Week 3: Computer-Controlled Cutting

Assignments

Group Assignments:

- Do your lab´s safety training

- Characterize your lasercutter’s focus, power, speed, rate, kerf, joint clearance and types.

Individual assignments

- Design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf.

- Cut something on the vinyl cutter.

Group Assignment

In this group assignment, we characterized the laser cutting machines available at FabLab Puebla. We reviewed the lab safety procedures, analyzed the specifications of the CO₂ laser cutters, and tested different materials such as wood, MDF, and acrylic.

We evaluated key parameters including power, speed, focus, and kerf to understand how they influence cutting quality and precision. This process allowed us to determine optimal machine settings for future projects and ensured safe and accurate operation.

This documentation was developed collaboratively and can be found here:

Group Assignment – Laser Cutter Characterization

I learned a lot from this assignment, like how to calibrate the height of the laser, what is the correct form of turning on and off the machine, how to appropriately use the software for the lasercut and the parts of the machine and how it functions.

Individual Assignment

Laser cutting

Since we are in the month of love, I decided to design a 3D heart model as a gift for my girlfriend.

To make the model parametric, I used the Equations tool in SolidWorks. This tool allows you to define relationships between dimensions and create formulas that automatically update the model when you change a specific parameter. In my case, I defined the width of the heart as a parameter and created equations to maintain the proportions of the design as I adjusted the size.

I created global variables for:

- The diameter of the circle that forms the heart's top

- The length of the heart's sides

- The space necessary to fit the pieces together, taking into account the kerf of the laser cutter and the thickness of the material being cut

You can find the Equations tool in: Tools → Equations

I created an assembly in SolidWorks to verify that all the pieces fit correctly before manufacturing.

After finalizing the design, I exported the files in the appropriate format and sent them to the laser cutting machine.

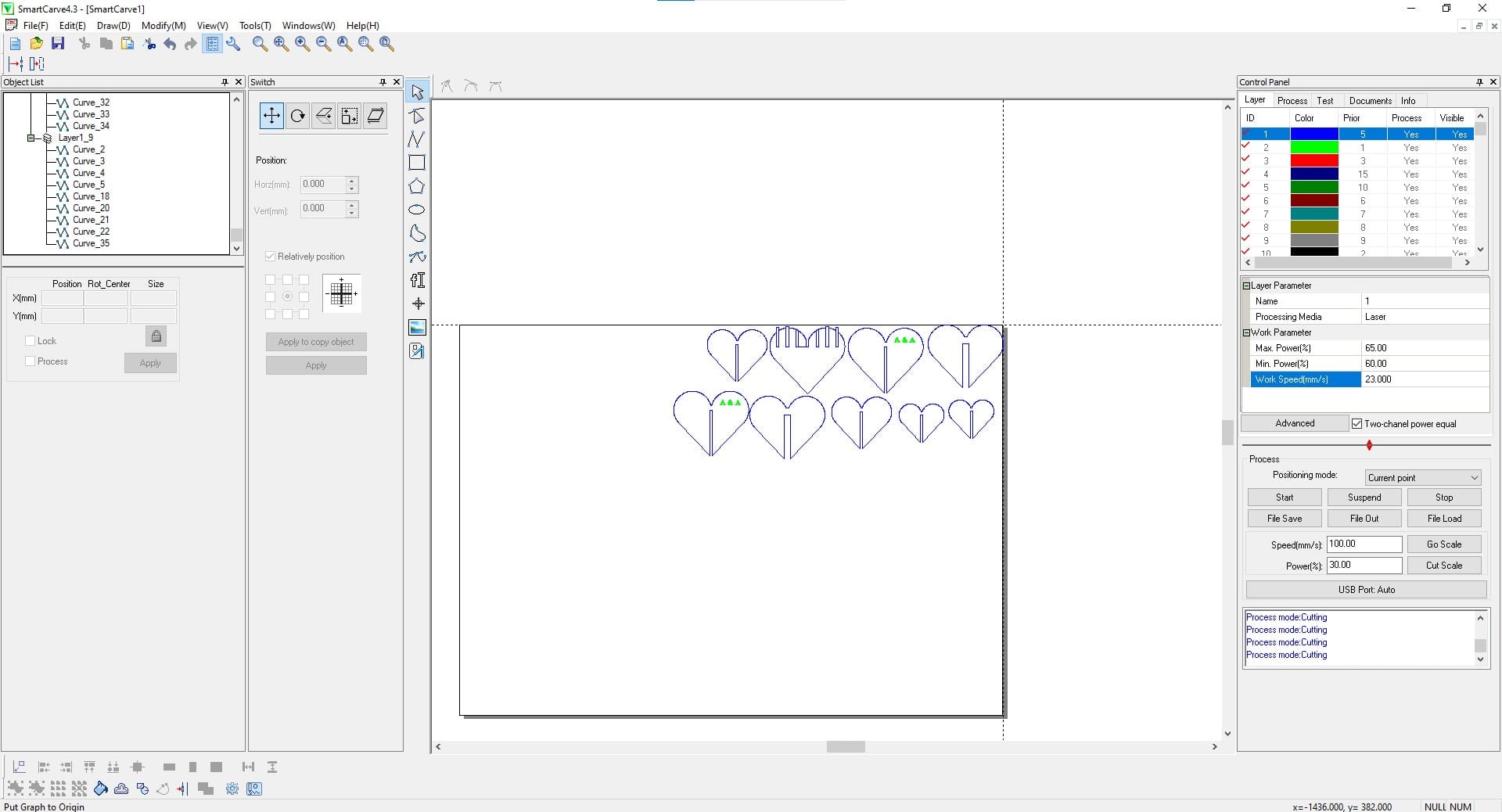

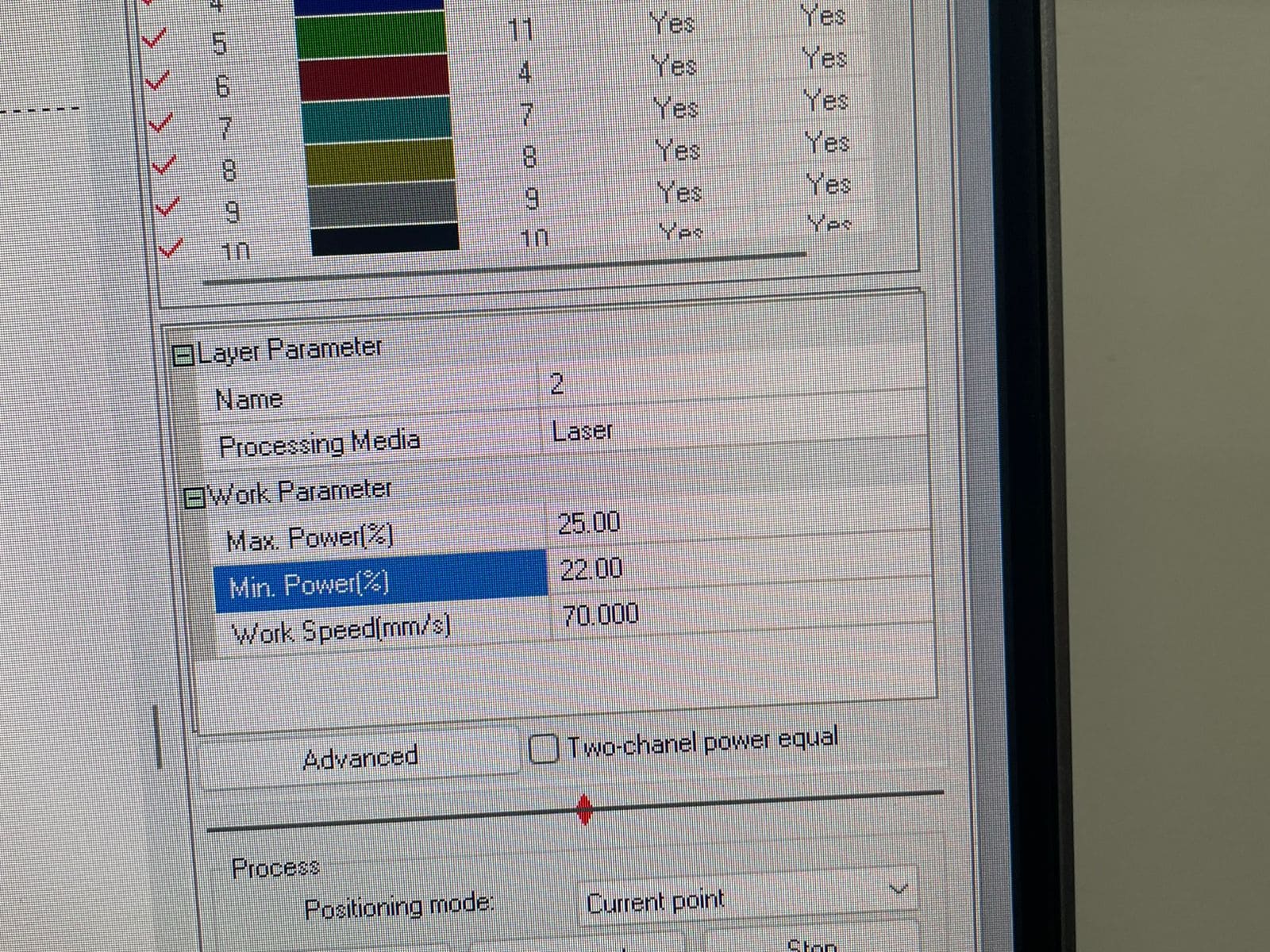

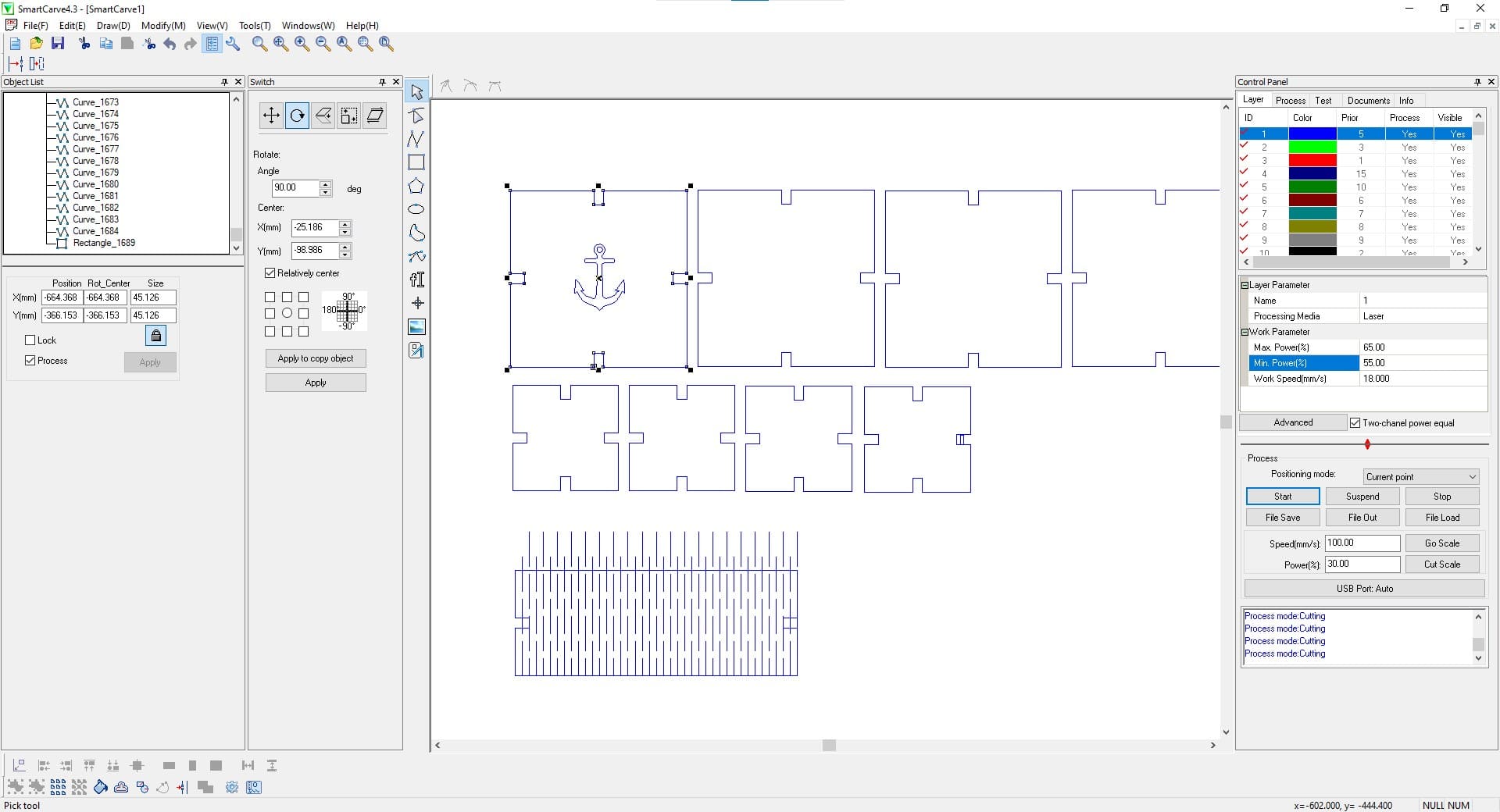

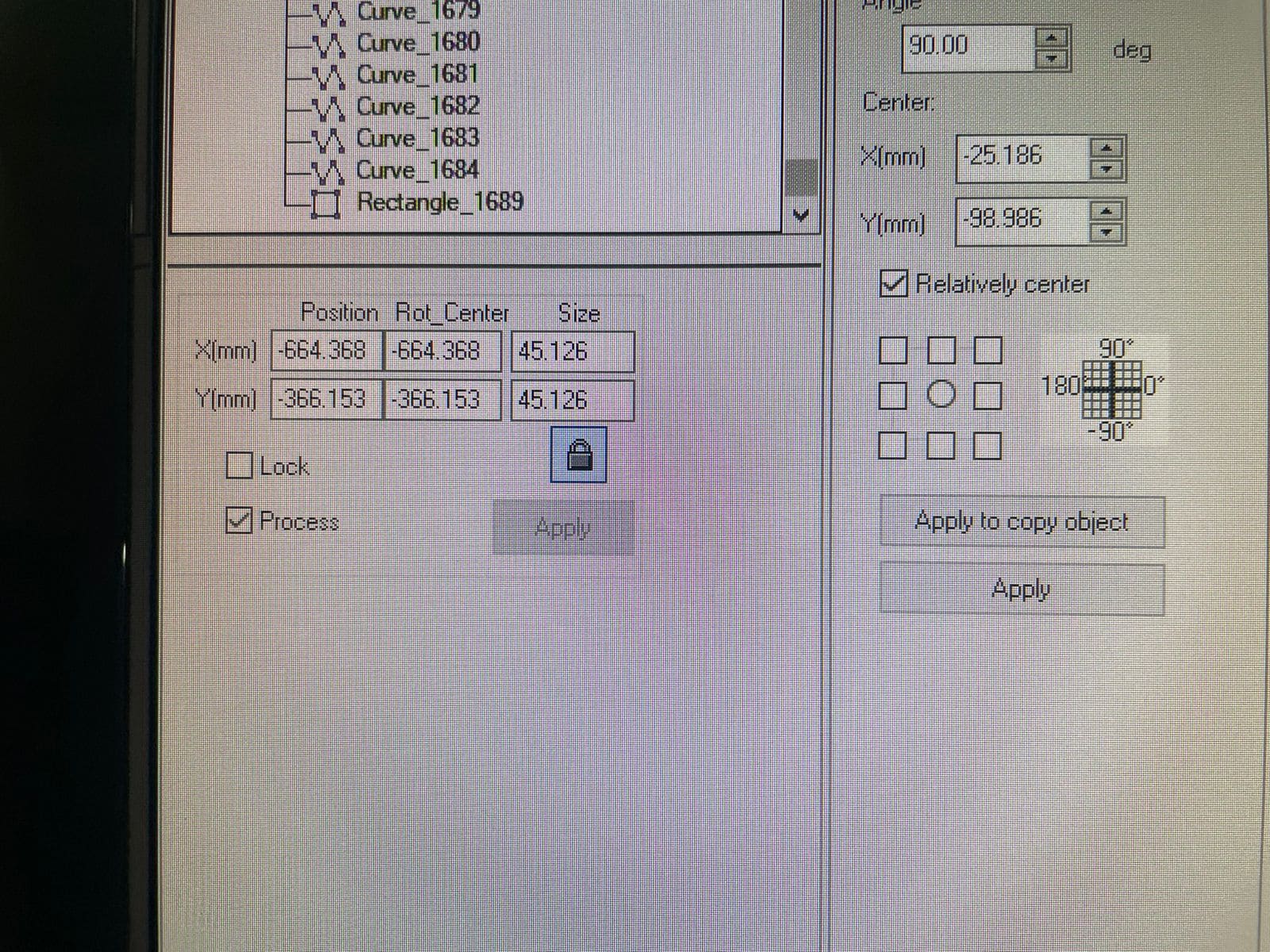

Laser Cutter Parameters

- Material: 2.5mm MDF

- Kerf compensation: +0.2 mm

- Max Power: 65%

- Min Power: 55%

- Work Speed: 18 mm/s

Why Max and Min Power?

The laser cutter uses both maximum and minimum power values to maintain energy consistency during acceleration and deceleration. The minimum power prevents incomplete cuts in corners and curves where the machine slows down.

Vinyl Cutter

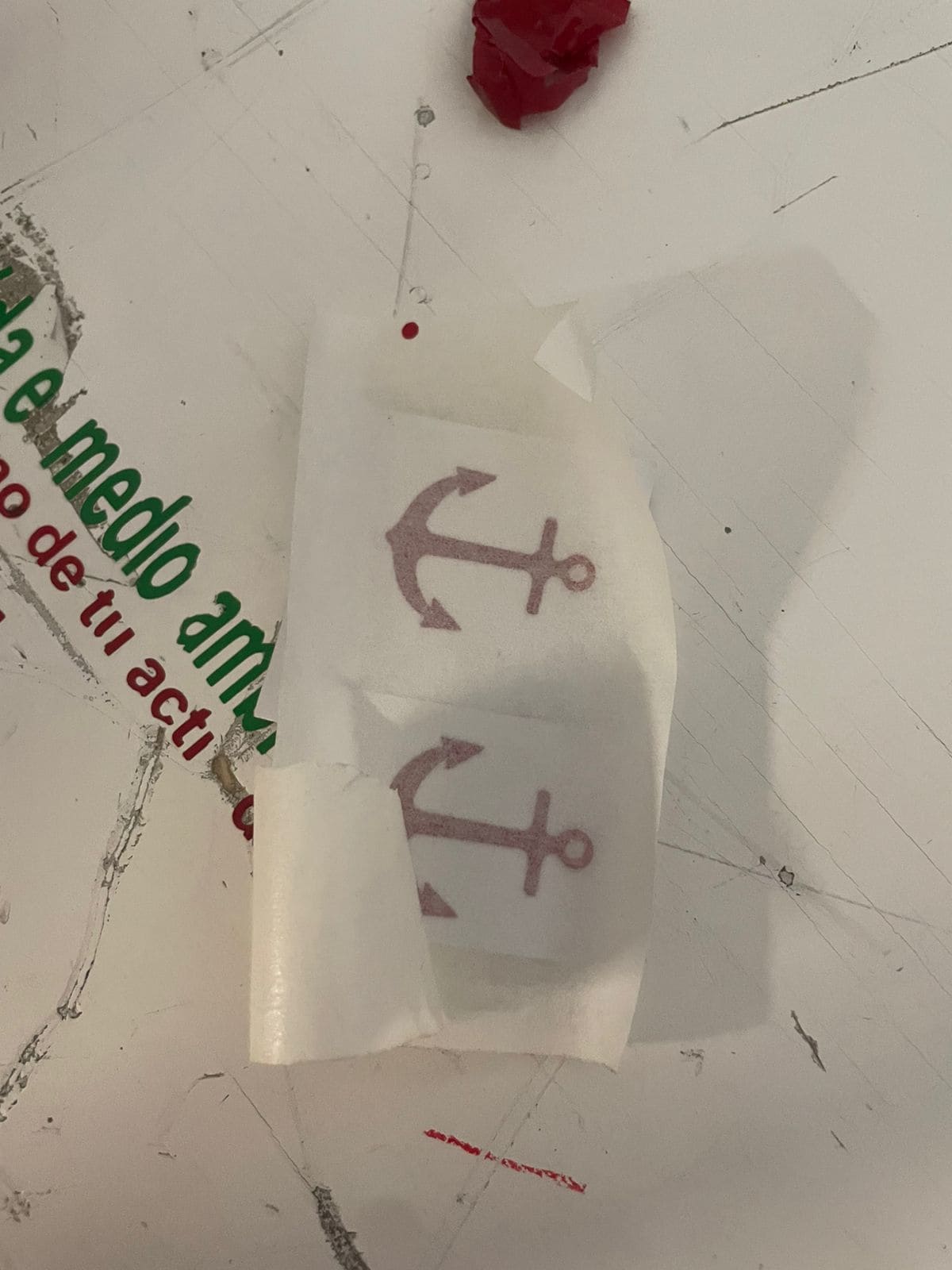

For the vinyl cutter assignment, I used an anchor design inspired by the name of my final project, “Ancora,” which means anchor in Latin.

I used Inkscape to vectorize the image and exported it as an SVG file in order to prepare it for the vinyl cutting software.

Here is a link for the inkscape page: Inkscape Official Website

Extra credit

- Design it to be assembled in multiple ways

- Include elements that aren't flat

- Engrave as well as cut

I made a parametric construction kit that allows for multiple assembly configurations.

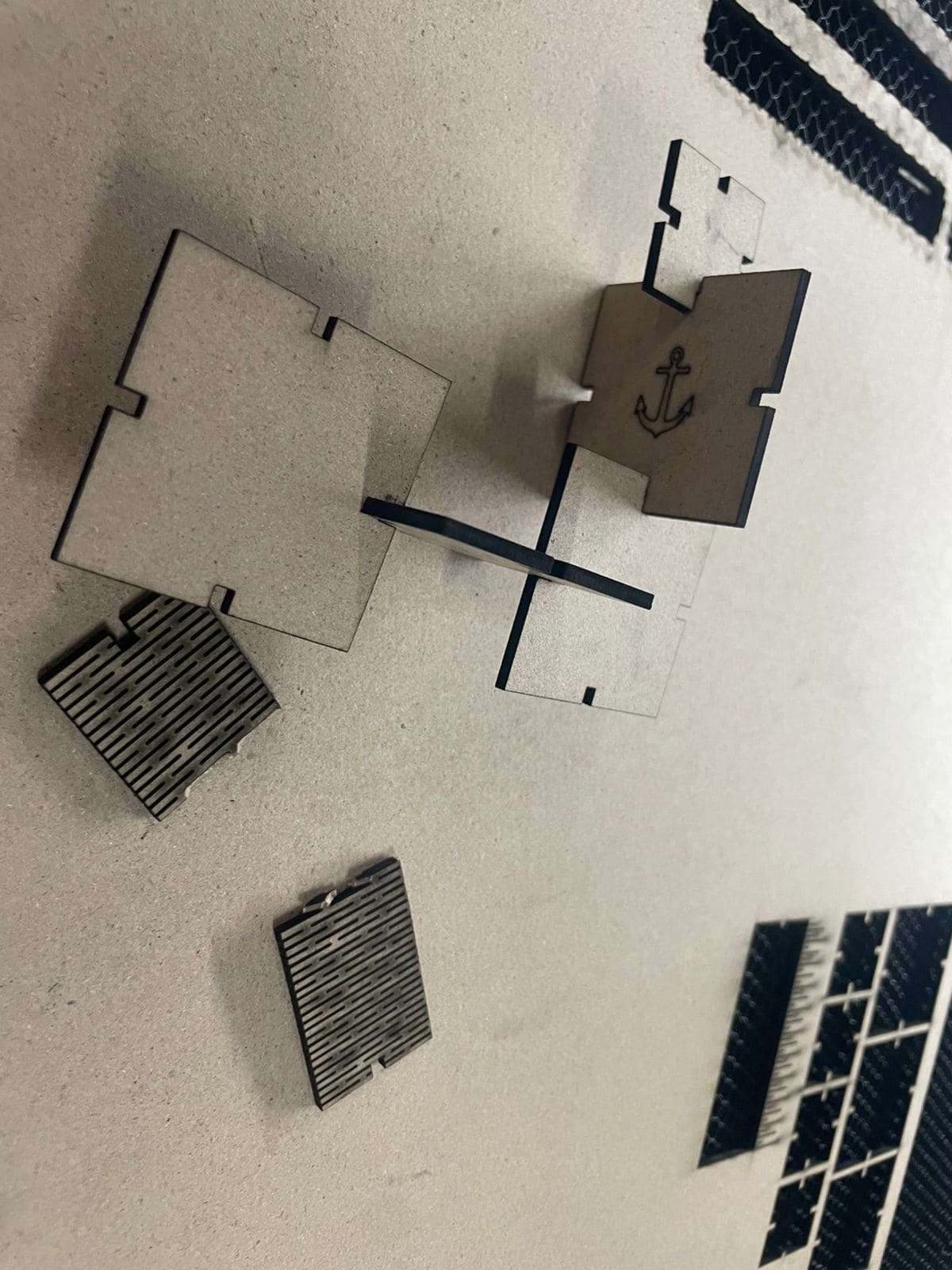

I tried to make the non-flat elements, by designing a flexible part, but first I put the lines horizontally instead of vertically so it would fold in the x axis

Then I corrected the design and put the lines vertically, but the mistake was that I put too little space between the lines

Because I didn´t realized that the space between the lines was too little at the time I tried to bend it broke

For the engraving assignment, I used the vectors from the SVG file I created for the vinyl cutter and imported them into Solid Works, I put in the lasercut software the parameters for engraving

There was a error with the scale in solidworks and when I put my design in the lasercut software it became bigger, so I had to manually adjust the size in the lasercut software.

Finally, here is the completed project: