Fab Labs. Advanced made simple.

Local Solutions for local problems.

Posted by James Akumu | For Fab Academy

Make Something Big Project

For this project, I collaborated with some students to make a press fit couch for the lab using the ShopBot CNC machine above.

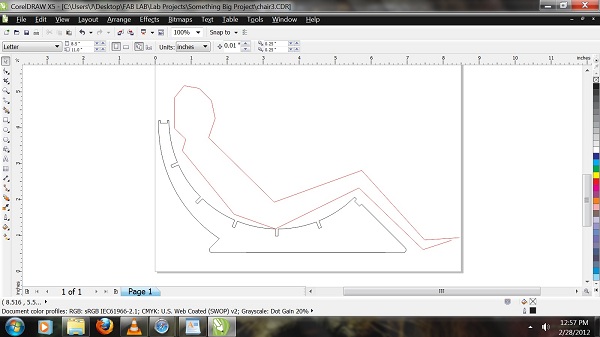

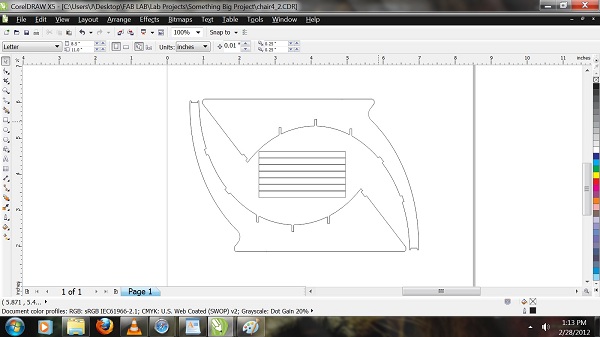

This picture shows the module that will be replicated 3 times and connected to form a couch for the lab. Each module consists of 3 vertical support frames and 7 horizontal support planks.

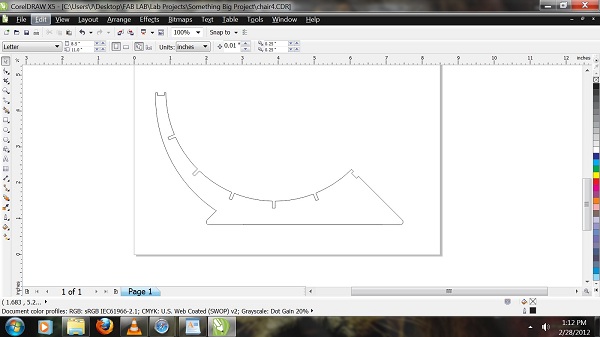

This picture shows how the horizontal support is slotted.

This picture shows the extended couch version.

The CAD drawings for this project were originally done to scale using AutoCAD 2011. My good friend and architect, Maina Gachiengo, helped me in designing the chair to human scale. We saved the files in .dxf format, but for some reason, they would not read on Rhino. We were successful in opening the files using CorelDRAW. After saving them on CorelDRAW, we were then able to open the files on Rhino.

Ken and I did some minor adjustments on the slots for the horizontal support planks using CorelDRAW. We also adjusted the total size of the chair for it to fit within the Shop Bot parameters.

After the adjustments, we saved the file in .pdf format.

The first problem we had was that the ShopBot was cutting inside the line on one end, and outside the line on the other. We adjusted the drawing to make the outline more defined, and set the ShopBot to cut outside the line. This worked.

The next problem we had was that we could not get the ShopBot to cut 1/2 inch vertical slots for the horizontal supports.

We were unable to resolve the above mentioned problem, so we decided to go with 1 inch slots, and to double the width of the horizontal support planks. It makes for a strong chair anyway. We will investigate why we could not get the ShopBot to cut 1/2 inch slots.

The last problem we had was that the horizontal support slots, at the ends of the chair, were too weak. We changed them, and the 2 back support slots, to be like the other slots along the frame of the chair.

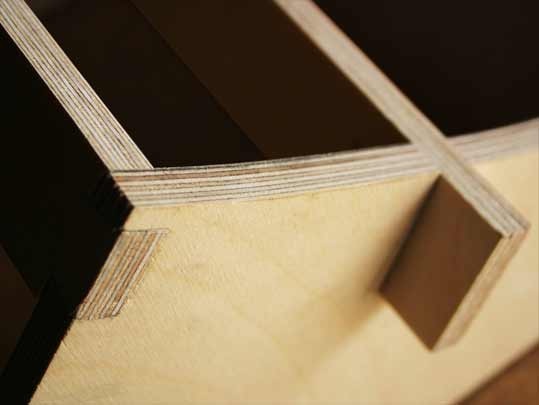

These are the finished vertical supports.

These are the finished horizontal supports.

This is the finished product, minus the bubble wrap cushioning that will be added later.

This is the finished product, minus the bubble wrap cushioning that will be added later.

Testing the finished product, minus the bubble wrap cushioning.

Testing the finished product, minus the bubble wrap cushioning that will be added later.