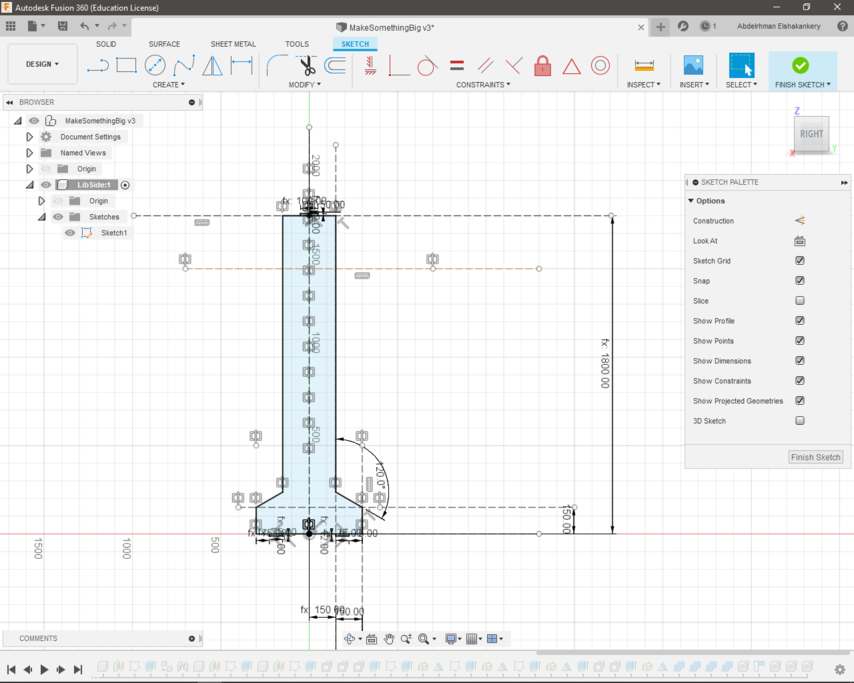

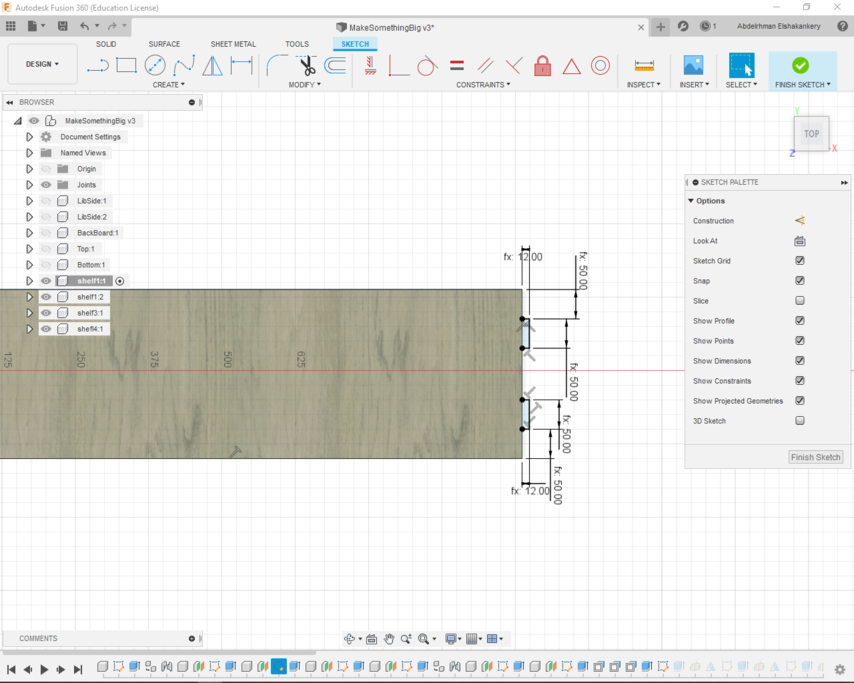

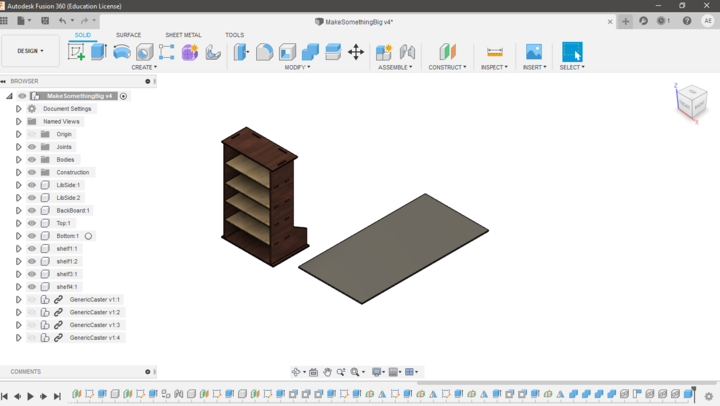

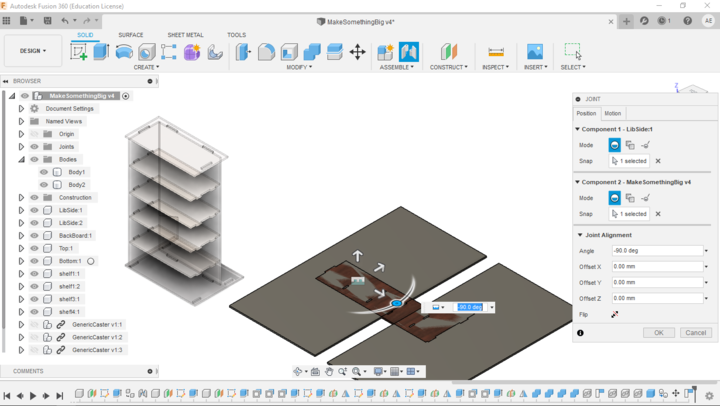

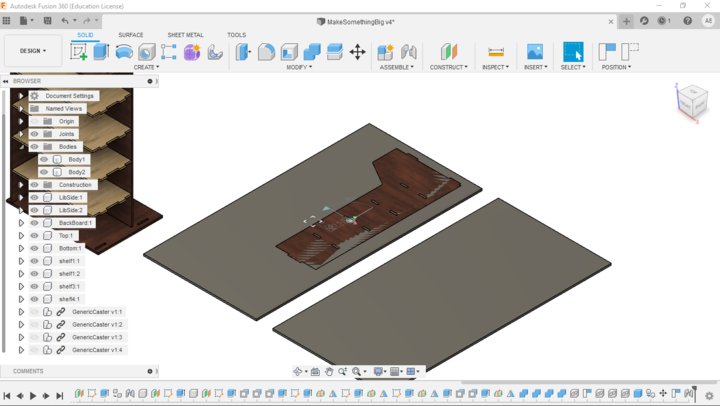

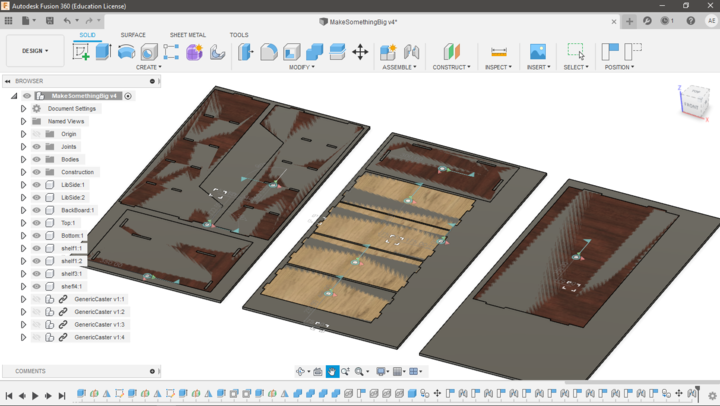

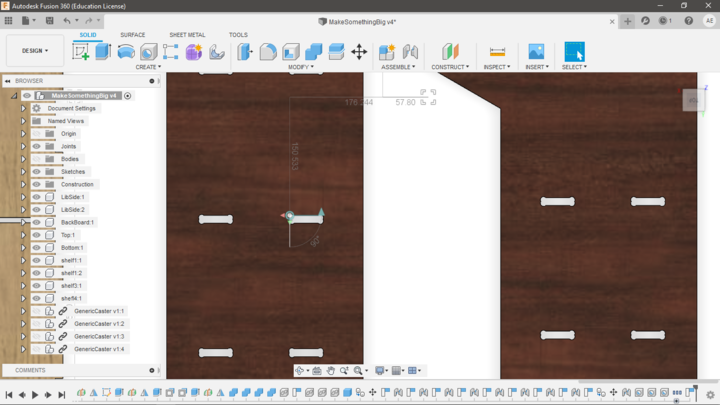

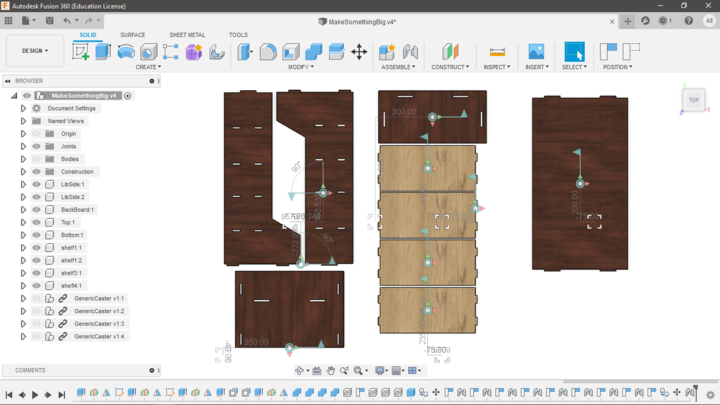

Flattening the design

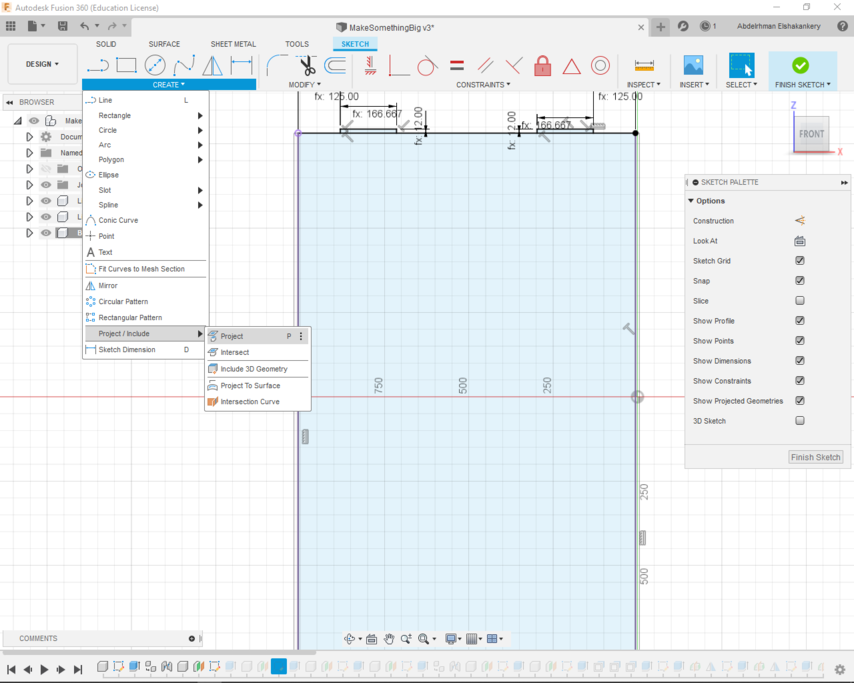

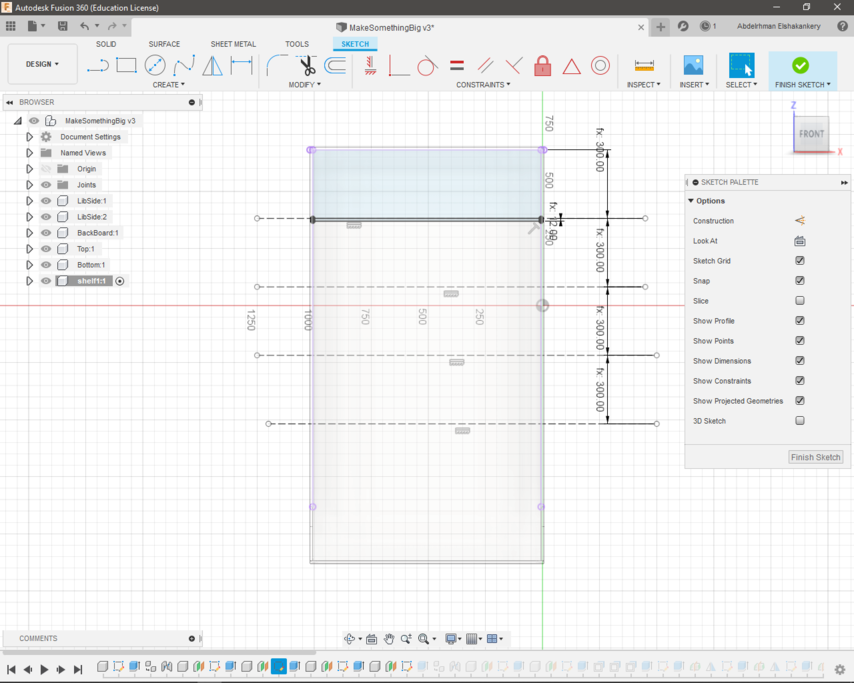

Start by laying all of my design part flat for preparing for CNC.

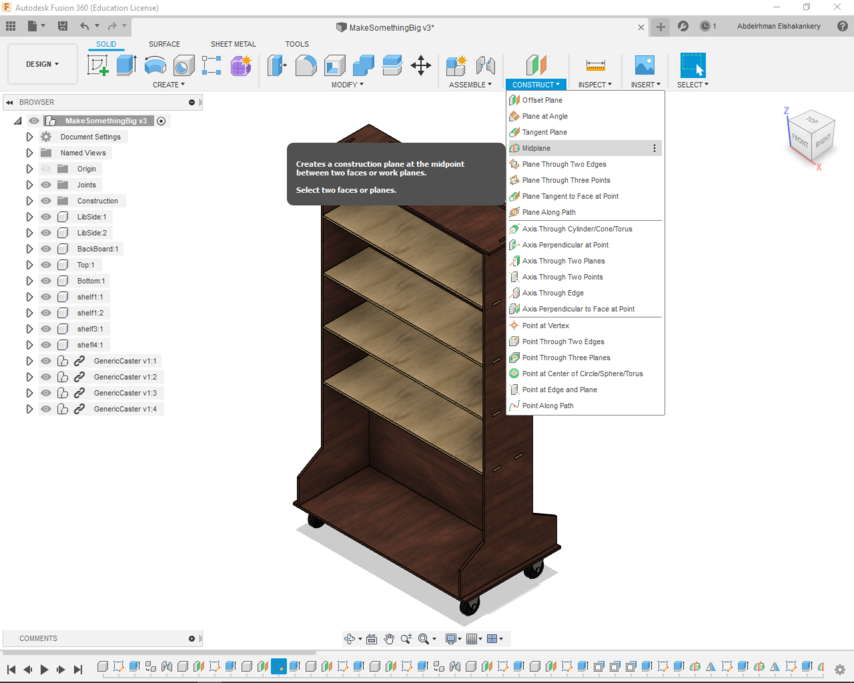

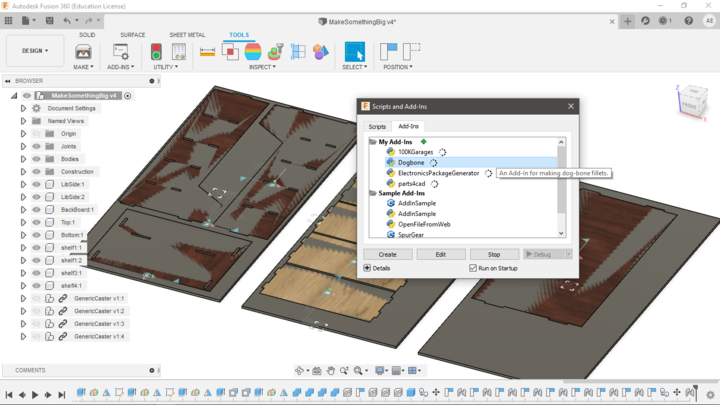

Creating the Dogebone fillets

Due to the roundness of the drill bit it can't create the inside corner sharp edges. so we have to create a dog bone fillet to smooth the manufacture operation.

instead of doing this manually I have downloade this online Dogbone Addin to automate the process

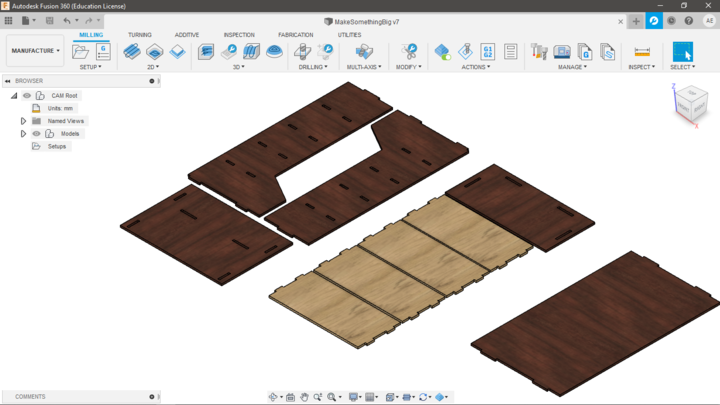

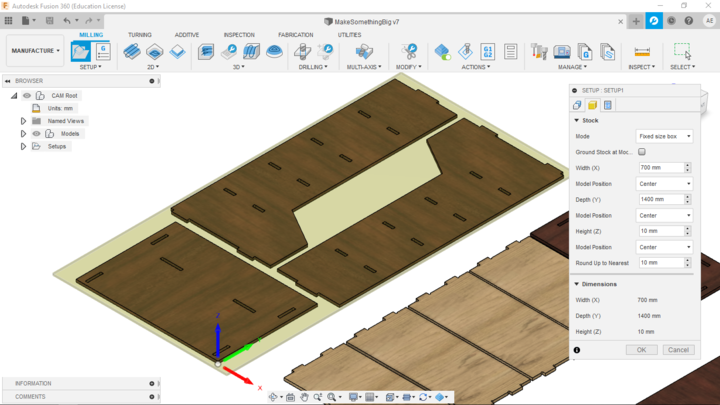

Machining Process

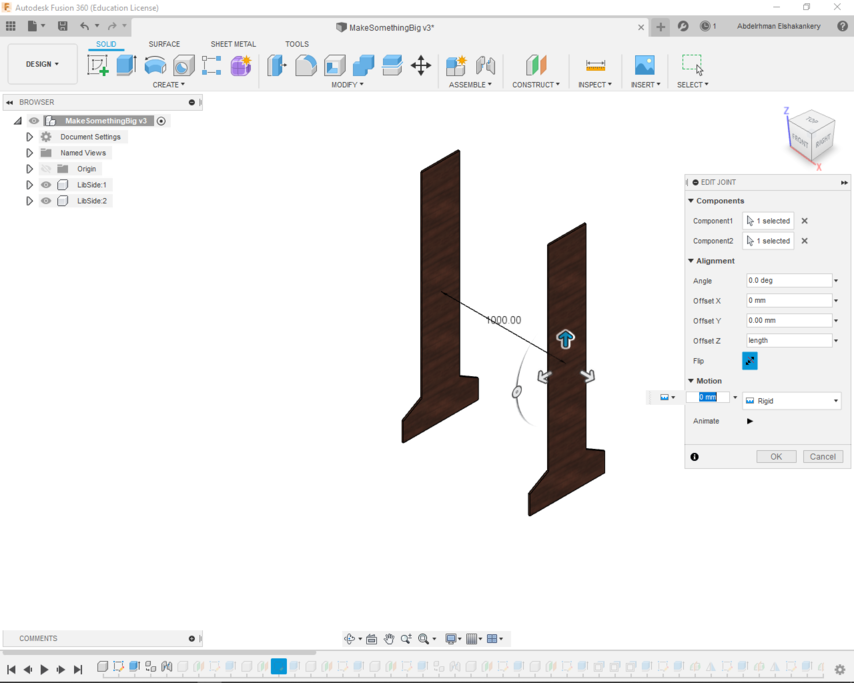

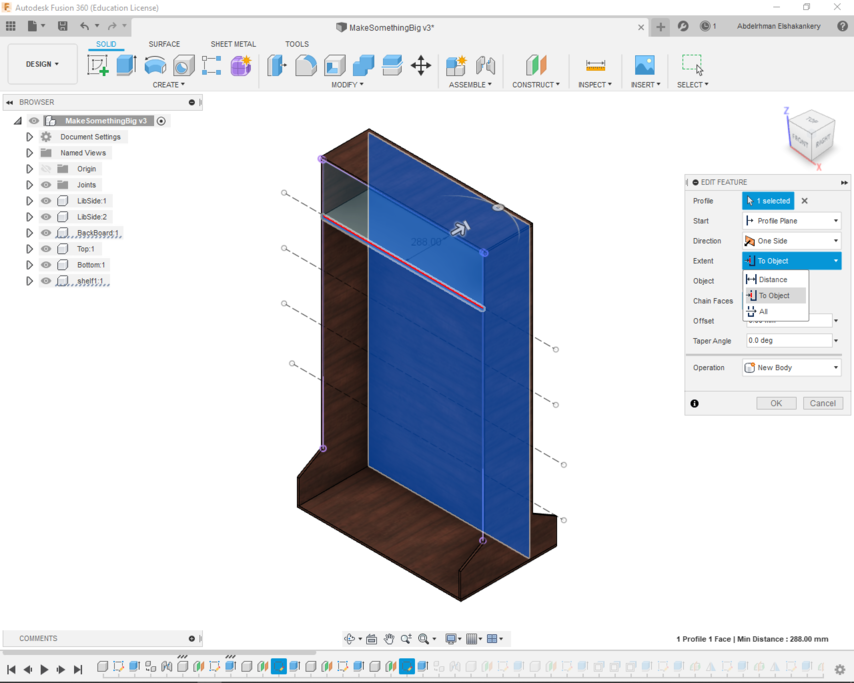

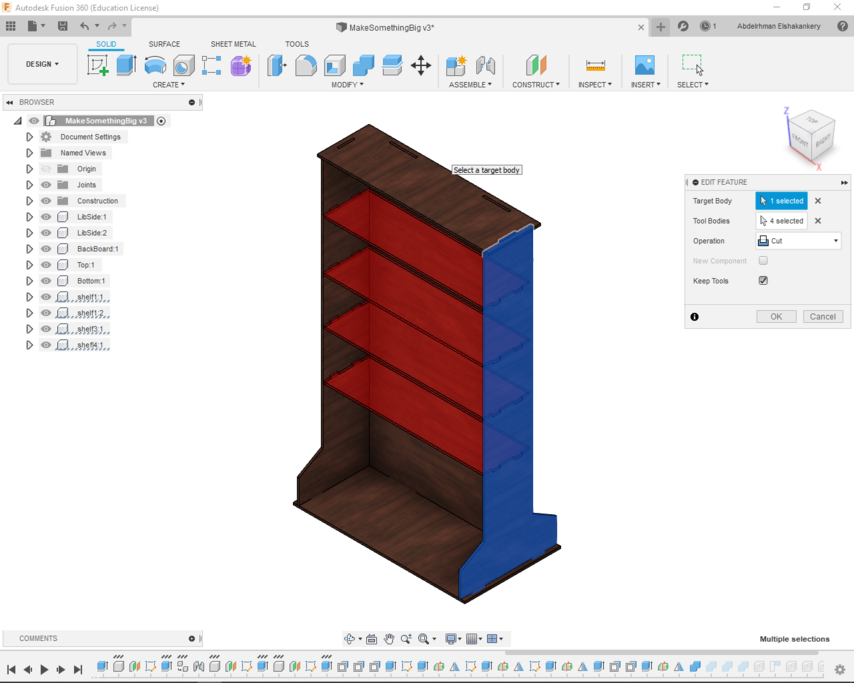

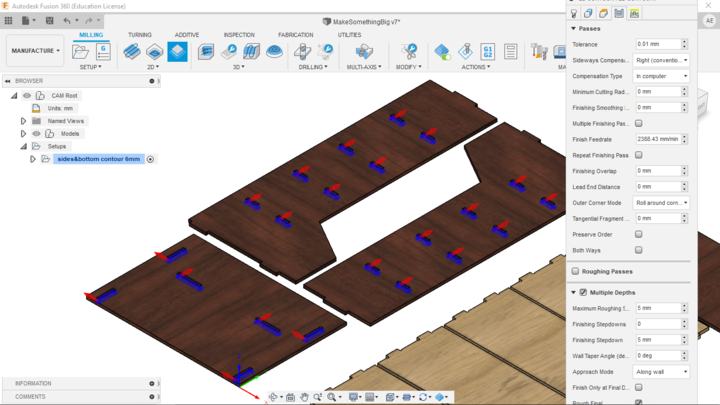

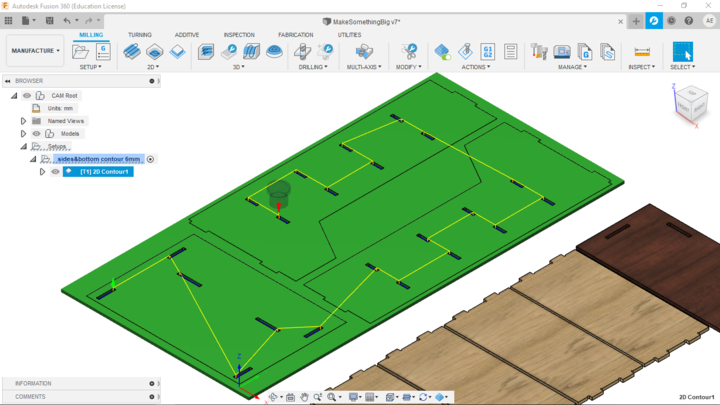

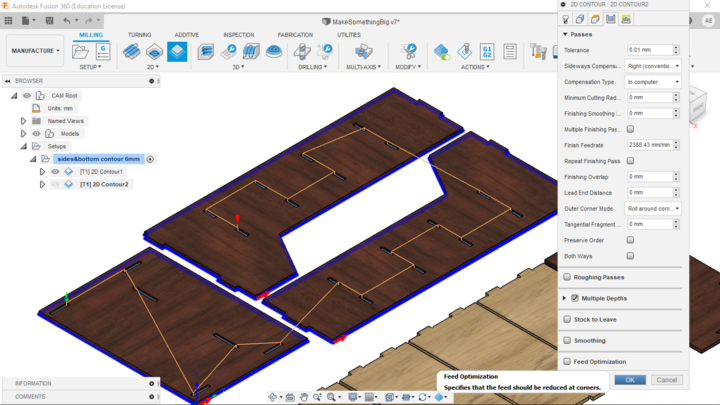

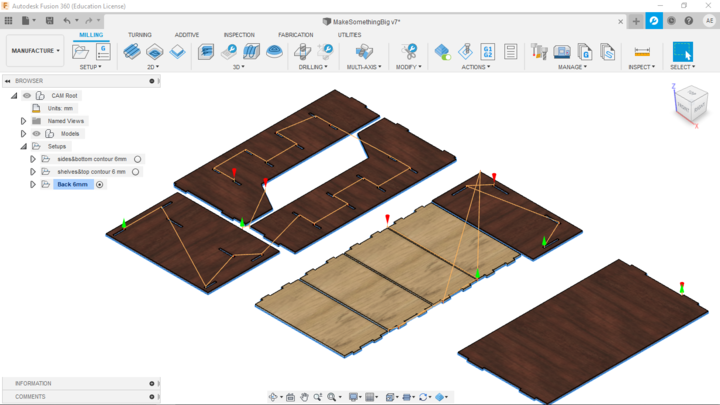

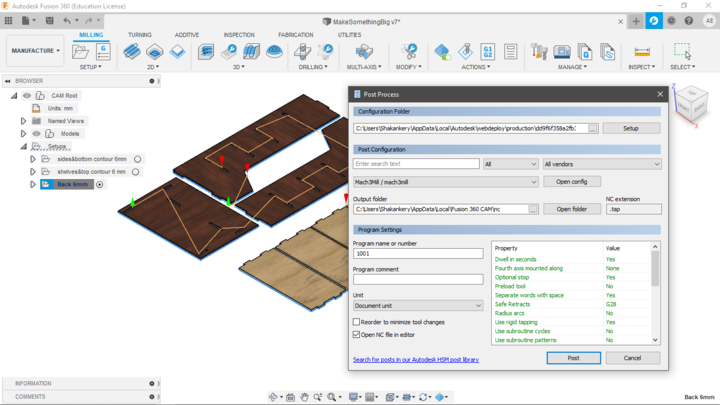

1- CAM in Fusion 360

Follwoing this simple and step-by-sgtep tutorial I was able to prepare my design for CNC manufacture.

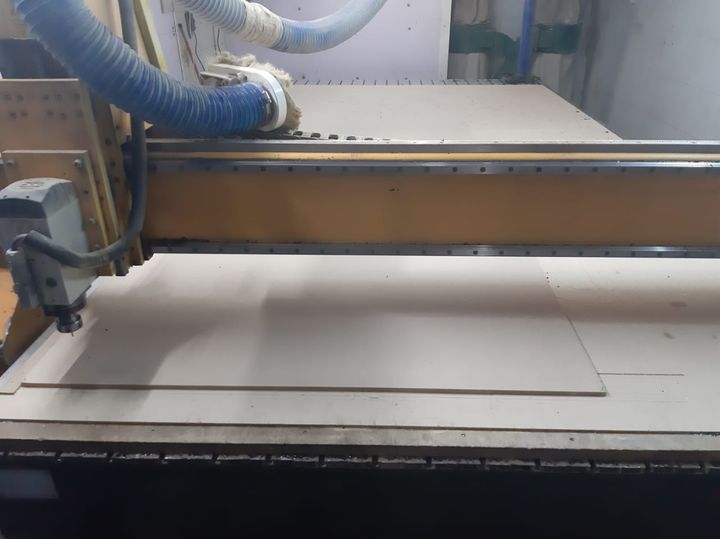

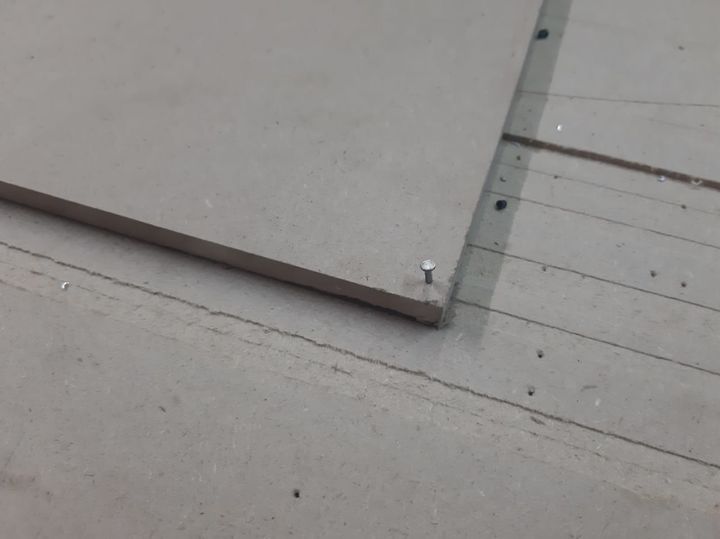

2- Machining using HH-CR1325 cnc router

Some of the machine specifications::-

Files:

Find below the files that I made for this assignment. Please do not hesitate to download it!!