Week 3: Computer Controlling Cutting

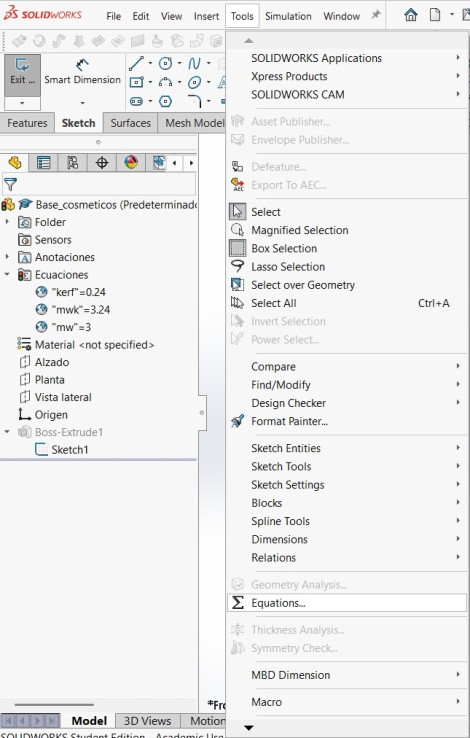

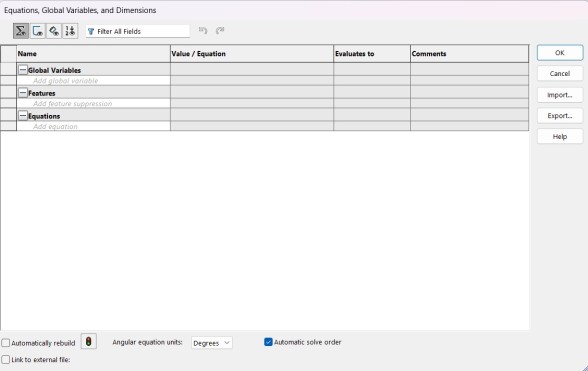

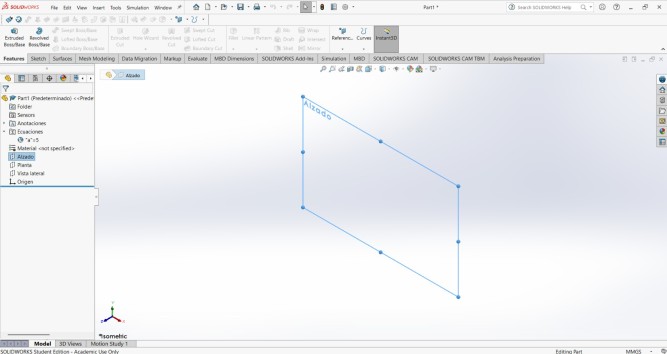

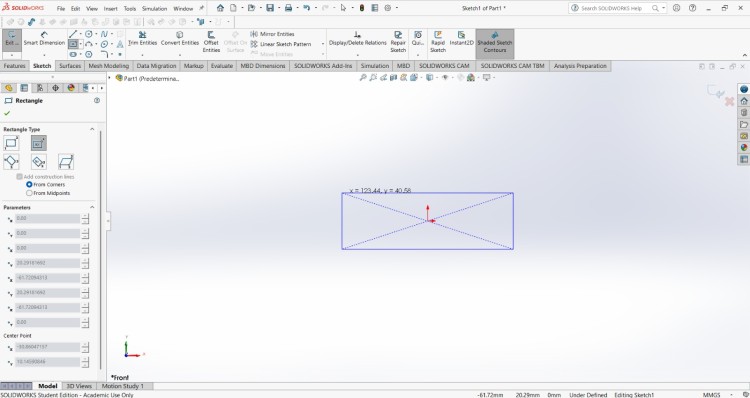

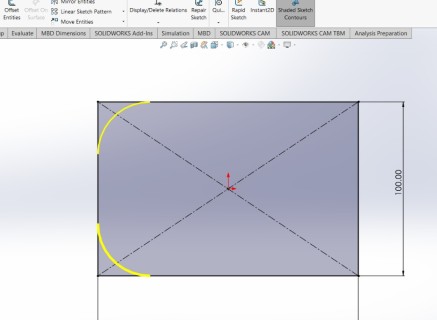

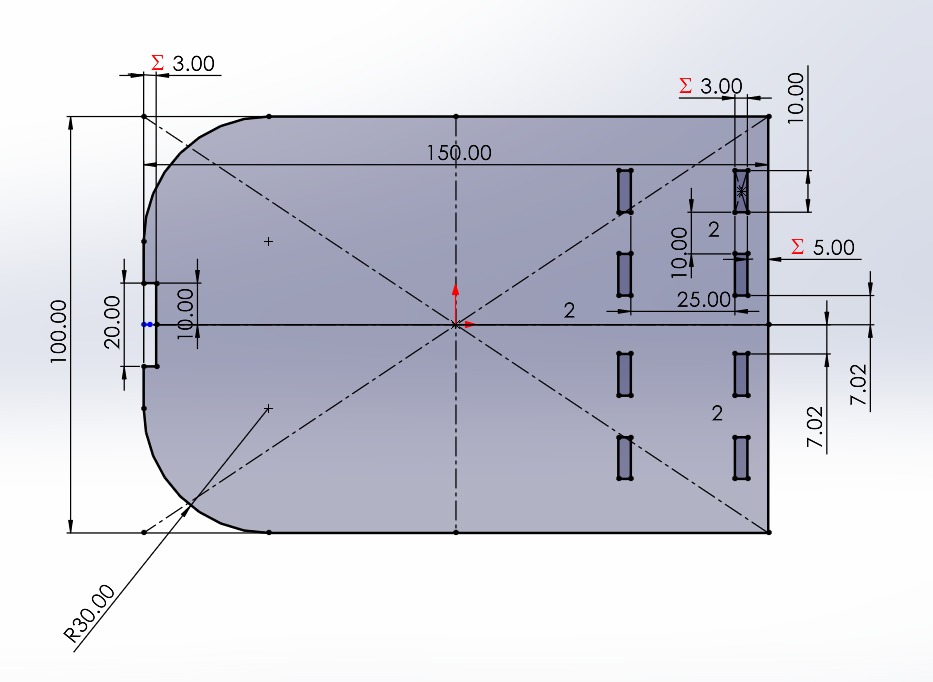

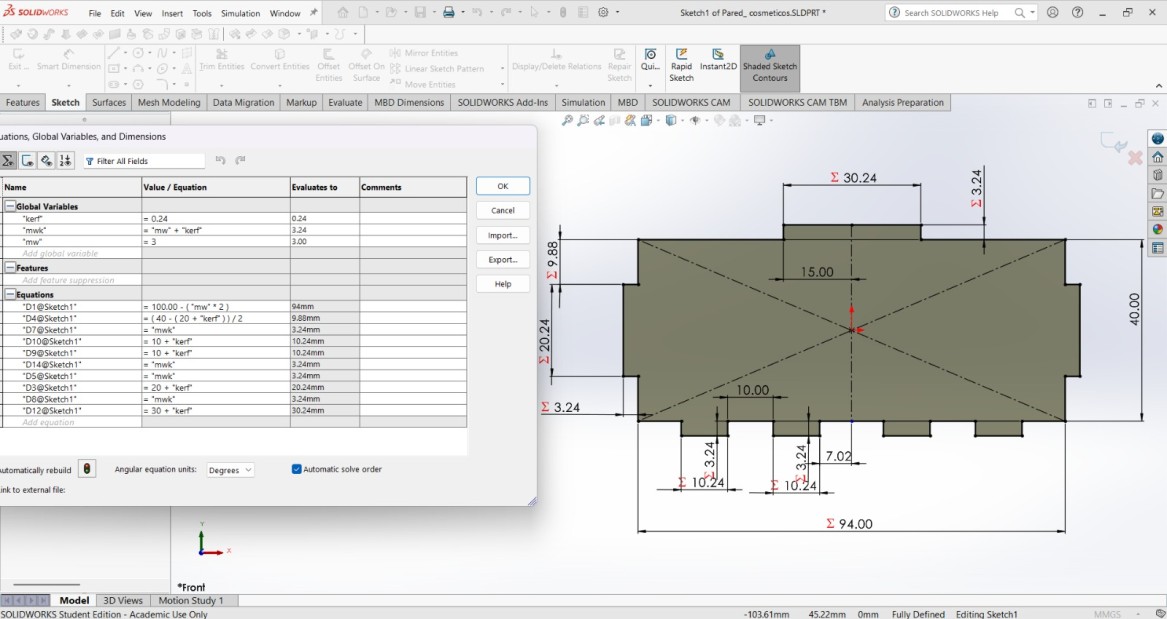

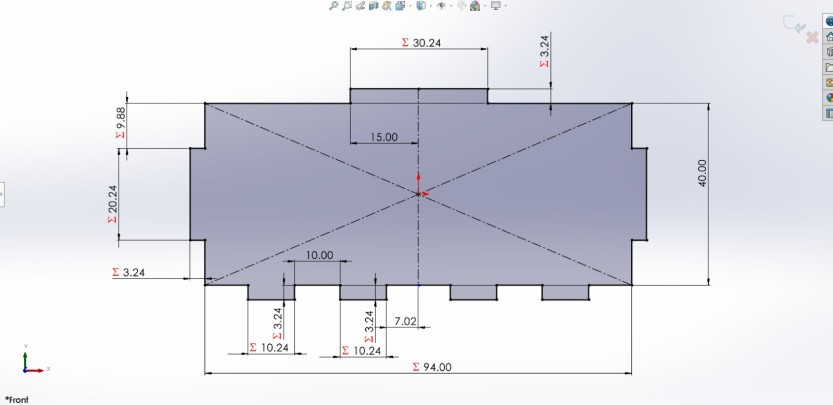

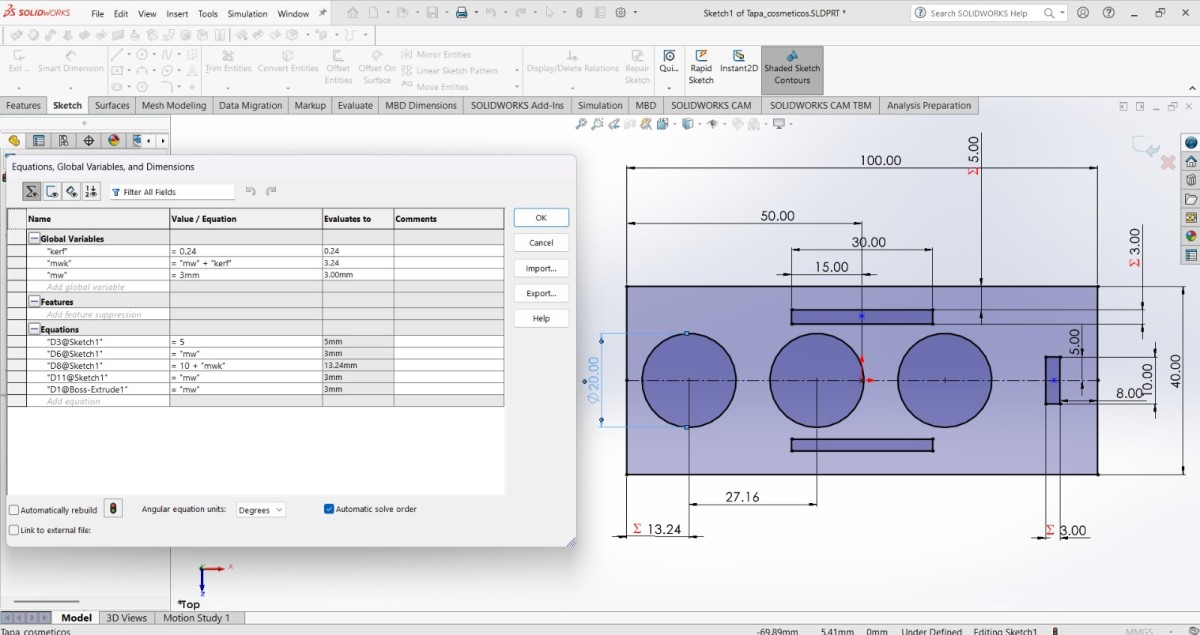

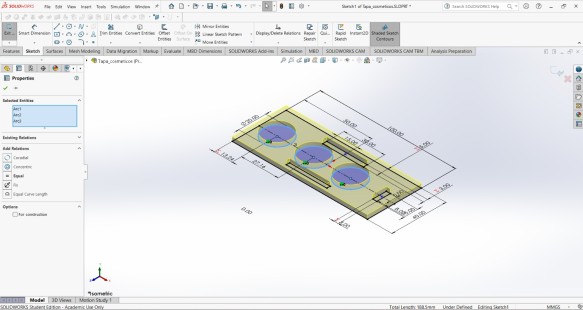

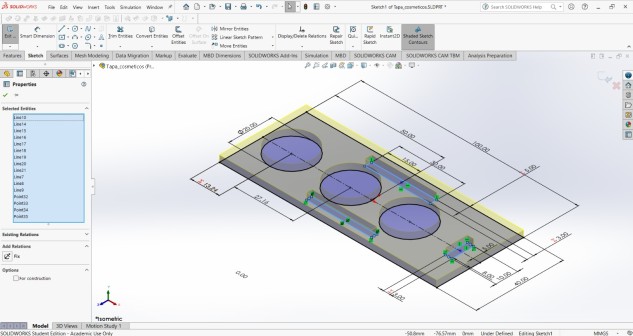

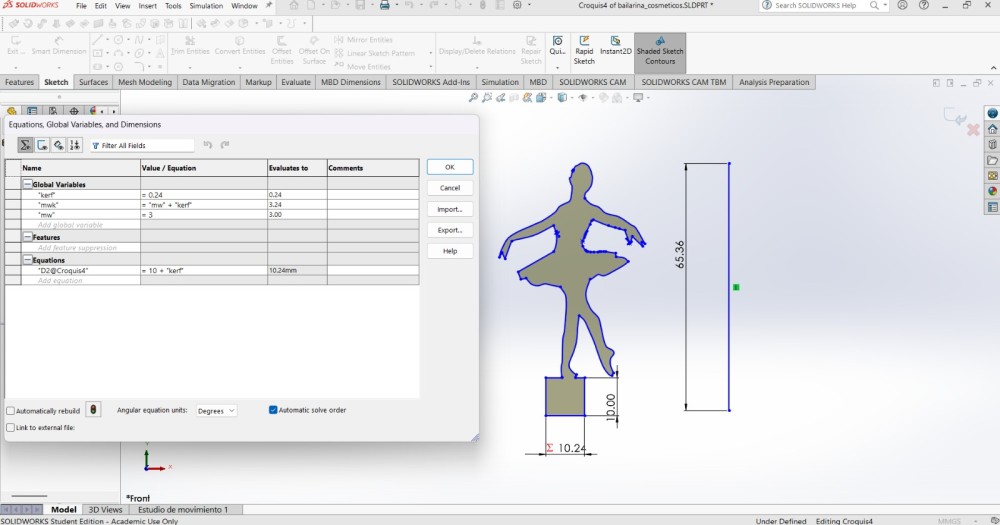

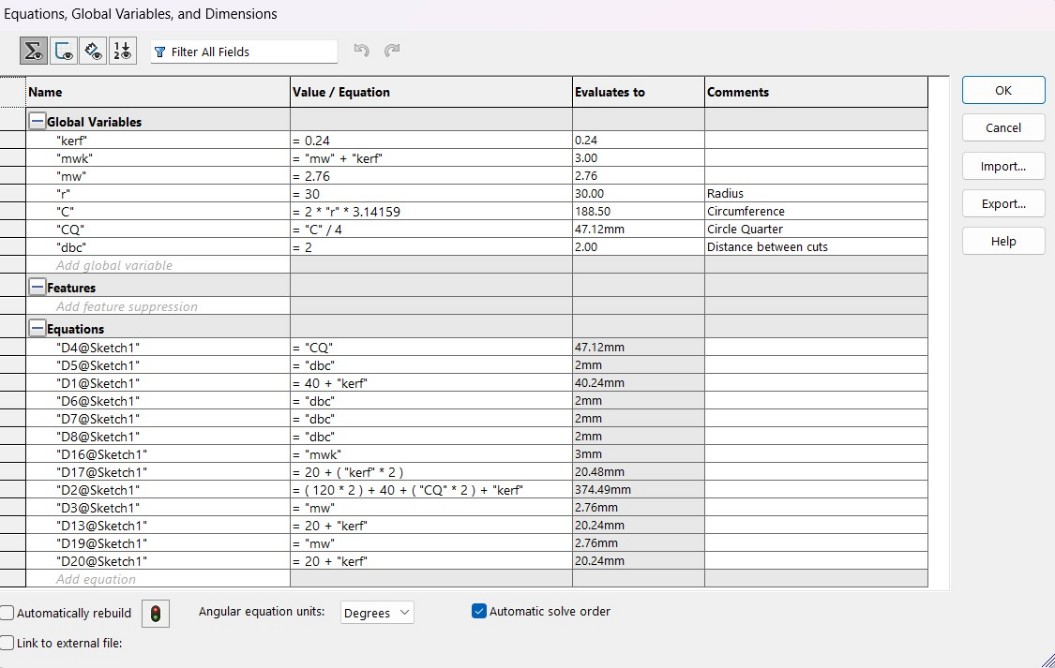

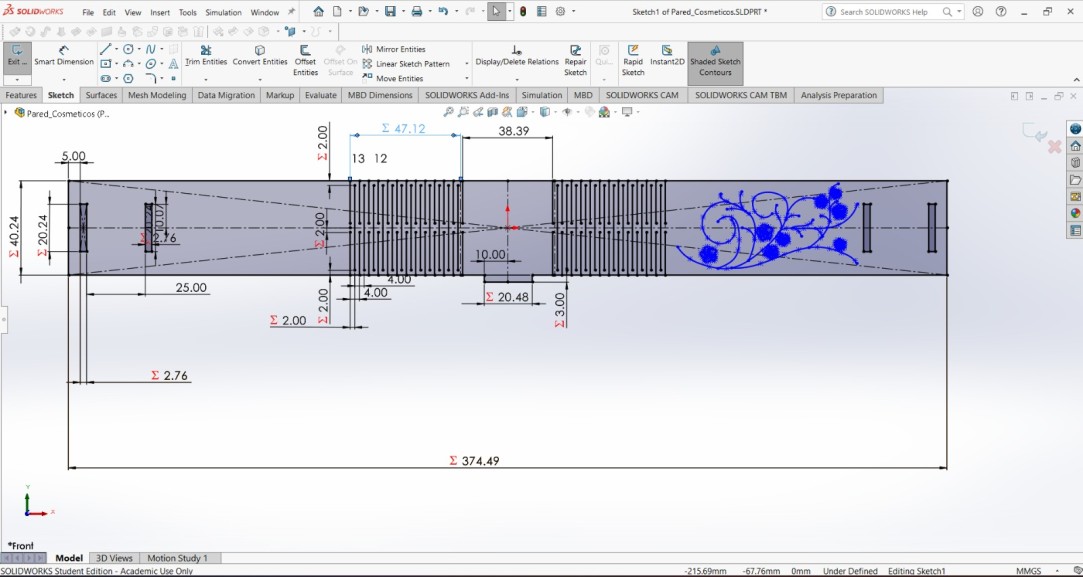

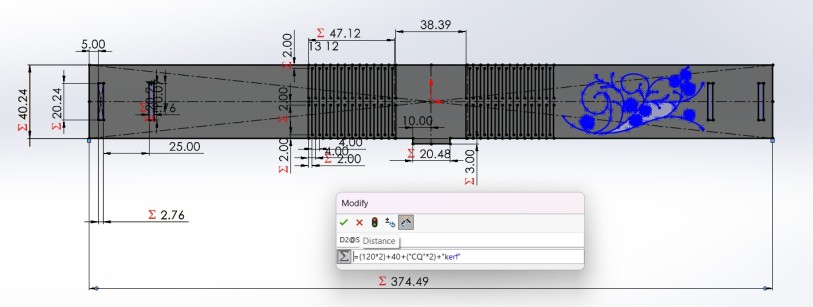

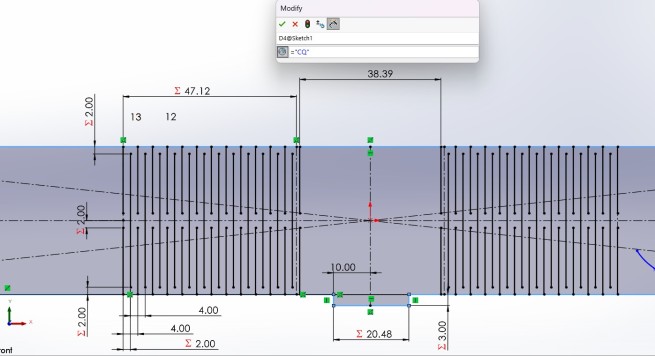

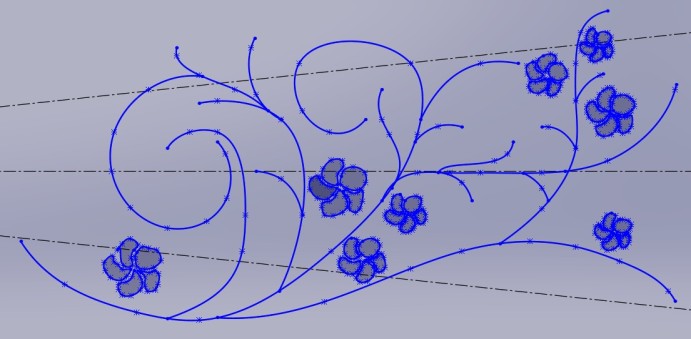

Parametric design

Parametric design is an algorithm-based methodology in architecture and engineering that uses parameters and rules to define, relate, and manipulate design elements, enabling the rapid generation of complex, flexible, and optimized shapes.

Exporting

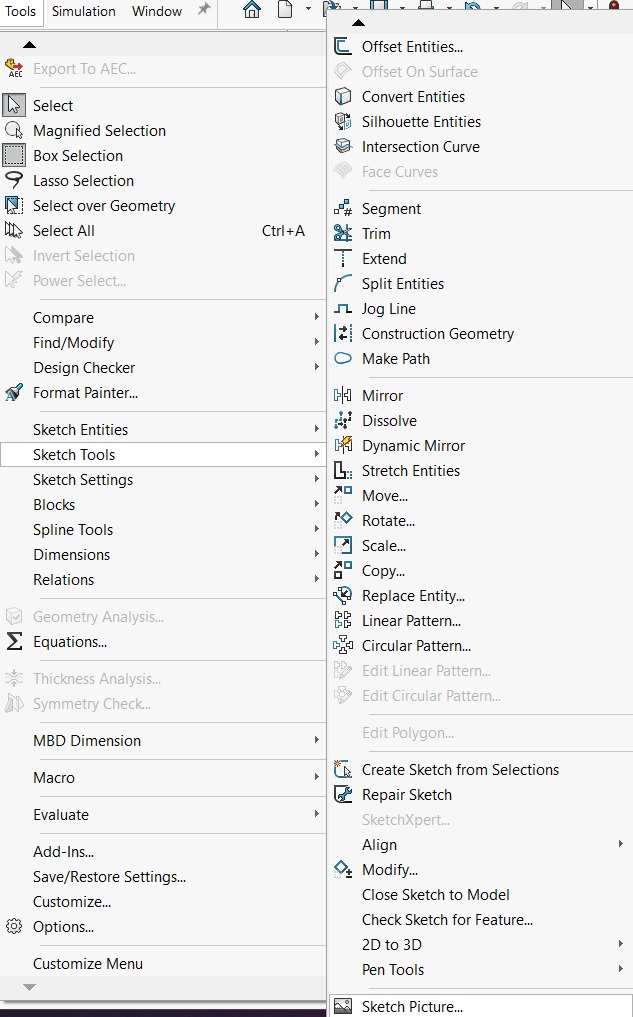

To cut our pieces we need to export them as DXF files. We have two easy ways.

1. The first one is to go to the top, and click File and Save as, then save each piece as a DXF file and open them in the laser cut program.

2.The other way is to open a new Drawing and paste each piece in it.

I used the first way and I'll show later how to cut those pieces.

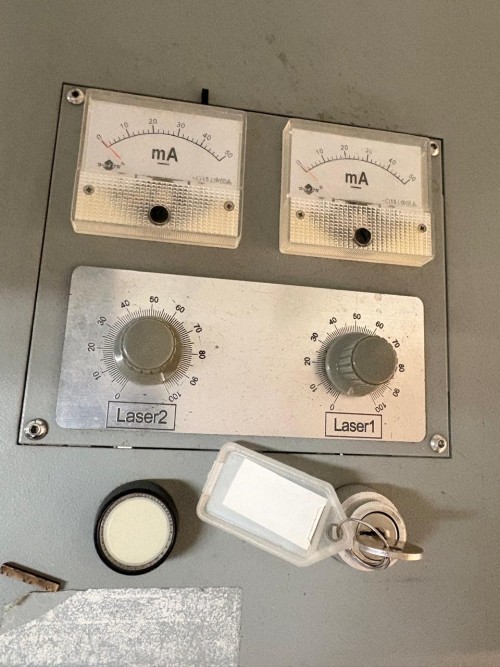

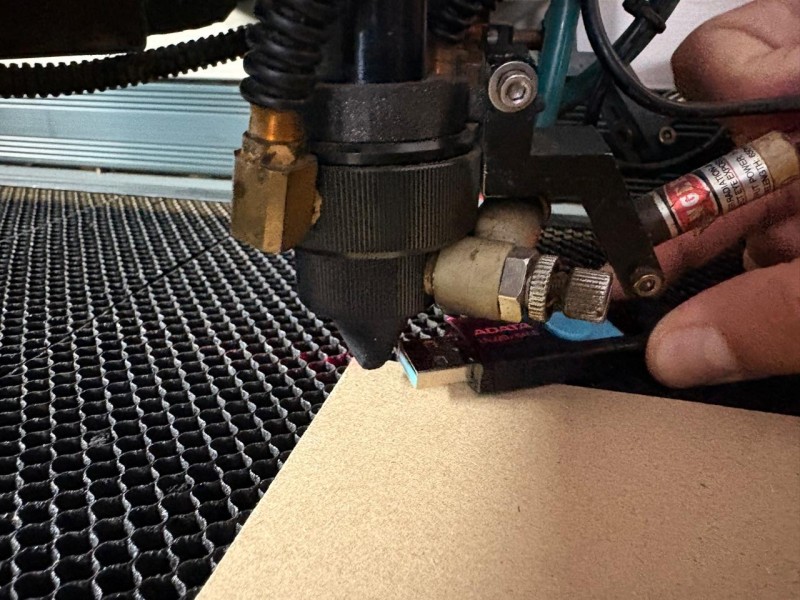

Laser Cutting

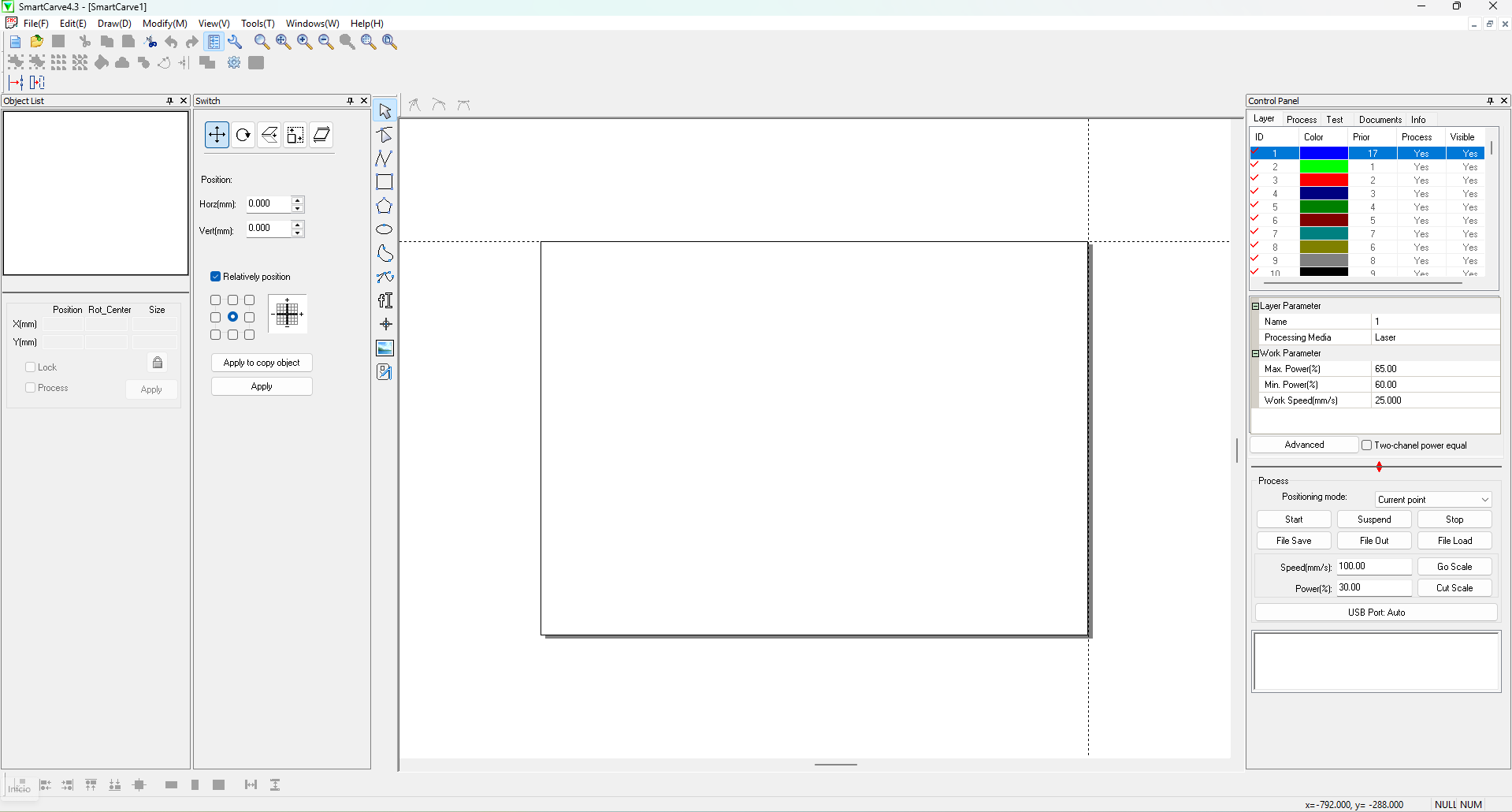

To cut our pieces I used Smart Carve. Smart Carve is a software and hardware license system that uses an usb key, designed for controlling laser cutting and engraving machines.

Smart Carve

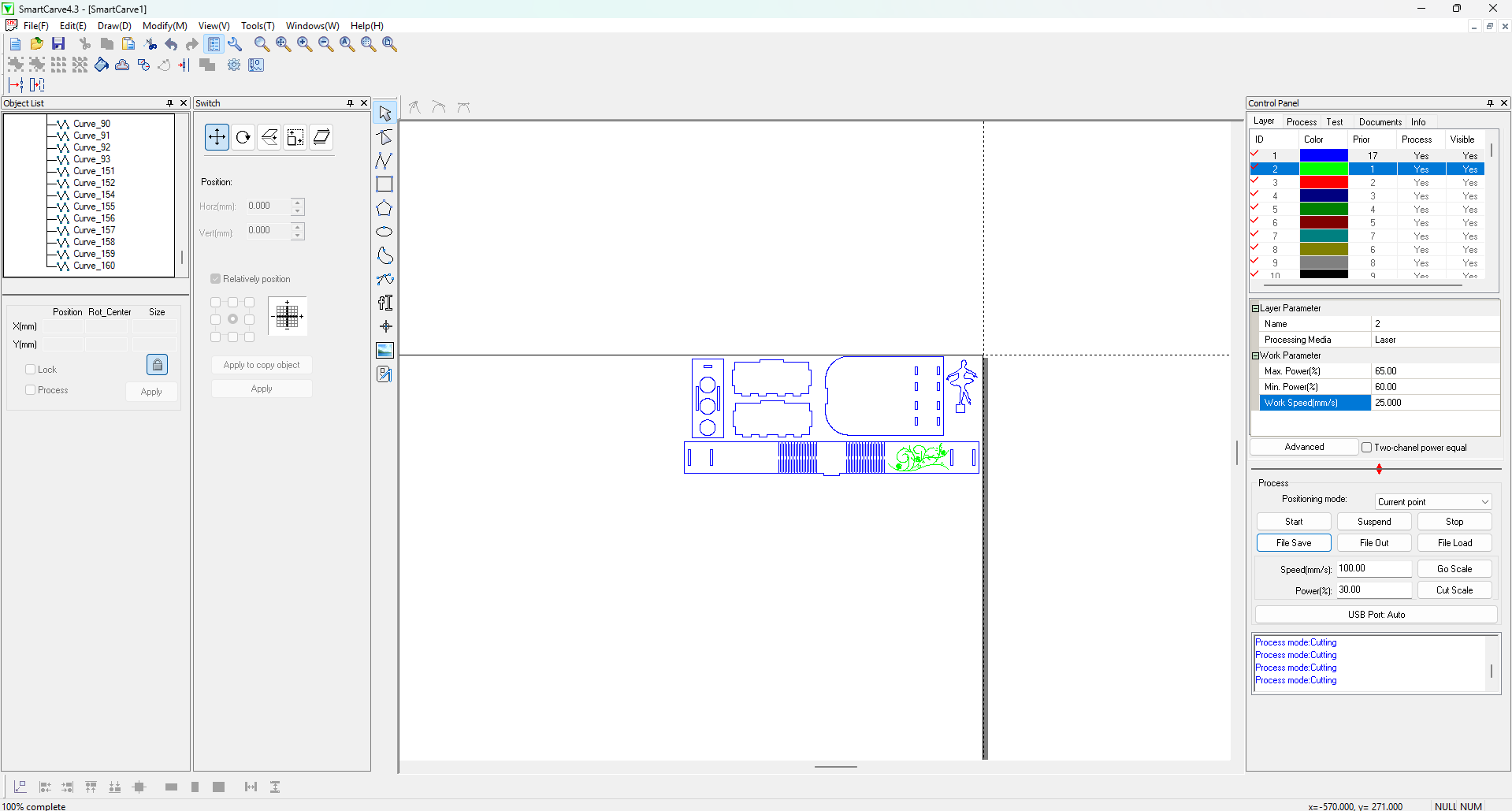

First, we need to have the program and the key. Once we have them we need to import our DXF files by clicking File in the top menu and selecting Import File.

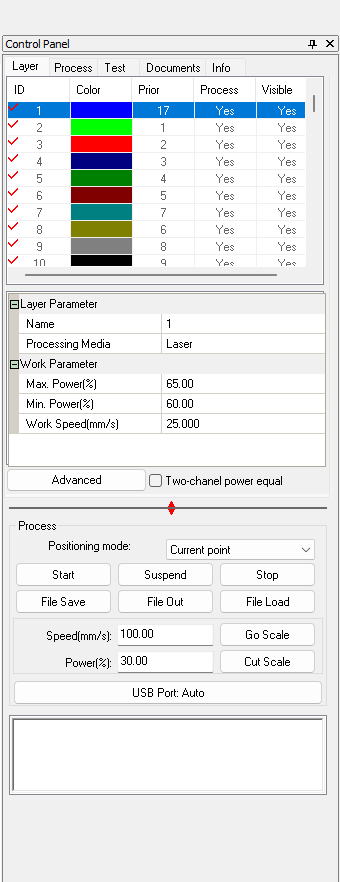

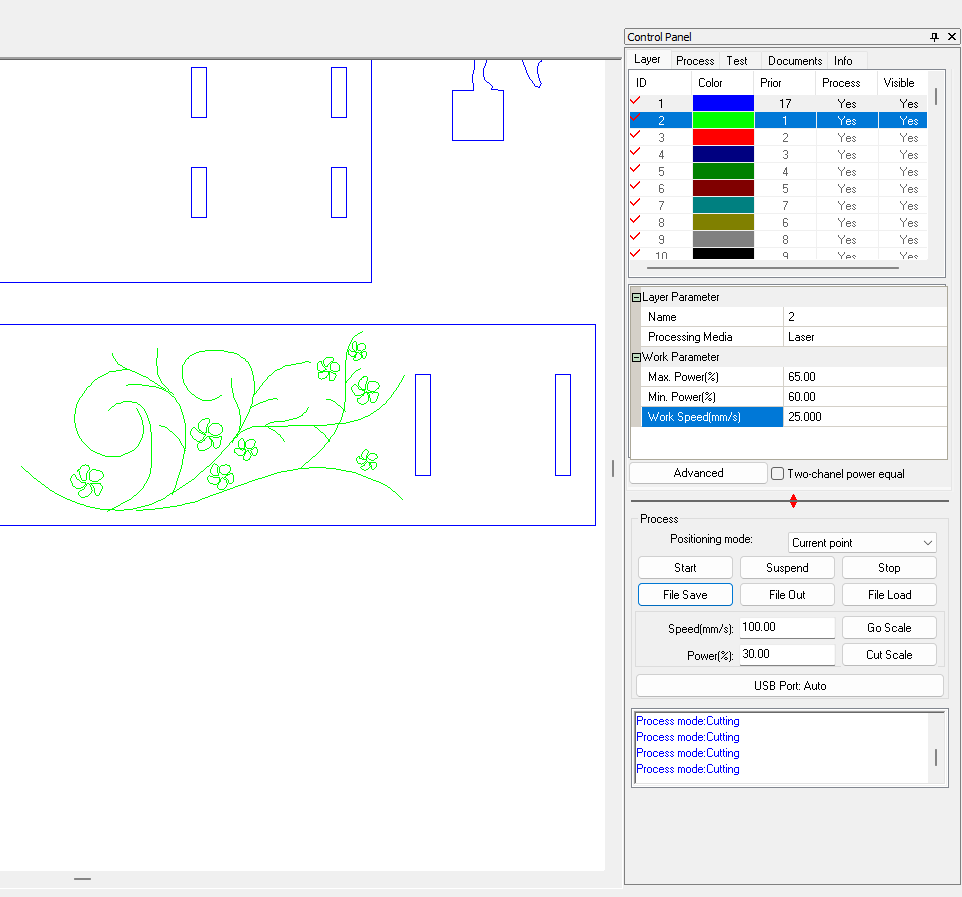

Having imported our files, in the left side we can choose between moving them around the workspace, edit the nodes, or even rotate them. In the right side we can apply different layers with different cut parameters and at the bottom we can export our cutting (.oud) document by clicking File Save.

The cutting parameters of the layers involve: Max. Power(%), Min. Power(%) and Work Speed(mm/s).

My parameters

Cut Max. Power(%): 65, Min. Power(%): 60 and Work Speed (mm/s): 20.

Engrave Max. Power(%): 25, Min. Power(%): 20 and Work Speed (mm/s): 200.

Safety reflection

During this process I learned a lot about the safety of the cutting process. First and foremost we never, never have to put our hand inside the machine while working, we cand get severe burns. We also shouldn't be looking at the laser for a long time because we can damage our eyes. It is recomended to close the machine cover while working in order to not inhale the smoke it produces. If the machine is producing fire while cutting we must turn it off inmediately to not provoque a fire.

Laser Results

Laser

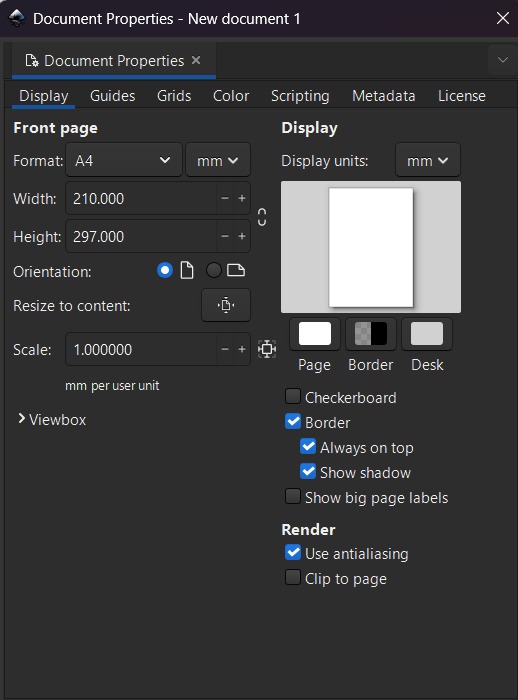

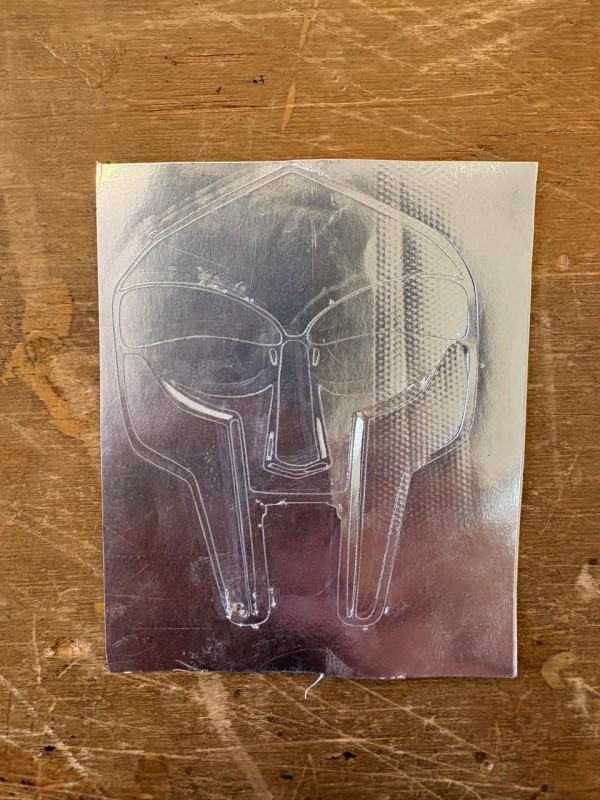

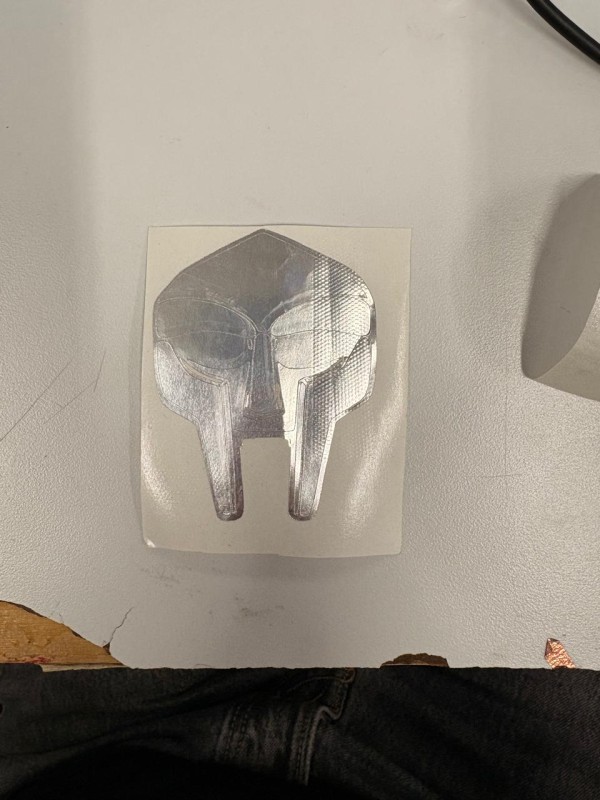

Vinyl Cutting

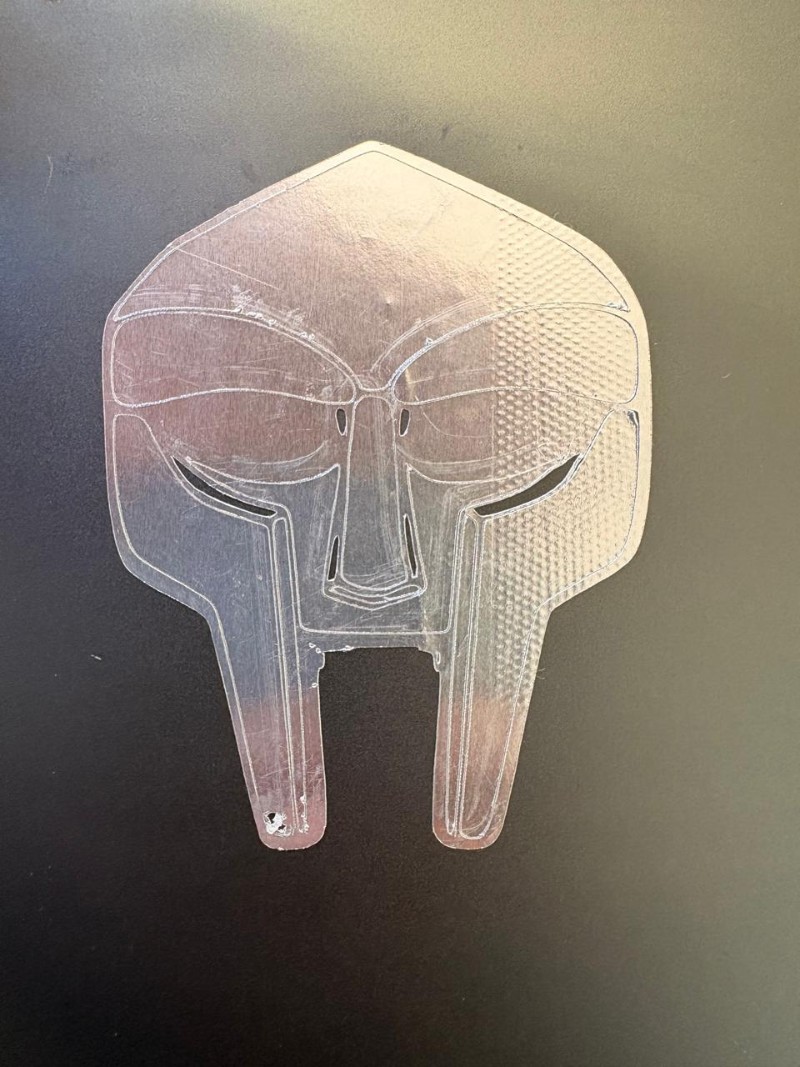

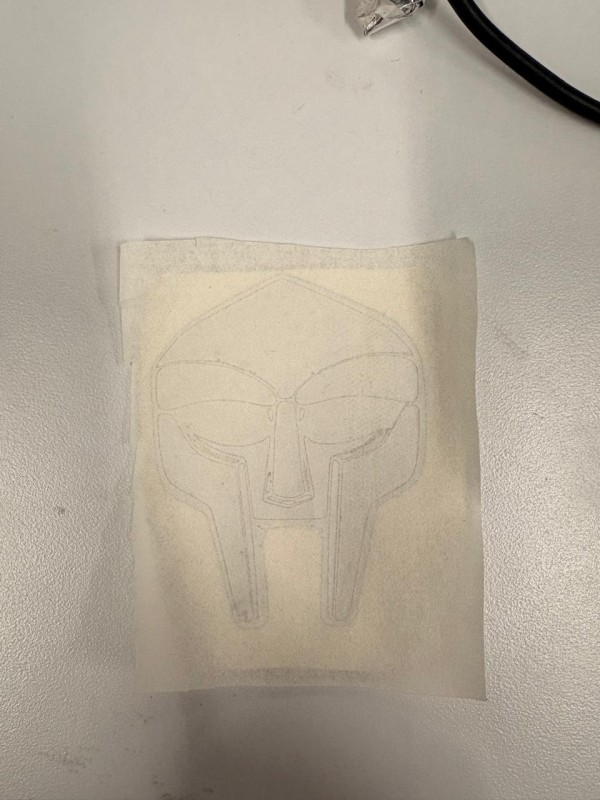

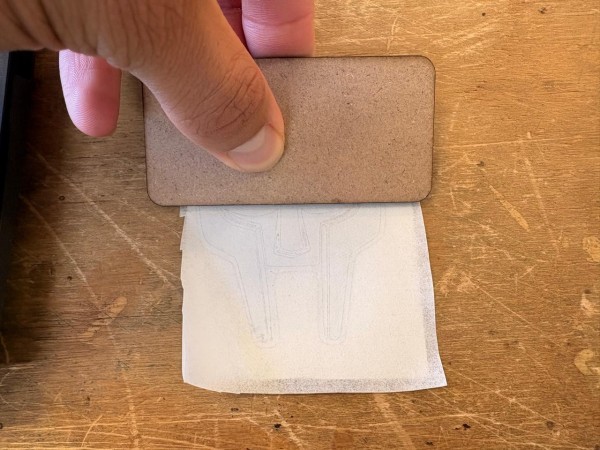

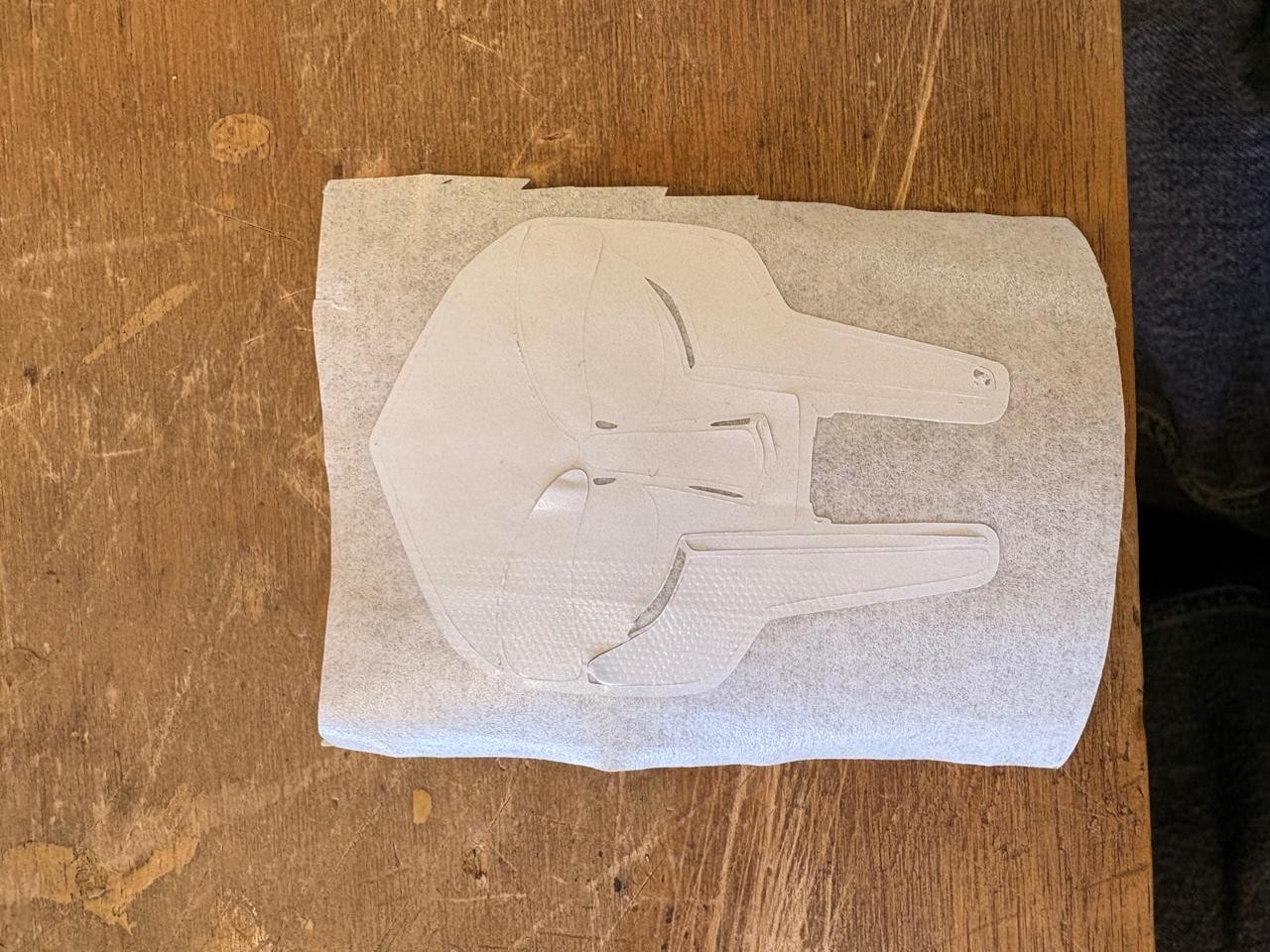

For the Vinyl cut I used a web PNG image of MF DOOM and vectorized it in Inkscape like I explained in my Week 02 page in the Inkscape section.

My parameters

Cut Speed (mm/s): 60, Force (g): 330.

Vinyl Results

Vinyl