W15 + W17 Mechanical Design and Machine Design

This week's aim was to develop a mechanical design based on computer based numerical controlling. It was decided to build a machine similar to a normal Pantograph. The machine has 2 degrees of freedom. The rotational movement of the stepper is converted to the desired translational displacements by means of interconnected straight link mechanism connected in parallelogram geometry.

Individual contribution

I had actively participated in the brainstorming session and in building a mockup of the project with available scarp resource to understand the movement and dimensions of the arms.

I had noted down the conclusion and also the inputs from my teammates and designed and fabricated the final product.

I had designed the project in 3D using Rhino for 3D print and 2D using Autocad for laser cut and CNC. Initially we had decided to 3d print the entire design but the results were not as expected, so we shift the fabrication process to laser cut. The results were much satisfying.

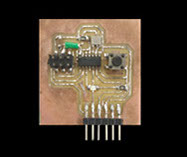

I studied the design of GT80 timing pulley and recreated it as it was not available. I incorporated the GT80 into the arm design so that it became a single entity. Apart of these I designed the,

- Board that housed the stepper motors, center shaft,

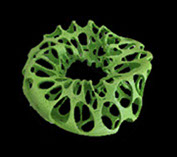

- Voronoi pattern on the arm to cut down weight,

- Pen holder and pen lifter,

- Multiple Shaft design options and got it 3d printed,

- Final Poster design.

I also assembled the components.

The link to Project: http://fabacademy.org/2019/labs/trivandrum/machine/index.html