W_03: Computer-controlled cutting (Feb 11)

To start this week of I made some inicial simple designs to get myself in the idea of press-fit constructions. I started with the idea of making a 3D geometrical construction out of smaller 2D geometrical laser cut pieces.

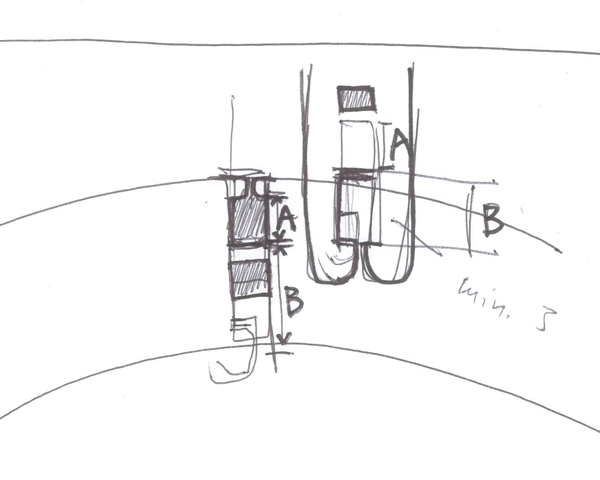

These are some of my inicial sketches:

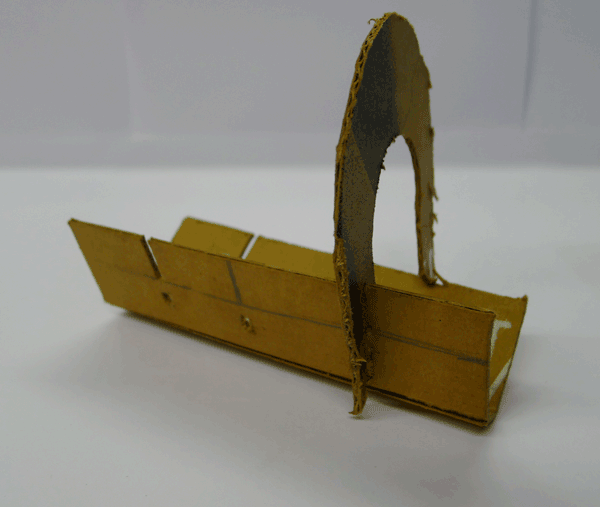

I took some photos of my first tests:

We can see first an image of a triangular shape with small hindges that fit echother(file in Rhino 5).

Following it another image of the cut out of my pieces in the laser machine (Epilog legend 36EXT).

These are a set of pieces i made with a different approach on the geometry and arrangment. My intention was to fit any side of the piece in any direction possible, even through the middle.

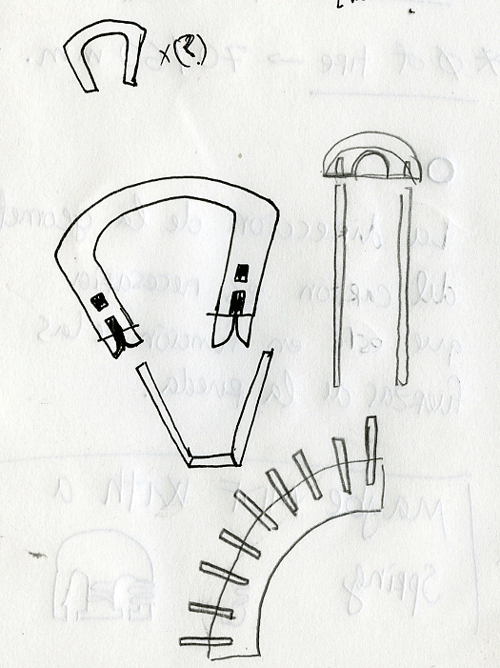

After playing with this material a bit, I focused on making something related to my final project, wich I thought of for some time. I came up with possible systems to create a cardboard bicycle wheel. Then after looking at some references on google images and a couple of websites(behance.net/Maker.com/thingiverse.com/etc). Then continued devising the press-fit pieces that would compose my cardboard wheel. This is a difficult task to acomplish because of the properties of a regular wheel. The first thing i thought of was making kind of a ribbed system between two vertical wheels/spokes. Herer are some scans of the ideas i first developed on paper:

Possible shapes for the pieces and there joints:

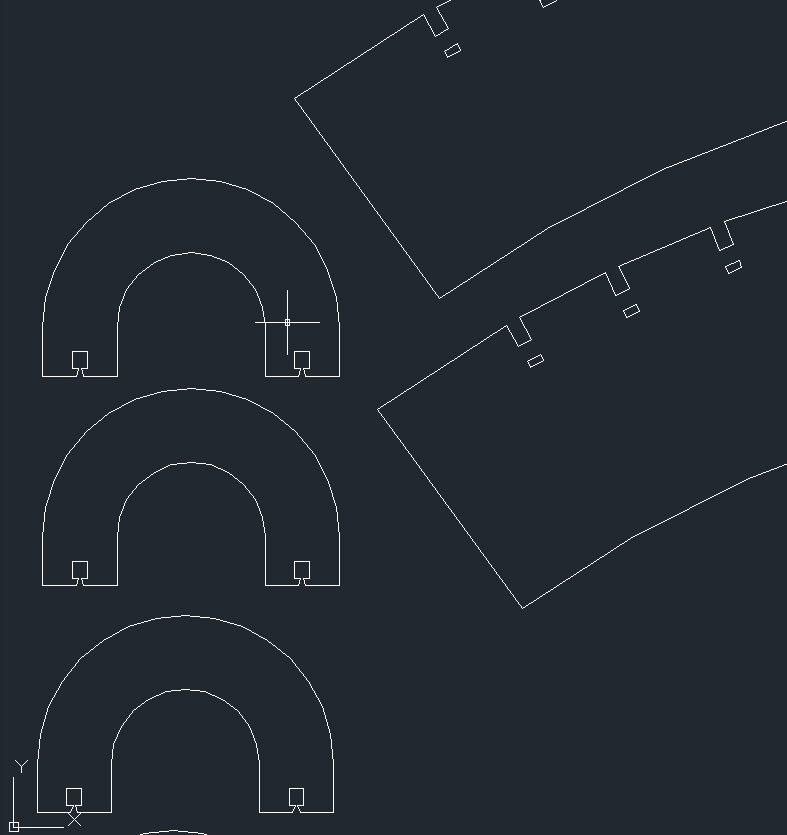

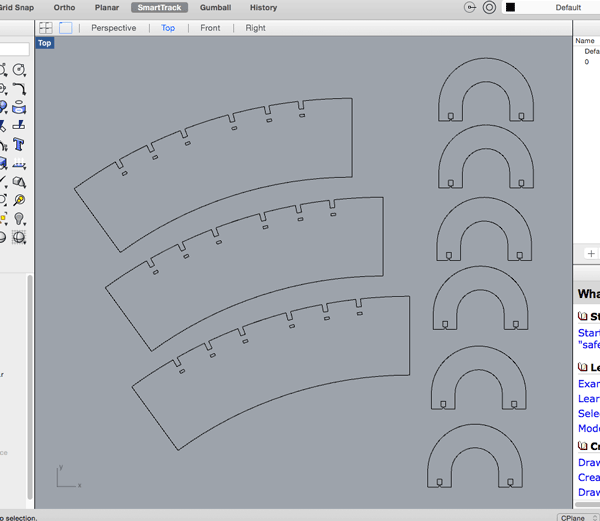

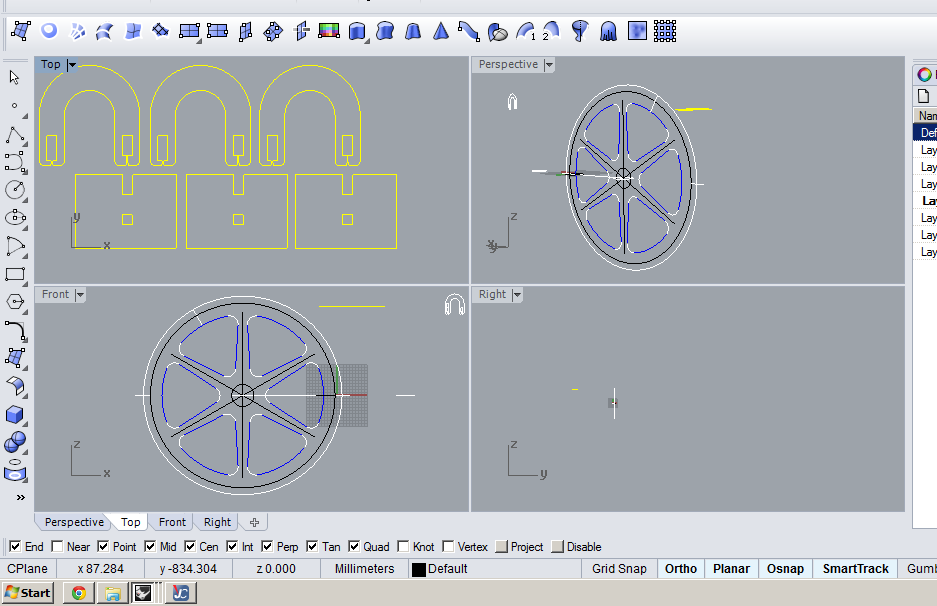

When I had a basic idea of how to shape the pieces I started designed it on rhino:

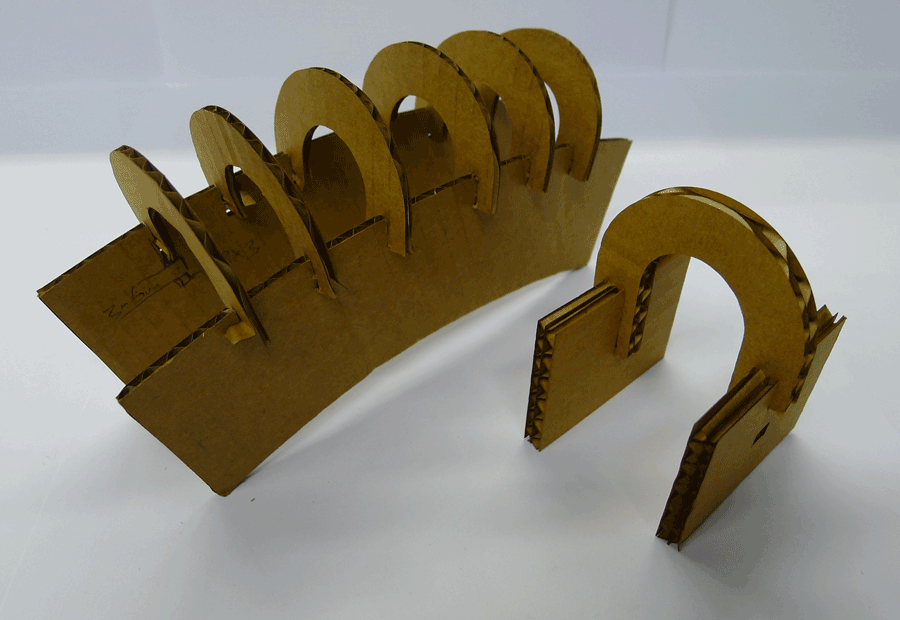

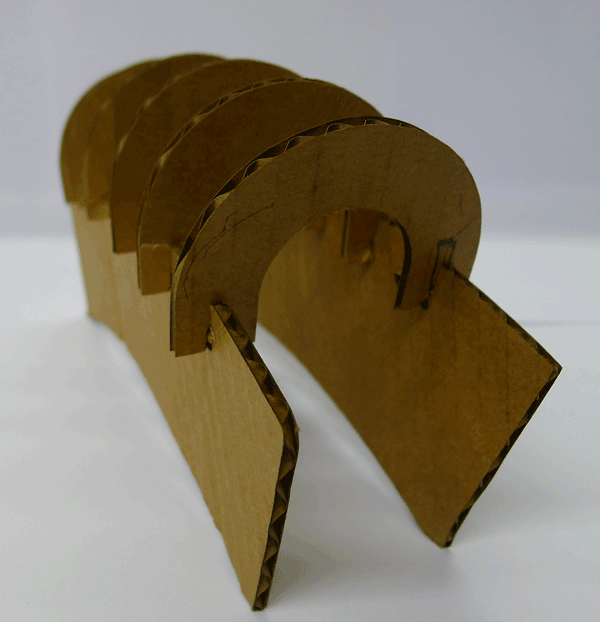

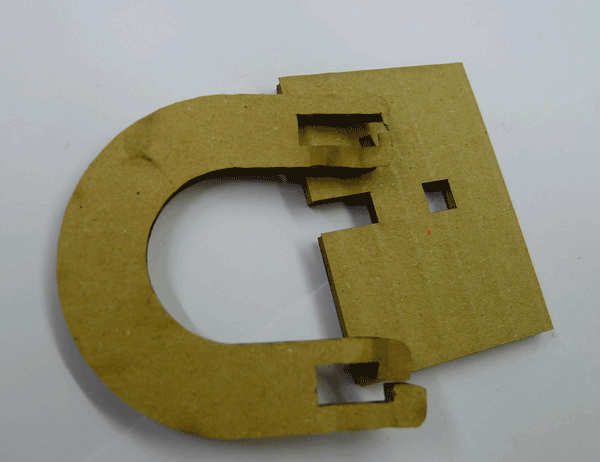

Here are the actual pieces after cutting them on the laser:

FILES

· RHINO FILE PRESS FIT QUARTER WHEEL

· RHINO PRESS FIT JOINTS

· RHINO PRESS FIT JOINTS