Fab Academy 2014

Fab Academy 2014

Fab Academy 2014 Fab Academy 2014

|

| Jeff Opichka |

|

|

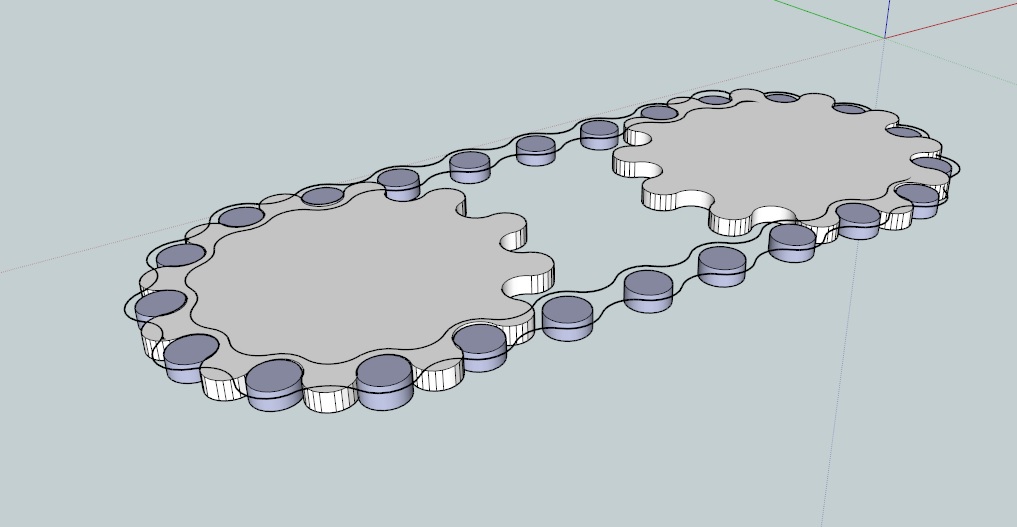

Computer Aided Design This weeks assignment was to design and simulate a possible final project using a variety of software programs. Many of these are free to download. I chose to use Autodesk Inventor and Google Sketchup to design my final project. For my final I would like to design and fabricate a # 40 motorcycle chain and sprocket that would rotate with the push of a button. The links of the chain would have names of companies that contributed to Johnson High School's engineering labs. The first image you see were developed on Autodesk Inventor. Inventor is a professional 3D cad software that offers many options to create very detailed geometric parts. This software is quite exssesive more than what most people would need. I was able to sketch the parts in 2D and extrude them to 3D. A chain and sprocket is a very complex part with many details. The sprocket was by far the hardest to design. After getting familiar with the key commands, sketching the pieces became easy. Once all the pieces were design, Inventor allows you to assemble the pieces to make a working prototype. I was able to assemble the two sprockets and rotate them around a fixed axle. The chain was not the easy. The only way to assemble the chain was piece by piece. One at a time I had to import the bushing, pin and link. Then, rotate to get close to alignment and constrain them. I also used Google Sketchup to design the chain and sprocket. This program is free and downloadable off the internet. Like Inventor, Sketchup is a 3D software that allows you to design and simulate parts. I found this software more difficult to learn than Inventor even though the key commands were less extensive. As you can see from the image below I was unable to complete the assembly as far as I did in Inventor. After several tries, I had to modify the sprocket from the original. After designing the sprocket, I was unable to make all of my lines intersect making an extrusion impossible. I felt this software was better suited for larger scaled projects. Working with small measurements was difficult, you lost precision when working in such small detail.  |