Group Task

Computer-Controlled Machining

Preparation

For this week's group assignment we were asked to test alignment, speeds, feeds, and toolpaths for our CNC mill.

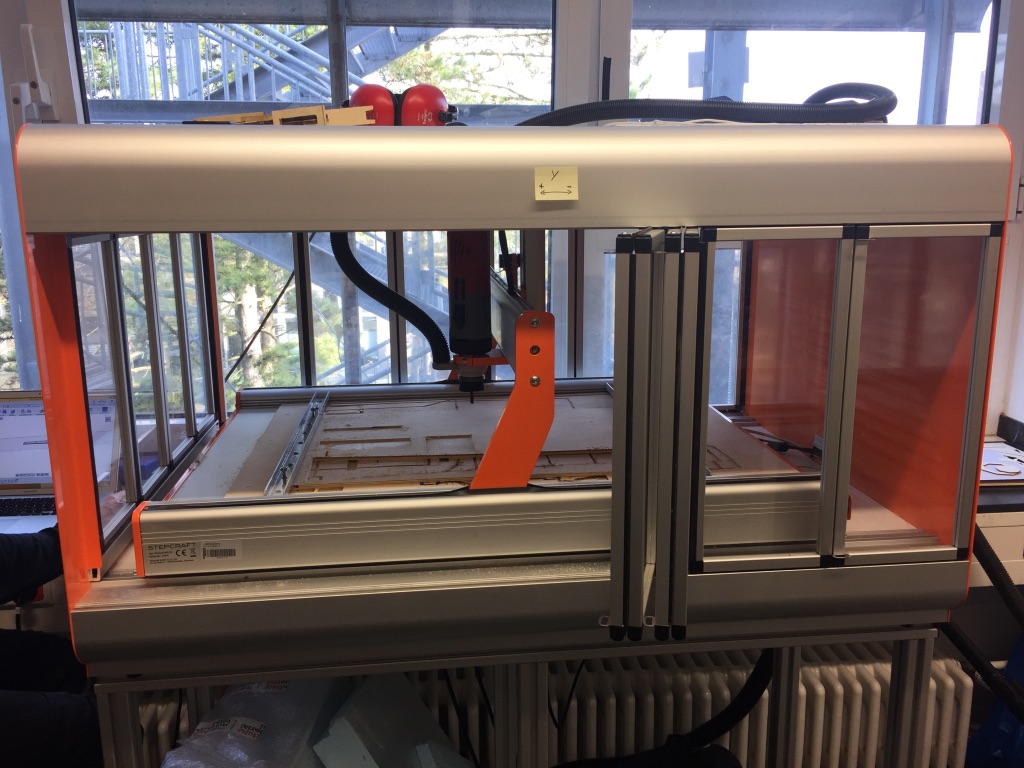

At our FabLab we have a

Stepcraft 840 CK mill.

You can use the laptop next to it where Fusion and the CNC UCCNC software is installed.

Milling Test Pieces

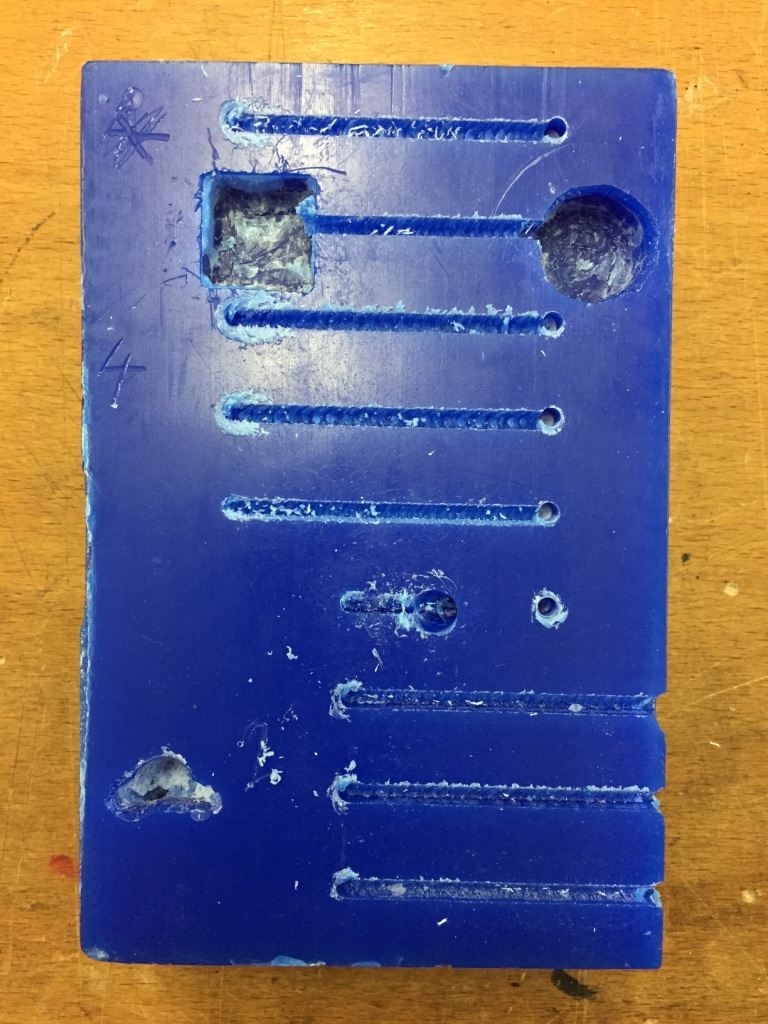

Milling the test pieces worked out good and was quite forward. Except the wax material, which was complicated. The metal stabilisers that are

suppose to fix the mill material do not work properly with the wax, as the wax is quite slippery.

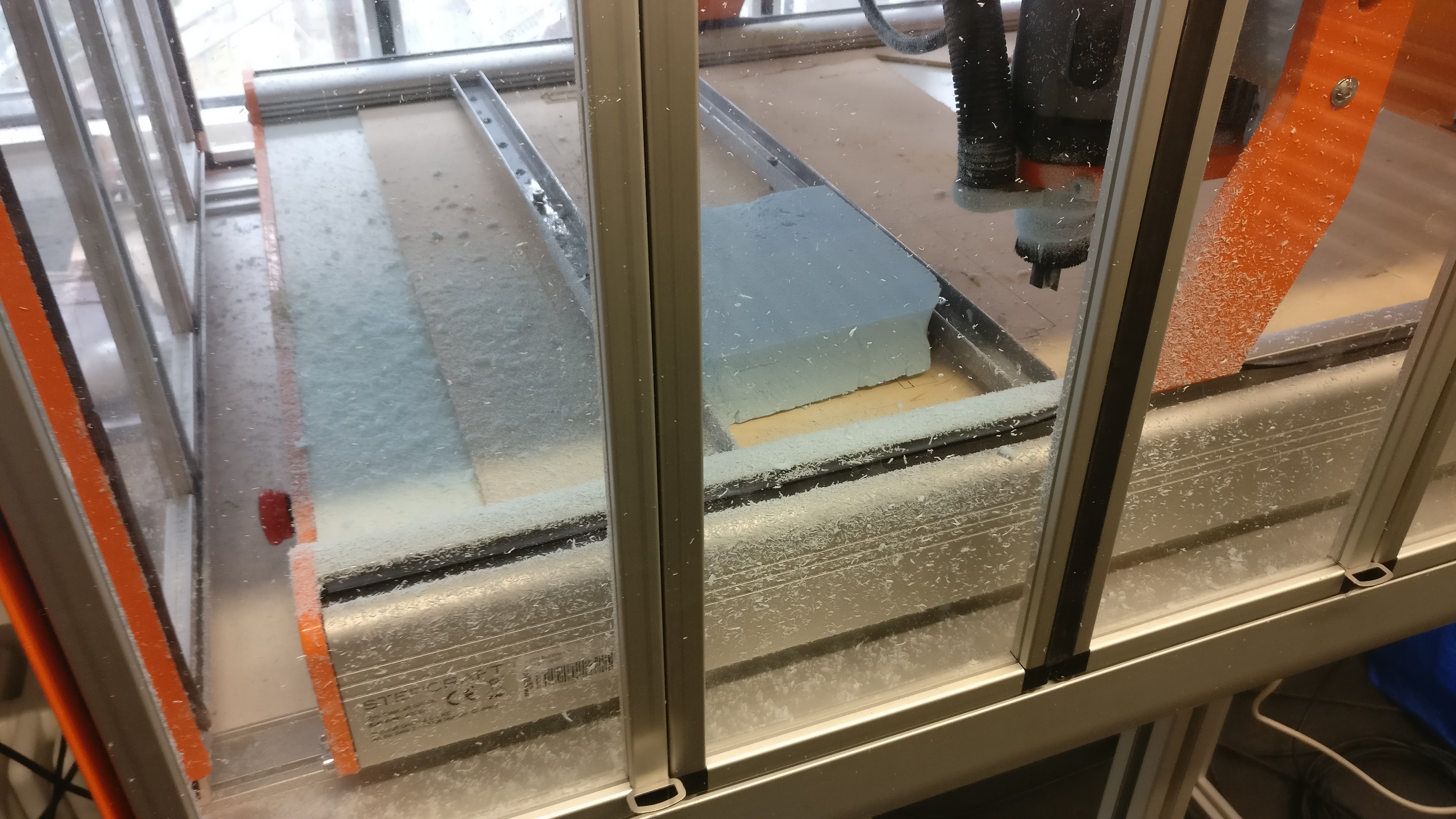

Furthermore, milling the foam did lead to a lot of foam dirt in the mill itself which had to be cleaned after milling.

(spindle rate, feed rate):

* (2, 300); (2, 500); (2, 700); (2,1000)

* (4, 300); (4, 500); (4, 700); (4,1000)

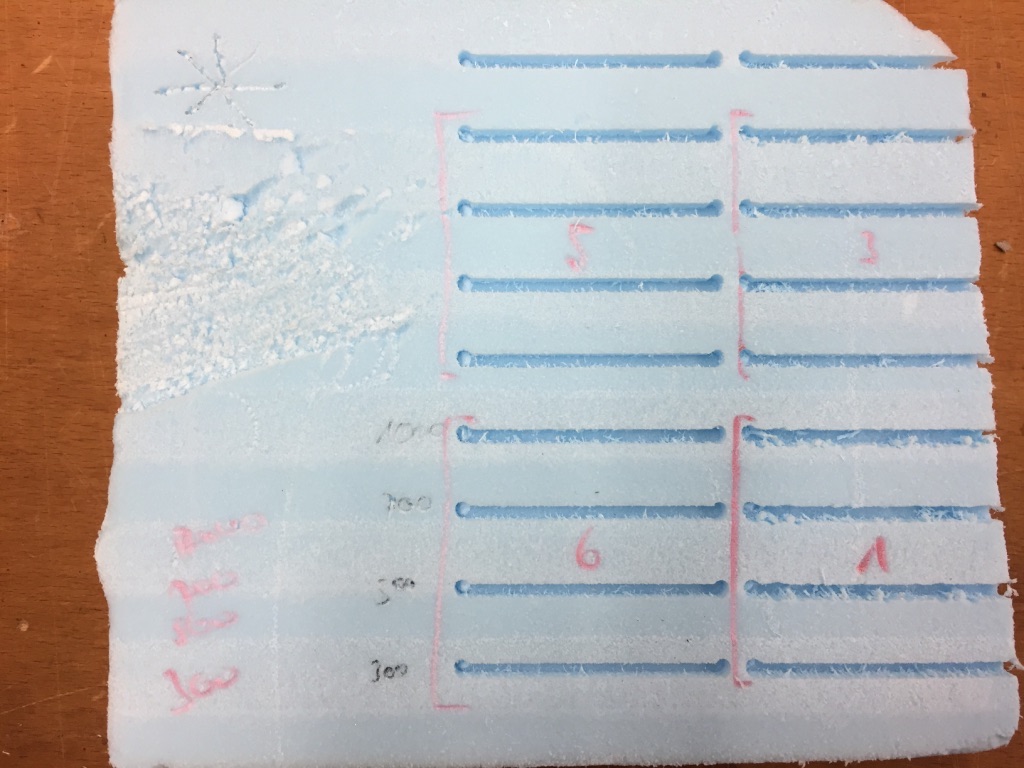

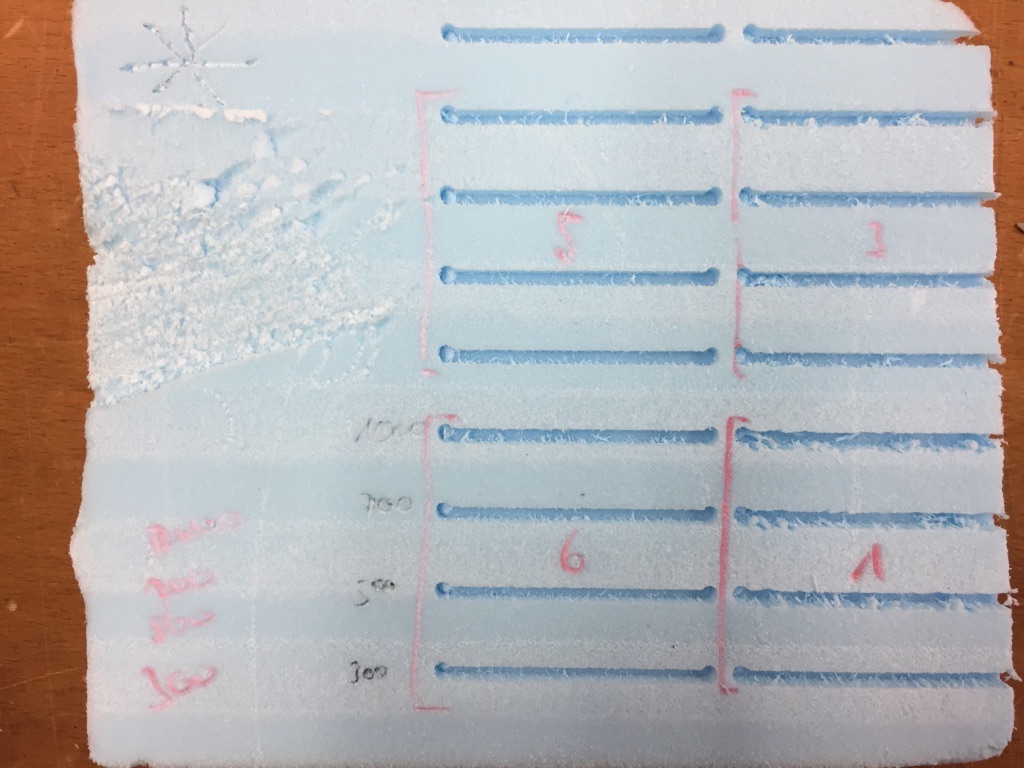

For the foam mill we varied the spindle rate and feed rate the following way:

(spindle rate, feed rate):

* (1, 300); (1, 500); (1, 700); (1,1000)

* (3, 300); (3 500); (3, 700); (3,1000)

* (5, 300); (5, 500); (5, 700); (5,1000)

* (6, 300); (6, 500); (6, 700); (6,1000)

For the wood mill we varied the spindle rate and feed rate even more. The exact values can be seen in the result section on the picture of the wood.

Results

Wax

With a spindle rate of 2 the wax was milled smoother then with the spindle rate of 4.

Foam

With a spindle rate of 1 the foam was milled a lot more messy than with the other spindle rates.

Wood

Varying the spindle rate and the feed rate led to the fact that sometimes the wood was milled through completely and sometimes not. Furthermore, especially spindle rates of 1 and 4 and small feed rates made the food burn during the mill process.