Fab Academy 2014

Fab Academy 2014

Fab Academy 2014 Fab Academy 2014

|

| Jeff Opichka |

|

|

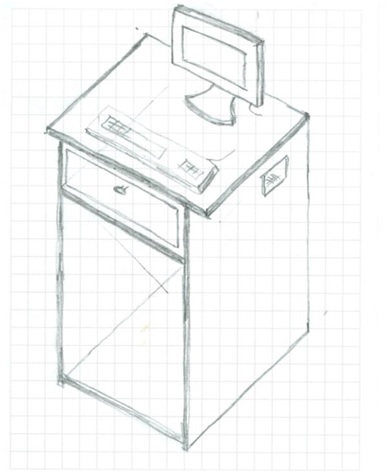

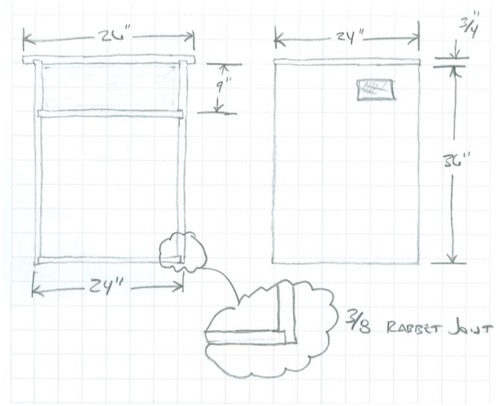

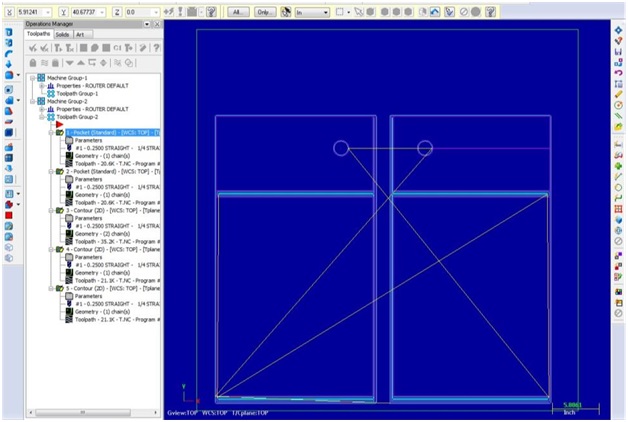

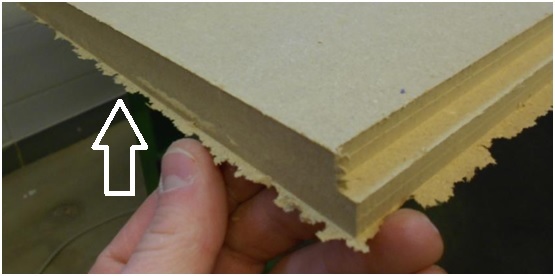

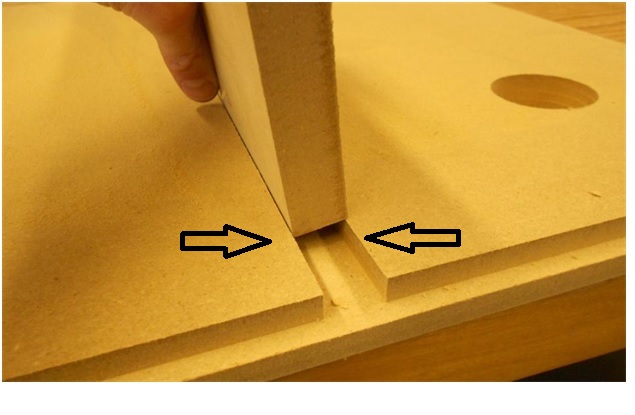

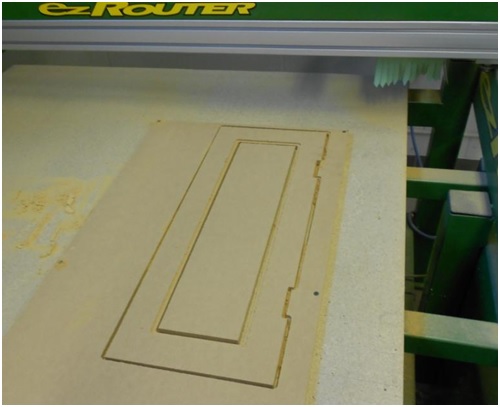

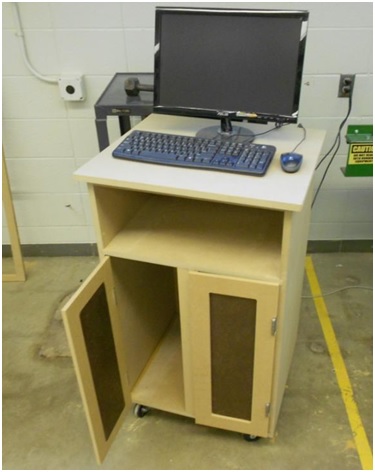

Computer Controlled Machining This week I designed and built a computer station for our CNC router. The computer station now sits on a table and is very unattractive. I would like to have a cart that is can be mobile, organized and dust free for the computer. Below are two working drawings that I used during construction. The workstation will be constructed using 3/4 inch MDF plywood with dado joints and wood glue with no mechanical fasteners.   Following the sketches above, I used Mastercam cnc software to draw individual parts for the computer workstation. Our router has a 4 x 4 bed so I needed to make the parts from two pieces of plywood 4 x 4 MDF.   MDF plywood is not the ideal material to used for cabinets but is is very easy to machine. After making the first two side pieces I noticed the router didn't cut all the way through the plywood. The depth of cut was set at 3/4 inch, for the next cut I made I set the depth of cut to .760 of an inch and it cut fine. The rabbet cuts were a little small as well. As you can see from the picture below the dado does not fit. To make the dado fit I had to set the width to .507 of an inch to fit properly.   With the proper settings as mentioned above, the top assembly fit much better. With some extra time I cut doors out of 1/2 inch MDF.   Below is the finished product.  |