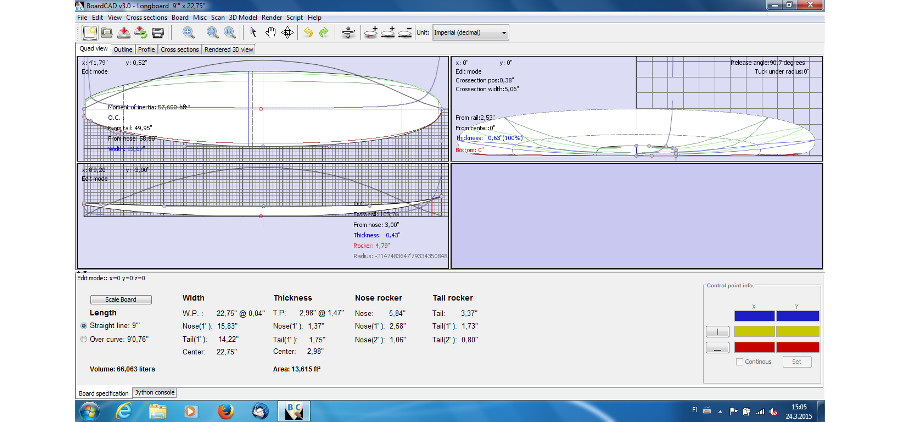

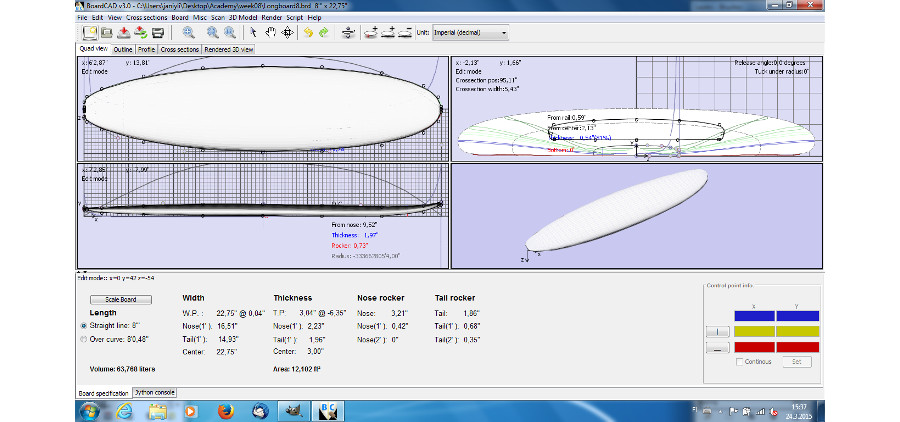

Week 8. Make something big. So I designed a surf board. The foam templates can be bought, but I wanted to mill my own as this week's task. There is a free and open source program called BoardCAD 3.0 dedicated to design surf boards, kite boards and sup boards. It's unbelievably easy to use. There is also an operating manual book written if you need any help. Free on the NET, of course. So I opened the program and selected a longboard template.

Then I made all the changes, I felt necessary to have a beginners board as easy as possible to start surfing. I scaled the board little shorter to be able to carry it to the beach instead of getting a car for it. Then I scaled it a little bit thicker to float better and as wide as I thought would be easy to paddle on. The scaling button below the images gives a menu for these tasks, and the window it's in gives a lot of information of the board. The flow rates can be seen in the information lines in pictures. I also lowered both end and head rockers to have stable behavior and to easy getting the wave instead of slipping over it. The rockers were lowered selecting all the points at once and moving down, after which, the handles were corrected to have nice thinning thickness to the rockers. Finally the board was rendered and exported as .stl. Rendering is necessary to avoid errors due to the bug in the program.

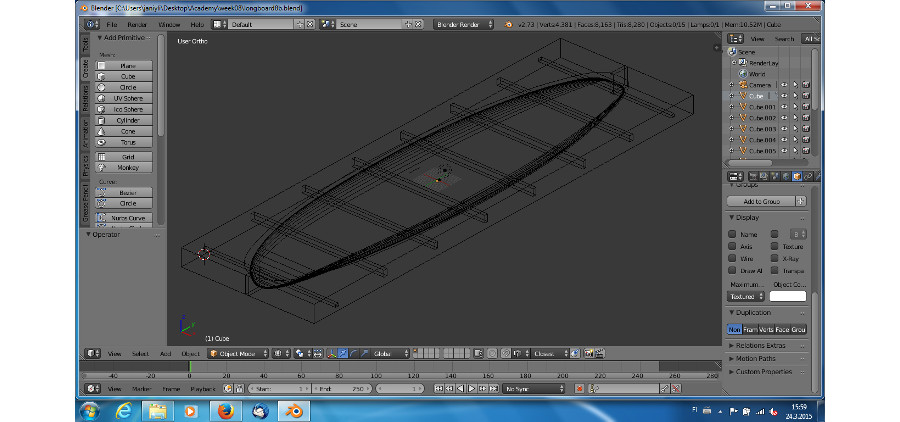

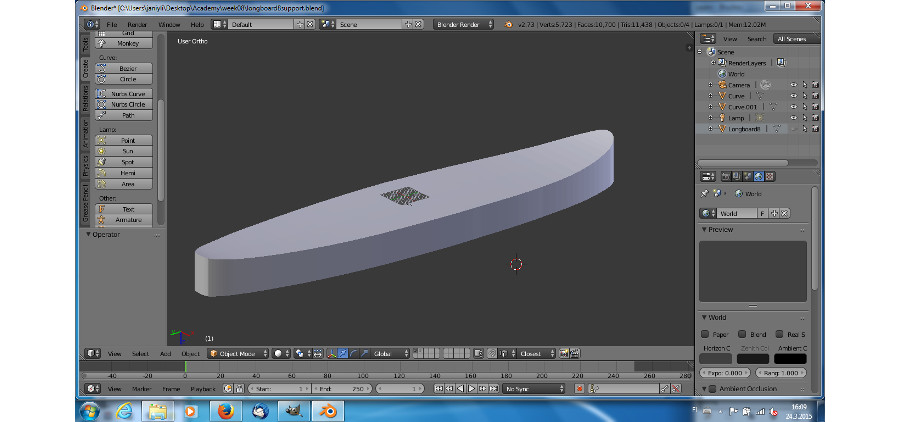

Then I imported the design into Blender. Finding non manifolds and removing doubles made design solid. The outline was drawn in Inkscape and the stock and supports are added in Blender. After this, the milling machine only mills the board out of the stock until it reaches the outline. Side supports are only on edges, head supports go from top to bottom.

Then I draw a supporting desk by scaling the outline, extruding thickness to it and making a boolean subtraction the board of it after small corrections to the extraction higth to match the form of the board. The support is a couple of centimeters smaller than the board to glass fiber to curve smoothly over the edges of the board. We'll see if this works!

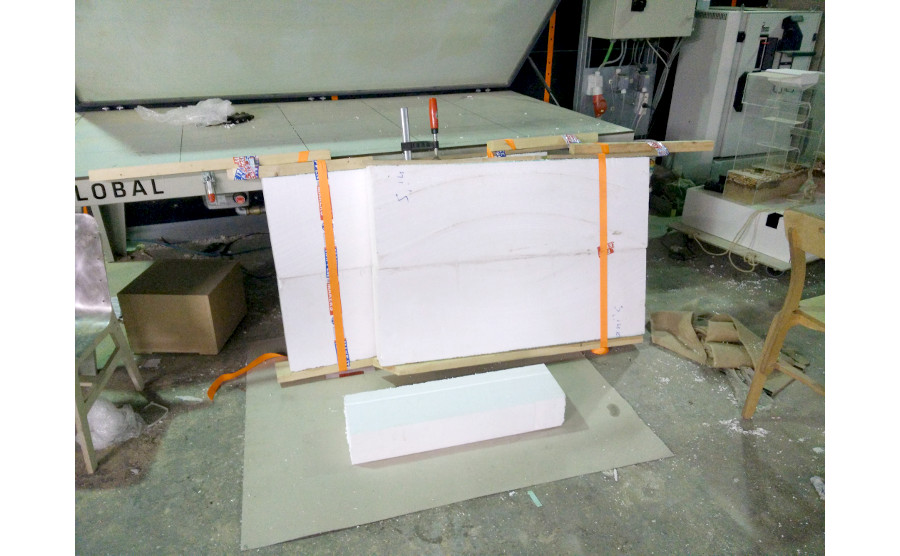

I used KUKA, the big industrial robot and hot wire to slice some foam.

The foams are glued together sideways at this point. I need to make another round with glue to have a stock big enough to mill the form of the board.

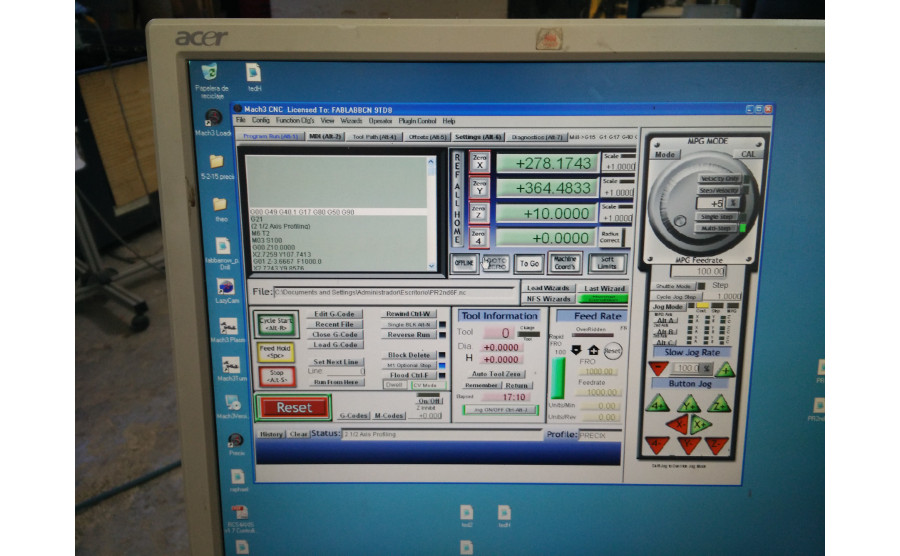

At this point ,I need to wait for the glue to dry, and the week to do something big is at the end. As a plan B, I need to get some artwork milled to finish the something big assignment. I downloaded Alfred Hitchcock's profile, bit traced it in Inkscape, made simplification and manual adjustments for it to be easier to mill and exported as DXF. Then in Solid Works I designed a plate, imported the silhuett in it and designed a stand for it. The stands serve also as a test for joints having three different width joints, so no wood is wasted testing. The result was milled with Mach3 software using 3 mm flat head milling bit. It is beautiful!

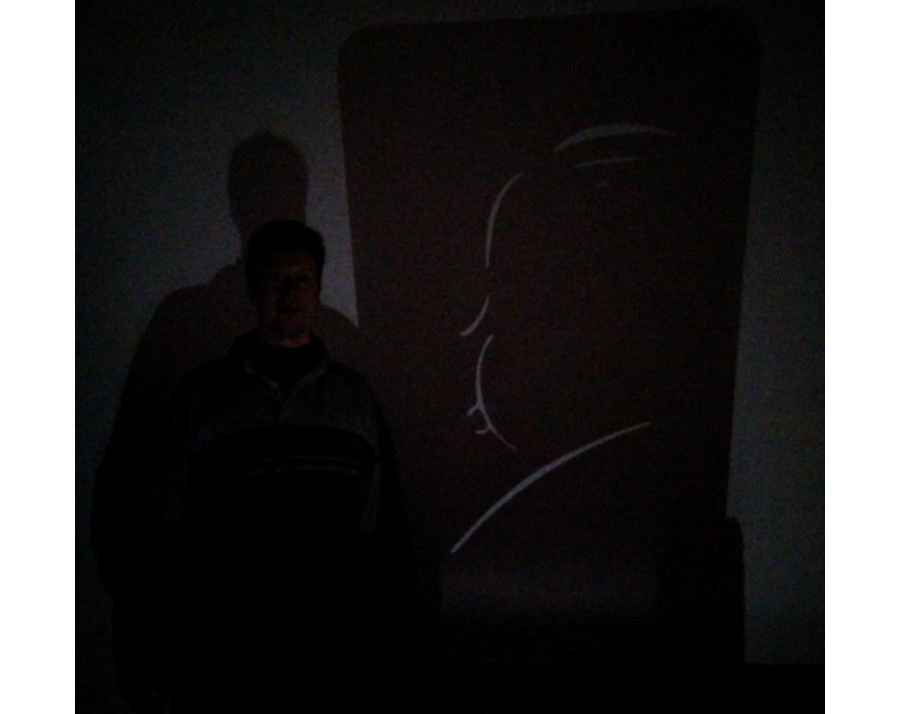

Then I made something big with this somewhat small art peace:

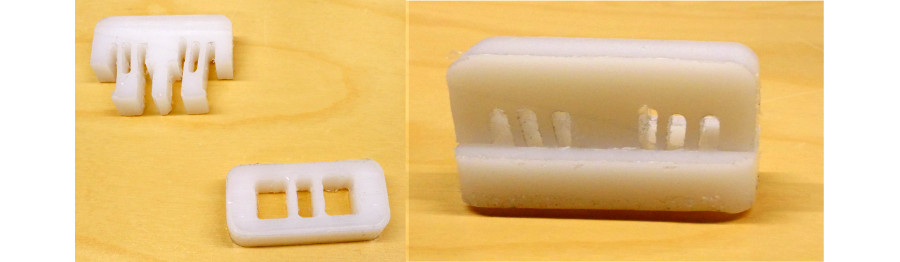

I also tested MIT:s snapfit. It needed some scaling, but it snaps and it fits!

Surfboard's template is milled on both sides on composite week.

Unfortunately, I found my template broken off of the stock one morning, leaving unwanted pockets all over the edges in place of the tabs. I used the regular filler to try to fix it, but it corroded the EPS underneath a little. However, the template is now fixed and ready to be coated with a composite.

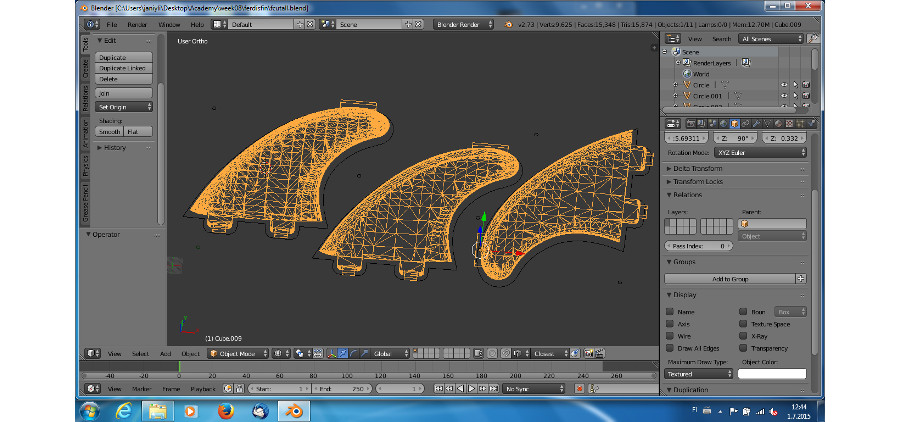

Someone had modeled a fin and I got half of the mold in .STL. I used it to draw a thruster set e.g.e a middle fin and two side fins in Blender. I also draw outlines, stock and screw holes. The file is ready to be milled. I just couldn't find time to mill it. Fin boxes and the leash box are ready too. Finishing the board requires milling at least the middle fin, gluing boxes to the board and covering the board with composite. Not much work left. Unfortunately, I can't finish it. Hopefully someone does.