How to use the laser cutting machine?

A laser cutting machine is a digital fabrication tool that uses a high-precision laser beam to cut, engrave, or mark materials such as wood, acrylic, cardboard, leather, and some plastics. It works from digital design files, allowing for accurate and repeatable results.

00. Machine Type

First, I used the CFL-CMA 1200 machine for this task

01. Chiller

The first step to use this machine is to turn on the chiller, which helps us maintain a safe temperature for us to work safely.

02. Automatic Voltage Regulator

The second step to use it is to turn on the automatic voltage regulator.

03. Turning on the machine

Then, we need to turn on the machine using the button on the side of the machine.

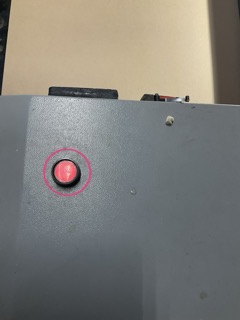

04. Emergency Button Release

The next step is to release the emergency button to be able to use it.

05. Start

Then, we need to start it by pushing this button located on top of the machine, above the control panel.

06. Control panel

Then, we can move the origin using the control panel.

07. Adjusting the laser head

Now, before cutting we need to adjust the head by turning the screws.

08. Measuring distance

Lastly, we need to leave a distance of approximately 5mm within the material and the laser head.

How to make a parametric design in Fusion 360?

Parametric design in Fusion 360 allows designers to create models whose dimensions and features are linked to parameters. When a parameter is changed, the entire model updates automatically, making it easier to test variations and refine designs.

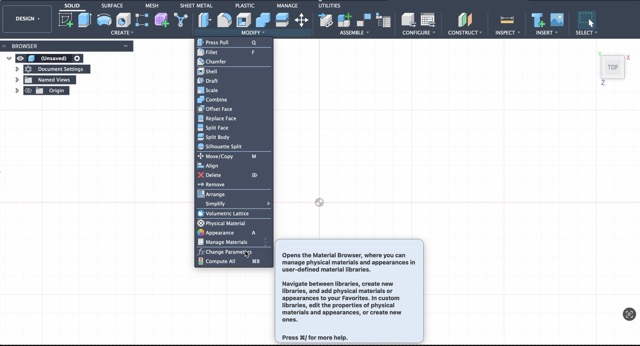

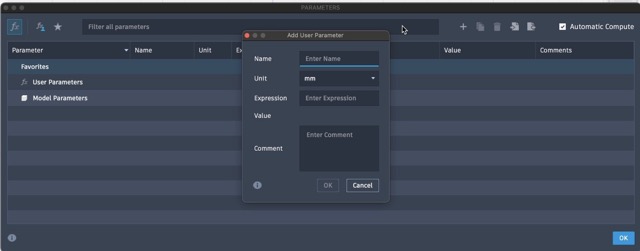

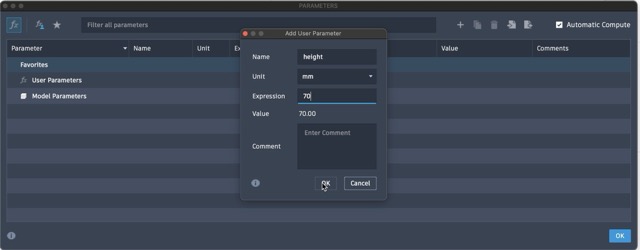

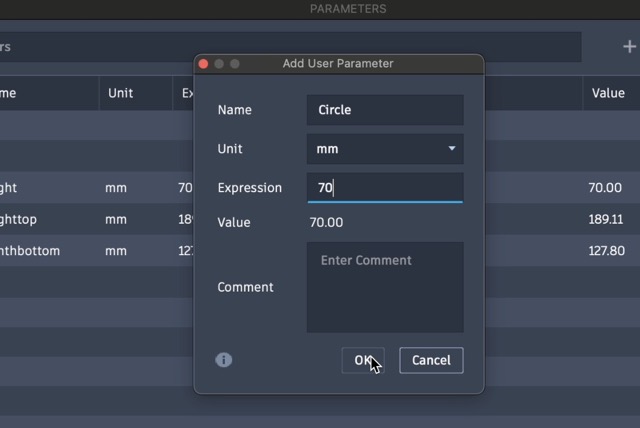

01. Where to start adding parameters?

In Fusion you can click on the "Modify" tab and click on "Change Parameters".

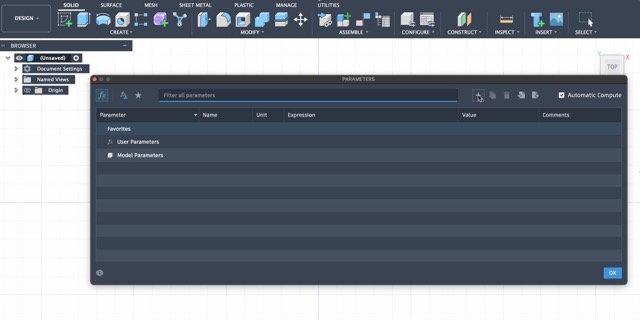

02. Add parameters

Then click on the "+" to add a new parameter.

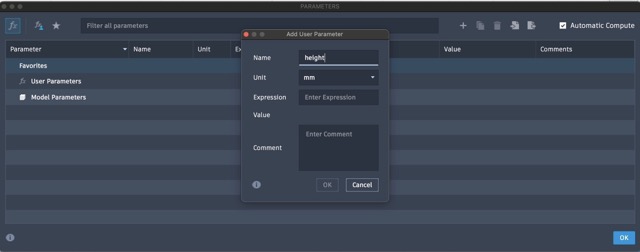

03. Naming

You can name your parameter, such as "width" or "length".

04. Choosing units

Select the units you will be working with.

05. Adding expressions

Add the expression for your parameter.

06. Saving the parameter

Press "OK" to save your parameter.

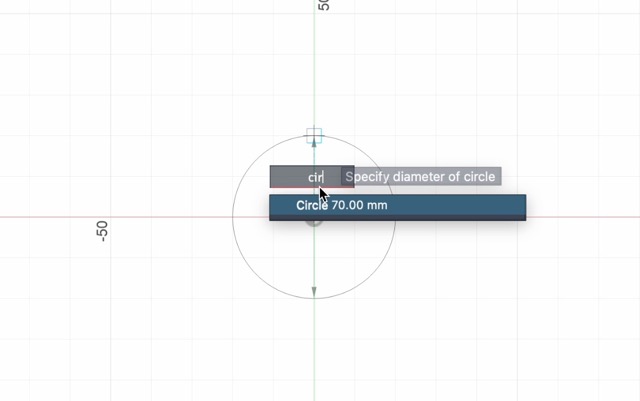

07. Sketching with parameters

Now, you can start sketching with parameters.

How to use SmartCarve 4.3?

SmartCarve 4.3 is software used to prepare and send designs from a computer to a laser cutter or engraver. It helps import and edit graphics, set cutting parameters, and control the machine’s processing tasks.

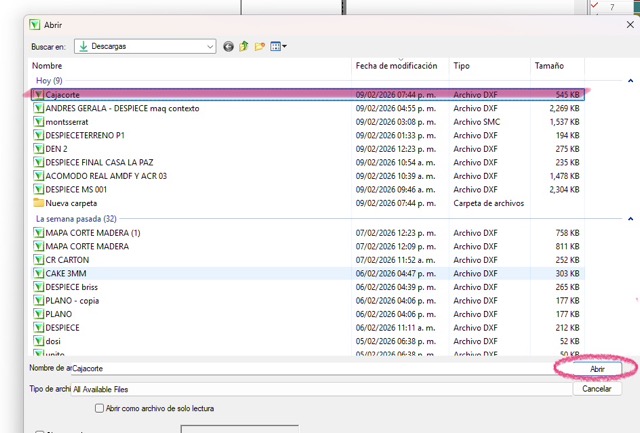

01. Importing file

First, you need to import your parametric file in dxf format.

02. Choosing file

You need to choose your cutting file.

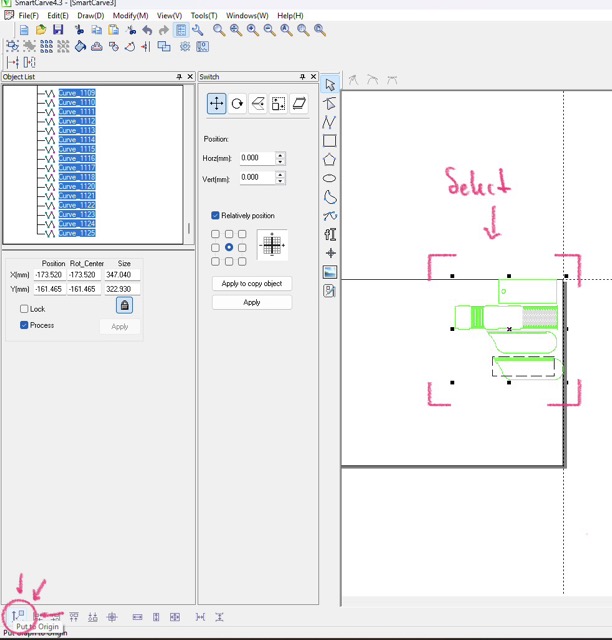

03. Aligning to origin

After opening your file you need to align the sketch to the origin.

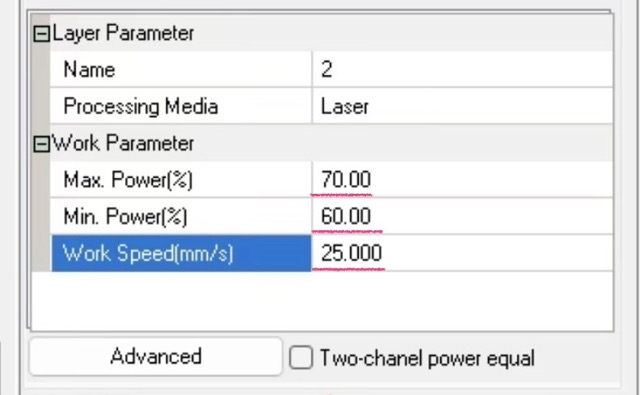

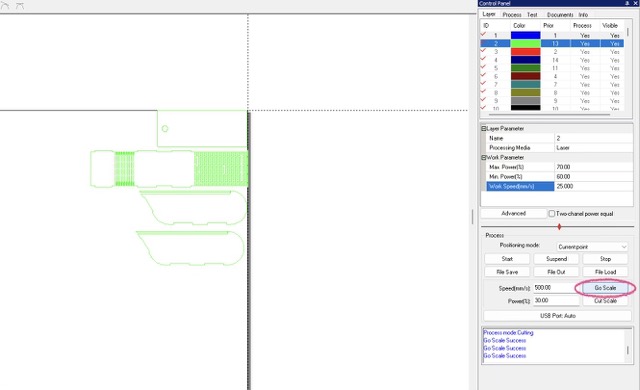

04. Cutting parameters

Then, you need to choose your parameters for cutting.

05. Go scale

Then you can use "go scale" to see if it fits on your material and where it'll start cutting.

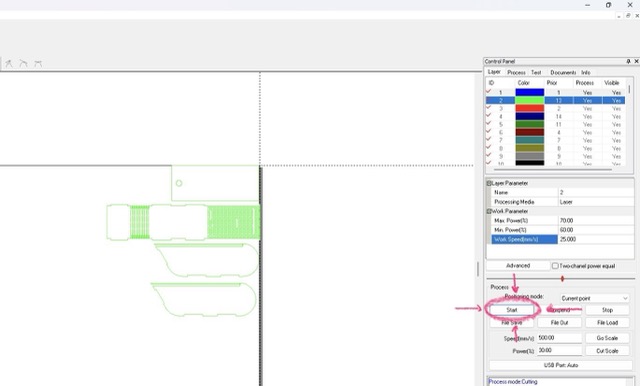

06. Start

Lastly, you'll press on start and the machine will start cutting your file.

Assembly of parametric design

After cutting all the parametric pieces, the next step is assembling the structure carefully to ensure proper fit and stability.

01. Pieces

02. Connecting wall to base

03. Connecting large curve to wall

04. Adding the other wall

05. Adding cover