Final project

The culmination of the Fab Academy journey

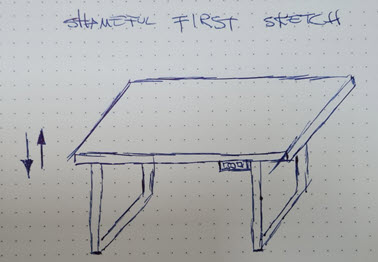

concept

An electrically adjustable standing desk with a 4-leg structure ( approx. 1800 × 850 mm surface), designed for smooth transitions between sitting (650 mm) and standing (1250 mm) heights. Four synchronized linear actuators provide superior stability compared to commercial 2-leg designs, with ±2 mm levelling tolerance under 150 kg load.

motivation

When I started thinking about my final project, I had to be honest with myself. I know how I work: if I pick something too ambitious and too complex, there is a real risk that I end up procrastinating and never finishing it. I have seen incredible Fab Academy projects — like Daniele Ingrassia drone with four motors and stability control so precise that he could place a cup of coffee on top and fly it without spilling a drop. That level of engineering is inspiring, but I also know my circumstances: a full professional life, responsibilities, and a limited time window to deliver. If almost forty years have taught me something, it is when to be strategic about your own limits.

So I chose to build a height-adjustable standing desk with four synchronized telescopic legs. It is not a simple project — it involves mechanical design, motor synchronization, PID control, embedded programming, networking between boards, and a user interface — but it is a project whose complexity I can manage and whose scope I can realistically complete.

What convinced me is that it covers almost every Fab Academy assignment in a meaningful way: CAD, electronics design and production, embedded programming, input and output devices, networking, interface programming, 3D printing, and system integration. It is not an artificial exercise — every skill I learn maps directly to something I need for the final result.

I also want this project to be thoroughly documented and shared with the community. I would not be here without the countless people who share their knowledge openly and selflessly. If this desk ends up being good enough to have a commercial path, I would explore that — but the open documentation will always be there. That is non-negotiable for me.

And finally, there is a personal health motivation. I spend far too many hours sitting. The growing body of scientific literature on the effects of prolonged sedentary behavior is hard to ignore:

- A meta-analysis across 19 cohort studies (over 1.4 million participants) found that high levels of sedentary behavior were associated with a 30% increased risk of cardiovascular disease, and that every additional hour spent sedentary corresponded to a 5% increase in CVD risk. (Saunders et al., 2023 — PubMed)

- The American Heart Association published a science advisory confirming that prolonged sedentary behavior is consistently linked to increased cardiovascular and all-cause mortality, independent of physical activity levels. (Young et al., 2016 — Circulation)

- A meta-analysis on occupational sedentary behavior specifically found that sedentary work increased the risk of mental health issues by 34%. (Leclercq et al., 2025 — PLOS ONE)

- Research on sit-stand desk interventions showed that workers using sit-stand desks significantly decreased their sitting time and had reduced neck and shoulder pain, along with increased subjective health and vitality. (Ma et al., 2021 — PMC)

- A 24-week workplace study demonstrated that replacing approximately 90 minutes of sitting with standing resulted in improvements in vascular function, insulin resistance, and triglyceride levels. (Gibbs et al., 2022 — PMC)

Building my own standing desk is not just a Fab Academy project. It is something I actually need, something I will use every day, and something that combines technical learning with a real improvement in how I work and live.

Requirements

At this point I see three major subsystems:

1. Mechanical Structure

- Frame: Welded or bolted steel tube construction.

- Legs: Actuator housings integrated into leg assemblies.

- Top: Solid wood or laminated panel with mounting interface.

2. Motion System

- Actuators: 4× linear actuators (likely 12V or 24V DC).

- Synchronization: Position feedback + control algorithm.

- Power: Adequate PSU for simultaneous 4-actuator operation.

3. Control Electronics

- Main PCB: Microcontroller, motor drivers, position inputs.

- Interface: Buttons, optional display, memory pre-sets.

- Wiring: Power distribution, signal routing, cable management.

Initial sketches